What it is

An LED is a semiconductor light source that emits light when current passes through it. Electrons in a semiconductor recombine with electron holes, releasing energy in the form of photons. This effect is called electroluminescence. The color of the glow (corresponding to the energy of the photons) is determined by the energy required for the electrons to cross the band gap of the semiconductor.

White light is produced using several semiconductors or a layer of light-emitting phosphor (a substance that converts the received energy into light radiation). SMD (surface-mount device) are devices designed for surface mounting SMT (surface-mount technology). SMT is a method of manufacturing electronic circuits in which components are mounted or placed directly on the surface of printed circuit boards. An electronic device made in this way is called a surface mount device.

In the industrial world, this technology has largely replaced the through-hole design method, which involved installing components using lead wires into holes on the board.

Dimensions of LEDs 1204, direction of radiation perpendicular to the plane of the board

Light-emitting diodes (abbreviated as LEDs) of SMD design consist of a semiconductor crystal mounted on a substrate and encapsulated in transparent plastic. Similar to other discrete surface mount components, SMD LED package sizes are determined by the frame size. In addition to the standard sizes presented on this page, three-color LEDs are available in a slightly larger standard housing size 0605 and two-color LED 1204. Low-power diodes and diode assemblies for wide applications, zener diodes, varicaps and diode bridges are produced in similar sizes.

Where and how it is used

LED strips are manufactured based on 3528 LEDs. They are also used as indicators of various devices, road signs, bedroom, kitchen, and hallway lighting. They are actively used for illuminating architectural objects, museum stands, as well as advertising signs and shop windows. Gauss LED lamps bring variety and quality to lighting.

Design Features

- SMD 3528 LED is manufactured in the shape of a rectangle with the following aspect ratio: 3.5 mm by 2.8 mm.

- Height 1.4 mm. Two contacts are visible on each of the diametrically opposite sides.

- The lens used in production is transparent.

- From the cathode side, a cut (aka key) is visible on the body.

- The working surface is covered with phosphor. It itself is round in shape.

Description and application features

The dimensions of the SMD 3528 LED are 3.5 mm by 2.8 mm. Crystal height 1.4 mm. On each side there are two contacts through which current passes. During production, only transparent lenses are used to ensure high-quality transmission of light.

From the cathode side you can see a special cut on the body. This slice is sometimes called a key. The entire surface of the product is covered with a phosphor, which, in addition to transmitting light, performs a protective function.

SMD 3528 belongs to the category of small ultra-bright LEDs , equipped with a housing for mounting on different surfaces. The crystal itself is made from a mixture of gallium nitride and indium nitride. The result is a special structure that creates bright radiation. The composition includes phosphide based on aluminum, gallium and indium.

The numbers in the model designation indicate the size of the product, so it is not difficult to imagine installing the device in a particular area.

On sale you can find a special model labeled SMD 5050. It is a prefabricated structure consisting of 3 standard 3528 crystals enclosed in one housing, which increases power. The products have a very low level of crystal degradation, which significantly extends their service life. At the same time, LEDs perform well even at temperatures above 100 degrees Celsius.

LED Strip Light

The relatively low cost and ease of installation have made it possible to use diodes of this type in many areas of life. They are most often found as the main components of LED strips, as well as various indicators on devices. They can be seen in lighting systems, signage and other areas where a small source of bright light is required.

Based on LED 3528, many modern devices with three-color RGB backlights and crystals with improved light output have been created.

Technical characteristics of SMD 3528

- The light-emitting crystal is made on the basis of InGaN (gallium nitride, indium nitride) and AlGaInP (aluminum, gallium, indium phosphate).

- Characteristics of white diodes 3528 (2800-7000K).

- The luminous flux is generated in the range from 5 to 11 lm.

- Light output is 40 lm/W.

- There is no heat sink.

- Dispersion angle 90.

- Light emission area 4.5 mm.

- Operating temperature from -40 to +85 degrees.

- Brightness is highly dependent on temperature.

