We need to bring some order to the terminology. Starters and contactors are often confused . To some they are the same thing, and some say that a contactor is just a big, powerful starter. But no one can really explain how powerful it is...

Previously, during the Soviet era, this was the case. Now starters that were produced or developed in those days are called starters (for example, PML, which is still produced in Ukraine), and new and foreign models are called contactors.

Electricians call the same devices starters, and sellers call them contactors. To be honest, I’m more used to talking about starters.

Comparison of contactor and magnetic starter

It is most convenient to determine the differences between these devices by considering them together according to certain parameters in different categories. Main categories in which comparison will be made:

- appointment;

- design;

- operating principle;

- equipment.

Description of the purpose of the devices

The contactor can be used to switch any DC or AC power circuits, while there are no contactors that are designed to switch currents less than 100 amperes, and the maximum current can reach 4800 A. The rated voltage of the main circuit can be 2 thousand volts.

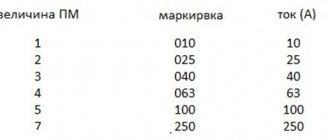

Therefore, contactors are often used to supply voltage not to individual devices, but to groups of electrical consumers. Magnetic starters can also operate in DC networks, but they are primarily designed for operation in AC networks. With their help, they remotely start, stop or reverse three-phase asynchronous electric motors with a squirrel-cage rotor, rheostat start or regulate the speed of machines with a wound rotor. Depending on the size of the device, the power circuit current ranges from zero to two hundred and fifty amperes at voltages up to 660 V.

Design features of the devices

In design, both devices are similar to each other . They consist of the following main components:

- electromagnetic drive;

- main contacts;

- auxiliary contacts.

The starter always has three power contacts, which is related to its purpose.

The entire device is placed in a protective housing made of dielectric material. The housing provides protection from accidental contact with live parts, as well as from adverse environmental factors. Therefore, this device can be installed in almost any room, you just need to ensure that it is protected from moisture getting inside the case. The difference between a contactor and a magnetic starter is that it can be used in a wide variety of electrical networks, so the number of main contacts, depending on the purpose, ranges from two to four . To ensure high switching frequency and extinguishing the electric arc, each power contact is equipped with an arc suppression chamber, which significantly increases wear resistance and switching capacity. It often has an open design, that is, the control coil and contacts do not have a protective housing, so such devices are mounted only in special control panels.

Both types of devices are not independent elements. For ease of use in control circuits, contactors and starters are equipped with auxiliary contacts that switch simultaneously with the main ones. Auxiliary contacts can be normally closed or normally open. Their number ranges from one to five pieces.

The principle of operation of the mechanisms

The actuator of the starter is always an electromagnet, which is why it is called magnetic. With this type of drive, the armature (moving part) of the electromagnet is connected to the main and auxiliary contacts. When voltage is applied to the control coil, current begins to flow through it, creating a magnetic field that attracts the armature and leads to switching of contacts. After the coil is turned off , the device returns to its original state under the action of a compressed spring when triggered.

The operation of a magnetic contactor follows the same principle as that of a starter. For powerful contactors, in addition to the electromagnetic one, an electropneumatic drive can be used. In this case, the main and auxiliary contacts are switched using the energy of compressed air, which is supplied through an electric valve.

In terms of coil supply voltage, with electromagnetic control, the devices do not differ. The value of this voltage for a direct current network can range from 12 to 440 volts, and for alternating current - from 24 to 660 volts.

Device configuration

Starters can be installed in fairly complex motor control circuits. For example, they are used to switch resistance stages during rheostatic starting. The presence of a large number of monitoring, control, protection and signaling circuits leads to the fact that the auxiliary contacts located on the device are not enough to construct the circuit. In order not to install additional relays, there are special latches located at the top of some types of starters, with the help of which you can attach additional contact groups, the number of which can reach up to eight. In the same way, instead of contacts, mechanical time relays can be connected.

To protect electric motors from overload, thermal relays are used, many of which are connected and attached directly to the magnetic starter. This design solution increases the reliability of the circuit, since the number of connecting wires is reduced. In addition, this makes installation easier and the arrangement of elements more compact.

Types of modular contactors

Manufacturers of electrical equipment produce a huge abundance of all kinds of contactors, differing not only in design, but also in technical characteristics, mechanical strength, type of operation, and scope of use.

