What is a primer composition, what types of primers are there?

A primer is a liquid that prepares the surface for the next coat. It is clear that the “surface” is different, with different characteristics and problems. And “next layer” is also a very general name. The purpose of the primer is to improve the conditions for laying the next layer. To solve various problems, compositions with different properties are needed. Therefore, there are many soils and they act differently.

To choose the right type of primer, you need to understand why you need it, what problem it will solve

It is necessary to select a primer based on what problems need to be solved. This means that you need to have at least a general idea of their types and how they change the properties of the treated surface. Based on their properties, primers are divided into three groups: adhesive, filling and deep penetration. Read more about what happens to the surface after treatment with each of the compounds.

Adhesive

The adhesion primer serves to increase the “adhesion” of the two layers. After drying, it forms a sticky film on the surface, so it can also be called film-forming. Often it contains sand of different fractions for better “adhesion” of the layers. Area of application: weakly absorbent substrates.

Low-absorbing bases are metal, glass, tiles, smoothed (reinforced) concrete. One of the most famous examples of an adhesive primer is BetonoKontakt. I advise you to use it almost everywhere, but it is only needed on very dense substrates that almost do not absorb moisture. In other cases, it is irrational to use it.

The most popular composition of adhesive primers is Betonokontakt.

There is only one example of using Concrete Kosntakt for a floor: if you lay new floor tiles on old ones. In a good way it should be removed. But sometimes you need to raise the overall floor level. And by removing the tiles and glue, you lose the desired height. Removing tiles and then pouring screed is expensive and time-consuming. If the old tiles lie “tight” on the floor, the floor is flat, then you can go through the old coating once or twice with Concrete Contact, and then lay the new floor tiles. This is all. There is no other use for this type of primer on concrete floors.

Filling

Filling impregnations, on the contrary, are applied to highly absorbent substrates. They clog some of the pores, reducing and leveling the absorbency of the surface. It makes sense to apply them to loose surfaces. In the case of a concrete floor, filling impregnation can be applied before:

- By painting or applying varnish. To reduce the consumption of paints and varnishes.

- Under tile adhesive. In case it is necessary to extend the “lifetime” of the glue. Due to the fact that less water will be absorbed, it will remain mobile longer. This will give you more time to bring the tiles into the level.

From the whole variety you need to choose the right composition - Before gluing the floor covering directly onto the screed. Some coverings (linoleum, parquet boards, carpet) can be glued directly to a flat concrete floor. To reduce glue consumption, you can use filling primer.

If you are preparing a concrete floor for painting, so that less paint is wasted and it goes on more evenly, it makes sense to coat it with a filling primer. Diluted paint and varnish composition is often used as this primer before painting. This gives the primary color and reduces absorbency. After all, any floor paint clogs pores, which means it performs the task of a filling primer.

Deep penetration

Deep penetration primers are used on surfaces that are constantly dusty and crumbling. The soil components penetrate deep into the material through the pores and bind (glue) unstable particles together. Thus, the material becomes denser and generates less dust. This composition has almost no effect on the amount of moisture absorbed. Deep penetration primers are also called penetrating or strengthening primers.

This is how deep penetration primer works on a concrete floor.

Actually, strengthening is a special subtype of soil of this type. They contain more adhesive components. So, when treated with a deep penetration strengthening primer, due to the gluing of material particles to each other, it becomes less dusty or friable. If you want your concrete floor to be virtually dust-free, you can treat it with a deep-penetrating strengthening primer. The effect is similar to painting, but without changing the color.

Composition of primer for concrete floor

We figured out what primers there are based on their properties. Such different effects are achieved because they are made on the basis of different substances. This is reflected in the properties of the final product and affects the scope of application. The following primers can be used for concrete:

- acrylic;

- silicone (organosilicon);

- epoxy;

- polyvinyl acetate;

- silicate.

