Aluminum soldering is a technological process used in the repair of internal combustion engines, connecting aluminum wires by twisting, sealing cracks and holes in pans, boilings, basins made of this metal and its alloys. Unlike a similar process for parts made of copper or its alloys, such soldering work requires a more careful approach to the choice of flux, solder, and tool (soldering iron or gas torch).

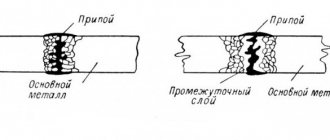

Solder seam between aluminum sheets

Process Features

The main features of this type of soldering work are:

- Application of special fluxes and solders;

- Careful preparation of the surfaces to be soldered: cleaning, degreasing, tinning.

- The use of powerful soldering irons and gas burners capable of heating working surfaces to a certain temperature.

Also, during soldering work on parts made of this metal, the heating temperature of the working surfaces is constantly monitored. This is done in order not to overheat the low-melting metal - when heated to a temperature above +250-300 degrees Celsius, the metal structure made from it begins to lose its strength and deform.

Properties of aluminum

The problem with soldering aluminum is due to its chemical structure. This metal itself is chemically very active; it reacts with almost all chemicals. This causes pure aluminum to instantly react with oxygen in air. As a result, a very thin and at the same time extremely strong oxide film is formed on the metal surface: Al2O3. In terms of their properties, aluminum and its oxide represent two extreme opposites combined into a single whole. For example :

- The melting point of pure aluminum is 660 degrees. Aluminum oxide, or corundum as it is also called, melts at a temperature of 2600 degrees. Refractory corundum is used in industry as a refractory material.

- Aluminum is a very soft and ductile metal. Corundum has extremely high mechanical strength, which makes it possible to produce all kinds of abrasive materials from it.

Aluminum oxide turns ordinary soldering into a rather complex process. For its successful implementation, it is necessary to use specific methods and special aluminum solders and fluxes.

Materials used

Fluxes for aluminum soldering

Soldering station - operating principle and types

Before soldering aluminum, it is necessary to remove the strong and refractory oxide film from its surface. To do this, before starting soldering work, a special composition is applied to it - flux, which promotes the rapid dissolution of the oxide and prevents its formation for some time.

Rosin, powder, and liquid compositions are used as flux for this type of work.

Rosin

This inactive flux for aluminum is used extremely rarely. It does not dissolve the oxide film and does not ensure the formation of a high-quality solder joint.

Rosin

Powder flux

Of the powder fluxes used for this type of work, borax, composition grade F-34A (active flux based on potassium, lithium and zinc chlorides, sodium fluoride), and solder fat are used.

Liquid flux

The following compositions are used as liquid flux for soldering aluminum:

- F-61;

- F-64;

- Castolin Alutin 51 L.

The advantages of liquid compositions, compared to rosin and powdered substances, are the convenience and uniformity of their application, and more economical consumption.

Solder for soldering aluminum

Solder for aluminum comes in the following types:

- Tin-lead alloy – POS-40, POS-61 (contain 41 and 61% tin, respectively);

- Zinc-tin alloy – TsOP-40 (zinc content – 40%);

- Aluminum alloys – HTS 2000, Castolin 192FBK, 34A.

Domestic solders

Among the domestic solders, zinc-tin grades with a zinc content of 40%, as well as special aluminum solder grade 34A, are suitable for this type of soldering work.

Comparison of solders for aluminum soldering

Of all the brands of solder used for this type of work, the maximum strength and reliability of the seam are provided by foreign alloys HTS 2000, Castolin 192FBK, as well as the domestic brand 34 A.

Conventional tin-lead alloys, unlike specialized ones, do not provide reliable adhesion to the working surface, are highly oxidized in air, and do not have the necessary tensile strength.

On a note. In order to solder copper to aluminum, both fluxes and solders of the same brands and types are used as for soldering work on aluminum parts.

Cored wire

Flux-cored wire is used for welding aluminum parts. It is not suitable for soldering them, as it has a very high melting point.

Flux Cored Wire for Welding

In order for the seam to be of high quality and reliable, the parts to be soldered are thoroughly degreased and cleaned with sandpaper or a metal brush. When using a soldering iron, the working surfaces become tinned.

Heating sources

Soldering irons and propane gas burners are used as heating sources for this type of work.

Soldering iron for soldering aluminum

To connect parts, seal holes and cracks in workpieces made of this metal, use a soldering iron with a nichrome heater and a wide copper tip. The power of this device should be at least 80-100 W.

