Soldering stations are mainly used in professional environments, although anyone can purchase them. This is quite powerful equipment that is suitable for many different operations, including the restoration of complex equipment. The station can include not only a standard soldering iron, but also a hot air dryer.

In addition, any station has a so-called control module and galvanic isolation from the network. The presence of galvanic isolation minimizes possible negative consequences from soldering (black smoke or electric shock).

The soldering station is also distinguished from ordinary soldering irons by its temperature stability during operation, which is critical when soldering printed circuit boards.

Contact and non-contact

Now soldering stations are presented in a significant variety.

They can be divided into groups according to several parameters. For example, they are contact and non-contact. A contact station is an ordinary soldering iron that has direct contact with the surface when soldering, equipped with an electronic control and temperature control unit. That is, this is the most standard variety, which is suitable even for beginners.

Contact stations, in turn, can be divided into two subtypes depending on the solder used. Some models use only lead-containing solders, while others also use lead-free solders.

In the latest modifications, the heating element has a power of up to 160 watts. In this case, increased power is absolutely necessary, because the melting temperature of lead-free solders is quite high.

As for contactless stations, they can be used, among other things, for operations with microcircuits. A non-contact soldering unit can be hot-air, infrared or combined, and each of these three types has its own principle of operation.

Purpose of individual modules

The main working module of a soldering station is a power supply with an electronic or analog control unit based on an autotransformer. It allows you to regulate the amplitude of the voltage supplied to the heating element and maintain the temperature in a given range. The soldering station can operate on 12V and 24V voltage.

The next two devices are a soldering iron and a hot air gun. Both are designed for soldering elements and differ in their scope. A soldering iron is used for soldering elements with side contacts, and a hair dryer is used for mounting elements with contacts under the body.

The stand is designed to safely hold the soldering iron and hot air gun during breaks between soldering. This device is not strictly necessary and is not included in the delivery package of all PSs, but it is highly advisable to purchase it. Safety and ease of use when using the stand increases significantly.

Vacuum desalting pump. Necessary for cleaning the soldering area from residual tin or solder. Just like the stand, it is an optional element. It does not directly affect the soldering process, however, it is highly desirable to purchase, as it minimizes traces of repairs and non-factory installation. This is especially true for inexperienced radio installers.

Tip cleaner. Availability and use is required! A cheap rag made of heat-resistant material for cleaning the soldering tip from dirt and carbon deposits. The thing is very cheap, but saving on soldering iron tips will help. The main thing is not to be lazy and clean them periodically.

Infrared devices and hair dryers

Hot air stations (sometimes simply called hair dryers) work like this.

First, a strong air flow generated by the compressor, passing through the heating coil, acquires the desired temperature, and then a stream of hot air is directed to the soldering area. The hot air station makes it possible to solder in hard-to-reach areas with simultaneous heating of several surfaces at once. Any hot air installation has a power that is sufficient for soldering with any type of solder, both with and without lead.

Hot air soldering has wide application, for example, in the field of repairing household electrical appliances and mobile phones. However, it is almost impossible to install and dismantle microcircuits (even in BGA format) with thermal air installations - this is a serious limitation.

Infrared-type stations must have a heating element in the form of an infrared emitter made of ceramic or quartz. And thanks to this, infrared installations have some advantages over their thermal air counterparts:

- soldering of complex-profile components is possible;

- there is no need to look for a nozzle for a hot air gun for a specific microcircuit;

- During soldering, no radio components are blown away by heated air flows from the printed circuit board;

- The soldering area heats up very evenly.

Infrared stations are not cheap and are considered equipment for true professionals. Beginners in soldering and radio electronics for the most part do not use such devices.

A few words should be said about combined soldering stations. They are called that because they combine several types of equipment in their design, for example, a soldering iron and a hair dryer.

Device classification

In stores you can find a wide selection of such devices. Basically, a soldering station is an electronic unit for setting the temperature and a soldering iron.

Despite the huge range, the following types of soldering stations can be distinguished depending on the solder used: the first are designed to work with tin-lead solders, and the second - without lead.

The second type is distinguished by the presence of a separate heating element. Its power can reach 160 W. This is due to the fact that the melting point of lead-free solders is quite high. In this regard, more power is needed.

At the same time, such devices have the ability to adjust the temperature, which makes it possible to work with low-melting lead alloys.

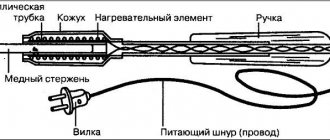

Drawing of a soldering iron and hair dryer in a soldering station.

