Modern mobile phones, laptops, and tablets use lithium-ion batteries. They gradually replaced alkaline batteries from the portable electronics market. Previously, all of these devices used nickel-cadmium and nickel-metal hydride batteries. But their days are over, since Li─Ion batteries have better characteristics. True, they cannot replace alkaline ones in all respects. For example, the currents that nickel-cadmium batteries can produce are unattainable for them. This is not critical for powering smartphones and tablets. However, in the field of portable power tools that draw a lot of current, alkaline batteries are still the way to go. However, work on developing batteries with high discharge currents without cadmium continues. Today we will talk about lithium-ion batteries, their design, operation and development prospects.

How did lithium-ion batteries come about?

The very first battery cells with a lithium anode were released in the seventies of the last century. They had a high specific energy intensity, which immediately made them in demand. Experts have long sought to develop a source based on an alkali metal that has high activity. Thanks to this, the high voltage of this type of battery and energy density were achieved. At the same time, the development of the design of such elements was completed quite quickly, but their practical use caused difficulties. They were dealt with only in the 90s of the last century.

Over these 20 years, researchers have concluded that the main problem is the lithium electrode. This metal is very active and during operation a number of processes occurred that ultimately led to ignition. This came to be called flame-generating ventilation. Because of this, in the early 90s, manufacturers were forced to recall batteries produced for mobile phones. This happened after a series of accidents. At the time of the conversation, the current consumed from the battery reached its maximum and ventilation began with the emission of flames. As a result, there have been many cases of users suffering facial burns. Therefore, scientists had to refine the design of lithium-ion batteries.

Lithium metal is extremely unstable, especially when charging and discharging. Therefore, researchers began to create a lithium-type battery without using lithium. Ions of this alkali metal began to be used. This is where their name comes from.

Lithium ion batteries have lower energy density than lithium batteries.

But they are safe if charge and discharge standards are observed.

What is a lithium ion battery made of?

To make lithium-ion batteries, cathode powder is used, which consists of lithium, iron and phosphate. It provides good value for money. Batteries based on this material are characterized by high energy density, safety, and ease of manufacture.

Manufacturing is carried out as follows:

1. Take copper and aluminum foil. 2. Graphite is applied to the first, and lithium oxide is applied to the second. 3. A plus charge is removed from the aluminum foil, and a minus charge from the copper foil. 4. A separating layer is placed between them. 5. Roll them up to make the battery more compact.

After performing these procedures, you will get a lithium-ion battery in the shape of a cylinder.

Reactions occurring in a Li─Ion battery

A breakthrough in the direction of introducing lithium-ion batteries into consumer electronics was the development of batteries in which the negative electrode was made of carbon material. The carbon crystal lattice was very suitable as a matrix for the intercalation of lithium ions. To increase the battery voltage, the positive electrode was made of cobalt oxide. The potential of lite cobalt oxide is approximately 4 volts.

The operating voltage of most lithium-ion batteries is 3 volts or more. During the discharge process at the negative electrode, lithium is deintercalated from carbon and intercalated into cobalt oxide of the positive electrode. During the charging process, the processes occur in reverse. It turns out that there is no metallic lithium in the system, but its ions work, moving from one electrode to another, creating an electric current.

Reactions on the negative electrode

All modern commercial models of lithium-ion batteries have a negative electrode made of carbon-containing material. The complex process of intercalation of lithium into carbon largely depends on the nature of this material, as well as the substance of the electrolyte. The carbon matrix at the anode has a layered structure. The structure can be ordered (natural or synthetic graphite) or partially ordered (coke, soot, etc.).

During intercalation, lithium ions push the carbon layers apart, inserting themselves between them. Various intercalates are obtained. During intercalation and deintercalation, the specific volume of the carbon matrix changes insignificantly. In addition to carbon material, silver, tin and their alloys can be used in the negative electrode. They are also trying to use composite materials with silicon, tin sulfides, cobalt compounds, etc.