Aluminum soldering torches

For this process, small propane gas burners with replaceable cylinders are used.

Gas-burner

Important! It is not recommended to use oxy-acetylene gas torches for this type of work, as they heat the low-melting metal to a high temperature in a short time, which can lead to overheating and melting.

Scope of application

The use of flux for soldering f 64 is quite extensive, and it is enough to indicate several technological areas where the aluminum base is widely used:

- Creation of heat transfer systems, for example, car radiators.

- In energy systems of a closed space, for example, the formation of a closed electrical circuit.

- Connection of live parts that were broken under the influence of mechanical force, for example, wires of a common main electrical network.

- Creation of technological structures that provide communication based on the principle of electrical conductivity.

Flux F 64

Solders, the basis for high-quality joining of aluminum products

As you can see, do-it-yourself flux for soldering will allow you to repair both complex and problematic sources of damage, as well as easy areas and components. The following traditional materials are used as solder:

- Tin;

- Alloy using zinc;

- Cadmium based alloy.

The melting point of the above listed materials is in the range from +200 C to +400 C, and for these purposes you can use a not very powerful soldering tool. Additionally, refractory substances, which contain copper, zinc and even silicon, are used as solder.

Soldering techniques

Soldering fat

The main technological methods used in this process are the following:

- Degreasing the working surface with a clean rag soaked in solvent or acetone;

- Initial cleaning with a wire brush or coarse sandpaper;

- Applying flux to a cleaned work surface;

- Heating the metal with a torch;

- Solder melting under the jet of a burner flame to form a seam;

- Cooling and hardening of the seam;

- Removing scale and loose oxide from the resulting seam using a metal brush or sandpaper.

On a note. To control the heating temperature of the working surface, place a piece of solder on it. If it begins to melt and turn into a small droplet in the form of a ball, then it means that the metal has warmed up, and it is necessary to immediately begin soldering it.

What is better - welding or soldering aluminum?

The debate over the answer to this question is not going to subside. It turns out it all depends on your purpose. More precisely, the purpose of your connected parts.

If you need to solder a car radiator, then soldering aluminum is better suited because it is cheaper. For critical work (load-bearing structures) and food containers (for example, a milk flask), welding is better suited because it is more reliable. This is how I would formulate the answer to this question.

It is clear that it is easier for a master with gas welding to weld a radiator, rather than solder it, and vice versa - it is easier for a master with a soldering iron to solder.

Read also: Recharging for batteries

Now look at TIG welding for beginners. Very helpful and well filmed.

Using improvised means

Among the available means to solder aluminum, the following are used:

- Acetylsalicylic and citric acids - an aspirin tablet or a bag of citric acid is dissolved in 150-200 g of water and the resulting solution is used as a simple liquid flux;

- Oil for lubricating sewing machines - with the help of an oil film, the mechanically cleaned area of the working surface of the part is protected from the formation of an oxide film.

Oil I-20 for sewing machines

Thus, having figured out how to simply solder aluminum at home, you can not only repair holes in old pots and buckets, but also run a full-fledged business at home or in the garage repairing car radiators, radiators, and engines.

Peculiarities

In order for the fluxes you use to properly perform their function, you must first prepare the metal. No welding is possible without preparation. It doesn’t matter what you use - flux, gas, or even resistance welding. The preparation process is mandatory in any case.

Degrease the aluminum surface. To do this, use any solvent and a lint-free cloth. Prepare your metal stripping tools. You can use a sander, sandpaper or grinder. When using a grinder, use abrasive wheels or replaceable metal brushes. We recommend combining different cleaning methods, depending on the degree of contamination of the metal.

If the metal is heavily contaminated, use the etching method. Place the part in a container of acidic solutions and wait until the dirt or corrosion dissolves. After stripping, the oxide film will also be removed, but this will not last long. As you now know, it is capable of self-healing under the influence of oxygen.

Why then do we need to clean it up at all? The fact is that after mechanical removal, the oxide film forms again, but it is much thinner and not so chemically active. In addition, aluminum soldering flux works great on a cleaned surface, making welding easier.

Solder selection

For soldering aluminum, it is better to choose ordinary soft tin-lead solder - PIC. The main thing is that it contains more than 50% tin, in order to make sure of this you need to look at the number following the name, it must be more than 50 (POS 50, POS 61, POS 90, etc.).

In addition to the above solders, you can use those based on silicon, copper, aluminum or silver. These include 34A and TsOP-40, which contain zinc, which increases their strength coupled with corrosion resistance.

Solder POS-61 0.8 mm