Depending on the principle of operation of the blocks, stations are divided into:

- analog and digital;

- according to the heating method - induction and non-contact.

The latter, in turn, can be infrared, thermal air or combined. When choosing this device, you need to decide what needs to be soldered. For example, infrared ones are perfect for microcircuits.

A soldering station with a hair dryer does an excellent job of dismantling radio components with a large number of leads. Conventional soldering irons will not cope with this task.

Hot air soldering stations

To work with circuits with a large number of pins, contactless stations are used. Infrared is one of their varieties. Heating in this device occurs due to a special ceramic element.

Such equipment has a number of advantages:

- the ability to work with complex-profile microcircuits;

- radio components are not blown away by air flow;

- uniform heating of the product.

The main disadvantage of this device is its high cost. In this regard, it can be safely classified as a professional station. Beginner radio amateurs very rarely use such equipment.

Soldering stations with a hair dryer are used mainly for dismantling microcircuits, as noted above. In the absence of this equipment, specialists can use an industrial hair dryer or burner. However, such devices do not allow high-quality work to be done.

A sufficiently strong air flow can blow away radio components, and an incorrectly chosen temperature regime can completely damage them.

Professional devices allow you to adjust operating modes, which greatly simplifies the dismantling process.

The combined version combines a hot air gun, a soldering iron for the station and other types of equipment. Using such devices is quite simple. For example, to solder wires, it is enough to set the temperature of the electric soldering iron and tin them using flux and tin.

Contact and non-contact soldering stations

All modern soldering stations are divided into two main categories: contact and non-contact. The first are most reminiscent of classic devices for working with tin-lead or lead-free solder.

Each of the noted types has its own advantages and finds its application in solving certain problems. Today, most radio amateurs prefer using a non-contact soldering station.

Of course, contact soldering irons cannot be classified as the most modern units. They are usually equipped with one tip. However, most devices allow you to easily replace them. Buying a sting is not difficult.

As a result, you can work with such a soldering iron on almost any part. With the exception of boards in complex electronics.

Such devices also allow you to regulate the temperature of the soldering iron tip, which is very convenient when soldering with solders with different melting temperatures. Working with this soldering station is very simple, because they resemble classic devices.

However, the possibilities of contact soldering are limited and not all problems can be solved with its help. This especially applies to SMT installation. Dealing with this with a classic soldering iron is not only difficult, but sometimes completely impossible.

For this type of work it is necessary to use non-contact soldering. The most common such equipment is hot air stations.

The principle of their operation is that a compressor or turbine creates an air flow. It passes through the heating element and reaches the set temperature. The resulting jet is directed to the soldering zone.

Electrical diagram of a soldering station.

These devices are widely used for repairing large and small household appliances. The station's power is sufficient to work with lead and lead-free solders.

At the same time, they have restrictions on their use. The station cannot be used for mounting or dismantling large BGA chips.

Thermal air stations have become especially widespread in combination with other types of devices. Thus, various options for tandem hot air gun and soldering iron are widely available on the market.

Another important element of such equipment is a compressor, which sucks heated solder into a special tank. Many experts have long appreciated the advantage of this structural element.

The most modern solution for working with complex microcircuits is infrared soldering stations. Infrared radiation allows you to avoid mechanical overheating of microcircuits, as well as their direct overheating.

Among the tasks that these devices allow you to solve:

- installation and dismantling of medium and large BGA chips;

- reducing the thermal effect by concentrating radiation where it is needed;

- no need to use different attachments for each chip.

Taking into account all the above advantages, infrared stations have almost completely replaced other options in professional service workshops. Especially when repairing computers, consoles, phones and laptops.

Analog and digital soldering stations

According to the operating principle of the soldering station, there is a division into analog and digital. They differ from each other in the way they stabilize the temperature for soldering.

Analog stations turn off the heater when a certain temperature is reached. If it decreases, the heater turns on again. This method is not ideal. In such devices there is a possibility of the tip overheating, since the accuracy of temperature setting is minimal.

Schematic diagram of a soldering station.

In digital stations, temperature control is carried out using a program in the microcontroller. The principle of operation of the device is the same as that of the analog version, only the accuracy of temperature control is significantly higher.

Soldering of the described device options is carried out in the same way. They allow you to set the necessary modes depending on the parts being repaired and the selected solder. However, when working with massive products, it is better to give preference to a digital station.

Which solder should I choose?

The difference between lead and lead-free solder is their melting point. The second option is more refractory. In this regard, more powerful soldering stations are used to work with lead-free solder.

When working with such refractory solder, it is better to give preference to a non-contact soldering station.

