Types of supports

All metal supports, depending on the purpose of their use, are divided into four types:

- Power

- Non-power

- Decorative

- High mast

Power

Power supports are used to suspend electrical cables and devices that illuminate highways, streets, enterprises and other objects. The structures are made of high-strength steel that can withstand loads of up to 300 kg. Their outer side is treated with zinc to prevent corrosion, which extends their service life to 30 years or more.

Non-power

Non-power supports are used to place lighting fixtures. The electrical cable is supplied to them from the ground and then passes inside the support element. They are made of steel, aluminum and, less commonly, cast iron. The most widespread are steel products that are treated externally with zinc and paint.

Decorative lighting poles

Decorative

The most attractive are decorative supports, which, in addition to lighting purposes, perform aesthetic functions, emphasizing the originality of the architecture.

High mast

High-mast structures have become widespread in recent years due to the possibility of placing a group of lamps or spotlights at a great height.

They are made from separate sections of a conical or faceted type, which gradually taper from the base of the support to the top point. Their height reaches up to 50 meters. Characteristics of metal lighting poles

| Name | Height, mm | Diameter of the lower part of the support, mm | Diameter of the upper part of the support, mm | Weight, kg |

| Flange supports | 5000-6000 mm | 108 mm | 133 mm | 90 kg |

| Cantilever supports | 5000-6000 mm | 130 mm | 159 mm | from 50 kg |

Types of metal lighting poles

Let us dwell on the fact that a support is a metal product for fastening street lamps and/or other equipment and materials.

The first sign of separation of lighting poles is to accommodate the power load if possible. Lighting supports are:

Non-power: intended only for mounting lighting fixtures, with underground power supply. For example, the NFG lighting support is a non-force flanged support, with a faceted design. More about the flange and the edges of the support below in the text.

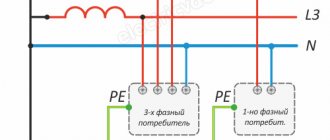

Related articles: Motion sensor connection diagrams

Power: this type of support can be used to mount not only lamps, but also overhead lines of group lighting circuits, SIP wires, and advertising boards.

The second sign of dividing the supports according to the method of installation (installation). Supports can be:

Flange: This support consists of two parts: the support itself and the embedded part. The embedded part (ZDF) is walled into the foundation. Only its flange connection remains on the surface. The support itself is attached to the flange by the supporting part using bolts.

Upright (supports in the ground): These supports are installed directly into the ground, possibly with concreting. For example, a support in the ground 11 meters long has an underground part of 2 meters. The lamp can be hung on a bracket at a height of 9 meters.

By the way, about brackets for installing lamps. The supports can be produced with brackets for installing the lamp, or the brackets come in separate positions. The latter is more convenient, since the brackets can be chosen in a variety of designs: straight, curved, single, double, etc.

The last parameter by which manufacturers divide lighting poles is the type of their design. Here they can be:

- Straight or conical. The cone increases the strength characteristics of the support.

- Tubular or multifaceted. Multifaceted supports are made from sheet iron by bending and welding. The edges, as well as the cone, strengthen the support structure. Pipe supports are more expensive.

Purpose of the support

Metal supports are used to illuminate various areas and objects.

Photo of a metal support

- Lighting on highways is a mandatory condition for their operation, ensuring traffic safety and preserving the health and lives of people. To do this, load-bearing metal supports are installed on which the lighting fixtures are mounted.

- Lighting of parks and gardens is important for the safe recreation of people. If there is no normal light in these areas, then psychological discomfort may occur, there is a possibility of injury or becoming a victim of a criminal.

- Home decorative poles are used to illuminate cottage villages, houses and local areas. Here, the main importance is attached not only to lighting fixtures, but also to the aesthetics of the supporting structures. It is easier to install power cables in a personal plot in the ground.

- Nowadays it is impossible to imagine such large objects as airports and stadiums without their high-quality lighting. For these purposes, high-height metal supports and mast structures are used - several lanterns or spotlights are installed on them, which can illuminate large areas inside and outside objects.

