General information about the technology

This is a joining method that uses a bonding melt (solder) with characteristics suitable for specific conditions. Both the active soldering element and the workpieces are subjected to preheating, due to which a material structure that is pliable for joining is formed. The temperature regime must exceed the peak heating point, past which the metal parts soften and begin to transition into a liquid state. An important characteristic of any type of soldering is the thermal exposure time under the melt. This is the interval from the start of heating until the solder hardens after the connection has been made. On average, the operation takes 5-7 minutes, but there may be deviations from this range - it depends on the characteristics of the workpiece and the area of the unit being processed.

Soldering lamps

The most common tool for soldering various workpieces, allowing high-temperature heating by burning alcohol, kerosene and other types of liquid fuel. During operation, a torch fuse is ejected from the apparatus nozzle, which is subsequently directed to the target area of the melt. Such devices can be used not only for connecting parts, but also in heating operations of structures and mechanisms. Soldering machines are also used before removing paint coatings. The average heating temperature of a lamp soldering iron is 1000 – 1100°C, so it can also be used in welding work. The most productive models include gasoline lamps. They quickly reach the optimal operating temperature and cope with most standard soldering operations. The design of the devices includes a fuel cartridge, as well as a flame regulator, which allows you to vary the power of the thermal effect.

What is soldering?

Do-it-yourself soldering at home comes down to the following technological operations:

- The soldered surfaces are cleaned of dirt, corrosion crusts, etc.

- Clean until shiny, i.e. until there are no visible traces of oxides;

- They are coated with flux - a substance that removes oxide residues and prevents oxidation of surfaces in the further process. For fluxing under tinning, it is preferable to use flux pastes rather than liquid or solid fluxes;

- Then the surfaces are tinned - molten solder (an alloy specially designed for soldering) is applied to them, while it spreads into a thin film and chemically combines with the base metal;

- The parts are pre-connected mechanically: by twisting, compression with tweezers, pliers, in a vice, clamp, etc.

- Flux is also applied to prevent oxidation of the solder under heat;

- While heating, more solder (perhaps a different one) is applied until a junction of the specified quality is obtained;

- If soldering was carried out with a soldering iron with a tinned tip (see below), upon completion it is cleaned and coated with inactive flux. To ensure high-quality soldering, a regular soldering iron must be stored with a fluxed tip!

Next, we will take a closer look at the key operations that you should pay special attention to in order to learn how to solder properly.

Necessary Retreat

In the comments on the topic of soldering, the topic is widely discussed: what is the correct way to tin or tin? According to the rules of the Russian technical language - tin, as in other word forms from “tin”; fornication has nothing to do with it. But it’s better, if possible, to do without consoles at all, because in the roots of word forms, “d” is often changed to “zh” (pudding), and then a parasitic association with a puddle is possible. What is tinning - dipping into a puddle? It is necessary to tinker. “Soldering” instead of “soldering” is clearly unacceptable, because these words have completely different meanings. Just like “solder” instead of “solder”. Fast ice is a strip of coastal ice formed when bodies of water freeze. And adhesions are an undesirable consequence of surgery. The place where parts are connected by soldering is a junction.

Note: in the northern dialects of Russian there are also luds - underwater rock ridges - and even the whitefish fish that is found there. But in canonical Russian luds appear extremely rarely, so they can be ignored.

Geodetic works. Mobile laser scanners- Necessary accessories for the bathroom. Toilet paper holders

Garden furniture is the main element in your local area

Stripping

Stripping after cleaning is the first tricky soldering operation. The use of abrasives for it is unacceptable! Their smallest particles, ingrained into the metal, cannot be completely removed. Subsequently, they become centers of processes that destroy the junction.

Clean the surfaces for soldering with a needle file, file, scraper tool (different types of scrapers) or just a knife. But it is best, especially if current-carrying wires are being prepared for soldering, to immediately coat them with activated flux (see below), and after soldering, carefully remove its residues. It is convenient to do this with a toothbrush moistened with alcohol.

Soldering torches

A wide group of gas soldering irons that can be connected to a fuel can or to a central fuel source. The first supply option has the advantage of autonomy. A burner with a spray can, like a gasoline lamp, can be used regardless of external communications. When choosing such a device, you should take into account power, operating temperature, type of gas used, readiness time, etc. For example, a standard gas torch for soldering runs on propane-butane and reaches heating temperatures of up to 1300°C. The period of continuous thermal exposure can reach 3 hours, but this time will also depend on the volume of the connected cartridge. Burners are also distinguished by the type of ignition system. The simplest models are turned on mechanically, while more modern modifications use piezo ignition.