The fact is that when repairing electronic devices made using lead-free technology, desoldering individual microcircuits can lead to peeling of the printed circuit board tracks due to higher temperatures.

It is extremely difficult to carry out such work using a regular soldering iron. But using a hot air gun with appropriate attachments will greatly simplify this task.

Analog and digital

It is also possible to classify soldering stations depending on the temperature stabilization mechanism and the operating principle of the control units. Based on these parameters, the following types of modern soldering stations are distinguished:

- analog;

- digital.

For analog models, the heating element is turned on until the soldering iron warms up to a certain temperature, then the power stops. When the temperature drops to a preset level, the heating element turns on again and continues heating.

The advantages of analogue stations include their affordable cost. A disadvantage of such models is considered to be low accuracy of operation, which sometimes leads to overheating of the soldering tip and radio components.

A digital soldering station is characterized by the fact that the heater is controlled and controlled using a PID controller. And this regulator, in turn, is controlled by a program embedded in the microcontroller. In general, the digital temperature stabilization method is much more accurate than the analog method.

TOP products

Before purchasing, be sure to familiarize yourself with the TOP best models of soldering irons for amateurs and professionals.

Best hot air soldering station

Zhongdi ZD-8907 - the best hot-air model

Among electronics lovers, Zhongdi Station ZD-8907 is especially popular. This is a fairly popular model that is of good quality and durability. With careful use, ZD-8907 will serve a person for decades.

One of the main advantages of this soldering iron is its compactness. It does not take up much space on the table, making it very convenient to work with. The power of the device is 300 W. This allows you to use it to repair any electronics.

The best two-channel soldering station

People who want to purchase a two-channel soldering iron should pay attention to the Element 937D. This is a universal tool that allows you to work with both large electronics and small microcircuits. Among the advantages of this model is its heating accuracy. The error is only 8-10 degrees, which is very small.

Additional Information! The Element 937D is equipped with an excellent ceramic heater. This allows you to use the device for high-quality repairs of the smallest parts.

Best Ceramic Soldering Station

Bison 55334 is one of the highest quality ceramic soldering irons.

Among the best devices with a ceramic heater is the Bison 55334. This is a budget model that is available to every electronics lover. The device is universal and suitable for both amateurs and professionals.

The device is equipped with a small screen that displays the heating temperature. Bison 55334 heats up to 550 °C, the error is 10 degrees. Because of this, some radio amateurs rarely use it to repair sensitive elements.

Best Induction Soldering Station

The best induction device is considered to be Quicko 202. This soldering iron is suitable for high-quality soldering and desoldering of microcircuits. The device is equipped with a temperature regulator and a special system that protects against overvoltage and overheating.

Quicko 202 is ideal for working with sensitive elements, as its temperature error is only two degrees. The main disadvantage of a soldering iron is its high cost.

Best digital soldering station

If you need a digital station, you need to pay attention to Yihua 992D. This model differs from other soldering irons in its temperature stability and almost instantaneous heating. The station body is made of high quality plastic.

The device is equipped with a built-in computer and a small display that displays temperature information.

Assembly and dismantling

It is also possible to divide all soldering stations into assembly and desoldering stations.

Assembly stations are any stations that perform soldering of parts. However, not all of them can unsolder any element from the overall structure.

For such purposes, special dismantling stations have been created. Their design includes a compressor that works to suck out solder. That is, the heated solder is removed from the working surface into a special container.

There are also assembly and disassembly installations for soldering that perform both functions at once. They are equipped with both mounting and dismantling soldering irons (by the way, they have different capacities).

Soldering station and its main types

Before choosing soldering irons for further use, you need to familiarize yourself with the main types of such tools.

Contact soldering stations

Contact models - ideal for beginners

Quite often, contact models are used to repair electronics. Most of them use lead-tin solder. However, some soldering irons can work without lead. There are two main types of contact devices:

- Analog. It is equipped with a special electromagnetic relay and a temperature sensor, which are responsible for automatically turning the soldering iron on and off.

- Digital. They have a built-in programmed microcontroller with which the heating temperature is regulated.

Additional Information! Such models are ideal for beginners who have not soldered before.

Contactless soldering stations

In such devices, soldering is carried out using thermal radiation or heated air. Contactless models can be divided into two categories:

- Thermal air. Equipped with a turbine hair dryer that supplies hot air to the surface.

- Infrared. They have an infrared emitter installed, with the help of which soldering work is carried out.

In rare cases, there are combined devices equipped with both a hair dryer and an emitter.

