Abstract “Quantity of heat. Specific heat"

Quantity of heat

The change in internal energy by doing work is characterized by the amount of work, i.e. work is a measure of the change in internal energy in a given process. The change in the internal energy of a body during heat transfer is characterized by a quantity called the amount of heat.

The amount of heat is the change in the internal energy of a body during the process of heat transfer without doing work. The amount of heat is denoted by the letter Q.

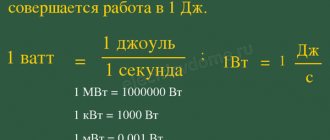

Work, internal energy and the amount of heat are measured in the same units - joules (J), like any type of energy.

In thermal measurements, a special unit of energy was previously used as a unit of heat - the calorie (cal), equal to the amount of heat required to heat 1 gram of water by 1 degree Celsius (more precisely, from 19.5 to 20.5 ° C). This unit, in particular, is currently used when calculating heat consumption (thermal energy) in apartment buildings. The mechanical equivalent of heat has been experimentally established - the ratio between calorie and joule: 1 cal = 4.2 J.

When a body transfers a certain amount of heat without doing work, its internal energy increases; if the body gives off a certain amount of heat, then its internal energy decreases.

If you pour 100 g of water into two identical vessels, one and 400 g into the other at the same temperature and place them on identical burners, then the water in the first vessel will boil earlier. Thus, the greater the body mass, the greater the amount of heat it requires to warm up. It's the same with cooling.

The amount of heat required to heat a body also depends on the type of substance from which the body is made. This dependence of the amount of heat required to heat a body on the type of substance is characterized by a physical quantity called the specific heat capacity of the substance.

Specific heat

Specific heat capacity is a physical quantity equal to the amount of heat that must be supplied to 1 kg of a substance to heat it by 1 °C (or 1 K). 1 kg of substance releases the same amount of heat when cooled by 1 °C.

Specific heat capacity is symbolized by the letter c. The unit of specific heat capacity is 1 J/kg °C or 1 J/kg °K.

The specific heat capacity of substances is determined experimentally. Liquids have a higher specific heat capacity than metals; Water has the highest specific heat, gold has a very small specific heat.

Since the amount of heat is equal to the change in the internal energy of the body, we can say that specific heat capacity shows how much the internal energy of 1 kg of a substance changes when its temperature changes by 1 °C. In particular, the internal energy of 1 kg of lead increases by 140 J when heated by 1 °C, and decreases by 140 J when cooled.

The amount of heat Q required to heat a body of mass m from temperature t1°С to temperature t2°С is equal to the product of the specific heat capacity of the substance, the mass of the body and the difference between the final and initial temperatures, i.e.

Q = cm (t2 - t1)

The same formula is used to calculate the amount of heat that a body gives off when cooling. Only in this case should the final temperature be subtracted from the initial temperature, i.e. Subtract the smaller temperature from the larger temperature.

Lesson summary “Amount of heat. Specific heat".

Next topic: “Heat balance equation.”

Quantity of heat. Specific heat

The amount of heat during various physical processes.

Most known substances can be in solid, liquid, gaseous or plasma states at different temperatures and pressures. The transition from one state of aggregation to another occurs at a constant temperature (provided that pressure and other environmental parameters do not change) and is accompanied by the absorption or release of thermal energy. Despite the fact that 99% of matter in the Universe is in the plasma state, we will not consider this state of aggregation in this article.

Consider the graph presented in the figure. It shows the dependence of the temperature of a substance T on the amount of heat Q supplied to a certain closed system containing a certain mass of a specific substance.

1. We heat a solid body having a temperature T1 to a temperature Tmelt, spending on this process an amount of heat equal to Q1.

2. Next, the melting process begins, which occurs at a constant temperature Tmelting temperature. To melt the entire mass of a solid, it is necessary to expend thermal energy in the amount of Q2-Q1.

3. Next, the liquid resulting from the melting of the solid is heated to the boiling point (gas formation) Tbp, spending on this amount of heat equal to Q3 - Q2.

