Everyone would like to provide their home with electricity, choosing the most economical and environmentally friendly option. Therefore, the modern owner began to pay more attention to this issue, considering alternative energy sources. The use of solar energy is becoming increasingly popular among consumers. Batteries for solar panels, which are so necessary in the energy supply system, are the topic of our article. You will find detailed information on how to create a battery system, what types they are and what should be considered when choosing such a device.

To supply electricity to a private home, a whole system of solar power plants is being built, for which batteries are needed to accumulate energy in cloudy weather, at night or in low temperatures, when it is not possible to use solar panels. These devices also help extend the life of the entire system. By combining them into a kind of block, you will increase the amount of accumulated energy. Selecting the appropriate batteries will allow you to set the maximum efficiency of the power plant.

Creating a Battery System

The creation of a battery system can solve such a problem as lack of energy. The capacity of one battery may be too small to power your entire home. It is important to consider that this is only possible if you have a sufficient number of solar panels that can provide you with the electricity you need for consumption.

You can combine the battery into a block in the following ways:

- parallel;

- sequentially;

- a combination of these methods.

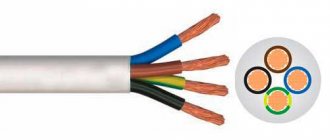

The connection diagram is created in accordance with the required voltage and output power. Batteries for solar panels are installed taking into account the operating parameters specified in the device instructions in order to achieve maximum efficiency and ensure the longest service life.

The devices should be located at a short distance from each other, taking into account their connection diagram. When placing, you also need to take into account the considerable weight of the products, which varies depending on the type of material and battery capacity.

AGM

The complex consists of adsorbing double-glazed windows that contain a thickened electrolyte solution. The batteries tolerate transportation well and can be placed in any position. The declared service life is 500-600 cycles, however, the equipment is sensitive to temperature, the recommended range is 15-25 degrees. When increasing or decreasing, the working resource decreases. Based on the combination of characteristics and efficiency, these are the best batteries for solar panels.

Among other advantages, the following stand out.

- There is no exhalation of harmful vapors, so the batteries are suitable for any premises.

- Small dimensions facilitate transportation and allow installation of the complex in small areas.

- The charged block is moved without loss of charge.

- Quick recovery: the battery accumulates a charge in 7-8 hours.

- The device operates stably even at a minimum charge level.

- There is no memory effect (the battery does not lose capacity when partially charged) and undercharging is well tolerated.

The discharge depth can reach 80% without consequences for the device. However, exceeding the norm leads to a battery defect that cannot be repaired.

Features of operation

You need to choose the battery connection diagram very carefully. In some cases, an unsuccessfully selected circuit can cause an imbalance of devices relative to charge levels. This can significantly reduce their service life. Battery pooling requires additional devices such as a controller and an inverter.

The controller monitors the battery charge level. When creating a battery pack, jumpers are installed to equalize the charge level. In addition to these elements, for uniform charging and discharging cycles, it is best to use identical battery models from the same manufacturer.

The solar energy with the help of panels undergoes the process of conversion into constant current. Electrical appliances consume different amounts of power. The inverter is designed to convert a constant current value into a varying value to ensure the full functioning of all electrical appliances.

Selecting a battery model

The main parameters of solar energy batteries that you need to pay attention to when purchasing are the following:

- voltage and capacity that determine the battery power;

- depth of safe maximum discharge, subject to which the battery can operate within the time limits stated by the manufacturer;

- guaranteed number of charge and discharge cycles subject to all technical conditions;

- self-discharge value, characterizing the intensity of electricity loss in a charged battery during idle time;

- maximum charge current, which determines the amount of electricity per unit of time that the battery can accept without compromising further operation;

- standard discharge current, which determines the amount of electricity per unit of time that the battery is capable of delivering for a long time without compromising further operation;

- maximum discharge current, which determines the amount of electricity per unit of time that the battery is capable of delivering for a short time without compromising further operation;

- optimal temperature for device operation;

- size and weight of the battery, knowledge of which is necessary to select their location and installation method.

These parameters are described in technical documentation, which is posted electronically on the website of all major manufacturers.

Battery types

There is a huge variety of batteries that can be used for a solar panel. The operating principle of the battery depends on the materials of the product and the type of its design. Of the options on the market, we will focus on only a few and describe each of them.