Repair

In addition, in specialized literature and on the Internet there are references to repair soldering stations. They are used to carry out repairs of all kinds of electronic devices or in those industries where it is necessary to independently or simultaneously perform various operations related to soldering.

In other words, a multifunctional repair soldering station is a single installation that combines several tools for different purposes.

Plus, there are 2 in 1 and 3 in 1 soldering stations. 2 in 1 models combine the functions of a hair dryer and a soldering iron. A 3 in 1 soldering station also contains a power supply.

And one more addition. Almost all soldering machines run on electricity. But some are interested in whether there are gas soldering stations. In fact, there is some confusion in terms here.

To perform significant volumes of work on construction sites or in public utilities, powerful devices with stationary gas cylinders are sometimes used to solder thick copper pipes. Of course, they can be called soldering stations, but in fact they are just large and powerful gas burners.

Review of soldering station models

The recognized leader among manufacturers of soldering equipment is the German company ERSA. The materials used, build quality, and highly functional digital control provide all owners of such equipment with effective soldering under any conditions. The disadvantage is the high price. The simplest analog model Analog-60A with one soldering iron costs from 200 EUR, and the two-channel digital ICON VARIO 2, equipped with a hot air gun, costs 1200 EUR.

An inexpensive alternative is the Chinese ones: ATTEN, QUICK, AOYUE, LUKEY. In the Russian Federation, the most popular are QUICK and LUKEY. In a much lower price range you can purchase a device of decent quality and with great capabilities. The QUICK202D ESD induction soldering station with digital control is sold at a price of 120 EUR, and the QUICK990 ESD hot air soldering station costs the same.

LUKEY soldering systems cause the most complaints regarding quality, but their low cost attracts buyers and makes the devices leaders in demand. The popular LUKEY 852 D+ model includes a hair dryer and a soldering iron with a ceramic element at a price of 80 EUR. The two-channel LUKEY 868 is designed for repairing portable devices.

Soldering station LUKEY 868

A wide selection of soldering equipment will allow you to decide on the purchase of a station. For beginners, it is better to purchase inexpensive models; for professionals with high requirements, high-quality devices are suitable.

What to look for when selecting and purchasing

The quality of soldering is directly and strictly dependent on the parameters of the soldering equipment and its design features, and all this is extremely important to take into account when purchasing.

Power

First of all, you need to pay attention to the number of functions and modes in which the station operates, as well as the rated power consumed and produced.

To repair printed circuit boards and install elements that are sensitive to static electricity, soldering irons with a power of 24 to 40 watts are used.

To work with power buses and conductors, soldering irons from 40 to 80 watts are needed. Soldering tools of 100 Watts and more are usually used for large-sized structures made of non-ferrous metal, which, in principle, have significant thermal conductivity.

Equipment

The equipment also plays an equally important role here; in particular, you should pay attention to the number of tips in the factory kit. The stings may differ from each other in shape and edge area.

These characteristics are noticeably reflected in the final soldering. The larger the area of the end of the tip, the better the heat transfer.

The presence or absence of an indication of the tip temperature on the screen is also an important parameter. All other things being equal, it is better to choose a model in which such an indication is present.

Even the weight and dimensions of the soldering station are of great importance. After all, sometimes during repairs you have to hold the tool in your hands for several hours.

Also, when choosing a soldering device for yourself, it is worth asking whether it is possible to replace spare parts if they break down and how easy it is to find and buy these spare parts.

Flux selection

It should be added that in the future, for work, the owner of the soldering machine will have to constantly purchase consumables, such as flux. And here, too, it is important to make a wise choice.

The functional purpose of the flux is to prevent oxidation of the surfaces being soldered.

There are a lot of brands of flux in stores, but they are almost always based on the same ingredients. This can be pine or spruce rosin, an alcohol solution of rosin, or a special soldering acid (it is considered the most powerful and active).

Features of choosing a soldering station

When choosing a suitable system, you must be guided by the following criteria:

- Power. Depends on the focus of the work. Soldering PC boards requires one power level, and working with mobile devices requires another;

- Type of heating element;

- Heating time;

- Temperature control limits;

- Design form, dimensions, weight.

Points to consider:

- Many global manufacturers have switched to lead-free soldering. Consequently, higher power devices will be needed that provide temperatures above 220°C;

- You should pay attention to the replaceable nozzles and tips. Some stations are already equipped with them. You can buy spare ones separately, paying attention to the material of the tip, which should have high thermal conductivity. The shape of the tip depends on the specifics of the soldering.

Types of soldering iron tips

Important! You should not purchase a device with a soldering iron whose tip cannot be replaced.