This is just the basics. Adhesives, abrasive particles, antifungal components, and other additives are added to the “base” solution. The specific composition varies depending on the manufacturer and on what work the composition is intended for.

Five types of primers are suitable for application to concrete

If we talk about fire properties, then acrylic, polyvinyl acetate and silicate soils are fireproof. They are low-hazard when liquid and safe when dried. Epoxy is dangerous until it dries.

Properties of primers for concrete

About solvents and odors. The least odorless primers are diluted with water. These are acrylic, silicone, silicate and polyvinyl acetate. Epoxy primers are diluted with organic solvents (white spirit, acetone, etc.) and have a strong odor. So they should be applied in ventilated areas.

Based on the resistance to film abrasion and weathering, three groups can be distinguished:

- High durability. These are alkyd, organosilicon, epoxy, silicate.

- Medium - acrylic primers.

- Low - polyvinyl acetate.

Not all characteristics are equally important when choosing a primer.

You should pay attention to the durability of the film if you are not going to apply a protective coating over the primer. Or time must pass until the next stage. If you paint or lay tiles immediately after the soil has dried, this characteristic is not so important.

Almost all soils can be used outdoors. The exception is polyvinyl acetate. They are for internal use only. Acrylic primers can be for exterior or outdoor use. So you need to pay attention here if you are going to prime concrete in an unheated room or in an open area.

Types of compositions

Today, in the sale of construction stores you can find primers for various purposes: for wet rooms (bathroom, kitchen), for strengthening concrete screeds. There are also universal formulations. Each of the soils has its own characteristics, which you need to know when choosing a product.

The compositions are as follows:

- Alkyd. Used for treating wooden bases before painting them. The drying time for such soil is 10 hours. Depending on the type of paint, the type of alkyd mixture will vary.

- Glypthal. Used for metal surfaces. The characteristics of the composition indicate that it should be used only in enclosed spaces. The period of complete drying is 24 hours. There are special primers for metal with the addition of zinc that significantly improve the structure of the base.

- Polyvinyl acetate. Regardless of what kind of base the floor has, such mixtures are used subject to further processing with polyvinyl acetate paint.

- Perchlorovinyl. Suitable for application on both concrete, brick and plastered surfaces. The main feature is its use in open areas located outside the building. Drying time – 1 hour.

- Acrylic. Ideal for concrete floors and cement screeds. Such mixtures are odorless and dry within 5 hours. They are considered the most popular among consumer choice today. The product penetrates deeply into the floor, improving adhesive properties.

- Polystyrene. They have a strong odor, so they are used strictly in ventilated areas. The mixtures are used to treat wooden floors and floors to be poured.

It is not recommended to use an acrylic primer on iron, since the special components in its composition will contribute to the appearance of rust.

Primers for concrete floors

The concrete base has a porous structure, so it requires soil that penetrates deeply inside. An important characteristic of such a floor is its problematic adhesion to the finish; therefore, the chosen product should significantly improve this indicator.

Here are examples of compositions that are ideal for concrete foundations:

- polymer-based;

- epoxy and polyurethane mixtures;

- concrete contact primers.

The polymer component of the soil suggests the presence of quartz sand in the base. This promotes increased adhesion due to small projections in large numbers. This option is perfect for further laying linoleum on the floor.

An epoxy or polyurethane composition is able to penetrate deeply into the pores of the base, filling all voids. This is a big plus for floors used in industrial premises. It is these coatings that often experience increased loads, as well as exposure to chemicals. The epoxy mixture can protect the floor from these negative factors and extend its service life.

The concrete contact mixture acts on the principle of a polymer primer. It also contains fine quartz sand and creates a rough floor surface. This composition is appropriate before pouring the flooring.

Concrete floors can be monolithic or consist of a cement screed. In the first case, it is recommended to use a primer for poorly absorbent surfaces, since the top layer of the floor has a smooth structure and high density. Depending on the type of concrete base, the most suitable compositions should be selected.

