Sockets in the kitchen are extremely necessary, unfortunately, sometimes where they fit best, but installing them in such a place is not always possible. A socket that is hidden in the countertop has many advantages.

Hence the growing popularity of this solution. This is a functional solution and also has a positive effect on the aesthetics of the room. However, it is important to know what to consider when choosing such an outlet.

Built-in retractable sockets: pros and cons

Like any product, socket blocks have strengths and weaknesses. Before purchasing, they must be sensibly assessed and compared - only then will such an acquisition be justified. The table will help you compare the advantages and disadvantages of built-in retractable socket blocks with conventional sockets.

Table: comparative characteristics of fixed and retractable sockets

| Criterion | Fixed sockets | Built-in retractable sockets |

| Installation | A labor-intensive, dirty and expensive process: a groove is knocked out in the wall for laying the wire and a recess for installing the socket. | It is done quickly, easily and cheaply. Dust or chips are generated in minimal quantities. |

| Appearance | It catches the eye and somewhat spoils the design of the room. | When not in use it is hidden, so the interior remains immaculate. |

| Functionality | They serve as a source of 220 V alternating voltage. There are modular designs that allow you to use USB connectors, VGA/Audio, HDMI, RJ45 ports. | The same. |

| Quality requirements | Relatively low. It is required that the metal contacts do not overheat at rated load. | High - due to the presence of moving elements. Low-quality products soon fail: they spontaneously move out, stop functioning due to broken contacts in the area of the articulation of the moving and fixed parts. |

| Possibility of permanent use | Available. The socket is used to connect a refrigerator, microwave and other constantly or frequently used devices. | Not intended for permanent use. |

| Tightness | If there is a lid, it can be sealed tightly. IP67 dust and moisture protection class is achieved. | Complete sealing is not possible. The maximum class of dust and moisture protection is IP44. |

Features and advantages of built-in sockets

In terms of electrical parameters, sockets hidden in a countertop or cabinet differ little from ordinary ones. Their main advantage is different: when folded, the socket block is hidden inside a table or any kitchen furniture. In this case, the surface of the tabletop can be used as usual with some restrictions.

If you need to connect any household appliance, the built-in sockets are easily removed from their hiding places, and then just as easily put back, as in the photo below.

Thus, their use brings the following benefits:

- Electrical safety is increased due to the absence of easily accessible wires. All electrical wiring is securely hidden inside the kitchen furniture and is difficult to damage or get caught on.

- The likelihood of moisture or dust getting inside the sockets is reduced.

- Secret blocks are more protected from access by small children.

- When retracted, the devices save free space in the kitchen, for example by increasing the working area of the countertop.

- Many models are equipped with additional connectors for connecting electronic devices, such as USB ports.

- The original design of sockets built into the countertop organically fits into modern kitchen interior design styles.

However, these devices also have disadvantages:

- They are not suitable for connecting stationary appliances such as a refrigerator or TV. Hidden sockets are used to temporarily power mixers, electric meat grinders, and laptop chargers. It is impractical to keep them open all the time: it is much safer in such cases to use stationary, securely fixed sockets on the wall.

- Although the surface of the countertop appears solid when the devices are recessed, it is necessary to remember their presence. You can put some object on them, but cutting or placing wet vegetables or fruits is hardly worth it.

- Placed in hanging drawers, such devices save space in the kitchen, but at the same time take up space inside the furniture. For a countertop this is not so critical, but in a hanging drawer, drawers can take up a significant portion of the volume. The device inside the cabinet is in the next photo.

USEFUL INFORMATION: Installing a socket box in a concrete wall

In addition, certain types of such sockets have their own weak points. But we'll talk about them later.

Preparing for installation

As part of the preparation, a number of issues are considered - from choosing a location to safety precautions.

Choosing an installation location

Built-in socket blocks are installed in:

- countertops;

- cabinet walls.

Sockets can be built into the countertop or cabinet walls

Having chosen a location, you need to make sure that the unit in working position will not interfere with pulling out the drawer or opening the cabinet. It is recommended to install retractable units in a residential building or apartment:

- in the countertop of a kitchen table: a block with 3–5 power sockets is suitable here;

- in the eating area;

- in a resting place for family members: blocks of combined connectors would be appropriate here.

A socket block with connectors for a variety of equipment is suitable for the recreation area.

To connect large equipment, it is better to place built-in sockets at a distance of 1 meter from it inside an adjacent cabinet or cabinet. For small household appliances (blender, electric kettle, etc.), sockets are mounted in the countertop or kitchen apron. You cannot build sockets under or above the sink and stove: the minimum permissible distance between them is 60 cm.

Any outlet must have easy access in case of problems

Video: built-in sockets for the kitchen

Preparation of tools and materials

To install a built-in socket you will need:

- drill;

- drill bit or “ballerina”;

The ballerina, unlike a crown, is a universal tool: it allows you to drill holes of any diameter

- wire (if there is no standard wire or its length is not enough).

For cutting countertops made of artificial stone, diamond-coated crowns and ballerinas are used. In the absence of a drill, a jigsaw is used.

Safety precautions

Before installing the outlet block, the power supply line to which it will be connected must be de-energized. When drilling a hole, especially in countertops made of artificial stone, protect your eyes from splinters with glasses.

Basic requirements for installing sockets in the kitchen

The specific distribution of outlets in the kitchen depends on the location of the appliances. A competent design ensures convenient use and guarantees safety. There are several basic rules that are taken into account when choosing the number, type and installation locations of sockets. The installation of these devices ensures compliance with the requirements of the relevant SNiP and GOST. When choosing the location of the outlet, take into account:

- ease of use of household appliances;

- permissible distance to the baseboard;

- exclusion of splashes of water and steam.