The list is presented below:

- Gel.

- Alkaline.

- Lithium.

- Lead-acid.

In addition to these main types, we will describe AGM, OPzS, flooded nickel-cadmium batteries, as well as those intended for cars.

Gel

This type got its name because the electrolyte of these batteries is contained in a small volume and is a gel-like substance. At the same time, it does not spread thanks to the fiberglass layers.

Batteries of this type have a long service life, which is due to a large number of recharge cycles. Such a device is resistant to mechanical damage. Minor deformations of the housing will not affect its operation.

This type of battery can operate in low temperatures, reaching down to – 50 °C, while maintaining capacity. The properties of the device are fully preserved in the off mode during long-term storage.

The main thing to consider is that when working for a long time under the influence of low temperatures, the device should be insulated. It is very important to monitor the charge level. At its maximum value, there is a risk that the device may explode. Gel-based batteries are also highly sensitive to voltage fluctuations.

Alkaline

The electrolyte of devices of this type is contained in a small volume. This is explained by the fact that the final substances of electrochemical reactions do not dissolve in the electrolyte and do not interact with each other.

Alkaline batteries, also known as alkaline batteries, are characterized by a long service life and lack of sensitivity to voltage fluctuations. Unlike gel-based devices, they can be used at low temperatures for a long time.

The device should be sent for storage completely discharged to avoid loss of capacity during subsequent charging. This factor can also negatively affect the operation of the entire solar power plant system.

Lithium

The operating principle of such devices is the interaction of lithium ions with metal molecules, which are additional components.

Lithium devices have the ability to charge quickly, while having a large amount of capacity. Batteries of this type are small-sized devices with low weight.

Lithium batteries have a high cost. For this reason, they are rarely used for solar power plant equipment. The service life is almost half that of gel-based devices.

Also, this period is reduced significantly if the charge level exceeds 45%. It is this limit that is most effective and does not allow the volume of the container to decrease.

These batteries operate with a narrow range of voltages. One of the main disadvantages of the devices is the gradual decrease in the volume of the container, which does not depend on compliance with operating rules.

Lead-acid

The device has several compartments with electrolyte in aqueous solution. Lead electrodes mixed with other chemical elements are placed in this substance.

Thanks to the admixture of various components, the device becomes resistant to corrosion.

It should be noted that such batteries have a very short service life, which is explained by rapid discharge.

AGM batteries

These devices are a type of lead-acid, but they differ in that the inside contains a fiberglass material impregnated with an electrolyte.

Since acid fills the pores of materials, this contributes to resistance to its leakage with subsequent disruption of operation from minor mechanical damage. From this it follows that the battery can be placed in any position. In addition to the above, these batteries have a large capacity, have a long service life and have a sufficient resource for charge-discharge cycles.

The devices are sensitive to high current. Failure to follow the operating instructions may lead to swelling of the housing.

Batteries OPzS

Batteries of this type are lead-acid, but differ in the shape of the electrodes. The positive electrode has the shape of a tube, and the negative one is thickened.

This structure made it possible to increase the resource of charge-discharge cycles. Thanks to the presence of filters, it became possible to control acid consumption. The device has a long service life. Does not require special maintenance measures. A particular advantage of use is the low self-discharge rate.

Due to the high price, which automatically increases the cost and payback of the entire solar power plant, they are used extremely rarely.

Jellied nickel-cadmium

These devices are alkaline type batteries. The name characterizes the principle of their maintenance, that is, there is a need to fill their body.

Unlike gel based batteries, they are safer to use. It should also be noted that the price is very affordable. Batteries of this type cope well with high power levels. Their main advantage is the long service life of charge-discharge cycles, which can be compared with that of gel batteries.

Among the disadvantages, it is worth noting the short service life, which is determined by the high self-discharge rate of the device. In addition, the operating period also shortens the maximum charge level.

Comments:

Gregory

I have had a rack of 4 batteries running at my dacha for about 4 years now. These are ordinary car batteries. Sometimes I add acid and this is enough for them to work for another 2 years. So I strongly doubt that special batteries are needed.

Maksim

Gregory, I agree. I bought Bush batteries - they cost me pennies and have been working fine for 2 years now. In a car, the battery is subject to large loads, but in a house there are no such loads, so I think that the service life of new car batteries in the house will be much longer.