Electric soldering irons

This is also a common type of soldering equipment in the household environment, which is distinguished by its safety (compared to gas devices) and compact size. But it’s worth highlighting the disadvantages right away. Firstly, such devices are dependent on the electrical network, which limits their scope of application. Secondly, electric soldering equipment maintains a low heating temperature in the range of 400 – 450°C. This is due to the fact that part of the energy is lost in the process of converting electricity into heat.

When choosing a device, you must take into account the maximum voltage. Thus, in workshops and factories they use standard 220 V models. In domestic conditions, devices powered by 12 and 24 V transformers are often used. Tasks that can be solved with electric soldering irons are mainly limited to repairing small equipment, restoring contacts of microcircuits, connecting plastic parts, etc.

Soldering stations

To perform group or continuous soldering operations, multifunctional equipment is used. The soldering station is distinguished by wide possibilities for adjusting operating parameters, as well as higher heating temperatures. Suffice it to say that devices of this type operate at a power of 750 - 1000 W, connecting to networks with a voltage of 220 V. As a rule, this is professional soldering equipment, but there are also analogues for household use. For example, devices for group operations at home may include several interchangeable tips of different formats, stands, solder removers, wire cutters and other auxiliary accessories. Now it’s worth familiarizing yourself with different technological approaches to soldering processes.

Types and features of this method

The process is divided into the following categories:

– a method of heating and filling the molten solder of the seam at the joint;

– characteristics of hardening and crystal lattice of a seam or surface coating during tinning;

– method of removing oxide film from the surface;

– a method with improved time characteristics for heating the joint;

– type of loads on the parts being connected.

The main importance when choosing a welding method is the melting temperature characteristics of different types of solders. Solder melts at temperatures up to 4600 - the process is called low-temperature. Above this heating value – high temperature.

The simplest is low-temperature using flux. Its energy consumption is low, the ability to connect thin parts made of steel and alloys, an increased level of thermal conductivity and soldering of metals of different compositions are the main advantages of this type.

High-temperature soldering has some advantages:

- Under flux, the connection is sealed, with a dense base of the seam.

- For work at home, small gas burners are used.

- The connection is obtained only on materials with a melting point above 460 degrees.

Another type is the compositional method.

Used when installing metal structures with large bending angles. By using composite solder with fillers made from low-melting additives, a strong and reliable connection of structural components is achieved. At the same time, the edges of the workpieces only heat up, and the molten solder fills all the voids and connects the parts.

They are divided according to the methods of solder production. Here it is generally accepted that solder can be ready-made (tin) and obtained through a chemical reaction when heating the soldering materials. The most commonly used is ready-made solder. It is heated to a liquid state, it fills the joints of the parts and, when cooled, makes the connection permanent and reliable. It is held on the surface of the parts by capillarity, which guarantees a sufficient level of strength at the joint.

When a chemical reaction is used, solder and flux are released from the soldering materials. In this case, solder liquid is formed. It fills the seam between the parts, cools down and does its job.

To obtain good joining quality, the heat source used to melt the solder and carry out the soldering reaction is of great importance. The most famous and accessible to everyone is a soldering iron. The use of gas burners and industrial hair dryers is often required.

For the low-temperature method, various soldering irons are most often used. With this method, by heating the surface of the soldering area, remove part of the solder with the tip of the tool and fill the hole or edges of the surfaces to be joined in the molten state. To obtain a more reliable, hermetically sealed connection, be sure to heat the soldering areas.

For the high-temperature method, you can use high-power electric soldering irons. But it is better to use gas and other types of burners for this type. A blowtorch using gasoline, kerosene, as well as burners using methane or propane-butane - these tools will allow you to perform high-quality soldering even in the field.

After a short lesson in theory, we move on to the practical lesson. Soldering microcircuits and making circuit boards for radio equipment will always allow you to have a well-paid job, and the ability to solder will also come in handy for the household. Therefore, we will consider this type of soldering in more detail.

Main types of soldering

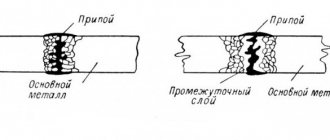

There are techniques for performing joint and gap operations. So, if the gap between the elements being connected is less than 0.5 mm, then the soldering will have a gap. Exceeding this interval means that the connection is made end-to-end. Moreover, the joints can have different configurations - for example, X- and V-shaped. Gap soldering is performed only with liquid solder, which is directed into the intermediate zone during operation. Standard types of butt soldering involve filling the free space with solder under the influence of gravity.