Several communications pass through this room. The electrical network circuit should not interfere with other utility lines.

A competent circuit guarantees safety when using sockets

The choice of device models is made by the consumer at his own discretion. If there is equipment in the room that requires grounding, this factor is taken into account when purchasing and placing sockets in the kitchen.

to contents

Installation of a built-in retractable socket

The block is installed in a certain order.

You can install the socket block yourself

Hole preparation

The hole is made as follows:

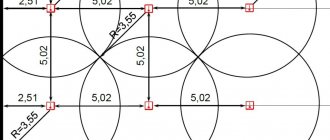

- On the countertop at the installation site, draw a circle equal in diameter to the block body.

- A hole is drilled in the center of the circle with a drill of the same diameter as the centering drill of the crown or ballerina.

- Change the drill bit in the drill chuck to a crown or ballerina bit, insert a centering drill into the drilled hole and begin cutting out a large diameter hole.

The hole is drilled using a crown or ballerina drill.

- Having gone through half the thickness of the tabletop, select the remaining material on the other side.

In the absence of a “ballerina” and a crown, another method is used:

- Along the drawn circle, many holes are drilled with a drill with a diameter of 5 mm, leaving thin walls between them.

- The walls are cut out with any suitable tool or broken out with wire cutters.

- Align the edges of the resulting opening with a grinding attachment secured in the drill chuck.

The edges of the hole need to be sanded with a sanding attachment.

Cutting a hole in an artificial stone countertop requires skill, so it is better for an inexperienced user to contact a professional craftsman. Holes in glass countertops are made only in specialized workshops.

After making a hole in a wooden tabletop, its walls are treated with a water-repellent compound.

Locking a block

The block is installed like this:

- Insert it into the hole.

- Fixed from below with screw fasteners included in the kit.

The block is fixed with fasteners

Connecting to the power line

The unit, equipped with a wire and a plug, is simply plugged into a stationary outlet. If there is no wire, lay a cable from the nearest point of connection to the electrical network to the outlet block. In this case, it is necessary to ensure that the total power of the line together with the new outlet does not exceed the maximum permissible.

If the unit is equipped with a wire, it is connected to a stationary outlet

If the unit's sockets are not connected to the terminal block, they are connected with pieces of wire 10–15 cm long. Wires with a cross-section corresponding to the rated load are used.

Video: how to embed a socket into a tabletop

Features of connecting rotary socket blocks

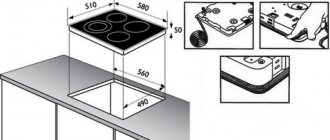

Installation of a rotary type block is possible only with a tabletop thickness of 3 to 5 cm.

Manufacturers of built-in socket modules

When choosing a socket module built into a countertop, you should take a responsible approach to considering the products of well-known manufacturers of these products. I will show you which brands are worth paying attention to, whose products are of proper quality and meet high international standards. Companies from Poland, Germany, Sweden, Spain and among them are represented on the electrical materials market.

She will be the first in my short review:

- The Russian one has been on the market for 15 years. Engaged in the production of plastic products for electrical applications.

Built-in sockets from a Russian company

The products of this company have gained popularity not only among domestic consumers, but also abroad.

Model of built-in socket "Ekoplast"

Products with the Ecoplast brand have a quality certificate ISO 9001:2008.

- "GTV" is a company from Poland that produces products certified according to European standards. Their products are distinguished by high quality and excellent consumer properties.

Built-in retractable socket GVT

Review of GTV mortise sockets

- Two and "Evoline". The quality and design of the products of these companies have won the sympathy of consumers around the world. Naturally, there are certificates according to EU standards.

Pull-out socket block “Evoline”

- A company from Sweden, Kondator, produces built-in socket blocks. The models of this company use not only socket connectors, but also other types (HDMI, USB).

Pull-out sockets in the tabletop

- Simon is a Spanish company producing electrical devices. The catalog of this company contains many socket modules of different types and purposes. The products of this brand are famous for the quality of their products.

Products

Retractable sockets of the Russian and Polish “GTV” can be classified in the middle price segment.

Products manufactured by Schulte Elektrotechnik, Evoline, Kondator and Simon belong to the premium segment. These devices have impeccable quality components and materials used for finishing. Corresponding to this is the high price of this product.

In terms of price, the products of the Chinese companies Displace, GLS, and Desk Socket are of greatest interest. Although it so happens that the quality of Chinese goods is not considered to be of a very high level. But in recent years this opinion has begun to change. In terms of design and appearance, they can easily be compared with leading brands.

Built-in socket from the Chinese company Displace

Location of sockets in the kitchen

The unit must be built in such a way that it is possible to place electrical appliances on three levels:

- Lower level. An electric stove, oven, laundry and dishwashing machines can be placed here.

- Average level. Electrical appliances such as an electric kettle, coffee machine, food processor, toaster, blender, microwave and others are installed here, which are placed on the table top.

- Top level. The installation of hoods, air conditioners and lighting is mainly provided here.

For mid-level sockets, it is better to build them into the countertop. There are two installation options to choose from: recessed into the countertop or on the apron.

For the upper level, the main retractable socket block is installed at a height of 10 cm above the cabinets.

Kitchen sockets can be placed in the closet. During installation, as a rule, several blocks are used. When you press the lid they can move out.