- Bridge lighting is important for the safety of pedestrians, cars and trains. Powerful lighting devices installed on power and non-power metal supports are used here. Without proper lighting, a bridge can pose a danger to people.

Cast iron lighting poles

Main types of lighting poles

The support itself is designed to support the lighting fixture. A street lamp, lamp, spotlight, etc. can be used as it. A variety of lighting devices allows you to solve any problem: from soft illumination of a small area to powerful directional spotlight-type light that “hits” several hundred meters.

Lighting supports are also called masts. They come in the following types:

- metal;

- reinforced concrete;

- wooden;

- composite.

The first type of street lighting poles is the most popular among customers. Made from metals such as steel, cast iron, aluminum, iron. These materials have such necessary quality as resistance to various influences: mechanical, atmospheric, temperature.

Metal supports are able to maintain their shape and original appearance for many years. They are made hollow to reduce the risk of life-threatening injuries and protect the vehicle from serious damage in the event of an accident. Such supports are installed to illuminate roads, pedestrian areas, and sports facilities.

Reinforced concrete supports are inferior to metal ones in many respects. Firstly, they are much more sensitive to external influences: temperature and mechanical. Over time, visible defects appear on such supports - cracks and chips.

Secondly, reinforced concrete supports are very dangerous if a car hits them. In the event of a collision, there is a high probability of life-threatening injuries, serious damage to the vehicle, and destruction of the support itself.

Thirdly, supports of this type are difficult to transport due to their heavy weight. However, these disadvantages are compensated by a more affordable cost. Used for lighting equipment for roads, residential areas, etc.

Wooden supports are used extremely rarely in industrial construction today. This material is short-lived and more susceptible to destruction than the previous two.

However, wooden poles are used to install temporary lighting lines. For example, for carrying out construction work in areas remote from the city. Wooden masts are easy and quick to install, dismantle and transport.

Another area for using this type of support is decorative. Such supports can take any shape, they are made to order and serve as decoration for the general outdoor interior of a personal plot or a hospitality establishment.

Composite masts surpass all of the above in technical parameters. They are produced by centrifugal casting or winding. The main advantage of these supports is safety, the indicators of which meet European standards. However, they also cost more than others.

Materials for production

Three types of metal are used for the manufacture of lighting poles:

- Steel

- Aluminum

- Cast iron

Steel support elements are used more often due to some advantages of this metal:

- cheapness

- wide choice of manufacturing methods

- reliability and durability

Galvanizing of lighting poles

The simplest poles are made from pipes of various diameters, suitable for constructing power and non-power structures. There are products made from rolled steel, which by bending is given the shape of a truncated smooth or faceted cone.

Lighting poles made of aluminum have the following advantages:

- small mass

- relative strength

- high anti-corrosion properties

- durability

Drawing of a metal lighting support

Aluminum products are designed for placing lamps at low heights. A high level of aesthetics of aluminum poles is achieved by painting them in any color using modern dyes.

Cast iron lighting poles are most often used on streets, parks and private properties. Cast iron is a traditional metal for making decorative products and has good characteristics:

- low price

- high anti-corrosion properties

- long service life - up to 100 years

Cast iron supports produced by casting are interesting and practical, fitting perfectly into classic or modern buildings.

Specifications

In the process of designing lighting systems and installing supports, their technical characteristics are taken into account:

- weight

- resistance to wind loads

- life time

- height

The weight of high-rise structures depends on several factors: purpose, vertical size and material of manufacture. Overall power and high-mast supports, given the large size of the luminaires, have a lot of weight. Aluminum structures are the lightest, cast iron ones have increased weight.

Almost all supports have good wind load and can withstand wind speeds of up to 44 m/sec, due to their cone-shaped shape. The maximum service life of metal supports is 50-75 years, but it all depends on the material of manufacture and the quality of the anti-corrosion coating. The height of supporting structures depends on the purpose and has some restrictions. The height of non-power supports can reach 12 meters, decorative ones – up to 6 meters. In urban environments, especially near residential buildings, the height of these structures should not be more than 12 meters.

