How to ground a metal hose

When a metal hose is grounded and how to do it, it is described in Chapter 1.7 of the Electrical Installation Code - “Grounding and protective electrical safety measures.”

The possibility of electric shock to a person upon contact with metal parts that are not normally energized is considered in the PUE to be indirect contact with live parts of this equipment.

The measure that provides the required protection determines the need to disconnect electrical equipment and lines from the power source by tripping the protection devices. To do this, the conductive parts must be connected to a solidly grounded neutral in TN type power supply systems, and grounded in IT and TT systems.

Important! When grounding a metal hose, you must remember that this operation should be performed in two places - at the beginning of the section of the electrical line laid using this electrical product, and at its end.

The connection of the protective conductor and the metal hose can be made in two ways:

- 1st method - using a clamp and a bolted connection.

In this case, a special clamp is used, the design of which includes a bolt (screw), through which the conductor is fastened, connecting the metal hose to the ground electrode.

- 2nd method - using soldering.

With this connection method, the conductor is connected directly to the surface of the metal hose.

Each of these methods has its own advantages and disadvantages.

- Advantages:

- for method 1: ease of installation;

- availability of execution, regardless of the location of the clamp installation.

- reliability of electrical contact.

- Flaws:

- for method 1: electrical contact is less reliable than with another connection method.

- the difficulty of performing work in cramped installation conditions.

When performing work, the surface of the metal hose is cleaned of dirt and dust, after which it is cleaned using abrasive materials or tools (sandpaper, needle file, etc.), after which a clamp is installed or soldering is carried out.

What to use as a grounding conductor

For grounding electrical equipment and metal structures, including electrical wiring using metal hoses, natural and artificial grounding conductors can be used.

Natural grounding conductors are metal structures and communications that are in contact with the ground according to the conditions of their operation. Such grounding conductors can be:

- reinforcement frame of reinforced concrete structures;

- metal structures of various orientations that have direct contact with the ground;

- utility lines laid in the ground.

Important! The following cannot be used as natural grounding conductors:

- pipelines with flammable and toxic substances;

- pipelines equipped with anti-corrosion insulation;

- sewer and heating main lines.

An artificial ground electrode is a special ground loop made from a metal profile and reinforcement on a selected area of soil.

The geometric dimensions of the ground loop, as well as the types and cross-section of the materials used, are determined in accordance with the resistivity of the soil at the installation site and on the basis of the calculations that determine them.

To perform calculations, there are special programs and separate formulas, using which you can obtain the required values.

Grounding a metal hose is not only a requirement of the rules, but also a condition for the safe operation of electrical networks for humans and other living organisms, which must not be forgotten both at the stage of installation work and during the subsequent use of electrical communications.

Source: 220.guru

A metal hose is a flexible hose twisted from a galvanized metal strip and its main purpose is to protect the cable from all kinds of mechanical damage and protection from negative environmental influences. If you need to protect your cable with a metal hose, then do not forget to ground it. And I will tell you how to do this in accordance with the requirements of the PUE in this article.

Why does it need to be grounded?

It is necessary to ground the metal hose in order to protect a person from possible electric shock if the insulation of the cable located inside is broken.

If the insulation of the conductor located inside the metal hose is broken, then the leakage current will flow through the grounding jumper into the ground. And if a person accidentally touches the metal hose, he will create another chain for the flow of current.

But due to the fact that the resistance of the human body is much higher than the resistance of the grounding conductor, the person will not be exposed to voltage dangerous to his health.

The PUE clause 1.7.76 says the following about the grounding requirement:

How to properly ground a metal hose

It is important to know that the grounding of a corrugated metal pipe must occur on both sides. And the grounding itself can be done in two different ways:

1. The first method is soldering. This grounding option is performed as follows: the soldering area is first cleaned of dirt and oxide to a metallic shine, then the grounding conductor is soldered to the structure.

2. The second method is to use a clamp with a clamping screw.

The installation site of the clamp is also carefully cleaned and the clamp is installed, and the grounding conductor with a crimped tip is secured with a clamping screw. Then it is necessary to apply a lubricant, for example, lithol, to the grounding connection.

This connection requires periodic maintenance, that is, pulling the bolted connection.

In this case, the grounding conductor can be made of steel, copper and aluminum.

Sections of grounding conductors:

Copper - minimum 4 sq. mm.

