Advantages and disadvantages

Currently, there are many lighting devices. Most of them have been produced in the last few years using high technology, but the classic LN still has many advantages or a set of parameters that will be more suitable if used correctly:

- fairly low price;

- resistance to different temperatures;

- instant ignition;

- do not flicker;

- have different light modes.

What does a classic LN look like?

But, unfortunately, incandescent lamps have their disadvantages:

- The main disadvantage is the rather reduced efficiency. For 100 W bulbs the efficiency will be approximately 17%, for 60 W products this figure will be only 5%. One of the methods for increasing efficiency would be to raise the filament temperature, but in this case the service life will noticeably decrease;

Spiral for incandescent lamp

- short service life;

- increased temperature of the surface of the vessel, which can be up to 250°C for a 100W light bulb. This increases the risk of lamps catching fire or exploding;

- sensitivity to the environment;

- use of heat-resistant fittings.

The types and characteristics of incandescent lamps are described in detail below.

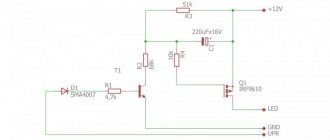

LED bulbs

LED lamps - this high technology product was first designed in 1962. Since then, LED lamps have gradually been introduced into the lighting market. Based on the principle of operation, an LED is the most common semiconductor in which part of the energy in the pn junction is discharged in the form of photons, that is, visible light. These lamps have simply amazing characteristics.

The LED flashlight is characterized by bright light and extremely low energy consumption

They are ten times superior to LON in all indications:

- durability,

- light output,

- efficiency,

- strength, etc.

They have only one “but” - the price. It is approximately 100 times the price of a conventional incandescent lamp. However, work on these unusual light sources continues, and we can expect that we will soon rejoice at the invention of a cheaper model than its predecessors.

LED lamp

Note! Due to the unusual physical characteristics of LEDs, real compositions can be made from them, for example, in the form of a starry sky on the ceiling of a room. It is safe and does not require much energy.

These articles may also be of interest to you:

- Selection and installation of switches

- Artificial lighting of the apartment

- Installation of street lighting

- Lighting design

Characteristics

One of the main parameters of incandescent light bulbs will be the power, indicated in watts. The purpose of the lamps is different, so the range of choice is large - from 0.1 W “lamp” to 23 thousand W floodlights for airfields.

In everyday life, low-power light bulbs are used, usually from 15 W to 200 W, and in production they use lamps with a power of up to 2000 W.

The quality of the light beam and the level of dispersion are regulated by the material of the vessel.

car light bulb

The greatest light transmission is inherent in products with transparent glass, because they do not absorb light. The matte surface of the lamp absorbs 5% of light rays, and the white surface absorbs 15%.

The size of incandescent light bulbs can be from 60 mm to 130 mm. Depends on the scope of application.

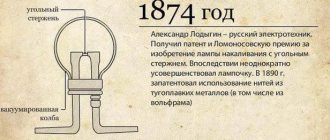

Features of the Lodygin light bulb

Modern incandescent lamps, which are direct descendants of Alexander Lodygin’s model, are characterized by:

- excellent luminous flux;

- excellent color rendition;

Color rendering of incandescent lamp

- low convection and heat conduction;

- filament temperature - 3400 K;

- at the maximum level of the filament temperature indicator, the efficiency coefficient is 15%.

In addition, this type of light source consumes a lot of electricity during its operation, compared to other modern light bulbs. Due to their design features, such lamps can operate for approximately 1000 hours. But, despite the fact that, according to many evaluation criteria, this product is inferior to more advanced modern light sources, due to its low cost, it still remains relevant.

Principle of operation

When electric current passes through the coil, it quickly heats up to high temperatures of almost 2500 degrees. This is due to the fact that the spiral has a high resistance to current and a large amount of energy is required to pass it.

The heat heats the metal (tungsten) and the lamp begins to glow. Since there is no oxygen inside the lamp, tungsten does not oxidize.