- By actively using the LED at a temperature of + 65, you can reduce the brightness by more than 10%. At a temperature of +80 it decreases by 25%. This is one of the obvious reasons why all semiconductor devices require high-quality cooling. All white LEDs, including SMD 3528, are subject to binning. This is the process of sorting into groups of finished light-emitting devices during mass production of LEDs. The BIN code is indicated during labeling. It remains the same for the entire batch of products. Using the color temperature and this code, the exact coordinates of the chromaticity bin are determined. The chromaticity bin contains three positions of letters and numbers, and the luminous flux bin contains two. For this, for example, in the SMD 3528 datasheet, each manufacturer indicates a color diagram.

- Power dissipation 100 mW.

- Forward voltage 2.8-3 V.

- Maximum operating current 25A.

Main parameters and characteristics

All Led 3528 SMD have characteristics independent of color:

- voltage 5 V

- current 20 mA

- operating temperature -40-+85оС.

The differences are visible in the datasheet:

| Direct voltage (V) | Voltage drop in diode (V) | Light Flux(lm) | Luminous intensity (mcd=1/1000 candela) | |

| Characteristics of red SMD 3528 LED | 1,7-2,4 | 1,8-2 | 1,2-1,6 | 200-500 |

| Characteristics of yellow SMD 3528 LED | 1,7-2,4 | 1,8-2 | 1,2-1,6 | 300-500 |

| Characteristics of green SMD 3528 LED | 2,8-3,6 | 2,8-3,2 | 2,8-3,5 | 515-530 |

| Characteristics of SMD 3528 Blue LED | 2,8-3,6 | 2,8-3,2 | 0,6-0,85 | 300-600 |

| Characteristics of white SMD 3528 LED | 2,8-3,6 | 2,8-3,4 | 4,5-5,5 | 1600-1900 |

The voltage drop determines the color, the brightness depends on the temperature (at +80°C the parameter from the datasheet decreases by 25%). From the table data we can conclude that the light flux of the ruler made from SMD 3528 is 0.6-3.5 lumens.

Attention! For RBG LEDs, at a voltage of 2-2.8 V, the light flux is 0.6 lm, at 3.2-4 V - 0.3-1.6 lm.

You need to know the datasheet to correctly determine the resistance and power of the resistor for a specific light source.

Characteristics of LED strip 3528 60 LED

- The technical characteristics of the SMD 3528 LED strip indicate the number of diodes per meter. There can be 30, 60, 72, or 120.

- If it is indicated that 300 diodes are installed, then the tape length is 5 meters. You need to divide by 5, thus getting 60 pieces per meter.

- It is intended for both outdoor (street) and indoor and building use. Thanks to the good IP 54 protection standard, it can also be used in rooms with high humidity levels. You can control the light using an RGB controller.

- The luminous flux per meter ranges from 270 to 450 lm. This is equivalent to a regular 30W light bulb.

- Power consumption 4.8 W per meter.

- The operating voltage is 12 V. SMD 3528 practically does not heat up, therefore, it can be glued without an aluminum profile. Often, unscrupulous manufacturers, in order to increase the brightness of the diodes, install resistors of lower resistance that limit the current. As a result, the light is brighter, but the service life is significantly reduced.

- The tape can be cut every 5 centimeters. They contain 3 LEDs.

- In an RGB strip, in one module of three diodes, either one or two can light up. The rest are waiting for their glow. When creating a yellow color, two components will light up at once - green and red. The third diode will remain inoperative. Due to the low power and small number of LEDs, dips and scattering of light spots are inevitable. The backlight strip may not be continuous. To avoid this, it is recommended to use light diffusers.

- However, SMD 3528 LED is the most economical of LED strips due to its low energy consumption. To illuminate a ceiling with a total length of approximately 20 meters, you will need a power supply with a power of 100 W. The tape is also well suited for illuminating stage costumes. Small pieces of tape can be safely powered by batteries.

LED strips SMD 3528

There are 60, 120, 180 or 240 LEDs on a SMD 3528 strip. First, current-carrying tracks, chips and resistors are mounted on the surface.

There are one or three crystals in the chip. The diodes are grouped in groups of three; there can be 1 or 3 resistors in a group (depending on the parameters of the chips). LED strip, consisting of sources with one crystal, monochrome (one-color glow). If there are 3 crystals in the diode, the stripe is colored, the color of the glow can be changed.

The method of placing chips on the surface depends on their number (determined per linear meter). If a meter-long segment is 60 or 120 SMD 3528, they are placed in 1 row. If there are 180 chips, groups of 3 are placed crosswise, if 240 are placed in 2 rows, the groups consist of 6 elements. The power per linear meter of a module directly depends on the number of light sources. If there are 60 of them, the power is 4-5 W. With 120 chips the figure increases to 9.5-10. The most powerful products, which have 240 diodes per meter, are 16.5-17 W.

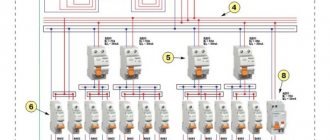

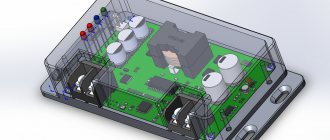

Connection diagram

To connect SMD 3528 to a standard 220 V network, you must use a driver that acts as a source of stabilized current. There are two types of driver circuits for LEDs:

- On the capacitor.

- Expanded, using stabilizer chips.

Assembling the driver itself on a capacitor is not difficult. This will require a minimum of details and a little time.

Thanks to the high-voltage capacitor, the 220 V voltage is reduced. It then straightens and stabilizes. It is used in inexpensive LED lamps. The main disadvantage is the high level of light pulsations, which adversely affects health. The circuit is quite difficult to calculate due to the variation in the characteristics of the electronic components.

Improved circuitry with special chips significantly improves stability directly at the driver output. With good control of the load, the driver will not allow the ripple factor to exceed 10%. The driver can also be taken from a failed light bulb.

If you have a stabilizer, you can easily regulate the current strength. It is possible to add more resistance to the technical characteristics of the driver chip or remove one of the resistors. This way you can get the required current strength.

The simplest current stabilizer circuit specifically for LEDs consists of the LM317 microcircuit, as well as analogues of this model. The output current can range from 0.1 to 5A. There are two disadvantages - low efficiency and rather strong heating.

When connecting in parallel, it is highly recommended to use a separate resistor for each LED circuit. You can also put one powerful resistance on several diodes.

Number of diodes per meter

Another feature of this LED strip is the number of LEDs per linear meter. This number determines how they are placed. The SMD-3528 LED strip itself can have 60, 120, 180 or 240 LEDs.

Various types of LED strip

In the first two cases, all elements are placed in one row (A and B). If the number of LEDs per linear meter is 180, then they are placed in three rows (B). In this case, three diodes of one group are placed across the strip.

If the number of LEDs is 240, then they are placed in two rows (D). One indivisible particle has six diodes.

The power of the SMD-3528 LED strip also depends on the number of diodes per linear meter. The power of one meter of SMD-3528 with 60 diodes per meter is 4.8 watts.

As for this value of the tape that has 120 diodes per meter, it is equal to 9.6 watts. A meter of LED strip, which has 240 diodes, is characterized by a power of 16.8 watts.

In order for the SMD-3528 to be used in different interiors and to harmonize with different design styles, manufacturers paint the printed circuit board in different colors. So, the printed circuit board can be:

- white;

- black;

- brown;

- yellow.

All elements (diodes, tracks and resistors) are varnished

It is important to mention here that SMD-3528 can also be coated with silicone and sealants

In other words, the simplest SMD-3528 is not protected from water. Those that are coated with silicone (it is applied only to the upper part) are partially protected from water. This LED strip 3528, which can accommodate 60, 120 or 240 LEDs per linear meter, is marked IP65.

Also, SMD-3528 can have continuous sealing. It can be distinguished by the IP67 and IP68 markings.

To make attaching the LED strip easy, the manufacturer installs adhesive tape on the bottom of the printed circuit board. It provides reliable and long-lasting fastening.

Helpful advice: in order for the fastening to be more reliable, the surface of the object must be cleaned and degreased. Some manufacturers install low-quality double tape.

This may cause premature peeling. To avoid this scenario, you must additionally use your own glue.

A noteworthy fact is that only the SMD-3528 LED strip with the designation IP67 and IP68 is not equipped with double tape.

What are the types?

- There are improved versions of SMD LEDs.

- Among them, it is worth noting SMD 5050. They have a low level of degradation (no more than 4%) after approximately 3000 hours of operation. The maximum crystal temperature can reach 110 degrees.

- The emergence of three-color RGB diodes.

- SMD 5730 LEDs already have an improved crystal with a luminous efficiency of 158 lm/W.

- The color rendering index varies from 60 Ra to 80 Ra.

- The color temperature range is slightly higher than that of SMD 5328, and varies from 3000K to 7500K. They are considered the most powerful to date.

How to distinguish a bright 2835 diode from a fake?

First of all, you need to pay attention to the brightness of 1 meter of strip with a 2835 diode. To do this, you need to calculate the energy efficiency of LEDs - this is the amount of brightness that a strip with 1 W can provide. To calculate it, you need to divide the specific brightness by the specific consumption.

The average energy efficiency of one real LED is 2835 – 100 lumens/watt. For fake diodes this figure is 2-3 times lower.

However, counterfeit manufacturers sometimes resort to cunning by indicating inflated specifications. Then it is impossible to check the diodes without equipment. But you can pay attention to the specific consumption of LED strip. This parameter is usually indicated correctly, since it is taken into account when selecting a power source.

For comparison, here are the performance of popular models with a 3528 diode:

- 3528 60 ice - consumption 4.8 Watt/m

- 2835 60 ice - consumption 7.8 Watt/m

- 3528 120 ice - consumption 9.6 Watt/m

- 2835 120 ice - consumption 14.4 Watt\m

As you can see, the consumption of bright tape 2835 is significantly higher than that of tape 3528 - this is a standard indicator. And if a strip with 2835 diodes has the same consumption as a backlight with SMD 3528, then it’s a cheap fake and not an ultra-bright strip.

How to choose

- The packaging must be dry, clean and undamaged.

- Mandatory presence of a barcode (and/or QR code).

- The packaging lists all parameters, functions and technical specifications.

- Some unscrupulous manufacturers practice using smaller chips while maintaining the same dimensions of the case itself. In this case, the power and brightness of such samples is much lower than that of the original products.

SMD 3528 LEDs are an affordable, economical and safe option for implementing a wide variety of household, design and construction solutions. Thanks to their low energy consumption, these light sources will shine for a long time, and together with the GX53 LED lamp they will create an unforgettable lighting atmosphere.

Areas of application

Due to its design and technical characteristics, the SMD-3528 LED strip can be used in many areas. So, it can be used for highlighting:

- suspended ceilings;

- furniture, shelves, separate areas of furniture, walls;

- goods and advertisements on shop windows, advertising signs;

- individual elements of cars;

- buildings and various structures (it can be used to highlight various architectural elements)

- swimming pools, baths, aquariums;

- various landscape elements (stairs, trees, benches).

Advantages

Such widespread use of this LED strip is due to a large number of advantages. The list of these advantages consists of the following points:

- Possibility of use in various conditions (except for rooms where the temperature exceeds 60 degrees Celsius).

- Wide range of colors and brightness.

- Compact sizes. This type of LED strip can be installed in different places, and it is possible to install it behind some objects (cornice, mirror, etc.).

- Easy installation procedure. In this case, installation can be carried out on horizontal, vertical and inclined surfaces.

- Low operating temperature (due to this, the SMD-3528 LED strip is convenient to use in rooms that are poorly ventilated).

- The ability to bend makes it possible to form an image with various shapes.

- Such a tape can be cut into pieces and each of them will not lose its working properties.

- Long working life (up to 50,000 hours).

- High efficiency (average quality ribbons create 70-80 lumens per watt).

- Ability to work in wet conditions as well as in water.

- The need for current, the voltage of which is 12 volts (this voltage is safe for humans).

- The angle of light emission is 120 degrees. This indicates that the light is not directed to one point.

Flaws

As for the shortcomings, their list is very small. One of them lies in the fact that to operate the SMD-3528 you need to use a power supply, and this is an additional cost.

If the SMD-3528 LED strip is used in a bathroom or sauna, then problems arise with the placement of the power supply. As you know, it should be located outside with high humidity. Here you need to use more wires.

The joints between different parts are delicate and must be handled with care, especially if the connection was made by soldering. It should not be bent too much, nor should it be used in rooms where the air temperature exceeds 60 degrees Celsius.