4. Now, at a constant boiling point Tbp, the liquid boils and evaporates, turning into a gas. To transform the entire mass of liquid into gas, it is necessary to expend thermal energy in the amount of Q4-Q3.

5. At the last stage, the gas is heated from temperature Tkp to a certain temperature T2. In this case, the amount of heat consumed will be Q5-Q4. (If we heat the gas to the ionization temperature, the gas will turn into plasma.)

Thus, heating the initial solid body from temperature T1 to temperature T2, we spent thermal energy in the amount of Q5, transferring the substance through three states of aggregation.

Moving in the opposite direction, we will remove the same amount of heat Q5 from the substance, going through the stages of condensation, crystallization and cooling from temperature T2 to temperature T1. Of course, we are considering a closed system without energy loss to the external environment.

Note that a transition from the solid state to the gaseous state is possible, bypassing the liquid phase. This process is called sublimation, and the reverse process is called desublimation.

So, we realized that the processes of transitions between aggregate states of matter are characterized by energy consumption at a constant temperature. When heating a substance that is in one unchanged state of aggregation, the temperature rises and thermal energy is also consumed.

Space heating balance

Preparation of a project for any facility begins with a thermal engineering calculation designed to solve the problem of providing the structure with heating, taking into account losses from each room. Balancing helps to find out how much heat is retained within the walls of the building, how much is lost outside, and the amount of energy required to ensure a comfortable climate in the rooms.

Determination of thermal power is necessary to solve the following issues:

- calculate the load of the heating boiler, which will provide heating, hot water supply, air conditioning and the functioning of the ventilation system;

- coordinate gasification of the building and obtain technical conditions for connection to the distribution network. This will require volumes of annual fuel consumption and power requirements (Gcal/hour) of heat sources;

- select the equipment necessary for heating the premises.

Don't forget about the corresponding formula

From the law of conservation of energy it follows that in a limited space with a constant temperature regime the heat balance must be maintained: Q gains - Q losses = 0 or Q excess = 0, or Σ Q = 0. A constant microclimate is maintained at the same level during the heating season in buildings socially significant facilities: residential, children's and medical institutions, as well as in industries with continuous operation. If heat loss exceeds heat gain, the premises must be heated.

Calculation of boiler room thermal power

Consumers are served by the following types of boiler houses:

- local (for one or more houses);

- block (for houses of an entire block);

- regional (large structures).

All boiler rooms can be heated with the following types of fuel:

- hard (wood, peat, coal);

- gaseous;

- liquid (fuel oil, oil, oil, diesel fuel);

- combined.

The use of solid fuel requires equipping boiler houses with special grates that allow ash to pass through. The wood must be dry; sheds are used to dry firewood. It is better to use hardwood firewood, because... pine logs clog chimneys with combustion products.

Thermal energy for this type of fuel is calculated as follows: per 1 m² of building area there should be 100 W/h. For a house with an area of 100 m², the power is 10 kW. Knowing the number of days on which heating is produced, the total thermal output can be calculated.

Boiler houses can operate on liquefied and main gas. For gas boiler houses, there are special requirements for laying pipes to ensure the operation of boilers (piping). The simplest option for calculating the power of gas heating equipment is 1 kW of energy per 10 m² of area. In addition, the area of the room, its location in a particular climate zone, and the heat loss of the heated building are taken into account. Accurate calculations can be performed by heating engineers. They will also help determine fuel consumption over the required period of time.

The thermal energy released is calculated in megawatts (mW) or gigacalories (Gcal).

In combined boiler houses the following is used as fuel:

- gas and diesel fuel;

- gas and fuel oil;

- gas and oil;

- gas and waste oil.

The priority and secondary fuel is determined by the owner of the boiler house. The type of boiler depends on the type of coolant chosen.

When constructing and operating low-power heating boiler houses, several factors are taken into account to calculate thermal energy:

- wear and tear of heated buildings;

- the degree of their insulation;

- sizes of windows and doors.

During operation, heat leaks appear in buildings, which can be found using a thermal imager. If it is impossible to seal these places, increase the power of the boiler installation by 30% or more.

Calculation of thermal power: formula

Let's look at the formula and give examples of how to make calculations for buildings with different dissipation coefficients.

Vx(delta)TxK= kcal/h (thermal power), where:

- The first indicator “V” is the volume of the calculated premises,

- Delta "T" temperature difference is the value that shows how many degrees warmer inside the room than outside,

- “K” is the dissipation coefficient (also called the “heat transmittance coefficient”). The value is taken from the table. Typically the figure ranges from 4 to 0.6.

Approximate dissipation coefficient values for simplified calculations

- If it is an uninsulated metal profile or board, then “K” will be = 3 – 4 units.

- Single brickwork and minimal insulation - “K” = from 2 to 3.

- Two brick wall, standard ceiling, windows and

- doors – “K” = from 1 to 2.

- The warmest option. Double-glazed windows, brick walls with double insulation, etc. - “K” = 0.6 – 0.9.

A more accurate calculation can be made by calculating the exact dimensions of the surfaces of the house in m2 that differ in properties (windows, doors, etc.), making calculations for them separately and adding up the resulting indicators.

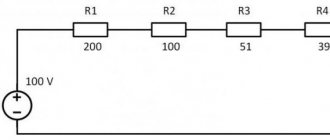

Calculation of pipe capacity.

For accurate and professional calculations, you must use the following indicators:

- The material from which pipes and other elements of the system are made;

- Pipe length

- Number of water consumption points (for water supply system)

The most popular calculation methods:

1. Formula. A rather complex formula, which is understandable only to professionals, takes into account several values at once

The main parameters that are taken into account are the pipe material (surface roughness) and their slope

2. Table. This is a simpler way by which anyone can determine the throughput of a pipeline. An example is the engineering table of F. Shevelev, from which you can find out the throughput capacity based on the pipe material.

3. Computer program. One of these programs can be easily found and downloaded on the Internet. It is designed specifically to determine the throughput for pipes of any circuit. In order to find out the value, you need to enter initial data into the program, such as material, pipe length, coolant quality, etc.

It should be said that the latter method, although the most accurate, is not suitable for calculating simple household systems. It is quite complex and requires knowledge of the values of a wide variety of indicators. To calculate a simple system in a private house, it is better to use tables.

Calculation of boiler thermal power

The thermal power of a boiler or several boilers (working together) is selected taking into account all possible heat losses of the heated building.

Boiler power (in rough form) consists of the following components:

- Thermal power required to fully compensate for the maximum heat loss of the building;

- Power for heating the room in which the boiler installation is located.

- If the boiler room is located in a separate building, then the required power is added to the total power of the boiler installation to compensate for heat loss in the pipelines that are located between the heated building and the boiler room.

- If the functions of the boiler installation include the preparation of hot water, then the thermal load required to heat water for the DHW system is added to the total required power. At the same time, today, when using modern insulating materials in the construction of houses, this thermal load sometimes makes it predominant, compared to the thermal load required for other needs.

- Required thermal power for other consumers (ventilation, pool heating, heating of outdoor areas, etc.)

The required thermal power for heating the building, boiler room and heat loss of external pipelines is determined on the basis of a thermal calculation

(calculation of heat loss) and is the main one for choosing the power of the heating system.

When providing thermal energy to the hot water

All factors affecting the normal supply of hot water to consumers should be taken into account to obtain the most reliable, efficient and economical option. This may be the water consumption mode, the design features of the water heater and boiler installation, the required volumes of hot water, etc. For example, in private housing construction, due to the small volumes of hot water consumption, a variable operating mode of the boiler system is often used between space heating and hot water preparation. This makes it possible to significantly reduce the power of boilers and, consequently, the costs of equipment and subsequent operation of the heating system.

If there are additional circuits in the heating system, their heat consumption is taken into account by an addition to the heating power in the amount of the maximum heat consumption value of each circuit. Thermal power for preparing hot water in buildings with significant hot water consumption (baths, saunas, hairdressers, etc.) is necessarily included as an additional heat load.

When choosing the thermal power of a boiler installation with atmospheric burners, seasonal fluctuations in gas pressure should be taken into account. When gas pressure decreases, the power of the gas boiler drops sharply. When choosing the thermal power of a gas boiler, it is advisable to take into account one and a half times the rated power of the boiler. At the same time, it is recommended that, in order to prevent premature failure of a boiler constantly operating at maximum heat load, in any case, provide a 30% margin when choosing.

When using a system of instantaneous water heaters for significant volumes of hot water preparation, the power of the boiler installation cannot be less than the power consumed by the water heater at maximum water consumption of hot water. If the power required for heating exceeds the heat consumption of an instantaneous water heater, then a fifty percent increase from the power required for preparing hot water is sufficient.

In the case of using boiler systems with a variable mode of providing heat consumption to the DHW circuit and heating (double-circuit boiler), it should be taken into account that the DHW capacity of the installation is usually indicated on the basis that the entire power of the installation is used for the preparation of hot water. In this case, during the preparation of hot water, the heat supply required for the needs of the heating system is turned off. With insignificant water consumption of hot water, this factor does not greatly affect the climatic conditions in heated rooms due to the thermal inertia of the building structures. But if this condition is significantly exceeded, it is better to provide at least a twofold increase in the installation power. The final option should be made based on an accurate thermal calculation and a detailed analysis of the operating features of the building's engineering systems.

Calculation of thermal power

It is difficult for a non-specialist to make accurate calculations on the heating system, but simplified methods allow an untrained person to calculate the indicators. If you make calculations by eye, it may turn out that the power of the boiler or heater is not enough. Or, conversely, due to an excess of generated energy, the heat will have to be wasted.

Methods for self-assessment of heating characteristics:

- Using standards from design documentation. For the Moscow region, a value of 100-150 watts per 1 m² is used. The area to be heated is multiplied by the rate - this will be the desired parameter.

- Application of the formula for calculating thermal power: N = V × Δ T × K, kcal/hour. Symbol designations: V - room volume, Δ T - temperature difference inside and outside the room, K - heat transmittance or dissipation coefficient.

- Reliance on aggregated indicators. The method is similar to the previous method, but is used to determine the thermal load of multi-apartment buildings.

The values of the dissipation coefficient are taken from the tables, the limits for changing the characteristics are from 0.6 to 4. Approximate values for a simplified calculation:

Heat gains from electric furnaces.

These heat inputs are calculated as a fraction of the installed electrical power Nset., indicated in the catalog (sometimes this value is called “idle power”).

The maximum heat input occurs from a heated furnace in stationary heat transfer mode. During this period, electrical power will be spent to replenish the heat losses of the furnace and it is this that is called idle power.

There are several ways to determine heat emission into a room from electric stoves:

by idling power Nxx, kW

Qelectric ovens = 1000 Nx.x., W;

as a share of P% of the rated electrical power of the furnace consumed for heat losses by the furnace:

Qelectric furnaces = 1000 (P/100)Nset, W.

If the specified values are unknown, approximately the heat input can be determined by the purpose of the furnace.

The following table shows the values of heat release in W per 1 kW of installed power for furnaces for various purposes.

| Electric oven type | α value |

| Chamber, mine, methodical | 200 |

| Bells | 130 |

| Muffle | 150 |

| Stoves-baths | 400 |

| Furnaces, no type specified | 250 |

Heat gains are determined as:

Qelectric furnaces = α × Nset, kW

where: Nset – installed electric power of the furnace, kW.

Why do you need a thermal calculation?

How did builders of the past manage to do without thermal calculations?

The surviving merchant houses show that everything was done simply with reserves: smaller windows, thicker walls. It turned out to be warm, but not economically profitable.

Thermal engineering calculations allow us to build in the most optimal way. No more or less materials are taken, but exactly as much as needed. The dimensions of the building and the costs of its construction are reduced.

Calculating the dew point allows you to build in such a way that materials do not deteriorate for as long as possible.

To determine the required boiler power, you also cannot do without calculations. Its total power consists of energy costs for heating rooms, heating hot water for household needs, and the ability to cover heat loss from ventilation and air conditioning. A power reserve is added for periods of peak cold weather.

When gasifying a facility, coordination with services is required. The annual gas consumption for heating and the total power of heat sources in gigacalories are calculated.

Calculations are needed when selecting heating system elements. The system of pipes and radiators is calculated - you can find out what their length and surface area should be. The loss of power when turning the pipeline, at joints and passing through fittings is taken into account.

What is thermal design?

Simply put, thermal calculations help to find out exactly how much heat a building stores and loses, and how much energy heating must produce to maintain comfortable conditions in the home.

When assessing heat loss and the degree of heat supply, the following factors are taken into account:

- What kind of object is it: how many floors does it have, the presence of corner rooms, is it residential or industrial, etc.

- How many people will “live” in the building?

- An important detail is the glazing area. And the dimensions of the roof, walls, floors, doors, ceiling heights, etc.

- What is the duration of the heating season, the climatic characteristics of the region.

- According to SNiPs, the temperature standards that should be in the premises are determined.

- Thickness of walls, ceilings, selected thermal insulators and their properties.

Heat gains from the technological equipment of the canteen.

where: KO is the coefficient of simultaneity of operation of thermal equipment; for canteens KO - 0.8 for restaurants and cafes KO - 0.7NМ - power of installed modulated technological equipment, kW.

Characteristics of thermal equipment of a public catering establishment.

| Thermal equipment | Equipment dimensions | Installed power of a unit of equipment, kW | KZ equipment load factor |

| Sectional modulated equipment | |||

| Plates: PESM - 4sh | 840 x 840 x 860 | 18 | 0,65 |

| PESM - 2k | 420 x 840 x 860 | 3,8 | 0,65 |

| Frying pans: | |||

| SESM - 0.5 | 1470 x 840 x 860 | 13 | 0,65 |

| SESM - 0.2 | |||

| Deep fryer FESM - 2 | |||

| Boiler KPESM - 2 | 420 x 840 x 860 | 7,5 | 0,65 |

| Wardrobe SHZhESM – 2 | 1050 x 840 x 860 840 x 800 x 1500 | 8,6 3,8 | 0,30 0,65 |

NН is the installed electrical power of non-modulated technological equipment, kW;

| Thermal equipment | Equipment dimensions | Installed power of a unit of equipment, kW | KZ equipment load factor |

| Non-modulated equipment | |||

| Digester capacity, l: | |||

| 40 | — | 5 | 0,3 |

| 60 | 6,8 | 0,3 | |

| 125 | — | 8,5 | 0,3 |

| Boiler capacity, l: | |||

| 200 | — | 10 | 0,3 |

| 100 | — | 8,3 | 0,3 |

| 25 | — | 3,3 | 0,3 |

NP is the installed power of electrical equipment in the distribution opening, kW;

| Thermal equipment | Equipment dimensions | Installed power of a unit of equipment, kW | KZ equipment load factor |

| Equipment located in the dispensing opening | |||

| Thermal rack SRTESM | 1470 x 840 x 860 | 2,0 | 0,50 |

| Food warmer MESM-50 | 840 x 840 x 860 | 4,0 | 0,50 |

KZ - equipment load factor (see table); K1 - efficiency coefficient of supply and exhaust localizing devices for modulated equipment - 0.75; K2 - efficiency coefficient of localizing devices for non-modulated equipment: for supply and exhaust localizing devices - 0.75; for curtains - 0.45.

Calculation of the number of sections of heating devices

The heating system will not be effective if the optimal number of radiator sections is not calculated. An incorrect calculation will lead to the rooms being heated unevenly, the boiler will work at the limit of its capabilities or, conversely, “idlely” wasting fuel.