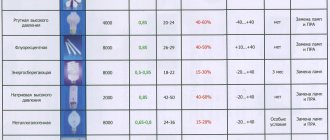

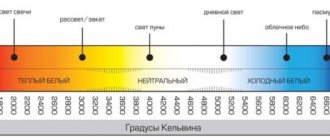

Color temperature table

The efficiency of the old-style 100 W incandescent lamp, where the role of the filament body was played by a coal rod, was much less than that of the latest models. This is due to the additional costs of convection. Spiral filament bodies have a lower percentage of such losses.

LED lamps depending on the color temperature of light

When considering the types and characteristics of LED lamps, one cannot help but dwell on such a parameter as the color temperature of the light. Despite the word “temperature,” this concept has absolutely nothing to do with the heat generated by the light bulb. It means the visual perception of the color spectrum of light that the lamp emits.

Therefore, there is no need to confuse physical and color warmth. Color temperature is measured in Kelvin, which for LEDs can reach readings of up to 7000 K.

Warm light

There are certain rules for choosing LED lamps. Depending on the purpose of the room, lamps with suitable heat are used. For example, lamps with temperatures in the range from 2500 to 3500 K, which have a “warm light”, create a comfortable atmosphere. Yellow color, similar to the light emitted by an incandescent lamp, is suitable for recreational areas.

Daylight

Fluorescent lamps with temperatures in the range of 4000 to 5000K have a neutral color emission and are used primarily in work areas. They are well suited for the desktop, kitchen, bathroom.

Cold light

The brightest cold light is emitted by lamps with temperatures above 5500 K. Such lamps are installed in places where it is necessary to maintain an energetic state: in workshops, garages, etc. However, if you stay under cold lighting for a long time, you may feel tired.

Types of lamps

Incandescent lamps are divided into several types:

Decorative light bulb models

- vacuum;

- argon or nitrogen-argon;

- krypton;

- halogen with a connected infrared light reflector inside the bulb, which increases efficiency;

- with the coating necessary to convert infrared light into the visible spectrum.

General, local purpose

The characteristics of general purpose LN are specified in GOST 2239-79. These light bulbs are used to connect to luminaires for the main lighting of domestic and public places, as well as outdoor spaces.

The main voltage can be 127 and 220 V. The range of products is divided into groups depending on the type of filament (spiral or bi-spiral) and medium (vacuum, gas).

Proper storage of the product

The shape of the vessel, installation method, product brand and type of base are selected based on cost, practicality of technology, and at least 100 hours of operation. It must be emphasized that in recent years the efficiency of such lamps has been assessed based on a variety of characteristics.

You might be interested in this: The difference between white and yellow light

LN for local use, produced under GOST 1182-78, the voltage should not be higher than 36 V, and for industrial premises where there are flammable substances - 12 V. The power of lamps for local use is limited and will be 15, 25, 40 and 60 W. The service life of each incandescent lamp must be at least 75% of the average glow duration.

For street lighting, more powerful lamps are used so that they do not have to be changed every month or two. Since this is a rather labor-intensive process.

Illumination lamps 15 W

Decorative

Decorative light bulbs can be of various shapes, round, oval, spiral and so on. The radiation source will be a tungsten filament. It creates a cozy and warm light in the room. The factory mainly produces designer products for the classic E27 base, but there are models for the E22 and E40 base. The voltage required for correct operation is 220 V. The service life of decorative products with tungsten filament can be in the range of 2000-3400 hours, but no more. The lighting temperature is characterized by a parameter of 2700 K.

Such products are often used to decorate rooms, staircases or Christmas trees. Large shopping centers use decorative light bulbs suspended from high ceilings. It looks truly beautiful and at the same time cozy. They will harmoniously combine with the Loft style in a house or apartment.

Illumination

These incandescent lamps are produced with a colored inner layer of the bulb and are necessary for New Year's garlands or illumination of stairs, shops and shop windows. It has a wide range of colors, including cold, white, day and night shades. Quite a long service life of up to 25,000 hours, with proper operation. The main disadvantage will be the heavy installation. The closer the end of the product's life, the weaker it will work. The light will begin to scatter poorly.

Airplane front lights

Signal

Signal lights are mainly used in various industries. The simplicity of the device and a large range of models help you choose products for work in different areas of production. Lamps can be mounted on machines, control panels, special vehicles, and so on. Very often used in mechanical engineering, woodworking or metallurgy.