Deep penetration primer is most suitable for concrete screeds that contain cement and expanded clay. The mixture strengthens the structure in the best way, penetrating deeply inside.

On the video: how and with what to prime a concrete floor.

Primer for wooden base

Wooden floors always remain in fashion: they are not only beautiful, but also create an atmosphere of comfort and warmth. In order for the base to serve for a long time, it is necessary to take care of its structure in advance by treating it with a special primer mixture for wooden surfaces. The composition is applied to the floor before painting - this improves its adhesion and reduces the consumption of paint and varnish products.

Wooden floors are impregnated with phenolic, glypthal, alkyd and polystyrene compounds. After application, the mixture is well absorbed and creates a beautiful silky surface.

Compositions for treating wooden floors contain the following components:

- Fire retardants - prevent the fire of lumber and are suitable for treating industrial floors.

- Biocides - repel harmful insects that can spoil the structure of wood.

- Antiseptics – prevent the appearance of fungus and mold.

Penetrating mixtures provide the most long-lasting effect - they penetrate deep into the structure of the tree and saturate it, thereby protecting it from negative influences. Depending on the color and composition, primers have the following properties:

- opaque primer is suitable for treating the floor before painting;

- the transparent composition is ideal before applying varnish;

- polystyrene-based impregnations are used only with similar paints;

- products with color are suitable for oil paints;

- alkyd primer penetrates well into pores and is suitable for impregnation of open areas.

For each case, the primer is selected individually. If you approach the issue correctly, you can get a high-quality, reliable result.

How and with what to apply primer to a concrete floor

The primer is applied to dry, clean concrete. If the screed is old, remove dust and dirt first. Oil stains also need to be neutralized. During preparation, concrete can be washed with special products, but after that you will need to wait until it dries completely.

The primer is applied to dry and clean concrete. The most convenient way is using a roller. Some primers have a faint tint (marker) that helps control application. But most markers on a concrete floor are not visible. It's usually too dark. So if there is a composition with and without a marker, then it makes no sense to overpay for the marker. If you still want to control the application, add a little paint. For water-soluble primers, you can add a coloring pigment for water-based emulsions or any other paint that is diluted with water.

It is not always easy to control the application of primer

The primer is applied to the floor in at least two layers. In order to avoid gaps, the direction of application is changed. For example, the first layer is applied along a long wall, the second along a short one. The second layer should be applied only after the first has completely dried. But there are exceptions. Some compositions can be applied after the first layer has partially dried. This is indicated in the description of the primer.

When it comes to drying time, epoxy and acrylic primers dry the fastest. The time until the layer of these compounds dries completely is 1-3 hours. Organosilicon and polyvinyl acetate dry in 3-6 hours, silicate - 6-12 hours, alkyd - 12-24 hours.

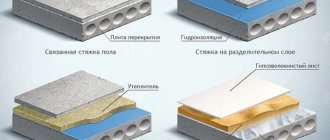

Features of applying primer after screed

The finished screed should be primed after the concrete surface has completely dried and hardened. Cement mortars can take three weeks or more to dry. Before applying the primer, the concrete floor is thoroughly cleaned of sand and dust - it is best to use a vacuum cleaner. The cleaner the surface, the better the adhesion.

Then a solution is prepared. If the primer is acrylic, it is recommended to mix it thoroughly. If the composition is epoxy, then mix the two components (the proportions are indicated on the packaging). If acrylic concentrate is used, then it is diluted with water according to the manufacturer’s recommendations and mixed thoroughly.

As for application, the first step is to treat all areas adjacent to the walls. It is quite problematic to process there with a roller. It is important to cover each area with soil - there should be no untreated areas. Then the primer is applied to the main surface. First, they pass over the surface several times - the composition should get on it, then they pass several more times over the already wet area in order to distribute the material as evenly as possible.

Epoxy primers are applied in the same way - the only difference is that they are primed in one layer. The acrylic composition is applied in two layers because it is impossible to achieve maximum surface reliability any other way.