Classification of soldering by temperature conditions

Today, soft, hard and high-temperature soldering is used, which is used mainly in production and construction. The first two techniques are similar in many ways - for example, in both cases the operating temperature is 450°C and below. For comparison, high-temperature connections are made at temperatures of at least 600°C, and more often above 900°C.

At the same time, low-temperature processing can provide a high-quality connection. The most advantageous would be the use of hard solder, due to which high strength and refractoriness of the parts are achieved. Adding copper to a gap or joint will also increase the ductility of the workpiece. If you want to obtain a flexible and elastic structure, then use soft soldering.

Solders and fluxes

Now it’s time to accurately select the working solder and flux for it, because... soldering, unlike half-solder, must not only adhere tightly to the base metal, but also be strong itself. A summary of information about solders and fluxes of widespread use from the old reference book is given in Fig. In relation to the present time, there is not much left to add to it.

Characteristics of solders and fluxes for wide application

Solders

Solders from POS-90 to Avia-2 are soft for low-temperature soldering. Only electrical contact is guaranteed. POS-30 and POS-40 solder copper, brass, bronze with inactive fluxes, and the same with steel, and steel with steel with active ones. POSSr-15 can be soldered galvanized sheets with inactive fluxes; other solders corrode the zinc to steel and the soldering soon falls off.

34A, MF-1 and PSR-25 hard solders, for high-temperature soldering. Solder 34A can be used to solder aluminum in a flame (see below, about soldering aluminum) with special fluxes, see ibid. MF1 solder is used to solder copper to steel with activated flux. “Low strength requirements” in this case means that the strength of the joint is closer to the strength of copper than steel. When soldered with a dry soldering iron (see below), PSR-25 is suitable for soldering jewelry, Tiffany stained glass, etc.

Fluxes

Soldering fluxes are divided into neutral (inactive, acid-free), which do not react chemically with the base metal or interact to an insignificant extent, activated, which chemically act on the base metal when heated, and active (acidic), which act on it even when cold. In regard to fluxes, our century has brought the most innovations; mostly still good, but let's start with the unpleasant ones.

First, technically pure acetone for washing rations is no longer widely available due to the fact that it is used in the underground production of drugs and itself has a narcotic effect. Substitutes for technical acetone are solvents 646 and 647.

Secondly, zinc chloride in activated flux pastes is often replaced with sodium teraborate - borax. Hydrochloric acid is a highly toxic, chemically aggressive volatile substance; Zinc chloride is also toxic, and when heated it sublimates, i.e. evaporates without melting. Borax is safe, but when heated it releases a large amount of water of crystallization, which slightly impairs the quality of soldering.

Note: Borax itself is a soldering flux for dip soldering, see below.

The good news is that there is now a wide range of fluxes on sale for all soldering occasions. For ordinary soldering work, you will need (see figure) inexpensive SCF (alcohol rosin, former CE, second in the list of acid-free fluxes in Table I.10 in the figure above) and soldering (etched) acid, this is the first acid flux on the list. SKF is suitable for soldering copper and its alloys, and soldering acid is suitable for steel.

SKF rations must be washed: rosin contains succinic acid, which destroys the metal with prolonged contact. In addition, accidentally spilled SCF instantly spreads over a large area and turns into an extremely sticky muck that takes a very long time to dry, the stains from which cannot be removed from clothes, furniture, or the floor and walls. In general, SKF is a good flux for soldering, but not for slow-witted people.

A complete substitute for SCF, but not so nasty if handled carelessly, is TAGS flux. Steel parts are more massive than is permissible for soldering with soldering acid, and more durable, they are soldered with F38 flux. The universal flux can be used to solder almost any metal in any combination, incl. aluminum, but the strength of the joint with it is not standardized. We'll come back to soldering aluminum later.

Note: radio amateurs, keep in mind that there are now fluxes on sale for soldering enameled wires without stripping!

Solder classification

Modern solders can be roughly divided into two groups:

- Melting at low temperatures.

- Melting under high temperatures.

As already noted, low-temperature soldering is performed at 450°C and below. The solder itself for this type of operation must soften already at 300°C. Such materials include a wide group of tin alloys with the addition of zinc, lead and cadmium.