Attention! You can connect one light bulb to perform several operations, or use 2-3 products for different purposes at the same time. Based on the scope of use, the color and shape of the lamp is selected.

Modern incandescent lamps are manufactured specifically for use for industrial purposes, which provides a number of advantages over conventional light signaling lamps:

Mirror lamp r65

- various color modes providing more informative signaling;

- many choices of lamp shades;

- suitable for any electrical network;

- easy installation on machines using a screw connection system;

- ability to replace contacts;

- the use of high-brightness LED bulbs to improve visibility in any industrial areas;

- convenient case with the ability to select the desired size;

- energy saving;

- ease of use.

Mirror

The mirror-type product differs from other LPs in the rare shape of the bulb, as well as the presence of a coating with light reflection, which is similar to thin foil.

What is an incandescent light bulb made of?

This coating is sprayed onto the lamp in order to diffuse its light radiation in the room, in order to more correctly distribute it within a certain point, so that it is possible to clearly illuminate a certain room.

To get this option in a regular lamp, you need to place a large light reflector behind it.

Mirror bulbs are mainly connected to directional luminaires used for spot lighting of stores to illuminate the necessary areas. They are also used for offices, stairs, architectural monuments.

Mirror lamps can be multi-colored and transparent, matte, or with the effect of UV rays. They are produced by all well-known lighting factories.

Types of products

Transport

Transport incandescent lamps are used as lighting for cars. In an electrical circuit, the filament of the body heats up and at the peak temperature a glow begins. The energy of the light beam perceived by the ordinary eye will be small. The bulk of the energy will be in the form of heat.

A transport lamp consists of a bulb, several filaments, a base and leads.

You might be interested in How to recycle lamps

Filaments in two-filament products can work differently. Car headlights and interior lamps are equipped with double-filament bulbs.

The filament is sure to withstand elevated temperatures and is also quite small. Therefore, it is made from medium-sized tungsten wire, curled into an elongated spiral.

Double thread products

The spiral is connected to the electrodes and generally has the shape of a straight line or a semicircle arc. The melting point of tungsten will be about 4000 degrees. During operation, the coil heats up to 2500-2800 °C. As the tungsten temperature increases, the brightness and luminous efficiency of the rays on the laser increases. But if the readings exceed 2500 °C, tungsten will quickly evaporate and remain on the walls of the glass vessel, resulting in a layer of plaque that will reduce the quality of lighting. The service life of such products is usually from 4 months to six months. Depends on the manufacturer and the quality of production raw materials.

Double strand

This product can be of three types:

Traffic light lamps

- for cars. One thread is used for low beam, the second for high beam. If we talk about lamps for rear signals, the same threads can be used for brake lights and side lights. An additional screen will remove beams that in the low beam signal can blind the owners of oncoming cars;

- for an aircraft. In a landing light, the first filament is used for low illumination, the second for high illumination, but if the second one works for too long, cooling may be necessary, otherwise a fire may occur;

- for traffic lights on railways. Both threads are needed to increase reliability - if one burns out, the other will work.

Types of flasks

Types of lamps and their functional purpose

The type of lamp is determined by its structural purpose, functional:

- Normal lighting is the most common type. Designed for general and decorative lighting. The release of this type is limited.

- Decorative - of different sizes, with a figured glass bulb. The appearance is very unusual and beautiful. Therefore, the application is special, decorative.

- Illumination - multi-colored external color. The tone is applied to the inside of the glass bulb. Inorganic pigments are used for coloring. External coloration is very rare. Power limit is up to 25 watts. The more use, the more the color and brightness changes.

- Signal - for illuminating signal devices. Now they have been replaced by LED lamps.

- Mirror incandescent lamps are of a peculiar shape. The inner glass surface is coated with a layer of aluminum. This gives the product a mirror-like appearance. The principle of operation is that the light flux is distributed and collected in a certain area. Application: trading floors, showcases, incubators (heating newborn chicks).

- Transport. Scope of application: car, motorcycle, tractor headlights, lighting. They differ in strength and vibration resistance.