Technical characteristics, such as current type, divide the modules into DC and AC contactors. For direct current switching, one- and two-pole contactors are used for a maximum voltage of 440 V and a current of 80-630 A. For alternating current circuits, three-pole devices are produced for a current of 63-1000 A.

Based on the type of operation, mechanical and electromagnetic contactors are distinguished. Today, the latter are most widely used in everyday life, due to their advantages - lack of vibration and noiselessness. Modular contactors have from one to four poles, they are called one-two-pole and so on, and they can be single-phase or two-phase. There are models with or without additional contacts; this is also a significant difference between the devices.

BUY MODULAR CONTACTORS

In addition to the contact system, the module includes an arc extinguishing system . Arc extinguishing occurs in different ways, depending on this, there are single contactors with effective arc extinguishing using an electromagnetic device; they are used in circuits of complex industrial or railway equipment, in induction furnaces. And also double contactors with double arc break, which are used in even more severe conditions.

Manufacturers produce different types of contactors, differing in additions and design:

- starters (improved types of contactors with auxiliary elements);

- magnetic contactors (device for frequent switching on and off);

- magnetic starters - three-pole AC contactor with two thermal relays;

An intermediate relay is a low-power contactor for low currents, but carries out a huge number of switchings.

To automate the equipment of residential buildings and public buildings, very popular modular contactors from the Swedish company ABB are used. They work in switching and control circuits of building engineering networks. For example, ABB ESB-63-40 is a contactor for controlling electrical equipment, operating in both direct and alternating current networks. These are four-pole contactors with high wear resistance, 5 kV overvoltage protection, easy to install and resistant to low temperatures.

Contactors of the MF and MT (Energy) series are installed in power circuits, the KM series have a very wide range of applications (offices, hospitals, industrial and residential buildings), and IEK contactors are used for remote control.

The advantages of modular contactors are that they solve many problems, are not difficult to install, are compact and convenient to place in a panel, and are silent in operation. In addition, modular contactors are connected to high-power networks and, at the same time, have good electrical safety (class 2), which is very important for unskilled users. The disadvantages sometimes include the not too large number of switching operations for some models.

Magnetic switch

A magnetic starter is an electromechanical control and distribution device, the purpose of which is to start an electric motor and ensure its continuous operation. This device works as a transformed (modified) contactor; it can be supplemented with components. Starters are equipped with an emergency shutdown system in case of an open circuit or one of the motor power supply phases.

The starter performs the function of changing (switching) the direction of the reversible circuit by changing the phases, for which, for this purpose, another contactor is placed in the device.

In order to reduce the motor current output, a three-phase power supply switch is used. The operation of the magnetic starter can be either open or protected (with built-in motor protection). Magnetic starters are reversible and modular. Reversible motors circulate three-phase electric motors by alternating voltage and consist of two contactors (contactors) connected in one device by an electrical or mechanical interlock. They eliminate the possibility of a short circuit (phase-to-phase).

Magnetic starter circuit

Magnetic starter device.

The magnetic starter consists of two parts: the starter

and

contact block

.

Although the contact block

and is not the main part of a magnetic starter and is not always used, but if the starter operates in a circuit where additional contacts of this starter must be used, for example, reversing an electric motor, signaling the operation of the starter or turning on additional equipment by the starter, then for multiplication of contacts, just and serves as a contact block or, as it is also called,

a contact attachment

.

Differences between contactors and magnetic starters

When considering purchasing a switching device, you need to have a good understanding of the difference between a starter and a contactor. The devices have a number of design and operational differences.

Dimensions, design features and security

A contactor can have up to five poles. Due to the presence of arc chutes, contactor devices are large in size and have significant weight. Often the “filling” of the product is not even placed in the body, so as not to create additional weight. However, this “nakedness” poses a danger to others. The lack of a housing also means there is no protection against liquid ingress, which limits where the contactor can be placed. It is placed in a special panel or electrical cabinet.

Starters are usually more compact devices. The “filling” is placed in a plastic case, which provides protection from moisture and safety for users and third parties. Thanks to this, the device can be installed even outdoors. But the device does not have an arc chute, which limits the possibilities of its operation. In high-power electrical circuits and where there is a large number of switchings, it is not recommended to use a starter.