High-mast products are assembled from 3,4,5,6 or more links. For example, at airports poles with a height of 20 meters can be installed, and at some facilities up to 50 meters.

Lighting pole grounding

How is a lighting mast different from a support?

Both the mast and the lighting support are designed for installing street lights at height.

A support is a mounting structure in the form of a pillar resting on a supporting base. A striking example of a support is urban street lighting. Everyone is familiar with the rows of evenly spaced street lights along the roads. The height of the supports is from 3 to 12 meters.

A lighting mast is a taller structure on which groups of lamps or spotlights are mounted to illuminate entire areas. A striking example here would be the lighting of stadiums with high-rise floodlight masts. The height of the masts is from 16 to 40 meters.

Installation process

According to the method of installation, supports are divided into two types:

- Upright

- Flanged

Straight supports are mounted in a prepared hole on the ground surface and filled with concrete.

The flange element consists of above-ground and underground parts. First, a flange-shaped embedded element is installed in the prepared pit, which should remain outside after pouring concrete. Subsequently, the support itself is bolted to it directly.

Foundation for lighting poles

The parameters of the foundation depend on the purpose of the support, its size, and weight. This takes into account the type of soil and possible wind loads, as well as the type of embedded elements. The size of the pit in plan is 1000 x 1000 mm, depth 1200 mm. The depth of cable laying under the lawn is at least 800 mm, under the road – 1200 mm. A sand cushion 150 mm thick is made at the bottom of the trench to protect the cable from possible soil subsidence.

Lighting pole grounding measurement

Lighting pole grounding

All metal supports must be grounded so that if voltage is accidentally applied to the mast, the electric current is diverted into the ground, which ensures the safety of people.

Grounding devices are iron pins or metal strips driven 3 meters into the soil, laid in a trench at least half a meter deep. All metal support elements, including hooks and light fixture holders, are connected to the metal sheath of the supply cable with an insulated neutral wire connected to the ground element. A similar system is used as lightning rods - when struck by lightning, the charge is directed to the ground and does not have a negative effect on humans and lighting elements.

Features of installing lighting poles

Supports are installed in three ways:

- flanged;

- upright;

- cantilevered.

A flange-type support has two plate parts - one is the foundation, the other is the base of the support itself. First, the foundation is installed and the support itself is attached to it. The flanges are bolted together through the mounting holes. The advantage is that this type is very versatile. If a support fails, it can be dismantled and another one installed in its place.

To install the support in a straight-line manner, it is necessary to prepare a pit for installing the support. The support is a single pillar, which is immersed to a certain depth in the pit, after which the base is concreted. Dismantling such a structure will be quite labor-intensive.

The cantilever type is used for installing supports in areas with difficult terrain (slopes, ravines). The foundation is a block installed in the ground. It is leveled and then fixed with cement. The support is installed on the console, tightened with bolts, after which the base is covered with a decorative plinth.

The supports themselves can have different shapes: round, polygonal, rectangular. It depends on the intended purpose of the lighting mast. To correctly select a support for a specific purpose, skilled and precise planning is required.

Support maintenance

Lighting poles and lamps must be maintained throughout their operation.

Check frequency:

- Once a month, the lines are inspected, the condition of the insulators and pendants to which the lamps are attached is checked. If burnt out lamps are detected, they are replaced, and the faults are eliminated.

- Twice a year, the optical part of the lighting devices is cleaned using solvent or white spirit, debris and branches are removed, and overhanging trees are trimmed.

- Once every three years, supports whose coating becomes unusable due to temperature changes and solar radiation are painted.

GOST

For the installation of metal lighting poles, suspension of electrical cables and further operation, GOST 32947-2014, approved on September 8, 2021, was established.

In accordance with the document, metal supports can be used in areas with a minimum permissible temperature of up to minus 40 degrees Celsius and taking into account the norms of wind and ice loads.

The standard specifies requirements for the accuracy of product dimensions, bolted and welded connections, appearance and anti-corrosion protection.

The completeness of metal supports is checked during acceptance tests using a random method.