- Double strand. Applicable for car headlights. One thread for low beam, the other for high beam. It is also used in places where constant lighting is required; when one thread burns out, the second one works.

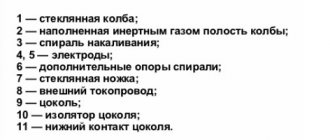

The structure of an incandescent lamp

The design of the different types of incandescent light bulbs does not differ much, but three common components can be emphasized, the filament, the glass bulb and the electrical inputs. They differ in the design of the filament body brackets, the type of bases, and sometimes come without bases.

To prevent the bulb from deforming when the coil overheats during operation, the incandescent lamp is equipped with a ferronickel fuse; it is mainly located in the leg. At the point where the spiral breaks, an electric arc appears, due to which pieces of the spiral melt and fall on the flask, which can lead to its damage. By using fuses this process can be avoided. But in the last 5 years they have rarely been used, as they are not very effective.

Argon light bulb

Incandescent lamp design:

- flask;

- filament coil;

- electrodes on both sides of the body;

- hooks on which the spiral is held;

- leg;

- current input;

- base with insulator;

- contact at the end of the socket.

Flask

The glass bulb protects the spiral from the harmful effects of air; when it is deformed, the filament body oxidizes and quickly explodes. The composition of the lamp bulb varies; it can be filled with a vacuum or a gaseous environment. The first incandescent lamps were produced with a vacuum container, but their power was not high. To fill modern products, nitrogen-argon substance or exclusively argon is used. Some types of light bulbs can be filled with krypton or xenon. The heat transfer of a light bulb depends on the molar mass of the filler.

Definition of LN

Gas medium

The gas environment in the lamp must be inert. Since the temperature of the spiral reaches 2500 degrees, it can react to any gas, but not inert. Therefore, argon is most often used for filling.

If water suddenly gets on a hot or working lamp, it may rupture under the influence of gas.

Sometimes lamps are filled with xenon, but this will be relatively expensive.

In many lamps, the gas environment will be a safety feature. In others, an electrical discharge produces beautiful colored radiation. The shade will depend on the properties of the inert gas.

filament body

The types of filament bodies can be different and depend on the functional purpose of the light bulbs.

Types of light sources

The most popular ones will be made from wire with an oval cross-section, but sometimes there are also strip filament bodies (consisting of a metal strip).

As already mentioned, the first filament bodies were made from coal. Modern LPs use only filament bodies made of tungsten, less often of osmium-tungsten substance.

You might be interested in: Operating principles and characteristics of lighting of induction lamps

To reduce the size of the filament, it is usually made in the form of a spiral, sometimes it is re-processed to form a coil. The efficiency of such products is higher due to reduced heat loss during convection.

Electrical parameters

The luminous efficiency of such products is quite low. It will be the lowest among popular light bulbs and ranges from 5 to 10 lm/W. The increased brightness of the filament in combination with its small size allows the products to be used in floodlights.

Classic plinths

LNs have a wide range of medium voltages and powers. This type of product can function in a wide range of ambient temperatures, which is limited only by the thermal stability of the raw materials used in its production (-100...+350 degrees). The light emission of the LN is adjusted by transforming the operating voltage.

With this minus, there will be an increased operating temperature and the amount of heat released during combustion. Since the temperature of the light bulbs is high, they become vulnerable under the influence of water or a sharp change in degrees (from minus to plus and vice versa).

In the modern world, many have long abandoned the use of incandescent lamps. In developed cities, only 20% of people use such products. Everyone is switching to halogen lamps.

When the light bulb is turned on, the filament body is at normal temperature, then the resistance of the product will be much less than the operating resistance. When turned on, a large amount of current flows. As the thread splits, its resistance increases and the current decreases.

Manufacturing process at the factory

Unlike the newest products, older models of incandescent lamps with carbon filaments had a reverse process when turned on, with an increase in current. The increasing resistance function of the filament allowed the lamp to be used as a primitive electrical stabilizer.

Base

The threaded base type for the classic incandescent lamp was designed by Joseph Wilson Swan. The sizes of the socles had their own standards. Products of the usual type (for home) had a base of E14, E27.

Sometimes there are bases without threads (in this case, the light bulb is held in place by friction), as well as baseless lamps, more often used in cars. The E40 size will be rare; it is used for more powerful products from 500 W.

Structure

A typical lamp consists of the following structural elements:

- flask;

- vacuum or inert gas pumped inside it;

- filament;

- electrodes - current terminals;

- hooks needed to hold the filament;

- leg;

- fuse;

- base, consisting of a housing, an insulator and a contact on the bottom.

In addition to standard versions made of conductor, glass vessel and leads, there are lamps for special purposes. Instead of a base, they use other holders or add an additional bulb.

The fuse is usually made of an alloy of ferrite and nickel and is placed in the gap on one of the current terminals. Often it is located in the leg. Its main purpose is to protect the flask from destruction in the event of a thread break. This is due to the fact that if it breaks, an electric arc is formed, leading to the melting of the remnants of the conductor, which fall on the glass bulb. Due to the high temperature, it may explode and cause a fire. However, for many years the low efficiency of fuses has been proven, so they are used less frequently.

Flask

The glass vessel is used to protect the filament from oxidation and destruction. The overall dimensions of the flask are selected depending on the deposition rate of the material from which the conductor is made.

Gas environment

If previously all incandescent lamps without exception were filled with vacuum, today this approach is used only for low-power light sources. More powerful devices are filled with inert gas. The molar mass of the gas affects the heat emitted by the filament.

Halogens are pumped into the bulb of halogen lamps. The substance with which the filament is coated begins to evaporate and interact with the halogens located inside the vessel. As a result of the reaction, compounds are formed that decompose again and the substance returns to the surface of the thread. Thanks to this, it became possible to increase the temperature of the conductor, increasing the efficiency and service life of the product. This approach also made it possible to make the flasks more compact. The design flaw is associated with the initially low resistance of the conductor when applying electric current.

Filament

The shape of the filament can be different - the choice in favor of one or the other depends on the specifics of the light bulb. They often use a thread with a round cross-section, twisted into a spiral, and much less often - ribbon conductors.

A modern incandescent lamp is powered by a filament made of tungsten or an osmium-tungsten alloy. Instead of conventional helices, bi-helices and tri-helices can be twisted, which is made possible by repeated twisting. The latter leads to a decrease in thermal radiation and an increase in efficiency.

Best before date

The service life of a product depends on its quality. LN should be stored in a cardboard box. This is necessary so as not to accidentally break it or so that it does not give an imperceptible crack that will ruin the whole work. Because of such a crack, the gas will evaporate; as a result, after the light bulb is screwed into the lampshade, it will work for no more than 2-3 hours. You must follow safety rules when screwing the lamp into the lampshade. Children should not be allowed to participate in this process, and it is also advisable to completely turn off the electricity supply in the room.

Note! Used light bulbs must be disposed of properly and should not be thrown away with food waste. Every city has special bins for such waste.

If you follow all the rules of storage and use, the lamp will last as long as possible, without defects.

Vintage Edison lamp

LED lamps depending on the type of bulb

The variety of shapes of modern lamps allows you to choose suitable types for any purpose. The most common shapes of flasks are “corn”, “pear”, “candle”.

Corn

As the name suggests, the flask resembles an ear of corn. It has an elongated cylindrical shape, its diameter not much larger than the size of the base. Many yellow diodes are arranged on substrates in the form of a polyhedron and resemble corn kernels on the cob. The lamps have a good ability to diffuse light, the angle of which can exceed 300 degrees. These types of lamps are used with horizontal lamps, as well as with spot lighting with a shading shade.

Various options for flasks in the shape of corn

A rare type of lamp with a corn-shaped bulb is the filament lamp. Placing the filaments in a cylinder does not provide the product with almost any advantages, but only reduces the amount of helium. At the same time, power is significantly reduced and thermal conductivity deteriorates. Therefore, a corn lamp using filament diodes can be used as a moderate point source of lighting.