After a day, the primer will dry, and you will have an ideal, protected base, fully prepared for subsequent finishing. On such a floor you can lay tiles, ceramics, and other finishing floor coverings. After the primer dries, the floor will not become dusty. Also, there will be good adhesion with any adhesives.

Recommendations for priming (2 videos)

Different types of primers (35 photos)

Why do you need a primer for a concrete floor?

Despite the fact that there are many types of primer compositions, their use for floors is limited. It’s just that the technologies and finishing materials are such that they do not require additional processing. When is a concrete floor primer needed? It makes sense to use in the following situations:

- Before painting. To reduce paint consumption, it is worth applying a filling primer. Select the base according to the type of paint. A couple of examples. If it is acrylic paint, then acrylic primer is also needed. For paints based on natural solvents (for example, oil), epoxy primer is suitable.

- For dust removal. In technical rooms, painting the concrete floor does not always make sense. The paint wears off, which makes it look “not very good” after just a couple of months. But I want to solve the problem of “dusting” of concrete. A strengthening primer is suitable for removing dust from a concrete floor. It almost does not change color, but binds the particles to some depth. Of course, the “bound” layer wears out, and part of the primer composition is washed away. But for some time the amount of dust decreases significantly.

Before applying a leveling screed (self-leveling solution), primer is only needed if the base is old - Under tile adhesive. If the life of the cured adhesive is short, it makes sense to apply a filling primer to the screed. By reducing the absorbency, the tile adhesive will “live” longer. But not by much. You can count on the upper limit of the range specified by the manufacturer. Hardly any more.

- Before applying the leveling layer. Modern flooring requires a level base. Therefore, various types of levelers are often poured over a regular screed. If the screed is “fresh”, then no additional processing is required. If it is old but strong, it makes sense to go through the ground. Binding or strengthening - depending on the situation.

- On old tiles before laying new ones. In this case, an adhesive primer is applied. It is possible with abrasive particles (with sand).

- A fill primer is used before gluing the final floor covering.

As you can see, there are not many situations for using a primer on a concrete floor. There may be other situations where their use is justified. But always think carefully about whether this layer is really needed. And won't he make the situation worse?

Primer consumption per 1 m2 of concrete floors

Silicone primer Polyurethane primer Epoxy primer

Acrylic. Applicable for all surfaces, except metal. No pungent odor, diluted with water, dries quickly.

Silicone. They are very elastic, have high water-repellent properties, an ideal solution for treating facades. The price is significantly higher than acrylic ones.

Alkyd. Excellent for wooden bases. The wood structure swells, resulting in a rough surface that is highly susceptible to most finishing coatings. When applied to metal, they remove rust and prevent further corrosion, so even water-based paint can be used for subsequent work. Not recommended for priming plaster and gypsum surfaces. Dry for at least 12 hours.

Polyurethane. Designed for priming concrete and asphalt concrete floors before applying polyurethane-based materials. There are one-component (moisture-curing) and two-component ones.

Epoxy. Used for priming concrete and magnesium floors before epoxy, water-based epoxy, water-based and organic-based coatings. Consist of two components.

Silicate. A specific product, the use of which is justified in old buildings constructed using materials containing silicates.

- Deep penetration primer, Tiefengrund according to the European classification. Used for penetrating priming. The main purpose is to increase the strength of the base. Does not leave a film on the surface, is completely absorbed, and practically does not reduce the water absorption capacity of the base. Apply to loose surfaces that require preparation before applying base materials, such as old lime plaster.

- Universal, Putzgrund according to the European classification. Designed for surface priming. Increases adhesion, forms a film, which greatly reduces moisture absorption by the surface and allows you to work longer with the leveling material. Partially absorbed, strengthening the surface layer. Used for priming durable smooth and porous substrates, processing between layers or for finishing.

- Specialized. A primer with special properties, for example, betokontakt, containing quartz sand and used to prepare poorly absorbent smooth concrete and cement surfaces for gypsum compositions.

The quality of the product itself and what kind of coating will subsequently be applied also matter. In an unsuitable environment, a primer can behave unpredictably, so it is better to work with compatibility-tested complete primer plus coating systems from one manufacturer that has already proven itself in the market.

The choice of primer for a concrete floor depends on the base of the future coating.

| Primer base | Coating base |

| acrylic | gypsum, cement, water |

| polyurethane | polyurethane |

| epoxy | epoxy, water-based epoxy, water-based, organic |

One of the important parameters of acrylic primer is the degree of concentration, or dry matter content. While for walls this figure may be low, when arranging floors, a dry residue of 12–14% is required.

The quality of the concrete surface and the degree of its readiness for subsequent finishing is assessed using classes. There are 4 main classes (listed in descending order of quality):

- A3 – the base is ready for high-quality painting without additional putty;

- A4 – wallpapering and tiling possible;

- A6 – the surface can be used completely without finishing or with regular painting;

- A7 - the base can be used for applying plaster, installing concrete screed and self-leveling floors, or covering with plasterboard, siding and other materials.

READ MORE: Do-it-yourself reinforcement of a floor screed with fiberglass reinforcement

The primer is applied in one layer; for porous, loose and unevenly absorbent substrates, it is recommended to apply the treatment twice. The application rate depends on the type and condition of the base, as well as the type and brand of primer. In most cases, it is 100–200 ml/m2, for highly absorbent bases up to 400 ml/m2. The consumption for the second layer is slightly less than for the first.

The rule “more is better” does not apply in this case. If the primer is too concentrated or applied too thickly, the primer layer will delaminate and the coating will peel off.

Since there are often doubts about the quality of the goods offered by stores, and your budget does not allow you to purchase products in a higher price segment, you can prepare a primer for a concrete floor yourself. For manufacturing, you will need an antifoam, a biocide and a concentrated styrene-acrylic dispersion.

First, dry biocide in an amount of approximately 1 g is diluted with a small amount of water and poured into the main volume of water. Then the defoamer in a tiny volume, literally hundredths of a percent of the final product, is diluted with a small amount of water (water is added to the defoamer, and not vice versa) and is also poured into the main volume. Strict proportions of defoamer and biocide are not required.

At the final stage, a styrene-acrylic dispersion is added, for floors the recommended ratio is 1:3, and the entire composition is mixed with a mixer at low speeds.

During production, you can do without any defoamer or biocide at all. Then you will get a composition without antiseptic properties, and when stirred it will give abundant foam that will settle for a long time.

It is recommended to use a different primer for each type of concrete base. This is due to a set of specific properties and individual characteristics. Among the available types of surfaces made of this material, the following representatives are distinguished:

- Monolith. This species is characterized by a high density of the top layer. This base is resistant to moisture, which is why applying any liquid compounds to it is pointless.

- Screed. This type of base is a lightweight structure. They often include expanded clay, quartz and similar additives. To treat these surfaces, it is recommended to use deep penetration impregnations.

The above calculation of the required amount of composition is subject to the following conditions:

- humidity – 75%;

- cooking temperature – at least 50°C.

Fluid consumption also depends on the topography and grade of concrete used as the base of the floor. On average, this figure is 350-500 g/sq.m.

Construction technologies do not stand still and you can constantly find all different technologies and materials for work. The same applies to types of primers. They are not only intended to prepare the base for subsequent finishing, but also to strengthen the surface. Each such material has its own formula.

- Regulating porosity.

- Designed to strengthen the foundation.

- Penetrating.

- Increases grip levels.

- Creating a smooth and even surface.