Aluminum - minimum 6 sq. mm.

Steel - in a room of 5 square meters. mm, outdoors 6 sq. mm.

Note.

It is prohibited to use aluminum conductors without a protective PVC sheath as jumpers.

What can be used as grounding

The remaining unconnected ends of the jumpers connected to the metal hose should be connected to the grounding circuit.

For grounding you can use: reinforcement of reinforced concrete structures and foundations and metal braiding, copper cables laid in the ground. If there is no connection option to such grounding electrodes, then a grounding circuit should be organized.

Conclusion

This is how the metal hose is grounded in accordance with all the requirements of regulatory documentation.

If the article was useful, please give it a thumbs up and thank you for your precious attention!

Source: zen.yandex.ru

Cable laying in a metal hose

Cable laying in a metal hose

To protect wiring from exposure to dust, moisture, to protect from fire in the event of a short circuit, and from various mechanical damage when connecting electricity, a flexible metal pipe is used - a metal hose. It is very easy to install due to its large bending radius.

The metal hose is made of steel or galvanized tape, and all hoses have their own designations (markings). Marking RZ - for steel metal hoses, RZ-Ts for galvanized ones, sealed ones are marked with the abbreviation - RZTsP, hoses that have explosion protection are designated - VSG.

This product is used for laying electrical cables, as well as for computer network cables or communication cables.

Laying electrical cables in a metal sleeve

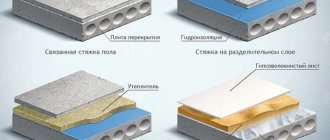

The metal sleeve acts as a protective case for the wire. The case is installed indoors, most often non-residential, because this type of installation on top of walls in a flexible pipe is less aesthetically pleasing. Metal flexible pipes are installed in industrial premises, basements, garages, and so on. Laying the cable in a metal hose provides reliable protection of the conductor, subject to compliance with all electrical installation rules (PUE). It is the rules for the design of electrical installations that determine the permissible conditions for the electrical installation of a metal product, how the cable should be laid in a metal hose, and determine the service life of the metal case. There are two ways to install the hose indoors. The first method is an open gasket, the second is a hidden one. In both the first and second cases, brackets or mounting clamps are used to fasten the sleeve. The brackets or clamps are attached to the mounting surface using self-tapping screws or nails.

One of the important criteria for installing a metal hose is the unacceptable laying of the hose on flammable surfaces and substrates made of wood, plastic, plasterboard, etc. It is important to know that laying power wiring in a metal hose is allowed only when it is surrounded on all sides by non-combustible materials. You can lay a metal conduit with an electrical cable inside yourself, but it is best to use the services of an electrical contractor. The work of an electrician will cost more, but the installation of the hose will be carried out in accordance with all the rules and established standards. It is very important how the cable is laid in the metal hose; the price of the specialist’s services will depend on the entire volume of work done. The price also depends on the cross-section and number of cable cores; the smaller the cross-section and number of cores, the cheaper. In total, all the work of an electrician to install a metal hose with wiring inside will cost from 130 to 1000 rubles.

Types, application, installation and grounding of flexible metal hose

When laying electrical wiring and cables, and transporting various media, a flexible sealed metal hose, which is quickly installed thanks to the presence of connecting fittings, becomes a help. The metal hose is grounded in accordance with the requirements of the Electrical Installation Rules (EPR), so that in the event of an emergency, the electric field strength between the surface of the earth and the metal of the hose is safe for humans.

When laying wiring in a metal hose, it is necessary to take measures to ground it

How to produce corrugated stainless steel hoses

Such flexible and sealed corrugated stainless steel metal hose designs are usually made using high quality steel or other metal. The design is equipped with connecting fittings made of the same material, which simplifies the joining of individual pipeline elements. The produced metal hose must receive a passport and a certificate.

Sealed stainless steel hoses are produced in several ways. The two most common are:

- Forming a seamless metal tube with a diameter of up to half a millimeter.

- By overlapping winding of the profile tape and connecting the edges of the corrugation using contact-roller welding.

The method of formation and the choice of metal for production determine what type of product will be given:

Sleeves are available with or without braiding, but even the presence of such a protective coating does not negate grounding

The production of corrugated metal hoses includes reinforcement with steel wire. The spiral sleeve is reinforced in a spiral manner.

