Methods for making bitumen mastic

There is a cold and hot cooking method. The latter must be performed at the work site, or more precisely 3 hours before the start of the work.

Construction companies often need such material when constructing large projects. It is important here that all manipulations are carried out by professionals, because the method requires strict adherence to safety precautions. For large volumes of work, the hot method can significantly save funds allocated for construction. Cold-prepared bitumen mastic goes on sale in a completely ready-to-use form; the absence of the need for heating makes this type of material safer. But the special feature is the higher price.

Let's discuss with the specialists in individual construction of houses "InnovaStroy" the use of bitumen material in different cases.

Applications of bitumen mastic for foundation waterproofing

First of all, the material is used to protect objects located underground. Often this is the foundation, communication systems (oil, gas, water supply), when there is a need to protect reinforced, wooden, concrete, reinforced concrete structures. Connections between concrete and brick, surfaces in bathrooms, wells, basements, welded joints are carefully treated with this material. In swimming pools, resin-bitumen mastics or thiokols are used, filled using pneumatic syringes.

Mastic made from petroleum components together with solvents and organic additives is considered:

- characterized by a high level of frost resistance;

- quite elastic;

- excellent adhesion;

- resistance to UV rays;

- ease of use.

To achieve excellent waterproofing of the base of the building, the foundation is treated on all sides with material (several layers need to be made). If there are limitations on funds, then it is better to prefer hot mastic, but in this case, all work should be carried out exclusively by professionals. To simplify the work, in order to avoid difficulties in the process, it is better to prefer cold bitumen mastic - here it will be enough to “arm yourself” with only a spatula and a brush. Between each layer it is necessary to maintain a certain time (technological pause), the duration of the break will depend on the composition of the material.

Inside, the foundation is treated with a water-based mastic, which has no foreign odors and dries very quickly. Special latex emulsions are indispensable for industrial construction, which are applied automatically.

Application of bitumen mastics

Bituminous mastics are used in any field of construction, covering most surfaces with them, including their use:

For the roof

Using bitumen mastic for roofing, you can quickly and efficiently seal the surface, without the use of equipment. The mastic can be applied to any cleaned and smooth roof surface.

Brief instructions and reminder:

- Bitumen mastic is applied with a hard brush or brush in a thin layer. It is better to apply to a small damaged surface with a spatula.

- When repairing a soft roof, the swelling area is cut crosswise, the interior is cleaned and dried, and then thoroughly treated with mastic.

- Mastic “patches” are sprinkled with sand to protect them from overheating.

- After cleaning, a cracked roofing felt roof is covered with hot mastic, when working with which you must be as careful as possible. Coating waterproofing is the simplest, most reliable and economical type of repair work.

Roofing work using bitumen mastic:

Roofs treated with mastic have a long service life. If it does need repairs, repairing the roof will be very simple.

To repair the roof with bitumen mastic, the following work is carried out:

- Eliminate coating defects.

- Cut the bubbles on the coating by making cross-shaped cuts and dry them.

- The surfaces inside the cut are coated with mastic.

- The edges of the incision are connected, aligned and fixed.

- A layer of mastic is applied to the cuts, fiberglass is laid in the form of a strip 10 cm wide and the mastic is reapplied.

- Large cracks and breaks are treated in the same way.

For roofing felt

Mastic for roofing felt is one of the most reliable methods of fastening it. Mastic helps to securely fasten roofing felt to the roof and remove air pockets. The roof surface is smooth and can withstand loads well. Hot and cold mastic are suitable.

For waterproofing

To protect structures located in the ground from moisture, waterproofing mastic is used. It waterproofs bathrooms, pipelines, and creates seamless waterproofing coatings in basements, wells and swimming pools.

For the foundation

For all types of waterproofing, one cannot do without mastic made from petroleum bitumen, to which organic and mineral solvents and fillers are added.

This mastic is the best waterproofing material due to the following properties:

- elasticity;

- frost resistance;

- good adhesion;

- resistance to ultraviolet radiation;

- ease of application.

The foundation is treated in several layers of bitumen mastic on all sides, making it completely hydrolyzed. The cheapest coating is with hot bitumen, but it is more difficult to work with. To avoid difficulties, it is better to choose cold bitumen mastic with organic solvents (polymer). To work with it, you only need brushes and a spatula.

To treat the inside of the foundation, use water-based mastic. It has a neutral odor and dries quickly. In industrial construction, bitumen-latex emulsions are applied mechanically.

Waterproofing the foundation with mastic is carried out using brushes, rollers, and any tools that can be used to apply the composition to the surface. The mastic is applied in two layers, maintaining a technological pause between them. Its value depends on the characteristics of the composition.

The video shows how to properly waterproof a foundation with bitumen mastic:

For floor

Modern bitumen mastic is often used for floor protection. It is non-toxic and dries quickly. Bituminous floor mastic does not emit unpleasant odors. Most often it is used for waterproofing a bathroom.

Application of bitumen mastic for flooring

Today, floor mastic is invariably used in residential buildings - this material is non-toxic, dries quickly and is easy to apply. The cold type is applied to the parquet, this is necessary for securing it to sand and concrete screeds. Suitable for this type of application:

- rubber-butumen;

- cookersolnaya;

- bituminous

In the same way, mastic is used for installing laminate flooring. Then the floor will be warm, moisture-resistant, soundproofed.

If you plan to have a wooden floor in the house, then it is better to take MBU mastic. This also applies to the construction of wooden buildings. Waterproofing material is especially necessary for elements that are buried in the ground.

Each individual type of linoleum requires the use of a specific type of mastic. The material is distinguished by:

- for fabric base;

- for dispersive materials;

- for baseless linoleum (the special characteristics of bitumen mastic are ensured by the content of resins and rubbers).

It is worth remembering that before distributing the mastic and installing the linoleum, the floor is first thoroughly primed.

Bitumen mastic for roofing - subtleties of use from professionals

An excellent option, when you do not need to use specialized equipment, is to apply mastic to the roof. Coating waterproofing is considered a fairly economical, effective and simple method. Such a roof will serve for a long time and with its help you can quickly and efficiently create protection on the surface. InnovaStroy specialists give some recommendations for working with mastic:

- If you plan to install or repair a softened roof, you need to cut the problem area, clean it, dry it, and then treat it with mastic. Next, the edges of the cut are connected and fixed, then specially prepared fiberglass is placed on them and mastic is applied on top again. With large cuts and cracks, the actions are similar.

- To distribute bitumen mastic for the roof, take a special brush (must be hard), each subsequent layer must be thin.

- To protect mastic “patches” from heat, it is necessary to pour sand on them.

- If the roof has a roofing material and it has cracked over time, you should first devote enough time to cleaning it. After this, hot mastic is used, which should be handled in accordance with safety rules.

Application: where and when you need bitumen mastic for roofing

Let's list the main areas of construction where bitumen mastic is used today:

- Seamless waterproofing. We are talking about waterproofing foundations and piles, as well as installing a monolithic mastic roof).

- Repair and sealing of cracks in almost any roof, repair of roll coverings.

- Bonding roofing materials such as shingles and roofing felt, as well as fixing expanded polystyrene to the foundation of the house.

- Internal waterproofing of the house: basements, bathrooms and screeds.

And this is an important point: bitumen mastics are used not only on the roof, but also for waterproofing the foundation, and compositions developed for one task are not always suitable for another!

Installation of mastic roofing

Bituminous mastic, while still in liquid form, is applied to the base, and during the hardening process it forms a durable waterproofing film without seams. This quality is indispensable for roofing. Thanks to this, the roof has protective properties, excellent waterproofing and high adhesion.

Good mastic does not deteriorate over time from ultraviolet radiation and does not become brittle from frost:

Let’s immediately make a reservation that most professional roofers are convinced that a reliable bitumen roof is impossible without reinforcement. One of the most proven technologies is laying reinforcing mesh.

To do this, you first need to thoroughly clean the roof surface, treat it with a primer, lay the mesh and fill it with mastic in two layers:

Hot bitumen mastic is used for laying roofing membranes using the following technology:

- Step 1. The first layer of membrane is laid on bitumen.

- Step 2. Make an incision at the seam.

- Step 3. Place the tape over the hot bitumen, with the fabric inserts facing up. Press it so that these inserts on the underside are completely saturated with bitumen.

- Step 4. Now lay the second layer so that the membrane covers 10-20 mm of the tape. In this case, hot bitumen is poured under the fabric inserts of the membrane.

The main thing in all this is personal safety, because hot mastic can leave serious burns.

Roof repair: description of the process in detail

Bitumen mastic is simply irreplaceable for urgent roof repairs. In this case, any other materials usually fail, because constantly falling rain causes a lot of problems, and the leak needs to be stopped. For example, local damage to ondulin is most often eliminated with bitumen mastic, which is additionally reinforced with fiberglass.

Here's how to repair a damaged area of the roof using cold bitumen mastic:

- Step 1. Cut the swollen area crosswise and bend the edges with a spatula.

- Step 2. Apply a sufficient amount of mastic inside the damaged area.

- Step 3. Press the edges of the cut to the center of the layer.

If necessary, install a new patch and reinforce it with additional construction mesh:

If you need to repair a metal surface, then follow these instructions:

- Step 1. Clean the metal parts of the roof from rust, organic pollutants and oil stains.

- Step 2. Apply the first layer of mastic with a brush or wide brush (preferably coarse).

- Step 3. Now - the second layer, using a brush or spraying.

At the same time, make sure that all cracks and seams are filled and coated, but the thickness of one layer does not exceed 4 mm.

Roof passage elements are also coated with mastic:

Unlimited material possibilities

Nowadays there are often situations when bitumen mastic is used to fix polystyrene foam to metal, concrete, expanded clay, and wooden surfaces. For horizontal slabs, a load is used, and for vertical slabs, special supports are used.

When lining fireplaces, you also cannot do without a bitumen-polymer strong, bactericidal, durable, heat-resistant adhesive material.

There are also mastics that are used specifically for road repairs. They work in tension and compression, tolerate temperature changes, and have good adhesion. Before you start using it, you don’t need to wait a long time – just an hour and you’re done.

Rubber-bitumen, bitumen-polymer mastics are used for metals and cars. But before application, as in all cases, the surface should be thoroughly cleaned, rinsed and dried.

No matter how durable a material such as concrete is considered, there is a problem of moisture seeping through micropores. Mastic also improves the characteristics of concrete structures by filling all cracks and cracks. The material can be prepared from solid or rubber bitumen, liquefied materials.

Types and features

Before you run to a service station or store to make a purchase, you should figure out what types of mastic exist and what their properties are.

Depending on the type of application and preparation, mastics are divided into:

- one-component (not intended for storage after use because they harden quickly);

- multicomponent (applied after dilution with a thickener, undiluted is stored for a very long time).

Depending on what additives are used in production, mastic can be epoxy, bitumen-polymer and rubber-bitumen. A lot of tests were carried out to show the wear resistance of one type or another in order for these materials to go on sale.

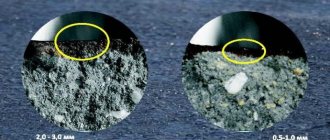

Verifications were carried out through the use of sandblasting machines. And here's what can be said about each of the above types.

Rubber bitumen mastic for cars in a jar

Rubber-bitumen mastic is quite wear-resistant. It began to collapse after 4 minutes and completely disappeared after 8. Which is a pretty good result.

And finally, bitumen-polymer mastic turned out to be last in the wear resistance rating. Only 2 minutes passed before the destruction began. And not a trace of her remained after 5 minutes. Let us clarify that a minute of exposure to mastic with a sandblasting machine is equal to 20,000 kilometers of car mileage.