But there is another classification, which is focused on composition indicators:

- Acrylic. It is also called emulsion. Suitable for preparatory work regardless of the substrate. In addition to concrete floors, they are applied to wood, fiberboard or chipboard, brick, cement, etc. Under no circumstances should dark-colored iron be treated with this composition. Here, rust will inevitably appear on the surface. This should be taken into account when reinforcing elements appear on a concrete floor. To work, just dilute the composition with a certain amount of water. The primer dries within 2-4 hours after application. The estimated cost is $0.6 per liter of mixture.

- Alkyd. Used for subsequent application of a layer of paint.

- Polyurethane. Suitable for concrete floors if enamel is subsequently applied. It is also commonly called epoxy. It is considered a deep penetration primer. In addition to covering a concrete floor, this mixture is intended for subsequent pouring of self-leveling compounds. All pores in concrete are clogged due to the smallest particles in the primer. To put it simply, they seem to glue two layers together - the concrete floor and the finishing.

- Polyvinyl acetate. When using it in the future, you should purchase polyvinyl acetate paints for work. After application, the surface dries within 10-15 minutes.

Building codes indicate that a primer should be applied before the waterproofing layer of the floor screed without any interruption. The layer should be continuous.

READ MORE: Concrete floor in a bathhouse - several installation methods

We must not forget about concrete contact. It is created from quartz sand and acrylic. The surface is slightly rough, which significantly increases the level of adhesion of the subsequent layer. It has a certain set of advantages, which include:

- Fast drying. The next stage of repair can begin 2-3 hours after application to the surface of the concrete floor.

- Protection against moisture ingress. After drying, a film is obtained on the base, which can additionally perform the function of waterproofing.

- Long service life. It can be fully used for 80 years. But much will depend on the manufacturer and the quality of the primer.

Concrete contact can only be used 4-5 hours after the cement screed is laid. This is provided for in building codes and regulations. Only in this case the quality of the material will be at a high level.

This building material is divided into two large categories:

- universal products (they can be used both indoors and outdoors);

- highly specialized, intended only for internal or external surfaces.

When a primer is not needed on a concrete floor

If the leveling layer is planned to be poured onto a previously “iron” screed, the top hard layer should be removed. It has very high strength and even the best composition will not stick to it. The top film is sanded off (a lot of dust), then the debris and dust are carefully removed, and after that a binding primer is applied.

It is better to remove crumbling concrete and iron film...

As you can see, both deep penetration and adhesive primers are needed very rarely for concrete floors. The property of a deep penetration primer is to increase the strength of loose and dusty substrates. If the concrete floor is “loose”, this means that errors were made in the technology during its manufacture. It makes sense to remove it rather than increase strength. After treating concrete with a primer, the strength will not increase enough to guarantee its long-term operation.

The adhesive primer forms a sticky film, but closes some of the pores. This reduces the absorbency of concrete. And this reduces the “adhesion” of the two layers. This is especially true for two layers of concrete. The concrete mixture of the layer being laid will not be able to penetrate to a sufficient depth. This will reduce the adhesion of the two layers. So the situation can get worse, not better. It is better not to apply any primer to a “fresh” cement or concrete screed. The next layer - be it a leveling layer or tile adhesive - will “stick” very well. And the rest of the situations have already been described.

Water-repellent primer for concrete

Another situation that we sometimes encounter is the need to improve the water-repellent properties of a concrete floor. There are two methods that work well for improving the water resistance of concrete.

- Use waterproofing materials. With their help, you can make a concrete or cement floor absolutely waterproof. If this is what you need.

- Apply special additives to the solution. They reduce the absorbency of the entire layer, not just its surface. But they must be introduced during kneading.

It is impossible to make a concrete floor waterproof using a primer.

This problem can be solved by other means. These are two ways to radically improve the water-repellent properties of concrete. Primer for concrete floors is not suitable for waterproofing. All of them, regardless of type, will only reduce absorbency, but will not provide a waterproofing effect. Even the most expensive and very good ones. These compounds have a different purpose. They can reduce moisture absorption, but do not prevent its penetration.