Nastena

Gregory, if we are talking about use in the country, then they may well be enough, but if solar panels are in the house, i.e. in a place of permanent residence and constant year-round use, an unsuitable battery will quickly fail.

Igor

It’s not clear how the author of the article divided 500 A by 1.03 and got 515 A? If you follow the rules of mathematics, you should get 485.44 A. Or do the mathematical rules change at 25 degrees Celsius?

Dima

Lithium ion batteries are suitable for solar panels

umbrella

Igor! And you weren’t confused by the magnitude of the electrical power of a light bulb or TV, W/H. I wonder what he smokes?

Connoisseur, yup

Comrades, refrigeration units consume 150 watts only when the compressor starts, while the compressor is running it is more like 60-70 watts, but the compressor does not operate 24 hours a day. so your 3.6 kWh per day for the refrigerator is nonsense. In reality, an ordinary Atlant consumes about 1 kWh per day, and all sorts of A+++ Boshis consume 0.5 kWh or even less.

Yurich

I believe that there is no need to install an inverter on a permanent basis. LED lamps are now produced immediately at a nominal value of 24-48V. There are domestic refrigerators for 50-52V, but they have not been produced for many years, this voltage is still used to this day on railways. TVs and computers, sorry laptops without a power supply, see for yourself what voltage they work at. Draw your own conclusions, gentlemen. I’ll also note that in addition to solar, you need to use wind. Batteries, if there is free space and ventilation, are more profitable to use TZN-300 or 500. With proper care, they last forever. If anyone needs clarification , which is unlikely, they will already be paid.

Pilgrim

In my apartment, even in winter, it rarely goes beyond 100 kW/h. That is, 3.(3) kW/h per day with a microwave, washing machine, hair dryer, vacuum cleaner and a system unit running for several hours. Where the author got the figure almost twice as large without all this is not clear.

Leave a comment Cancel reply

Related Posts

Types of solar-powered garden lamps and lanterns, how and where to use them.

Fuel-free generator - a way to make money on illiteracy

Do solar panels for a private home pay off?

The principle of operation of solar panels.

Car batteries

Good, in terms of cost, are batteries designed for cars. They are very often used by those who design a solar power plant system on their own. The price of batteries automatically reduces the cost of the system several times.

The only problem is that car batteries are designed for a slightly different operating mode. As a result, they have to be changed very often due to high wear rates and subsequent breakdown. Therefore, such devices can only be used for low power solar panels and only for a short period of time.

What batteries are used in solar panels

It is not possible to choose just any battery for solar panels. For example, a regular car one, which is traditionally designed for short-term peak loads when starting a car (starter operation) with subsequent restoration of charge as it moves, will not work. It is undesirable to allow such a battery to discharge below 45–50%, which is not suitable in the case of solar panels. After all, at night, batteries installed in solar panel systems begin to lose charge to levels unacceptable for conventional starter batteries. For solar systems, it is necessary to use deep cycle batteries, that is, those that are often discharged to at least 50% or even 80–90%. Today there are several main types, let’s look at their features.

Criteria for choosing a battery for solar panels

Anyone who has the goal of providing electricity to their home using solar panels is wondering which batteries are the best and most suitable option for creating a solar power plant. We will help you determine which battery to choose in this case.

When choosing a battery model, you must be guided by the relationship between the specified characteristics and the conditions of use. The parameters you should pay attention to when purchasing are described below.

- Resource of charge-discharge cycles. This characteristic allows you to guess the approximate life of the battery.

- An indicator of the speed of the charging and discharging process. This indicator also affects the service life of the device.

- Device self-discharge rate. This also affects battery wear.

- Battery capacity volume. This parameter helps determine the power with which the device can operate.

- Maximum current value during charging and discharging. The charging value determines how much current the device can accept. The discharge value determines how much current the device can deliver without affecting operation.

- Weight and dimensions of the device. These parameters are necessary to draw up a diagram for connecting the batteries, as well as determine their location.

- Terms of use of the battery. This should be taken into account due to the fact that different models operate at different temperature conditions.

- Service. The instructions should indicate what maintenance measures each specific model requires. But this is not the main parameter that can influence your choice.