Reactions on the positive electrode

Primary lithium cells (batteries) often use a variety of materials to make the positive electrode. This cannot be done in batteries and the choice of material is limited. Therefore, the positive electrode of a Li─Ion battery is made of lithiated nickel or cobalt oxide. Lithium manganese spinels can also be used.

Research is currently underway on mixed phosphate or mixed oxide materials for the cathode. As experts have proven, such materials improve the electrical characteristics of lithium-ion batteries. Methods for applying oxides to the cathode surface are also being developed.

The reactions that occur in a lithium-ion battery during charging can be described by the following equations:

positive electrode

LiCoO2 → Li1-xCoO2 + xLi+ + xe—

negative electrode

С + xLi+ + xe— → CLix

During the discharge process, reactions go in the opposite direction.

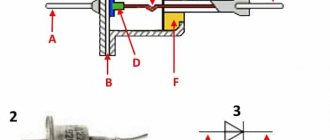

The figure below schematically shows the processes occurring in a lithium-ion battery during charging and discharging.

Reactions occurring in a Li-Ion battery

Working principle of lithium ion battery

This type of battery has 2 types of electrodes:

- Cathode located on aluminum foil.

- Anode located on copper foil.

The electrodes are separated from each other by a separator, which is impregnated with electrolyte.

The principle of operation of a li ion battery is as follows: when voltage is applied to the electrodes, lithium ions move to the carbon cathode, which contributes to the occurrence of a chemical reaction.

If you apply a load instead of voltage, the principle of operation will be the same, only it is carried out in the reverse order. It should be noted that when charging, the cathode is not completely restored, so external batteries begin to gradually lose their capacity. An example is a mobile phone, which in the first days of operation worked for 12 hours in active mode, and after a year this value decreased significantly.

When the battery capacity decreases by 30%-35%, it must be replaced.

Lithium-ion battery design

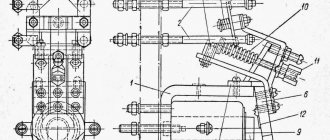

According to their design, Li─Ion batteries are made in cylindrical and prismatic designs. The cylindrical design represents a roll of electrodes with separator material to separate the electrodes. This roll is placed in a housing made of aluminum or steel. The negative electrode is connected to it.

The positive contact is output in the form of a contact pad at the end of the battery.

Cylindrical lithium-ion battery

Li-Ion batteries with a prismatic design are made by stacking rectangular plates on top of each other. Such batteries make it possible to make the packaging more dense. The difficulty lies in maintaining the compressive force on the electrodes. There are prismatic batteries with a roll assembly of electrodes twisted into a spiral.

Prismatic lithium-ion battery

All lithium-ion batteries are designed with measures to ensure their safe operation. This primarily concerns the prevention of heating and ignition. A mechanism is installed under the battery cover that increases the resistance of the battery as the temperature coefficient increases. When the pressure inside the battery increases above the permissible limit, the mechanism breaks the positive terminal and the cathode.

In addition, to increase operating safety, Li-Ion batteries must use an electronic board. Its purpose is to control the charge and discharge processes, to prevent overheating and short circuits.

There are many prismatic lithium-ion batteries currently being produced. They find application in smartphones and tablets. The design of prismatic batteries can often differ between different manufacturers, since they do not have a single unification. Electrodes of opposite polarity are separated by a separator. For its production, porous polypropylene is used.

The design of Li-Ion and other types of lithium batteries is always sealed. This is a mandatory requirement, since leakage of electrolyte is not allowed. If it leaks, the electronics will be damaged. In addition, the sealed design prevents water and oxygen from entering the battery. If they get inside, they will destroy the battery as a result of a reaction with the electrolyte and electrodes. The production of components for lithium batteries and their assembly takes place in special dry boxes in an argon atmosphere. In this case, complex welding techniques, sealing, etc. are used. As for the amount of active mass of a Li-Ion battery, manufacturers are always looking for a compromise. They need to achieve maximum capacity and ensure safe operation. The ratio is taken as a basis: Ao / An = 1.1, where

Ао – active mass of the negative electrode;

An is the active mass of the positive electrode.