High-temperature melt media are used for soldering at temperatures of around 500°C. These are mainly copper compounds, which also include nickel, phosphorus and zinc. It is important to note that, for example, tin-lead-cadmium solder, in addition to its lower melting point, will differ from copper alloys in mechanical strength. The ratio of resistance to physical pressure can be represented as follows: 20 – 100 MPa versus 100 – 500 MPa.

What and how to tin/solder?

For the following operations you will need a special electric heating tool: a soldering iron, a futor or a soldering torch. Soldering at home most often involves an electric soldering iron with a tinned copper tip. Its device is shown in pos. 1 pic. “For complete happiness,” an amateur solderer needs 16-20 W rod soldering irons for microcircuits and printed circuit boards, pos. 2a, 40-50 W (item 2b), for electrical wires and mounted mounting of radio electronics components, and 80-150 W (item 2c), for assembling small metal structures by soldering.

Design and types of electric soldering irons with tinned copper tip

If you are not going to work with microchips (phones, tablets, computers) and soldering steel with a thickness of more than 0.5-0.6 mm, you can get by with a set of soldering irons of 25 W (pos. 3a) and 60-65 W, pos. 3 b. Suddenly there will be a need to solder metal profiles with a wall thickness of up to 3-4 mm and/or a thick steel sheet, you will need a radiator “axe” soldering iron for 300-400 W, pos. 4.

The tips of low-power soldering irons (items 2a, 2b, 3a, 3b) are not initially forged and therefore oxidize (burn) quite quickly. To increase their durability, and at the same time to mold them in the desired way, the rod removed from the soldering iron is forged with a mechanic’s hammer on the anvil of a table vice. There is no need to “sharpen” it with a file after this, and it is not necessary, so as not to erase the outer compacted layer of copper. After forging, the tip is immediately coated with activated flux.

Now you will need hard rosin and soft, fairly refractory solder (see below): POS-10, POS-30 or POS-40. The soldering iron rod is inserted into place, fixed if there is a locking screw, and the soldering iron is connected to the network. As the flux boils away during heating, the tip is immersed in rosin so that it does not become exposed. When the rosin around the tip begins to bubble, rub it with a stick of solder until an even, dense layer is obtained over the entire surface of the tip. Filamentous solder on a coil is not very good in this case; it is for soldering small parts.

While we were preparing the soldering iron, the flux on the soldering surfaces did its job: under its layer they are clean, you can tin. The critical point here is the thickness of the parts:

- Less than 1/8 of the diameter of the soldering iron rod - will heat through to the melting temperature of the solder in less than 7 seconds. The flux will not have time to boil away.

- More than 1/6 of the same value - it will warm up in more than 10 s, the flux will boil away, the parts will become exposed and oxidize.

- 1/8-1/6 of the diameter of the rod - it is necessary, most often based on your own experience, to tin with low-melting solder under a high-boiling flux. Or use a more powerful soldering iron.

In the first case, a drop of solder is taken onto the tip, transferred to the soldered surface, and if:

- The wire is thin - easily, without pressure, move along the bare end with a tip from one side and then from the opposite side until the solder spreads. The wire is held with the tip down. A drop of excess solder that has flowed down there is removed with a soldering iron.

- The wire is thick - the tip is moved in a spiral back and forth.

- A flat thin long part - solder is applied to the end and the tip is moved along. When the untinned edges of the part appear behind the tip, apply more flux to the untinned area, take another drop of solder and continue tinning.

- The long, wider part is the same as in the previous one. case, but the sting is led like a snake.

- Wide part - the sting is moved in a spiral from the center to the edges.

To tinning thick parts, use filament solder with flux, the so-called. harpius: this is a thin flexible tube of solder foil, in the lumen of which there is powdered rosin. Tinning begins from the edge of long or from the middle of wide parts. The end of the harpius is applied to the place where tinning begins, and heated with a soldering iron until it melts. The sting movements are the same as before. cases. Solder is fed under the tip as it is consumed. Apply it to the sting - it will stick to it until a large drop forms, which flows where it is not needed.

Types of fluxes

When exposed to heat, an oxide coating is formed on the surface of the metal workpiece, which prevents the formation of a high-quality connection with the solder. To remove such obstacles, different types of soldering fluxes are used, some of which also eliminate traces of rust and scale.

Fluxes can be classified according to their compatibility with solders (hard and soft) or temperature resistance. For example, for soft soldering of heavy metals, products marked F-SW11 and F-SW32 are used. For hard joints of heavy alloys, soldering fluxes F-SH1 and F-SH4 are used. Light metals like aluminum are recommended to be pre-treated with compounds of groups F-LH1 and F-LH2.