Helpful information! The braid is designed to protect the product from mechanical damage. Depending on the purpose of the product and the pressure of the working environment, it is possible to produce several braids.

Manufactured products must be marked with nine meanings:

- year of issue;

- serial number;

- main technical characteristics.

Application of flexible metal hoses

Flexible metal hoses provide reliable protection against mechanical damage and fire caused by a short circuit when laying:

- computer network;

- television cable;

- video surveillance systems;

- telephone cable;

- electrical wiring.

Various types of cables are laid in metal hoses in domestic and industrial environments.

In rooms with high humidity, products equipped with an additional protective PVC coating are used. The PVC shell prevents dust and water from entering, even with a directed jet. Therefore, the PVC-sheathed structure successfully protects the cable laid inside it:

- in a production area with high humidity levels;

- in the shower and bathroom;

- in the kitchen;

- in the sewer line.

Mounting coupling for metal hose

Installing metal hoses is not difficult. Fastening to surfaces is made possible by brackets, and individual structural elements are connected by couplings. The latter are distinguished by several characteristics:

- length;

- diameter of the connecting passage;

- material of manufacture;

- conditional working pressure;

- operating temperature.

The most common types of couplings are:

- pipe Serves to connect a metal hose and an electrical wiring pipe. Made of zinc alloy, equipped with a cylindrical thread;

- introductory The inlet coupling for a flexible metal hose allows its sealed insertion into the installation box. Self-extinguishing PVC is used for production.

- connecting. Made from zinc alloy for joining individual sections.

The input coupling ensures the safe operation of the most complex sections of electrical networks, where they are branched and special distribution boxes are installed. The coupling, without reducing the level of protection of the wires, leads the cable route into the junction box.

You can ground a hose with an electrical cable passing through it using a steel clamp, which should wrap around the pipe as tightly as possible

Where in the PUE is it stated that the metal hose must be grounded?

Vasily Today we sealed the meter and the electrician made a comment that the metal hose of the input and output cables on the metering panel was not grounded! The shield is metal and mounted on a support! Where in the PUE is it stated that the metal hose must be grounded?

Answer: 1. Based on the PUE, table 2.1.2., it is prohibited to use a metal hose in an outdoor installation, since the wall thickness of the metal hose is less than 2 mm.

2. Installing a metering board on a support contradicts the requirements of the PUE, clause 1.5.27, since electricity meters must be placed in dry rooms with a temperature not lower than 0 °C.

3. In accordance with the PUE, clause 1.7.76., the metal hose must be connected to the grounding conductor.

PUE-6 Table 2.1.2 Selection of types of electrical wiring, installation methods and wires and cables

2. It is prohibited to use steel pipes and steel blind boxes with a wall thickness of 2 mm or less in damp, especially damp rooms and outdoor installations.

1.5.27 Meters must be located in dry rooms that are easily accessible for maintenance, in a place that is sufficiently free and not cramped for work, with a temperature in winter not lower than 0 °C. General industrial meters are not allowed to be installed in rooms where, due to production conditions, the temperature can often exceed +40 °C, as well as in rooms with aggressive environments. It is allowed to place meters in unheated rooms and corridors of switchgears of power plants and substations, as well as in outdoor cabinets. In this case, provision should be made for their stationary insulation for the winter through insulating cabinets, hoods with heating of the air inside them with an electric lamp or heating element to ensure a positive temperature inside the hood, but not higher than +20 ° C.

Types of corrugated metal hoses

According to the molding method, the sleeve is divided into:

- Accordion type. It is completely sealed and holds its shape perfectly.

It is usually made of stainless steel. It has two serious drawbacks: it is very expensive, and limited in flexibility. Curvature radius up to 20 sleeve diameters. If you bend it too much, it will simply burst. It is used to a limited extent, only for use in special conditions. - Mass corrugation of turn type. The most common hose: used without restrictions both in industrial facilities and in residential premises.

A complex configuration of joints: on the one hand, allows you to obtain a strong, unbreakable pipe, on the other hand, the sleeve can be bent to small radii. The only drawback is that the coil sleeve is not sealed. If moisture gets inside, it stays there for a long time. - Corrugated with PVC coating. A polyvinyl chloride sleeve is located on top of the coil spring.

This reduces flexibility, but the pipe becomes completely sealed. The strength characteristics are unchanged: steel coils protect from mechanical stress. Fire safety is also not reduced: flame propagation does not occur in a closed environment.