This balance prevents the formation of lithium (pure metal) and prevents fire.

Parameters of Li-Ion batteries

Lithium-ion batteries produced today have a high specific energy capacity and operating voltage. The latter is in most cases between 3.5 and 3.7 volts. Energy intensity ranges from 100 to 180 watt-hours per kilogram or 250 to 400 per liter. Some time ago, manufacturers could not produce batteries with a capacity higher than several ampere-hours. Now the problems hindering development in this direction have been eliminated. So, lithium batteries with a capacity of several hundred ampere-hours began to be found on sale.

Lithium-ion battery

The discharge current of modern Li-Ion batteries ranges from 2C to 20C. They operate in the ambient temperature range from -20 to +60 Celsius. There are models that are operational at -40 Celsius. But it’s worth saying right away that special battery series work at subzero temperatures. Conventional lithium-ion batteries for mobile phones become inoperable at subzero temperatures.

The self-discharge of this type of battery is 4-6 percent during the first month. Then it decreases and amounts to a percentage per year. This is significantly less than that of nickel-cadmium and nickel-metal hydride batteries. Service life is approximately 400-500 charge-discharge cycles.

Now let's talk about the operating features of lithium-ion batteries.

Operation of lithium-ion batteries

Charging Li─Ion batteries

The charge of lithium-ion batteries is usually combined. First, they are charged at a constant current of 0.2-1C until they reach a voltage of 4.1-4.2 volts. And then charging is carried out at a constant voltage. The first stage lasts about an hour, and the second about two. To charge the battery faster, pulse mode is used. Initially, Li-Ion batteries with graphite were produced and a voltage limit of 4.1 volts per cell was set for them. The fact is that at a higher voltage in the element, side reactions began, shortening the life of these batteries.

Gradually, these disadvantages were eliminated by doping graphite with various additives. Modern lithium-ion cells charge up to 4.2 volts without any problems. The error is 0.05 volts per element. There are groups of Li─Ion batteries for the military and industrial sectors, where increased reliability and long service life are required. For such batteries, the maximum voltage per cell is 3.90 volts. They have a slightly lower energy density, but an increased service life. If you charge a lithium-ion battery with a current of 1C, then the time to fully gain capacity will be 2-3 hours. The battery is considered fully charged when the voltage increases to maximum and the current decreases to 3 percent of the value at the beginning of the charging process. This can be seen in the graph below.

Dependence of charge current and voltage of Li─Ion battery during charging

The graph below shows the stages of charging a Li─Ion battery.

Stages of charging a lithium-ion battery

The charging process consists of the following stages:

- Stage 1. At this stage, maximum charging current flows through the battery. It continues until the threshold voltage is reached;

- Stage 2. At a constant voltage on the battery, the charging current gradually decreases. This stage stops when the current decreases to 3 percent of the initial value;

- Stage 3. If the battery is stored, then at this stage there is a periodic charge to compensate for self-discharge. This is done approximately every 500 hours. It is known from practice that increasing the charge current does not reduce the battery charging time. As the current increases, the voltage rises faster to the threshold value. But then the second charging stage lasts longer. Some chargers (chargers) can charge a Li─Ion battery in an hour. In such chargers there is no second stage, but in reality the battery at this point is charged by about 70 percent.

As for jet charging, it is not applicable for lithium-ion batteries. This is explained by the fact that this type of battery cannot absorb excess energy when recharging. Jet charging can lead to the transition of some lithium ions to the metallic state (valence 0).

A short charge well compensates for self-discharge and loss of electrical energy. Charging in the third stage can be done every 500 hours. As a rule, it is performed when the battery voltage is reduced to 4.05 volts on one element. The charge is carried out until the voltage rises to 4.2 volts.