Some home owners believe that the more batteries the better. However, this lengthens the path of the coolant, which gradually cools, which means that the last rooms in the system risk being left without heat. Forced coolant circulation partly solves this problem. But we must not lose sight of the power of the boiler, which may simply “not cope” with the system.

To calculate the number of sections, you will need the following values:

- the area of the heated room (plus the adjacent one, where there are no radiators);

- power of one radiator (indicated in the technical specifications);

take into account that per 1 sq. m

living space will require 100 W of power for central Russia (according to SNiP requirements).

The area of the room is multiplied by 100 and the resulting amount is divided by the power parameters of the installed radiator.

Example for a room of 25 square meters. meters and radiator power 120 W: (20x100)/185=10.8=11

This is the simplest formula; if the height of the rooms is not standard or their configuration is complex, other values are used.

How to correctly calculate heating in a private house if the power of the radiator is unknown for some reason? By default, the average static power is 200 W. You can take the average values of certain types of radiators. For bimetallic ones this figure is 185 W, for aluminum ones - 190 W. For cast iron, the value is much lower - 120 W.

If the calculation is carried out for corner rooms, then the result obtained can be safely multiplied by a factor of 1.2.

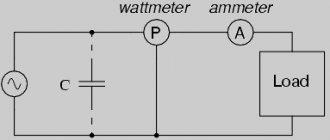

Heater efficiency

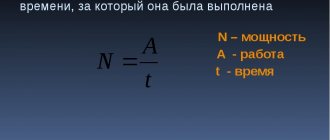

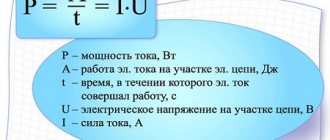

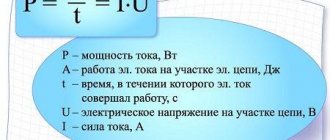

Power is the physical definition of the rate at which energy is transmitted or consumed. It is equal to the ratio of the amount of work for a certain period of time to this period. Heating devices are characterized by electricity consumption in kilowatts.

To compare energies of various types, the thermal power formula was introduced : N = Q / Δ t, where:

- Q is the amount of heat in joules;

- Δ t is the energy release time interval in seconds;

- dimension of the resulting value J/s = W.

In this video you will learn how to calculate the amount of heat:

To assess the efficiency of heaters, a coefficient is used that indicates the amount of heat consumed for its intended purpose - efficiency. The indicator is determined by dividing useful energy by expended energy, is a dimensionless unit and is expressed as a percentage. In relation to different parts that make up the environment, the efficiency of the heater has unequal values. If you evaluate the kettle as a water heater, its efficiency will be 90%, and when used as a room heater, the coefficient increases to 99%.

The explanation for this is simple : due to heat exchange with the environment, part of the temperature is dissipated and lost. The amount of energy lost depends on the conductivity of the materials and other factors. You can theoretically calculate the heat loss power using the formula P = λ × S Δ T / h. Here λ is the thermal conductivity coefficient, W/(m × K); S—area of heat exchange area, m²; Δ T—temperature difference on the controlled surface, degrees. WITH; h is the thickness of the insulating layer, m.

It is clear from the formula that to increase power it is necessary to increase the number of heating radiators and the heat transfer area. By reducing the surface of contact with the external environment, temperature losses in the room are minimized. The more massive the wall of the building, the less heat leakage will be.

Heat gains from people.

They enter the environment in the form of sensible and latent heat. Sensible heat is released to the environment as a result of convective and radiant heat exchange. Latent heat - represents the heat content of water vapor evaporating from the surface of the human body and lungs.

The total amount of heat generated by a person depends mainly on the severity of the work performed and, to a lesser extent, on the temperature of the room and the heat-protective properties of clothing. With increasing work intensity and ambient temperature, the proportion of heat transferred in the form of latent heat of evaporation increases. At an air temperature of 34°C, all the heat generated by the body is released through evaporation.

Indicators of human heat emissions into the external environment are given in the table below.

In this regard, several comments can be made:

- regardless of the type of activity, the total amount of thermal energy released by the body at low ambient temperatures is higher than at high temperatures;

- at low ambient temperatures, the value of sensible (sensible) heat is significantly higher than that of latent heat, and vice versa, at high temperatures the release of latent heat predominates;

- at temperatures corresponding to a comfortable state (22 ± 2 ° C), with a sedentary occupation, the total amount of heat generated is distributed approximately in the following proportion:

60 - 65% sensible heat and 40 - 35% latent heat.

With increasing physical activity, the release of latent heat begins to predominate.

Indicators of human heat generation at various ambient temperatures are shown in the following graph.

When calculating heat input from people, one must take into account the fact that the number of people stated in the initial data will not always correspond to their simultaneous presence in a given room. This fact justifies the use of the simultaneous presence coefficient

To perform a calculation that corresponds to reality, this coefficient is usually taken in the range from 0.9 to 0.95. In other cases, for example in hotels, restaurants, etc., such a coefficient should be established on the basis of the Customer’s Technical Specifications.

The amount of heat generated by one person is determined based on the following expressions:

sensible heat amount

amount of total heat

Amount of heat and moisture generated by adult males

| Indicators | Amount of heat, W, and moisture, g/h, emitted by men at room temperature, °C | |||||

| 10 | 15 | 20 | 25 | 30 | 35 | |

| At rest | ||||||

| Warm: | ||||||

| explicit | 140 | 120 | 90 | 60 | 40 | 10 |

| complete | 165 | 145 | 120 | 95 | 95 | 95 |

| Moisture | 30 | 30 | 40 | 50 | 75 | 115 |

| For light work | ||||||

| Warm: | ||||||

| explicit | 150 | 120 | 100 | 65 | 40 | 5 |

| complete | 180 | 160 | 150 | 145 | 145 | 145 |

| Moisture | 40 | 55 | 75 | 115 | 150 | 200 |

| For moderate work | ||||||

| Warm: | ||||||

| explicit | 200 | 165 | 130 | 95 | 50 | 10 |

| complete | 290 | 290 | 290 | 290 | 290 | 290 |

| Moisture | 135 | 185 | 240 | 295 | 355 | 415 |

Note. Women produce 85%, and children 75% of heat and moisture compared to men.

Categories of work depending on the type of activity.

| Categories of work | Energy consumption, W | Types of jobs |

| Lungs (category I) IaIb | No more than 174 No more than 139 Up to 174 | Performed while sitting and accompanied by minor physical strain. Occurred while sitting, standing or walking and accompanied by some physical exertion |

| Moderate severity (category II) IIa IIb | 175-290 175-232 233-290 | Associated with constant walking, moving small (up to 1 kg) products or objects in a standing or sitting position and require a certain amount of physical stress. Associated with walking, moving and carrying heavy objects (up to 10 kg) and accompanied by moderate stress. |

| Heavy (category III) | More than 290 | Associated with constant movement, moving and carrying significant (over 10 kg) weights and requiring great physical effort. |

1. Category of work - differentiation of work by severity based on the body's energy consumption. 2. Under the working area there should be a space limited in height by 2 m above the floor level, or a platform on which there are places for permanent or non-permanent (temporary) stay of people.

Advantages and disadvantages

Like any household appliance, fan heaters have their pros and cons.

| Advantages | Flaws |

| Fast heating | Relatively high noise level due to fan operation |

| High heat dissipation | Low power for normal room ventilation without heating, comparable to a low-power table fan |

| Small dimensions and weight | Models with wire nichrome burn oxygen |

| Easy to use | An unpleasant odor may appear upon first use after a long period of inactivity - dust burns off |

| Mobility (except for stationary models) | |

| Possibility of installation in any room |

The energy consumption of such devices is difficult to categorize because If you take a separate fan heater and use it around the clock, it will “burn” a lot of electricity. There is no such heating device that would consume little electricity; all devices, be it a convector, an electric battery, a conventional heater or a split system, are very “gluttonous”.

We calculate the heat consumption by quadrature

To roughly estimate the heating load, the simplest thermal calculation is usually used: take the outside area of the building and multiply it by 100 W. Accordingly, the heat consumption of a 100 m² country house will be 10,000 W or 10 kW. The result allows you to select a boiler with a safety factor of 1.2-1.3; in this case, the power of the unit is taken to be 12.5 kW.

We propose to perform more accurate calculations that take into account the location of rooms, the number of windows and the region of development. So, for ceiling heights up to 3 m, it is recommended to use the following formula:

The calculation is carried out for each room separately, then the results are summed up and multiplied by the regional coefficient. Explanation of formula symbols:

- Q – required load value, W;

- Spom – square footage of the room, m²;

- q – indicator of specific thermal characteristics, related to the area of the room, W/m²;

- k is a coefficient that takes into account the climate in the area of residence.

In an approximate calculation based on the total quadrature, the indicator q = 100 W/m². This approach does not take into account the location of the rooms and the different number of light openings. The corridor located inside the cottage will lose much less heat than a corner bedroom with windows of the same area. We propose to take the value of the specific thermal characteristic q as follows:

- for rooms with one external wall and a window (or door) q = 100 W/m²;

- corner rooms with one light opening - 120 W/m²;

- the same, with two windows – 130 W/m².

How to correctly select the value of q is clearly shown on the building plan. For our example, the calculation looks like this:

Q = (15.75 x 130 + 21 x 120 + 5 x 100 + 7 x 100 + 6 x 100 + 15.75 x 130 + 21 x 120) x 1 = 10935 W ≈ 11 kW.

As you can see, the refined calculations gave a different result - in fact, 1 kW more thermal energy will be consumed to heat a particular 100 m² house. The figure takes into account the heat consumption to heat the outside air entering the home through openings and walls (infiltration).

Calculation of thermal power

To estimate thermal energy, there is a formula for determining power through the amount of heat: N = Q/Δ t, where Q is the amount of heat expressed in joules, and Δ t is the time of energy release in seconds.

In evaluation calculations, a special coefficient (efficiency) is also used, indicating the amount of heat consumed. It is found as the ratio of useful energy to heat loss power and is expressed as a percentage.

The amount of energy expended for premises depends on their construction features. The same indicator for batteries is determined by the materials used in their manufacture and design features.

More accurate thermal calculation

A competent choice of heating equipment is possible only after becoming familiar with the procedure for calculating the thermal power required in each specific case. The formula used to accurately determine it is: P=V∆TK= kcal/hour:

- V is the volume of the heated room, measured in cubic meters.

- ∆T – the difference between the air temperature outside and inside the room.

- K – heat loss coefficient.

The last value depends on the material of the walls. Based on measurements taken by specialists for an uninsulated wooden structure, it is 3.0-4.0. The exact K values for various insulation options are given below:

- For buildings made of single brickwork and with simplified window and roof structures (so-called “simple” thermal insulation) K = 2.0-2.9.

- Insulation of average quality (K=1.0-1.9). This is a typical design, which means double masonry, a conventional roof, and a limited number of windows.

- High-quality insulation (K = 0.6-0.9), involving brick walls with enhanced thermal insulation, a small number of windows with double frames, a solid floor base and a roof with reliable heat insulators.

As an example, we will consider the exact calculation of power for a heated room with a volume of 5 x 16 x 2.5 = 200 cubic meters. ∆T is defined as the difference between the indicator outside -20 °C and indoors +25 °C. The option with average specific thermal insulation (K = 1-1.9) is accepted. Based on average operating conditions, we take 1.7. We calculate: 200 x 45 x 1.7 = 15,300 kcal/hour. Based on the fact that 1 kW = 860 kcal/hour, we ultimately have: 15,300\860 = 17.8 kW.

Source