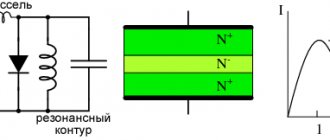

Induction soldering method

This soldering technology has several advantages over the classic hot melt joining method. Among them, one can highlight the minimum degree of oxidation of the workpiece, which in some cases eliminates the need to use fluxes, as well as a low warping effect. As for the target materials, these include both soft and hard alloys, as well as ceramics and plastic. For example, the optimal solder for copper in this case will be marked L-SN (modifications SB5 or AG5). Both hand-held lamp devices and machine units of appropriate power can act as a source of thermal energy during induction exposure. In production, generator sets are also used when it is necessary to obtain long-term soldering of large-area components. A multi-place inductor is also included in the work, which can accept workpieces one by one. This technology is used, in particular, to produce hand-held cutting tools.

Ultrasonic soldering

Another modern high-tech soldering method, the development of which was caused by the need to eliminate a number of characteristic disadvantages of electrochemical joining methods. A key feature of this technique is the ability to replace conventional flux as a means of removing oxides. The stripping function is performed by the energy of ultrasonic waves, which causes cavitation in the liquid solder. At the same time, the tasks of thermal binding action from the melt are fully preserved.

The superiority of the technology in terms of connection speed is also noted. If we compare ultrasonic radiation with the effect that tin-lead solder gives, then the intensity of the slamming of the cavities of the processed unit will be several times higher. As observations show, ultrasonic waves with a frequency of 22.8 kHz provide a solder closing speed of 0.2 m/s.

There are also economic advantages of this method. They are also associated with changes in approaches to the use of fluxes and solders. In the production of electrical devices, when assembling monolithic capacitors, current converters and other devices, metallization with palladium, silver and platinum pastes is widely used. The ultrasonic soldering process allows you to replace precious metals with cheaper analogues without losing the performance of the future product.

Features of soldering wires

In the preliminary connection of soldered parts, the most problems arise with the wires: to do this, you have to touch them with your hands, which causes the metal surface to become dirty, and the wire solders have to withstand mechanical loads more often than other soldered joints.

Twists of wires

Before soldering the wires, they must be twisted correctly. The main types of wire twists for soldering are shown in Fig. Each of them has its own purpose:

- Bandage twists are used to connect rigid (thick single-core) current-carrying wires, i.e. through which electrical power is transmitted. Especially – external wires. The band connection ensures sufficient electrical contact even if the oxidized junction is not soldered or overheated.

- Grooved twists are made on wires in low-melting insulation (plain PVC, polyethylene), when complete spreading of the solder with minimal heating is required. Grooved twists are heated only along the groove.

- Simple twists can be used to connect both single-core and multi-core wires that have just been stripped of insulation (shiny).

- Simple sequential twisting, so-called. straight British, or simply British, is applicable for connecting current-carrying wires of flexible cables with a cross-section of up to 1.4 square meters. mm, not subject to regular heavy mechanical loads, e.g. electrical extension cords or temporary sheds.

Electrical wires that experience regular and/or constant mechanical stress must be multi-core. They are twisted as shown in the figure below: the ends are marked, the “brooms” are pushed into each other and twisted in the British way. Soldered with high-strength low-melting solder, e.g. POSK-50 (see below) with activated flux that does not require removal of residues, also see below.

Parallel (dead-end) twists of wires with a cross-section of over 0.7 square meters. mm, it is advisable to solder by immersion in molten solder, see below. Otherwise, you will have to heat it either for a long time, or with a too powerful soldering iron, which will cause the insulation to creep and the flux to boil away prematurely.

Note: single-core tinned wires – leads of radio electronics parts – can be soldered end-to-end or with a crochet hook, see fig. on right.

What is soldered, but not soldered

Flexible coaxial cables and cables for computer networks such as twisted pair (“vitukha”) are not intended for connection by soldering. An experienced cable technician who has a complete understanding of the electrodynamics of signal transmission lines can, in exceptional cases, make a coupling on them. But when performed by an amateur, even if he is otherwise a qualified electronics engineer and installer, the throughput and noise immunity of the line will fall below the permissible level, up to complete loss.