It is worth noting the poor resistance of lithium-ion batteries to overcharging. As a result of the supply of excess charge on the carbon matrix (negative electrode), deposition of metallic lithium may begin. It has very high chemical activity and interacts with the electrolyte. As a result, the release of oxygen begins at the cathode, which threatens an increase in pressure in the housing and depressurization. Therefore, if you charge a Li─Ion element bypassing the controller, do not allow the charging voltage to rise higher than what the battery manufacturer recommends. If you constantly recharge the battery, its service life will be shortened.

Manufacturers pay serious attention to the safety of Li-Ion batteries. Charging stops when the voltage increases above the permissible level. A mechanism is also installed to turn off the charge when the battery temperature rises above 90 Celsius. Some modern battery models have a mechanical switch in their design. It is triggered when pressure increases inside the battery housing. The voltage control mechanism of the electronic board disconnects the can from the outside world based on the minimum and maximum voltage.

There are lithium-ion batteries without protection. These are models containing manganese. When recharged, this element helps inhibit lithium metallization and release of oxygen. Therefore, protection is no longer needed in such batteries.

We recommend that you additionally read the material on how to properly charge lithium-ion batteries.

Storage and discharge characteristics of lithium-ion batteries

Lithium batteries are stored quite well and self-discharge per year is only 10-20%, depending on storage conditions. But at the same time, degradation of battery cells continues even if it is not used. In general, all electrical parameters of a lithium-ion battery may differ for each specific instance.

For example, the voltage during discharge changes depending on the degree of charging, current, ambient temperature, etc. The service life of the battery is influenced by the currents and modes of the discharge-charge cycle and temperature. One of the main disadvantages of Li-Ion batteries is their sensitivity to charge-discharge mode, which is why they provide many different types of protection.

The graphs below show the discharge characteristics of lithium-ion batteries. They examine the dependence of voltage on discharge current and ambient temperature.

Discharge characteristics of a lithium-ion battery at different discharge currents

Discharge characteristics of a lithium-ion battery at different temperatures

As you can see, as the discharge current increases, the drop in capacity is insignificant. But at the same time, the operating voltage decreases noticeably. A similar picture is observed at temperatures less than 10 degrees Celsius. It is also worth noting the initial drop in battery voltage.

Safety

In general, by now the problem of protecting lithium-ion batteries has already been solved. Electronic protection keeps the charging and discharging process under control. In addition, the cathode material is constantly being improved, including in the direction of thermal stability.

Li-Ion batteries have built-in protection against internal short circuit. Some categories of batteries are also equipped with protection against external short circuits. Internal protection is implemented in the form of a two-layer separator. One layer is made of polypropylene, and the second is made of an analogue of polyethylene. If a short circuit occurs as a result of the appearance of lithium dendrites, then this second layer melts due to heating. As a result, it becomes impenetrable, which prevents further growth of lithium dendrites towards the positive electrode.

Structure of a lithium-ion battery

A lithium battery consists of an electrolyte and a graphite anode. The graphite anode has a layered structure because they have little bonding with each other, as opposed to bonding between atoms. The electrolyte in lithium-ion batteries acts as a barrier, allowing only lithium ions to pass through. Therefore, electrons cannot penetrate through this substance and they simply bounce away from it.

Lithium salt is used as an electrolyte, which must be applied to the separating layer of ion batteries.

Lithium-ion battery protection

Above we mentioned several times the protection of Li─Ion batteries. Let's summarize all the information.

Lithium batteries use a field-effect transistor to open the circuit when the cell voltage rises to 4.3 volts. Thermal protection disconnects the circuit when the battery heats up above 90 degrees Celsius. You can also find a fuse in lithium-ion batteries that trips when the pressure in the housing increases to 1034 kPa. Circuits are also installed that protect the element from deep discharge. Their purpose is to break the circuit when the element voltage drops to 2.5 volts.

How does battery protection work?

The protection circuit for the lithium-ion battery when the phone is turned on has a resistance of 0.05-0.1 Ohm.