Grounding of metal hose

When using metal hoses, attention should be paid to the grounding device. The product itself provides protection for electrical wiring thanks to a layer of galvanized steel that conducts electricity well. Grounding will ensure an adequate level of safety. The use of natural elements as grounding conductors significantly increases the efficiency of grounding. In the event of an emergency, when a person is connected to an electrical circuit, the amount of voltage passing through him will not pose a threat to health and life.

Important! The protective case, which was not secured with brackets during installation work (or other fasteners were used), is especially grounded.

The protective case grounding technology involves several stages:

- The case is cleaned to a shine and secured with a metal bracket.

- The grounding screw is fixed nearby.

- The metal bracket and grounding screw are fastened with a jumper - a copper wire with a diameter of at least 4 mm.

When carrying out grounding, it is important to comply with the rules of the Electrical Installation Code, which prohibit, for example, the laying of cables even protected by a metal hose on a wooden surface.

How to ground a metal hose in accordance with the PUE

What causes the need for grounding?

Grounding of electrical equipment, armored cables, as well as electrical wiring laid in a metal hose creates conditions for protection against electric shock in the event of a breakdown of the insulating sheath of the current-carrying elements in them.

When the cable insulation resistance drops below normal, the metal hose will be exposed to leakage current, which will go into the ground along the grounding jumper. If a person touches it, another circuit is created parallel to grounding, but since the resistance of the human body is much greater than that of the grounding jumper, an insignificant current will pass through it, which is safe for health and life. According to the PUE, when installing cable lines, the metal hose that serves as protection for the wiring must be grounded and this must be done in accordance with the requirements of regulatory documents (PUE clause 1.7.76, see Chapter 1.7).

How to ground a metal hose

Before moving on to the consideration of grounding technology, it should be noted that the cable trunk is grounded on both sides, at the beginning and at the end of the line. There are two ways to secure the grounding jumpers to the surface of the metal hose: by soldering or with a metal clamp.

Soldering of grounding conductors to ensure reliable and durable contact is usually used by specialized electrical installation organizations. Since this method is not always available, in particular, when laying the wiring yourself, it is worth resorting to the help of tight-fitting clamps. Some of the most common samples are shown in the photo:

The areas where these devices are applied are first cleaned to a metallic shine. The threaded fasteners in the places where the jumpers are connected must be tightened firmly, after which it is recommended to apply a layer of lubricant. For this purpose, you can use lithol. In order to ensure guaranteed electrical safety during operation, it is necessary to periodically monitor the reliability of the point of attachment of the conductor to the metal hose, as well as its condition for breakage.

Grounding conductors can be made of steel, copper and aluminum. Their minimum cross-sections must correspond to the following values: copper - 4 mm 2, aluminum - 6 mm 2 (PUE clause 1.7.126). The diameter of the steel wire for installation indoors is 5 mm, outdoors – 6 mm. The ends of the conductors must be pressed into the lugs. Bare aluminum conductors without PVC insulation are prohibited from being used as jumpers.

What to use as a grounding conductor

The free ends of the jumpers connected to the metal hose must be grounded, that is, connected to a grounding circuit, which can be used as natural or artificial grounding conductors. If the situation allows, the most common option for connecting reinforced concrete structures and building foundations to the reinforcement is allowed as an artificial grounding system according to the PUE (clause 1.7.109). Connection to underground steel pipelines is not prohibited, but only if they do not serve to transport flammable substances or natural gas to the casing pipes of drilled wells. It is allowed to connect cables laid underground to metal sheaths, with the exception of products with aluminum current-carrying conductors (PUE clause 1.7.109). If there are no such connection options, it is necessary to install an artificial grounding device. The simplest device can be a metal conductor inserted vertically into the ground.

A more complex, and therefore reliable option, is the installation of a grounding loop, consisting of a group of such conductors connected to each other by horizontal jumpers.

The issue of arranging a grounding switch is relevant for electrical networks with a TN-C and TN-CS grounding system. For power supply systems using the TN-S principle, which has not yet found widespread use in the Russian Federation, the task is significantly simplified. A bus connected to the protective neutral conductor PE is used as a grounding device.

That's all I wanted to tell you about how to ground a metal hose according to the PUE. We hope the information provided and photo examples were useful to you!

It will be interesting to read: