What is electrolysis?

Electrolysis is a complex of specific processes in a system of electrodes and electrolyte when a direct electric current flows through it. Its mechanism is based on the occurrence of ionic current. An electrolyte is a type 2 conductor (ionic conductivity) in which electrolytic dissociation occurs. It is associated with decomposition into ions with a positive (cation) and negative (anion) charge.

The electrolysis system necessarily contains a positive (anode) and a negative (cathode) electrode. When a direct electric current is applied, cations begin to move towards the cathode, and anions begin to move towards the anode. The cations are mainly metal ions and hydrogen, and the anions are oxygen and chlorine. At the cathode, cations attach excess electrons to themselves, which ensures the occurrence of the reduction reaction Men+ + ne → Me (where n is the valence of the metal). At the anode, on the contrary, an electron is given up from the anion with the occurrence of an oxidation reaction.

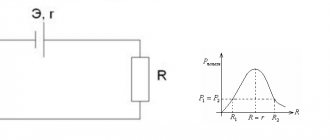

Thus, the redox process is ensured in the system. It is important to consider that appropriate energy is required for its occurrence. It must be provided by an external current source.

Industrial Applications of Electrolysis

Electrolysis is widely used in the following industries:

- Isolation and purification of metals.

- Production of aluminum, magnesium, sodium, cadmium.

- Production of alkalis, chlorine, hydrogen.

- Purification of copper, nickel, lead.

- Processes of spraying protective coatings to protect metals from corrosion. Electrolysis (from the Greek “lysis” - decomposition, dissolution, disintegration) is a set of physico-chemical phenomena on electrodes located in a liquid during the passage of an electric current. For example, by immersing two electrodes in water and connecting them to a direct current source, we will find that bubbles are released around the electrodes - these are hydrogen and oxygen gases. When they form, the mass of water decreases, that is, it decomposes into its constituent elements.

If the electrodes are immersed not in water, but in solutions or melts of salts, acids and alkalis, then you can observe the release of other gases and even solids deposited on the surface of the electrodes. For this reason, electrolysis is widely used in technology. Let's consider the most important areas of its application. But before that, remember that the electrode connected to the “+” of the current source is called the anode, and the electrode connected to the “–” of the current source is called the cathode.

Obtaining refined copper.

Electrometallurgy

Many metals are produced by electrolytic methods in industry: aluminum, copper, magnesium, chromium, titanium, etc. For example, to obtain pure aluminum, ore molten at 900 °C, containing aluminum in a chemically bound form (usually in the form of oxides), is poured into a special metal bath. . Carbon rods are lowered into the bath, which serve as anodes, and the bath itself serves as a cathode. When current passes through the melt, liquid aluminum is released at the bottom of the bath, which is drained through a hole at the bottom of the bath.

Electrometallurgy.

Refining (purification) of copper

Copper used in electrical and radio engineering for the manufacture of conductors must be pure, since impurities reduce electrical conductivity. To clean copper from impurities, a solution of copper II sulfate (the outdated name is copper sulfate) is poured into an electrolytic bath and two plates are lowered: the anode - a thick plate of crude copper and the cathode - a thin sheet of pure copper.

When an electric current is passed, the anode gradually dissolves, impurities precipitate, and pure copper settles on the cathode. Other pure metals - nickel, lead, gold - are also obtained in a similar way.

Galvanostegy

To give products a beautiful appearance, strength or to protect them from corrosion, they are coated with a thin layer of some metal: nickel, chromium, etc. To do this, the product is thoroughly cleaned, degreased and placed as a cathode in an electrolytic bath containing the salt of the metal used. want to cover. For a more uniform coating, it is useful to use two plates as an anode, placing the product between them.

The result of galvanostegy.

Electrotype

This is the electrolytic deposition of metal on the surface of an object to reproduce its shape. To do this, a cast is first taken from the object (from wax or plaster) and covered with a conductive layer, for example, a layer of graphite. An object prepared in this way is placed as a cathode in a bath with a solution of a salt of the corresponding metal. When the current is turned on, the metal from the electrolyte settles on the surface of the object. Electroplating is used to make an unlimited number of exact copies of the product from which the impression was taken.

Interesting on the topic: What is Ohm's law

Galvanopolishing

If a carved metal product is placed in an electrolyte solution and the current is turned on, the strongest electric field is formed at microscopic protrusions on the surface of this product. If it is connected to the “+” of the current source, then the metal ions will “break out” most intensely from the protrusions, and the surface of the metal will be leveled.

It will be interesting➡ Joule Lenz's Law - the most complete theory

Electrophoresis

From Greek "phoresis" - transference), is a medical procedure. Electrodes are placed on the human body. Paper or cloth impregnated with an electrically conductive drug is placed between the body and the electrode. When the current is turned on, charged particles begin to move from paper or fabric into the skin, and then into the human body. This is how the process of administering drugs occurs, the speed of which can be adjusted by changing the current strength. Electrolysis is also used for the synthesis of various inorganic and organic substances; this is studied in a separate science - electrochemistry.

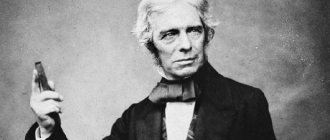

Faraday's Laws of Electrolysis

The great physicist M. Faraday, with his research, made it possible not only to understand the nature of electrolysis, but also to make the necessary calculations for its implementation. In 1832, his laws appeared, linking the main parameters of the ongoing processes.

First Law

Faraday's first law states that the mass of the substance being reduced at the anode is directly proportional to the electric charge induced in the electrolyte: m = kq = k*I*t, where q is the charge, k is the coefficient or electrochemical equivalent of the substance, I is the strength of the current flowing through electrolyte, t – current flow time.

Second Law

Faraday's second law made it possible to determine the proportionality coefficient k. It sounds like this: the electrochemical equivalent of any substance is directly proportional to its molar mass and inversely proportional to its valency. The law is expressed as:

k = 1/F*A/z , where F is Faraday’s constant, A is the molar mass of the substance, z is its chemical valence.

Electrolysis of melts

One of the electrolysis options is to use a melt as an electrolyte. In this case, only melt ions participate in the electrolysis process. A classic example is the electrolysis of molten salt NaCl (table salt). Negative ions rush to the anode, which means gas (Cl) is released. Metal reduction will occur at the cathode, i.e. precipitation of pure Na, formed from positive ions that have attracted excess electrons. Similarly, other metals (K, Ca, Li, etc.) can be obtained from the solution of the corresponding salts.

During electrolysis in a melt, the electrodes do not undergo dissolution, but participate only as a source of current. In their manufacture, you can use metal, graphite, and some semiconductors. It is important that the material has sufficient conductivity. One of the most common materials is copper.

ELECTROLYSIS

ELECTROLYSIS

- chemical reactions occurring under the influence of electric current on electrodes placed in solutions, melts or solid electrolytes. Electrolysis is used in some physiotherapeutic procedures (see Galvanization), in the polarographic method of analysis (see Polarography), widely used in biochemistry, it underlies the electrochemical method for obtaining a number of important substances and storing electrical energy in batteries.

In industry, electrolysis is used to obtain aluminum (see), magnesium (see), titanium, zirconium, uranium (see) and beryllium (see) from ore melts, as well as to produce chlorine (see), chlorates, perchlorates , persulfates, organic compounds (see), hydrogen (see), oxygen (see), fluorine (see), etc. In addition, thin metal coatings are applied to various products, including medical instruments, using electrolysis , to protect them from corrosion, increase wear resistance and heat resistance, and improve appearance. Electrolysis is also used in the manufacture of metal copies.

In addition to electrolysis, electric current passed through solutions, melts and solid electrolytes (see) can cause various electrokinetic phenomena (see) - electroosmosis (see), electrophoresis (see) and thermal effects.

For the first time, quantitative relationships between electrical energy and chemical transformations associated with it were established by M. Faraday, who in 1833-1834 formulated the basic laws of electrolysis: 1) the amounts of substances isolated or dissolved on the electrodes are directly proportional to their chemical equivalents ( see Chemical equivalent), as well as the amount of electricity passing through the electrolyte; 2) to release a gram equivalent of any substance, the same amount of electricity (F), equal to 9.650 k, is always required.

During electrolysis at the anode, ions and molecules of the electrolyte or electrode material (see Electrodes) give up electrons (oxidize), for example: 2Al + 3(H2O) → Al2O3 + 6H+ + 6e, and at the cathode they accept electrons, that is, they are reduced: Fe3+ + e → Fe2+. At the cathode, a discharge of metal and hydrogen ions usually occurs: Cu2+ +2e → Cu, 2H+ + 2e → H2. The nature of the anodic processes depends on the anode material. In the case of soluble anodes made of silver, copper, zinc, cadmium, metal atoms give up electrons to the external electrical circuit and become cations, that is, the anode dissolves: Ag → e + Ag+. On insoluble anodes made of platinum, iridium, and graphite, the discharge of anions is most often noted: 2Cl- + 2e → Cl2. Some materials (iron, nickel, cobalt, gold, chromium, aluminum, tin) can be soluble under various conditions. and insoluble electrodes.

To isolate any ion as a free substance, it is necessary to apply a potential to the electrode that is at least slightly higher than the intrinsic electromotive force (emf) of the galvanic pair formed as a result of electrolysis. These are the so-called decomposition, discharge or release potentials. The magnitude of this potential is measured experimentally for each electrode, most often by the method of polarization curves. The sum of the potentials for the release of substances at the anode and cathode determines the decomposition voltage of the electrolyte under given conditions. The accumulation of substances on the electrodes leads to the emergence of potentials and polarization current (see), directed opposite to the polarizing current. Primary electrode processes are sometimes followed by secondary, purely chemical reactions: the formation of molecules from gas atoms released on the electrodes, for example, hydrogen H2; the formation and growth of metal crystals and the formation of continuous metal deposits, for example, cathodic deposition of copper; interaction of electrolysis products with each other, with the electrolyte, solvent or with impurities, for example, the formation of hypochlorous acid during the electrolysis of chlorides due to the interaction of chlorine released at the anode with water. The release of atomic oxygen or hydrogen at the electrodes leads to secondary oxidation or reduction reactions (see Redox reactions); for example, nitrobenzene (see) at the cathode is reduced to aniline (see), anthracene at the anode is oxidized into anthraquinone.

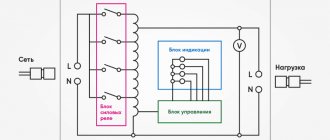

Electrolysis in order to obtain certain products is carried out in special devices - electrolyzers, electrolytic baths, cells. Mineral or organic acids, salts and mixtures thereof are used as electrolytes. In some cases, the electrolyte serves as the starting material for obtaining the desired product. To eliminate the interaction of electrolysis products formed on the electrodes, the electrolyzer is divided into two (or more) parts by a porous diaphragm made of asbestos, ceramics, ion-exchange membranes, permeable only to electrolyte ions. In this case, the solution in the anode space is called anolyte, in the cathode space - catholyte. The efficiency of electrolysis is assessed by voltage efficiency, energy yield, substance yield, etc.

Bibliography:

Glinka N. L. General chemistry, p. 293, L., 1978; Krishtalik L. I. Electrode reactions, Mechanism of elementary act, M., 1979; Electrosynthesis and bioelectrochemistry, ed. A. N. Frumkina et al., M., 1975.

V. A. Pekkel.

Features of electrolysis in solutions

Electrolysis in an aqueous solution differs significantly from a melt. There are 3 competing processes taking place here: oxidation of water with the release of oxygen, oxidation of the anion and anodic dissolution of the metal. The process involves ions of water, electrolyte and anode. Accordingly, reduction of hydrogen, electrolyte cations and anode metal can occur at the cathode.

The possibility of these competing processes occurring depends on the magnitude of the electrical potentials of the system. Only the process that requires less external energy will proceed. Consequently, cations with the maximum electrode potential will be reduced at the cathode, and anions with the lowest potential will be oxidized at the anode. The electrode potential of hydrogen is taken as “0”. For example, for potassium it is (-2.93 V), for sodium - (-2.71 V), for lead (-0.13 V), and for silver - (+0.8 V).

Theoretical part

Electrolysis is a set of redox reactions occurring under the influence of direct electric current on electrodes immersed in a solution or molten electrolyte. During electrolysis, a chemical reaction is carried out due to the energy of an electric current supplied from the outside. Electrolysis is carried out in special devices - electrolyzers. This is a vessel with a solution or melt of an electrolyte and metal or graphite electrodes lowered into it. A potential difference from an external direct current source is applied to the electrodes. The cathode gives electrons to the particles of the substance in the electrolyte and reduces them. The anode takes electrons from particles in the electrolyte, oxidizing them.

Electrolysis of base melts.

During electrolysis, oxidation and reduction processes occur at various electrodes - anode and cathode. The anode is the electrode on which the oxidation process occurs. During electrolysis, the anode is positively charged. The cathode is the electrode at which the reduction process occurs. During electrolysis, the cathode is negatively charged. The redox processes occurring during electrolysis are influenced by various factors:

- Nature of electrolyte and solvent;

- Electrode material;

- Electrolysis mode (voltage, current, temperature).

It will be interesting➡ What is electromotive force (EMF) and how to calculate it

There are 2 types of electrolysis: melt electrolysis and electrolysis of electrolyte solutions. Electrolysis of oxide melts At the cathode, metal cations are reduced: Men++ nē = Me0, i.e. Metal is deposited at the cathode. Oxygen is oxidized at the anode: O –2 –2ē = O2 For example, electrolysis of molten potassium oxide: 2K2O = 4K + O2 When studying aluminum and methods for producing metals, you need to know the electrolysis of aluminum oxide. Metallic aluminum is produced by electrolysis of a solution of alumina Al2O3 in molten cryolite Na2AlF6 at 960–970°C. The electrolysis of Al2O3 can be represented by the following scheme: in the melt, aluminum oxide dissociates: Al2O3= Al3++ AlO3 3–, Al3+ ions are reduced at the cathode: Al3++3ē Al0, AlO3 ions 3– are oxidized at the anode: 4AlO3 3– – 12ē 2Al2O3 + 3O2. The overall equation of the process is: 2Al2O3 4Al + 3O2. Liquid aluminum collects at the bottom of the electrolyser.

Electrolysis of base melts

The metal is traditionally reduced at the cathode: Men+ +nē = Me0 At the anode, oxygen in the hydroxide group will be oxidized: 4OH− −4ē =2H2O + O2 Electrolysis of molten salts 1. Electrolysis of a molten oxygen-free salt: Metal is always reduced at the cathode: Men + nē = Me0 An oxygen-free anion is oxidized at the anode: A n– – nē = A0 For example: Electrolysis of a NaCl melt: 2NaCl = 2Na + Cl2 2. Electrolysis of a melt of oxygen-containing salt (the anion element is not in the highest oxidation state): The metal is always reduced at the cathode: Men++ nē = Me0 The anion element will be oxidized at the anode: SO3 2– – 2ē = SO3 0 For example, electrolysis of molten sodium sulfite: Na2SO3 = 2Na + SO3 Sulfur S in sulfite has an oxidation state of +4, during electrolysis it is oxidized to +6 (SO3). 3.

Electrolysis of a molten oxygen-containing salt (anion element in the highest oxidation state): The metal is always reduced at the cathode: Men++ nē = Me0 At the anode: because element is already in the highest degree of oxidation, then oxygen will be oxidized, for example: 2CO3 –2 – 4ē = 2CO2 + O2 For example, electrolysis of a molten sodium carbonate: 2Na2CO3 = 4Na + 2CO2+ O2 It is important to understand that these reactions do not occur on their own. Their flow is possible only under the action of electric current. Electrolysis of solutions The following reduction reactions can occur at the cathode.

Electrolysis of base melts.

Cathode processes: Li K Ca Na Mg Al Li+K +Ca2+Na+Mg2+Al3+ Mn Zn Fe Ni Sn Pb Mn2+ Zn2+ Fe2+ Ni2+ Sn2+ Pb2+ H2 2H+ Cu Hg Ag Pt Au Cu2+Hg2 2+Ag+ Pt2+Au3+ Water is reduced : 2H2O+2ē=H2↑+2OH− ; M n+ is not reduced Metal cations and water are reduced: Mn++nē=M0 2H2O+2ē=H2↑+2OH− Metal cations are reduced: M n++ nē=M0 a) during the electrolysis of salt solutions containing ions located in the voltage series after hydrogen , metals are released at the cathode: (-) Cu2++ 2ē → Cu. b) during the electrolysis of salt solutions containing cations located between aluminum and hydrogen, competing processes of both cation reduction and hydrogen evolution can occur at the cathode: (-) Zn2++ 2ē → Zn; (-) 2H2O + 2ē → H2↑ + 2OH– . c) if salt solutions contain cations that are in the voltage series up to aluminum, then in an aqueous solution such ions cannot be reduced, hydrogen is released at the cathode: (-) 2H2O + 2ē → H2↑ + 2OH– . The process at the anode depends on the anode material and the nature of the anion. Oxidation reactions take place at the anode.

How does electrolysis work?

Electrolysis in gases

Gas can act as an electrolyte only if there is an ionizer. In this case, the current passing through the ionized medium causes the necessary process on the electrodes. However, Faraday's laws do not apply to gas electrolysis. For its implementation, the following conditions are necessary:

- Without artificial ionization of gas, neither high voltage nor high current will help.

- Only acids that do not contain oxygen and are in a gaseous state, and some gases, are suitable for electrolysis.

Important! If the necessary conditions are met, the process proceeds similarly to electrolysis in a liquid electrolyte.

Features of the processes occurring at the cathode and anode

For the practical application of electrolysis, it is important to understand what happens at both electrodes when electrical current is applied. The following processes are typical:

- Cathode. Positively charged ions rush towards it. Here the reduction of metals or the evolution of hydrogen occurs. Several categories of metals can be distinguished based on cationic activity. Metals such as Li, K, Ba, St, Ca, Na, Mg, Be, Al are well reduced only from molten salts. If a solution is used, hydrogen is released due to the electrolysis of water. It is possible to ensure reduction in solution, but with a sufficient concentration of cations, for the following metals - Mn, Cr, Zn, Fe, Cd, Ni, Ti, Co, Mo, Sn, Pb. The process proceeds most easily for Ag, Cu, Bi, Pt, Au, Hg.

- Anode. Negatively charged ions flow to this electrode. When oxidized, they take electrons from the metal, which leads to their anodic dissolution, i.e. transition into positively charged ions that are directed to the cathode. Anions are also classified according to their activity. Only from melts can such anions PO4, CO3, SO4, NO3, NO2, ClO4, F be discharged. In aqueous solutions, it is not they that undergo electrolysis, but water with the release of oxygen. The most easily reacting anions are OH, Cl, I, S, Br.

Processes occurring during electrolysis

Electrolysis has become widespread in the metallurgy of non-ferrous metals and in a number of chemical industries. Metals such as aluminum, zinc, and magnesium are produced mainly by electrolysis. In addition, electrolysis is used for refining (purifying) copper, nickel, lead, as well as for producing hydrogen, oxygen, chlorine and a number of other chemicals.

The essence of electrolysis is the separation of particles of a substance from the electrolyte when direct current flows through an electrolytic bath and their deposition on electrodes immersed in the bath (electroextraction) or the transfer of substances from one electrode through the electrolyte to another (electrolytic refining). In both cases, the goal of the processes is to obtain the purest possible substances that are not contaminated with impurities.

In contrast to the electronic electrical conductivity of metals, ionic electrical conductivity is observed in electrolytes (solutions of salts, acids and bases in water and some other solvents, as well as in molten compounds).

Electrolytes are conductors of the second kind. In these solutions and melts, electrolytic dissociation takes place - decomposition into positively and negatively charged ions. If electrodes connected to an electrical energy source are placed in a vessel with an electrolyte - an electrolyzer, then an ionic current will begin to flow in it, and positively charged ions - cations will move towards the cathode (these are mainly metals and hydrogen), and negatively charged ions - anions ( chlorine, oxygen) - to the anode.

What is electrolysis.

At the anode, the anions give up their charge and turn into neutral particles that settle on the electrode. At the cathode, cations take electrons from the electrode and are also neutralized, settling on it, and the gases released on the electrodes rise to the top in the form of bubbles. The electric current in the external circuit represents the movement of electrons from the anode to the cathode (Fig. 1). In this case, the solution becomes depleted, and to maintain the continuity of the electrolysis process it is necessary to enrich it. This is how certain substances are extracted from the electrolyte (electroextraction).

It will be interesting➡ All about Ohm’s law: in simple words with examples for dummies

If the anode can dissolve in the electrolyte as the latter becomes depleted, then its particles, dissolving in the electrolyte, acquire a positive charge and are directed to the cathode, on which they are deposited, thereby transferring material from the anode to the cathode. Since in this case the process is carried out so that the impurities contained in the anode metal are not transferred to the cathode, this process is called electrolytic refining.

If an electrode is placed in a solution with ions of the same substance from which it is made, then at a certain potential between the electrode and the solution, neither the electrode dissolves nor the substance is deposited from the solution on it. This potential is called the normal potential of a substance. If a more negative potential is applied to the electrode, then the release of a substance will begin on it (cathodic process), but if it is more positive, then its dissolution will begin (anode process).

Electrolysis of copper sulfate.

The value of normal potentials depends on the ion concentration and temperature. The normal potential of hydrogen is generally considered to be zero. If there are ions of different metals in the electrolyte, then the ions that have a lower negative normal potential (copper, silver, lead, nickel) are released first at the cathode; alkaline earth metals are the most difficult to separate. In addition, in aqueous solutions there are always hydrogen ions, which will be released earlier than all metals that have a negative normal potential, therefore, during the electrolysis of the latter, a significant or even most of the energy is spent on the release of hydrogen.

By means of special measures, it is possible to prevent the evolution of hydrogen within certain limits, but metals with a normal potential of less than 1 V (for example, magnesium, aluminum, alkaline earth metals) cannot be obtained by electrolysis from an aqueous solution. They are obtained by decomposition of molten salts of these metals. Normal electrode potentials of substances indicated in table. 1, are minimal, at which the electrolysis process begins; in practice, large potential values are required for the development of the process.

The difference between the actual potential of the electrode during electrolysis and its normal potential is called overvoltage. It increases energy losses during electrolysis.

On the other hand, by increasing the overvoltage for hydrogen ions, it is possible to hinder its separation at the cathode, which makes it possible to obtain by electrolysis from aqueous solutions a number of metals that are more negative than hydrogen, such as lead, tin, nickel, cobalt, chromium and even zinc. This is achieved by conducting the process at increased current densities at the electrodes, as well as by introducing certain substances into the electrolyte.

The course of cathodic and anodic reactions during electrolysis is determined by the following two Faraday laws.

The mass of the substance me released during electrolysis at the cathode or transferred from the anode to the electrolyte is proportional to the amount of electricity Iτ passing through the electrolyte: me = α/τ, here a is the electrochemical equivalent of the substance, g/C.

The mass of a substance released during electrolysis with the same amount of electricity is directly proportional to the atomic mass of substance A and inversely proportional to its valency n: me = A / 96480n, here 96480 is the Faraday number, C x mol-1.

Interesting read: what is a Hall sensor.

Thus, the electrochemical equivalent of a substance α = A / 96480n is the mass of a substance in grams released by a unit of electricity passing through the electrolytic bath - a coulomb (ampere-second). For copper A = 63.54, n =2, α =63.54/96480-2= 0.000329 g/C, for nickel α =0.000304 g/C, for zinc α = 0.00034 g/C . In fact, the mass of the released substance is always less than indicated, which is explained by a number of side processes taking place in the bath (for example, the release of hydrogen at the cathode), current leaks and short circuits between the electrodes.

Chemical reactions during electrolysis.

Factors affecting the electrolysis process

The electrolysis process depends on the following factors:

- Electrolyte composition. Various impurities have a significant impact. They are divided into 3 types - cations, anions and organics. Substances may be more or less negative than the base metal, which interferes with the process. Organic impurities include pollutants (such as oils) and surfactants. Their concentration has maximum permissible values.

- Current density. In accordance with Faraday's laws, the mass of the deposited substance increases with increasing current strength. However, unfavorable circumstances arise - concentrated polarization, increased voltage, intense heating of the electrolyte. Taking this into account, there are optimal current densities for each specific case.

- Electrolyte pH. The acidity of the medium is also selected taking into account metals. For example, the optimal electrolyte acidity value for zinc is 140 g/cubic dm.

- Electrolyte temperature. It has an ambiguous effect. With increasing temperature, the rate of electrolysis increases, but the activity of impurities also increases. For each process there is an optimal temperature. Usually it is between 38-45 degrees.

Important! Electrolysis can be accelerated or slowed down by various influences and the choice of electrolyte composition. Each application has its own regime, which must be strictly followed.