For the full functioning of a solar power plant, the technical characteristics of all components of this system should be taken into account. We hope the above information will help you select the right battery for your solar power system.

Gel storage

The battery reservoirs are filled with a gel substance, so if the integrity is broken, the electrolyte contents do not leak out. Another plus is that when charges accumulate, the design does not emit toxic elements, so the room where the complex is located does not require additional forced ventilation.

The devices boast good performance characteristics: high input currents, solid capacitance, minimal energy loss, complemented by excellent physical and electrochemical characteristics.

When considering the question of what batteries are used for a solar battery, it is quite possible to recommend this group of devices. They have two tangible disadvantages: high price and short service life. The second parameter is close to being corrected; models with a long service life are gradually appearing on the market.

Popular gel drives are the LP-GL and LPM-GL lines.

Calculation and selection of battery

Small set of SES

First you need to calculate the power of expected energy production. Calculations are made based on the solar radiation power, taking into account the weather at different times of the year.

In addition, when obtaining the result, it is imperative to take into account the angles of inclination of the solar panel, and it does not matter whether it is oriented horizontally or vertically.

The angle of inclination is extremely important, so it must be chosen correctly.

If you plan to operate the system throughout the year, then it is best to orient the panel at an angle fifteen degrees greater than the geographic latitude of the facility where the system is located.

In addition to all this, it is necessary to take into account that during operation, dust, ice and snow will accumulate on the solar panel. For the Moscow region, the panel tilt angle is seventy percent, oriented to the south. If you plan to use a photovoltaic battery, then it can be installed on the facade of the house or on the roof, and the angle of inclination should be oriented in the east or west direction.

After choosing the angle of inclination of the solar panel, you need to calculate the possible productivity of the solar power plant, the required number of solar modules necessary for the system to operate in a certain mode. All calculations are carried out using the example of the worst month, most often this month is January, and the best for a solar power plant is July, as well as for most of the year, the period from the last month of winter, February, to the last month of autumn, November.

It is during this period that the sun is most active. The standard insolation rate is calculated for an area of one square meter, while the nominal power value is determined at a temperature of twenty-five degrees of a standard light flux of one kilowatt per square meter.

Taking the maximum value of insolation (the radiation power of the sun falling on the surface), the calculation shows that the value of the electrical energy generated by the battery relates to the value of the insolation index of one square meter, in the same way as the generated energy relates to the value of the power of solar radiation on the surface of the earth in clear weather , which is per square meter, that is, thousands of watts.

By multiplying the value of monthly insolation by the value of the generated power of the solar battery, divided by the maximum value of insolation, you can more accurately determine the possible monthly energy production of the solar panels.

Calculation of solar panel output is carried out by multiplying the value of monthly insolation, electrical energy generation and the ratio of the efficiency of the solar battery and the nominal value of the battery power.

In turn, the value of the rated power of the device is calculated by multiplying the maximum value of insolation power and the generation of electrical energy received from a solar power plant, divided by the product of monthly insolation and efficiency.

Battery assembly (LiFePO4) for solar panel and more

The cost of solar panels has dropped dramatically over the past few years, but the overall cost of an off-grid solar system is still high. The cost of traditionally used lead-acid batteries and their limited lifespan compared to solar modules (25+ years) increases the overall cost of the entire system. If you are going to install new solar panels for your home or office, it is very important to choose the right battery for it. In this case, we need batteries with large capacity, high power potential, longer service life, stable and safe.Lithium-ion batteries have become a popular option for energy storage in solar systems, but as technology has advanced, there is a new winner in the race for energy storage solutions: lithium iron phosphate batteries (LiFePO4). LiFePo4 battery has many advantages over traditional lead-acid batteries.

In this article, the wizard will tell us how to assemble a battery for devices such as an off-grid solar system, solar generator, electric car, etc. LiFePo4 cells come in different sizes, but here the wizard used the 32650 type.

Tools and materials: - LiFePo4 batteries;

-Holder; -Nickel strip; -BMS module; -The wire; -PVC shrink film; -Heat-shrink tubing; -Insulation paper; -Fiberglass tape; -Kapton tape; -Double sided tape; -XT60 connector; -Spot welding machine; -Soldering equipment; -Pliers; -Tool for stripping wires; - Hairdryer; -Multimeter; Step One: Lead Acid Battery or LiFeP04 Constant Energy Delivery:

The main difference between LiFePO4 and lead acid batteries is that the capacity of Lithium Iron Phosphate batteries does not depend on the rate of discharge. It can continuously deliver the same amount of energy throughout the entire discharge cycle. However, for lead-acid batteries, the rated capacity decreases as the discharge rate increases.

Life cycle:

Lithium batteries also have a longer lifespan than lead-acid batteries. LiFePO4 batteries can also last a very long time. Good quality batteries are designed to last approximately 3000 cycles at a full 100% charge/discharge cycle. If you do this every day, you can ride an electric bike for more than 8 years without replacing the battery.

Charging time:

LiFePo4 batteries charge four times faster than lead-acid batteries. Therefore, less time to charge and more time to use the battery. The battery charges 100% in just 2-4 hours.

High/low temperature performance:

LiFePo4 battery also has superior high temperature performance compared to lead acid batteries. Lithium batteries perform better at high temperatures than lead acid batteries. Lithium batteries also have a higher discharge capacity at low temperatures.

Battery installation:

LiFePo4 batteries can be installed in any position as they do not leak. While for lead-acid batteries there is a high probability of leakage.

Weight:

A LiFePO4 battery also weighs less than 1/2 of a lead-acid battery of similar capacity.

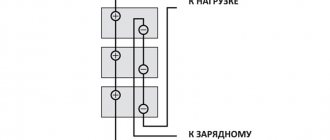

Step Two: Series and Parallel Connection Batteries can be used in series and/or parallel to achieve higher operating voltage and/or power to achieve the desired requirements for a particular application.

Serial connection:

Connecting cells in series increases the voltage of the two batteries while maintaining the same current rating (amp-hours).

Example:

When two 3.2V/6000mAh cells are connected in series, the battery will output 6.4V, but the total capacity will remain the same (6000mAh).

Parallel connection:

Parallel connection increases the current rating (amp-hours), but the voltage will remain the same. Ultimately, we get one cell with a larger capacity.

Example:

When two 3.2V/6000mAh cells are connected in parallel, the battery will output 3.2V, but the total capacity will be increased to 12000mAh.

To make a battery, you must first determine the rated voltage and capacity of the battery.

We have to connect the elements in parallel to achieve the desired capacity (mAh) and connect such parallel group in series to achieve the rated voltage (Volts). For this project, the battery specifications should be as follows: 12.8 V and 42 Ah. Specification of 32650 cells used: 3.2V\6000mAh Number of cells required for parallel connection = 42000/6000 = 7 pcs. Typically parallel connections are abbreviated "P", so this package will be referred to as a "7P package". When 7 cells are connected in parallel, we end up with one cell with a higher capacity (eg 3.2V, 42000mAh) Voltage (volts):

The desired nominal voltage of the battery is 12.8 V. Nominal voltage of each cell = 3.2 V Number of cells required for series connection = 12.8 / 3.2 = 4 pcs. Typically, cells connected in series are abbreviated as "S", so this package will be referred to as a "4S package". So you need to connect 4 parallel groups (7 cells in each group) in series to make a battery pack. The final unit configuration is designated as a "4S7P unit" with a final specification of 12.8V, 42Ah and has 28 individual cells.

Step Three: Checking the Cells Before connecting cells in parallel, you first need to check the voltage of each individual cell.

It is important to use batteries of the same model with the same voltage and never mix batteries of different production dates. For cells to operate in parallel, the voltage of each cell must be close to each other, otherwise large current will flow from the higher voltage cell to the lower voltage cell. This can damage the elements and even in rare cases cause a fire.

If you are using brand new cells, their voltage is between 3.1V and 3.2V. You can connect them together without worry. But if the voltages of the elements differ greatly, then first you need to balance them, charge the elements to the same voltage level. The cells in batteries must be balanced, especially when exposed to high charging and discharging currents.

A weaker cell in series connected cells will cause an imbalance. This is especially important in a series configuration because the power of the battery is determined by the power of the weakest element (similar to the weak link in a chain). A weak element may not fail immediately, but may discharge faster than the others. When charging, a weak cell can fully charge faster than other cells and eventually overcharge.

In simple terms, the full potential of the battery will not be used. It will charge, focusing on the most “live” cell, and turn off when discharged, focusing on the most “dead” one.

Step Four: Nickel Strip To assemble the battery, you need to connect the LiFePo4 cells together using nickel strips or thick wire. Typically, nickel strips are widely used for this purpose. There are two types of nickel strips available in the market: nickel-plated steel strips and pure nickel strips. The master advises buying pure nickel. This strip is slightly more expensive than nickel-plated steel, but has much lower resistance. Low resistance means less heat generated during charging and discharging, resulting in longer battery life.Nickel strips come in different sizes and lengths. We select strips according to the tasks.

Step Five: Holders You can assemble the cells into a pouch using hot glue or a plastic 32650 battery holder. The craftsman used plastic 32650 cell holders/spacers. The main benefits of using these holders are: 1. Can be customized in any size as per the requirement. They fit together like a puzzle. 2. This assembly provides space between the cells, which allows fresh air to pass through and the battery to cool easily. 3. Quite rigid design. 4. Provides safety and anti-vibration protection for the battery. First you need to arrange the cell holders so that you get 4 rows and 7 columns. We need to make 2 of these rectangular holders, one to be used at the bottom and the other at the top.

Place the first parallel group of cells (7 pieces) in the plastic holder with the positive side up, then place the second parallel group with the negative side up, then the third parallel group with the positive side up, and finally the last parallel group with the negative side up.

After installing all the elements, place the top battery holder.

Step Seven: Spot Welding or Soldering There are two options for mounting the cells together: soldering or spot welding. Spot welding is best, although it is much more expensive than a good quality soldering iron.Soldering: The problem with soldering is that when soldered, the element gets very hot and the heat does not dissipate quickly. This increases the chemical reaction in the cell, which impairs its performance. Ultimately, we lose some of the capacity and lifetime of the cell. If the work is one-time, then there is no point in purchasing an expensive spot welding machine. In this case, you can solder nickel strips following some rules. 1. To minimize soldering iron contact time, ensure that the surface is well cleaned and sufficient flux is used. 2. You need to use a high-quality soldering iron with high power (min. 80W) and good heat capacity, so that it can quickly transfer heat to the pad. 3. Soldering should be done as quickly as possible.

Spot Welding: Spot welding securely connects the cells together without overheating them. There are currently two classes of welding machines available on the market: amateur and professional. A good amateur spot machine costs between $200 and $300, while a good professional one can cost about ten times more.

The spot welding machine used by the craftsman has three welding options: fixed welding head, fixed welding head with foot switch, movable spot welding handle with foot switch. He prefers to use the second option. You can check the quality of welding by pulling the nickel tape. If the strip does not come off, then it is a good weld; if it comes off easily, then the current needs to be increased.

Step Eight: BMS Board The Battery Management System (BMS) is the electronic system that manages the lithium battery. Its main functions are: 1. Monitors all parallel groups in the battery pack and disconnects it from the input power source when it is fully charged. 2. Balances the voltage of all cells evenly. 3. Avoids over-discharging. BMS takes care of battery protection. The board turns off the battery when it is low or in danger of overcharging. The BMS also takes care of limiting charge and discharge currents, monitors cell temperatures (and reduces charge/discharge if necessary), and most modules balance the cells every time a full charge is performed. The two important parameters required for purchasing a BMS are: 1) Number of cells monitored - e.g. 4S/6S/8S. 2) Maximum discharge current - for example 20A / 30A / 50A For this project, I used a 4S and 50A BMS board. The BMS board is connected according to the connection diagram shown below.

Any short circuit in the battery may cause fire and explosion. For protection, the technician first places a layer of insulating paper over the top and bottom of the battery. Insulating paper is pure cellulose with high electrical insulating properties, which allows it to be used in the assembly of portable lithium-ion batteries.

This paper comes in different sizes, so you need to order the appropriate width and length according to the size of the battery pack. It is very easy to use because it has an adhesive layer. After gluing the paper, make sure there are no exposed parts. To ensure that the battery has the correct (rectangular) shape, the master added an additional layer of insulation on top of the paper.

The last layer is shrink film. Cut off the required amount of film. We wrap the battery. Warm it up with a hairdryer. All is ready. All that remains is to charge the battery and install it in the intended place. The entire process of assembling the battery can be seen in the video. SourceBecome the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.