These are two keys that are connected in series. The first is designed to operate at the upper, and the second ─ at the lower value of the battery voltage. Resistance doubles the internal resistance of the battery. The battery delivers maximum current with low internal resistance. The protection circuit is designed as an obstacle to an uncontrolled increase in current (both charging and discharging) of the battery. Also, the protection scheme can be implemented using chemical additives. Manganese is used for this. In such batteries, instead of a protection circuit, only a fuse is installed. And all this does not affect safety. Manganese prevents the battery from overheating and igniting. Eliminating electronic circuitry reduces the price of lithium-ion batteries, but this creates another problem. The user can charge such a battery with a “non-native” charger. And in this case, it may happen that the charger does not stop the process when fully charged. Then, without a circuit, the battery will overcharge and fail. Such things end with bloating of the body.

Degradation of Li─Ion batteries

What causes degradation of Li-Ion batteries and what factors lead to a decrease in capacity? This:

- delamination of the graphite matrix;

- destruction of the cathode structure;

- formation of lithium metal particles;

- the appearance of a passivating film on the electrodes. It reduces surface activity;

- destruction of the mechanical structure of the electrode due to changes in the volume of the electrodes during charge-discharge.

Experts have still not come to a consensus about which electrode (cathode or anode) changes more during operation. The final result is influenced by the material of the electrode, as well as its cleanliness. The declared resource of modern lithium-ion batteries ranges from 500 to 1 thousand discharge-charge cycles until the capacity is reduced by 20 percent. But the result strongly depends on the charging voltage. The results of specialist research showed the following results.

Dependence of the capacity of a lithium-ion battery at different threshold charge voltages

It is worth noting that when the “cycling amplitude” decreases, the service life increases. What does it mean? That is, there is no need to discharge the phone before turning it off and charge it to 100%. This reduces the mechanical load on the electrodes, which is caused by volume changes due to the introduction of lithium ions. The deeper the discharge and the more complete the charge, the greater the mechanical stresses the electrodes experience.

History and prospects

The first battery was released in 1912, and began to be used in household appliances closer to the 70s. Lithium-ion batteries were not an immediate success, if only because there were many problems with the safety of their use.

Researchers became interested in the new product and began to become more actively involved in the development of lithium non-metallic batteries.

Subsequently, energy densities were changed and precautions were taken to produce safer Li-ion batteries.

The energy density of the cells is twice that of standard NiCd batteries. In the future, through the use of advanced active materials, it should be further increased to achieve three times superiority over conventional NiCd.

Today there are quite a few types of Li-ion batteries, each with its own advantages and disadvantages.

Prospects for the development of lithium-ion batteries

Lithium-ion batteries have already become a full-fledged family of batteries, like alkaline or car batteries. They stand out from other groups of batteries due to their high energy capacity, charge-discharge modes and a number of other characteristics. Their operation requires the use of electronic charge-discharge control circuits and some other means of protection.

In the case of lithium batteries, the task of using them safely is complicated by size requirements. They must be as compact as possible, since they are used in portable electronics. Due to the close proximity of the electrodes and the desire to achieve maximum specific capacity, lithium-ion batteries could not be brought to market for commercial use for a long time.

Currently, new materials for electrodes are being actively developed. Moreover, when using a new material, a long time passes before it can be introduced into mass production.

There is quite a wide range of lithium batteries on the market in terms of electrical characteristics, dimensions, etc. This is partly due to the fact that there are no uniform standards in this direction yet. In addition, the market has been flooded with products from China and other countries in the Asian region. These manufacturers often do not adhere to any standards, trying to produce the most affordable batteries possible.

Where will the development of lithium-ion batteries go? Experts in this field believe that the main direction of development for them is “smart batteries”. This trend is now clearly visible in various electronic devices. That is, battery identification, state of charge, permissible voltage, temperature - all this must be exchanged between the battery and the mobile device. In addition, the improvement of lithium-ion batteries will be carried out in the direction of reducing size, increasing energy intensity, more flexible solutions in terms of shape, etc. Work is also being carried out in the direction of developing materials for the cathode based on lithium compounds. Their goal is to create models of lithium batteries that can replace nickel-cadmium batteries in devices that consume high current (portable power tools).