How to clean and preserve the sting

The soldering iron tip is cleaned of solder residues by rubbing it against a soft porous or fibrous pad. Foam rubber is most often used, but this is not the best option: it burns and sticks to the sting. The best material for cleaning it is natural felt or basalt cardboard. But even better is 2-step cleaning, first with a sponge-tangle made of metal tape, and then with felt. After cleaning, turn off the soldering iron, insert an even hotter tip into the solid rosin and wait until it stops bubbling. Then the tip is removed and held with the end down so that the excess rosin drains off. Once it has cooled completely, the soldering iron can be stored.

Features of soldering and welding

Soldering as such has many similarities with traditional welding technologies. Heating of the workpieces and third-party material are also used to influence the formation of the seam. But, compared to welding techniques, soldering does not involve internal melting of the workpiece structure. The edges of the parts, as a rule, remain hard, although they are subject to heating. Still, complete melting of the workpiece produces a stronger connection. Another thing is that to achieve such a result, more powerful equipment may be required. When using liquid solder for copper, non-capillary soldering with dense filling of the seam is quite feasible. This joining method is partially related to welding, since it increases the adhesion of the structures of two or more workpieces. It is recommended to perform non-capillary soldering using electric arc devices or an oxygen-acetylene torch.

Features of soldering with an electric soldering iron

Soldering with an electric soldering iron has a number of features compared to other connection methods. They must be taken into account when performing installation work.

Important! When working at home, try not to inhale fumes from a soldering iron. The smoke from rosin is relatively safe

And acid vapors are not at all beneficial for the respiratory system and lead to coughing. If there is no special hood, then soldering should be done with the windows open.

Flux selection

Most often, electricians use solid flux - rosin. There are two ways to apply it to the wires to be soldered:

The soldering iron tip touches the rosin pebble. The flux is then transferred from the heated tip of the tool to the wires being soldered.

It is important to have time to apply rosin to the current-carrying conductor before it evaporates from the tip. Usually this is 3-5 seconds. The stripped wire is placed on rosin and pressed on top with a heated tip.

In this case, the flux melts and the wire is immersed in the melt.

Rosin can be mixed with ethyl alcohol. The result is a good liquid flux, which is convenient to apply with a brush.

It is important not to overdo it here so that the solution does not flow down the wire insulation. After all, in the future dust will stick to this place

Soldering stranded wires

Stranded wire is a set of thin wires woven into one cable and covered with insulation. Such a conductor is easier to solder than a monolithic one. Any type of flux readily penetrates and is drawn into the voids between the thin wires of the core. This also applies to solders. They easily impregnate stranded wire. The main thing is to warm it up properly, and soldering will proceed by itself. To solder the wires securely, they must be carefully twisted with your fingers.

Soldering junction boxes using a crucible

This method allows you to conveniently solder twists that are in boxes and socket boxes. The solder is pre-melted in a small crucible with a volume of 20 to 100 ml. The wires to be soldered are immersed in a container of molten metal.

A compact gas burner is used to heat the crucible and melt the solder. Some experts use homemade devices for these purposes, made with their own hands from powerful electric soldering irons. But such devices require voltage, which is not always present in the apartment being renovated.

Flux for soldering aluminum

When soldering with regular rosin, the solder will not stick to the aluminum. Here you need to use a flux like F-64. It is produced specifically for aluminum wires. The product is sold in liquid form in the form of a jar with a brush.

After soldering with F-64, the twist must be washed with a slightly alkaline solution to neutralize the acidic properties of the flux. To obtain a cleaning mixture, simply dilute baking soda in warm water. Then you need to wash it with plain soapy water or liquid soap using a toothbrush.

Soldering allows you to reliably connect wires at minimal cost. All you need: soldering iron, solder and flux. A properly soldered contact will last no less than the wiring itself.

You should choose a soldering iron based on the power of the heater. The maximum thickness of the wires that can be connected depends on this criterion. The type of flux, solder, shape and material of the soldering iron handle are selected based on the individual preferences of the master.

How to solder wires correctly: choosing a soldering iron, fluxes and solders, soldering technology

0,00 / 0

Guru 220→Electrical wiring→Wires and cables→

Did not you find what you were looking for? See also:

- Homemade LED spotlight at home

- Options and nuances of connecting stranded and single-core wires

- Technology of tinning conductors - overview of methods

- Using a soldering iron and connectors to connect LED strips

- How to strip wires - an overview of tools

- Methods for terminating cable cores and wires using lugs

Add a comment Cancel reply

–

2016-2020. 220 GURU All rights reserved

- Site Map

Copying materials without permission from the site administration or the author is prohibited.