It makes sense to reduce the absorbency of a concrete floor before painting or laying tiles. In the second case - not always, but only with adhesive compositions for tiles that have a short “life” after mixing (or if you are laying tiles for the first time and are worried about not having time).

Main types of primer for concrete

Types of floor primers depend on the composition, form of release and the conditions in which you will use them. However, there are universal primers that are suitable for any surface and in different conditions. Specialized models have certain properties. When choosing, you need to take into account the composition of the mixtures and the functions that they will perform to fill the rough base.

If the area of application is a children's room, then an antibacterial solution must be used. For bathrooms, hydrophobic mixtures are used that fight water penetration. For attics, the best solution is a primer that fights fungus and mold.

By release form:

- concentrated;

- in finished form.

The concentrated mixture should be mixed with water to obtain the required consistency.

By degree of influence:

- deep penetration;

- superficial.

The first type penetrates up to 10 cm. This is necessary for dense strengthening, which needs it. The surface layer is 2 cm, in order to protect to a greater extent from mechanical damage.

By area of application:

- frost-resistant;

- antifungal;

- combating water penetration.

The different target load area is also important. For different rooms, a different soil is suitable for treating concrete floors, which has specific properties.

When do you need a primer for tiles?

Usually the tiles are laid on a screed. New or old. If the concrete is “fresh”, no additional treatment is needed. Tile adhesive should be cement based. Then there will be no problems with adhesion.

If there are problems, it may make sense to use a tile primer. This is worth doing if:

- Concrete is very dusty. Remove dust (as much as possible) and prime with deep penetration primer. Better strengthening. It will not leave a film, but the surface will stop dusting and adhesion will improve.

- There are greasy spots. Stains must be removed and grease neutralized. This is done using alkali (usually). Therefore, the floor is washed and dried. Since a “greasy” floor is clearly not a fresh screed, you can treat it with the same adhesive primer.

Preparing the floor before laying tiles does not always require applying a primer - Lay tiles on tiles. In order for the tile adhesive to “adhere” well to the old coating, you can make notches. This may be enough. If you are laying heavy tiles - large-format or porcelain stoneware - you can treat the old tiles with concrete contact (adhesive primer).

- Concrete was “rubbed” during laying; its surface is very hard and almost does not absorb moisture. According to the technology, the top layer must be sanded off and then the tiles must be laid. But grinding concrete is still a pleasure. The solution is concrete contact treatment and then laying tiles. But this is an option without guarantees.

- On the waterproofing layer. The floor in the bathroom and toilet is usually treated with waterproofing. This is a non-absorbent base. An adhesive primer is required to ensure adhesion. This is when a primer is necessary.

Which primer to use before laying tiles depends on the screed

These are all cases when a primer may be required for laying floor tiles. Once again: a newly poured concrete/cement screed does not need a primer. On “fresh” concrete, primer is only needed when the adhesive is used based on a binder other than cement. In this case, to avoid conflict, it is better to create a film using an adhesive primer.

Features of application

When it comes to monolithic concrete, there is no way to do without a primer. This is due to the very smooth surface, which will be very difficult for subsequent layers to cling to. But the primer itself must contain quartz sand. The level of adhesion will be significantly increased due to this. As mentioned earlier, this also allows you to get rid of existing dust, which will negatively affect the quality of adhesion.

When you apply a layer of polymer concrete floor coating to the floor, it covers the existing dust with a thin layer. Here it no longer affects the level of adhesion. A vacuum cleaner and a broom taken together are not capable of demonstrating their qualities in this form.

READ MORE: How to make a heated floor in the bathroom

When purchasing, you should take materials for work from one manufacturer. This is because there may be cases of incompatibility. Only high-quality products will contribute to high-quality finishing, as well as the safety of all layers.

The consumption of the primer mixture will depend on the material. The average is 100-300 grams. In this case, you should pay attention to the dryness of the surface and the level of humidity. We allow only the minimum indicator of the latter.