Options for filament lamps in the shape of corn

Pear

Pear-shaped LED bulbs resemble regular incandescent bulbs. Spot LED lamps have a beam angle of up to 180 degrees, since all diodes are placed on one side of the plate. Pears are used mainly for central lighting chandeliers with arms pointing downwards. If the sockets are oriented toward the ceiling, the lower part of the room will be shaded.

Variants of the pear-shaped flask

Bulb bulbs are often used in filament lamps. Thanks to the 360-degree flux dispersion, the room is illuminated evenly, and there are almost no shadowed areas. However, if you want to create a local light source, you will have to use a shading shade for such lamps.

Options for pear-shaped filament lamps

Candle

The LED “candle” has a limited dispersion angle and low power. To organize central lighting, such lamps should be presented in large quantities, using a chandelier with horns pointing downwards. If the sockets are facing upward, a shadow area will form under the lamp. The optimal use for a candle is bedside lamps or table lamps.

The shape of the flasks is varied; they can be either simple or twisted candles, as well as an imitation of a candle in the wind, with a curved top. The main disadvantages of such a bulb include low power and weak light flow. Therefore, it is better to use them in chandeliers with a large number of sockets or for local lighting (night light, sconce, bedside lamp).

Variants of the flask in the form of a candle

The filament design of the candle allows you to achieve almost the same benefits as a pear. These types of LED lighting lamps have a maximum beam angle and are almost universal. At the same time, they are compact and safe.

Options for filament lamps in the form of a candle

Incandescent lamp device

The main parts that make up the LN design are the base, vessel, electrodes, holders for filament filaments, filament body, contacts and insulation. In Figure 10 you can see the structure of a light bulb.

Before purchasing a lamp, it is advisable to consult a specialist. It is not recommended to choose an unknown manufacturer, as you may end up with defective products that will not work as expected, or even rupture under voltage. Quality manufacturers always provide a guarantee of at least 30 days on incandescent lamps. The buyer has the full right to exchange the product or return the money if the lamp's operation was less than 10 hours or it burned out instantly.

In conclusion, it should be noted that incandescent lamps have long ceased to be popular among people. However, it must be emphasized that among such products there is a huge selection, for cars, street lighting, airplanes and so on. Unfortunately, LN cannot be used near products made of wood. Since sometimes there is strong heating and rupture of the spiral, which can cause an emergency situation.

Halogen lamps

Halogen lamp with regular base

Halogen lamps are not much different from incandescent lamps; the operating principle is the same. The only difference between them is the gas composition in the cylinder. In these lamps, iodine or bromine is mixed with an inert gas. As a result, it becomes possible to increase the temperature of the filament and reduce the evaporation of tungsten.

Lamp for built-in lamp

That is why halogen lamps can be made more compact, and their service life increases by 2–3 times. However, the heating temperature of glass increases quite significantly, which is why halogen lamps are made of quartz material. They do not tolerate contamination on the flask. Do not touch the cylinder with an unprotected hand - the lamp will burn out very quickly.

Halogen linear lamp

Linear halogen lamps are used in portable or stationary floodlights. They often have motion sensors. Such lamps are used in plasterboard structures.

Halogen compact mirror lamps with G4 base

Compact lighting devices have a mirror finish.

The disadvantages of halogen lamps include sensitivity to voltage changes. If it “plays”, it is better to purchase a special transformer that equalizes the current strength.

Spotlight

Results.

Incandescent lamps served people faithfully throughout the 20th century. In the current century, LED and fluorescent lighting devices are replacing them. In our country, as part of the fight for energy efficiency, programs have been adopted that stimulate the development of the production of more modern light sources. Many Russians have already stopped using incandescent lamps in their apartments. However, some of their advantages are unique. For example, high color rendering is indispensable for photo and film production. Many special lighting devices still work only using old technology. Some people simply take care of their eyes and use Ilyich’s lamp. And for rooms with short-term light switching on once a week, an incandescent lamp is the most economically feasible option. The choice remains with the individual consumer!

- Related Posts

- Features and types of halogen lamps (hb4,h11,hb3,g9).

- Why do you need electronic ballasts (electronic ballast) for fluorescent lamps?

- Quartz lamp for home disinfection