Production factor

Another difference between a starter and a contactor is that only the former are manufactured in low-current versions. This feature is one of the circumstances that ensures the popularity of starters and their wide representation on the market of this class of devices. Contactors should not be installed in low-current circuits.

Purpose of devices

Although starters are general-purpose devices suitable for use in many systems, their main focus is on three-phase electric motors operating on alternating current. The device not only starts and stops the engine, but also protects it from unintentional starting. It can be used in electrical networks with voltages up to 380 W.

With regard to contactors, we can say that they can perform switching of any type of circuit, but their design features require the creation of certain conditions. The voltage limit will be 660 V. The products are suitable for use in systems such as reactive power compensation circuits. They are also used to work with electric motors and various types of circuits carrying high loads.

What is a contactor?

The contactor is an electromechanical executive mechanism made in the form of a block in which high-speed contact groups are located. The contactor can function as an independent device or be used in the design of other equipment or in a control and protection system for an electrified facility. The contactor system is a switching unit that supports remote control and can be used for frequent switching of electrical circuits operating under normal operating conditions. To close / open contacts, electromagnetic drives are mainly used, which drive the actuator. Unlike a relay system, which can also close or open contacts, a contactor breaks the electrical circuit simultaneously in several places at once, while a relay does this only in one place.

Mechanical characteristics of the ABB ESB modular contactor

| Frame | Sealed, protected from penetration of solid particles |

| Installation principle | Using cable and 4 mm2 clamps per rail |

| Wear resistance | 1 x 106 |

| Mechanical wear resistance | 30 000 |

| Switching | 300 cycles per hour |

The catalog of the 77 VOLT online store presents a wide range of ABB modular contactors at attractive prices. These devices are designed for remote control of the operation of power electrical circuits in standard mode.

8.6.3. Selection of thermal relays for 1st speed winding

1. Rated current of the stator winding of the 1st speed I n.d.

2. in accordance with the selection condition I n.tr =

I n.dv,

I select a thermal relay type

Read also: Corrosion protection method

TRT 136 with rated current I n.tr =

3. since the rated currents of the relay and the motor do not match, I change the relay setting by +5%, which will be 52.5 A. If you do not change (increase) the setting, the heat

the relay will turn off the motor at rated current;

4. Now the new value of the relay rated current practically coincides with the rated

motor current I N.M.

5. number of thermal relays – 2 pcs.

Contactors and magnetic starters

Introduction

At the beginning of this article, I would like to immediately determine what the difference is between a contactor and a magnetic starter, since this question often baffles even the most experienced electrical specialists, while many believe that the difference between them lies in their design, overall dimensions or the value of the switched (rated) current, but this is not so. GOST 30011.4.1-96 will help us understand this issue, which provides the following definitions:

A contactor is a switching device with a single rest position, not manually operated, capable of switching on, carrying and breaking currents under normal circuit conditions, including during operating overloads.

A starter is a combination of all the switching devices needed to start and stop the motor, with overload protection.

As follows from the definitions above, a contactor is a device designed to switch (turn on/off) any loads, i.e. any loads, while starters are a set of devices designed to control a specific electric motor, as well as providing its protection against overloads, while the contactors themselves are part of the starters:

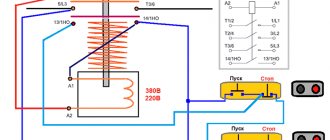

As you can see in the picture above, the starter includes: a contactor - to turn the electric motor on and off, a thermal relay - to protect the electric motor from overloads, buttons - to control the contactor, all of the above devices are placed in a common housing.

Also, according to the same GOST 30011.4.1-96, starters come in the following types:

Direct-acting starter - A starter that supplies mains voltage to the motor terminals in a single step. Reversing starter - A starter designed to change the direction of rotation of a motor by switching its supply connections without necessarily stopping the motor. Bidirectional Starter - A starter designed to change the direction of rotation of a motor by switching its supply connections only when the motor is stopped.

Thus, a direct-acting starter is designed to start, stop and protect the electric motor, while a reversing starter, in addition to all of the above, allows you to change the direction of rotation of the motor.

As you can see in the picture above, the reversible magnetic starter includes two contactors; switching between them changes the phase sequence, which leads to a change in the direction of rotation of the electric motor. (For more information about changing the direction of rotation of the electric motor and the operating diagram of the reversing starter, see here.)

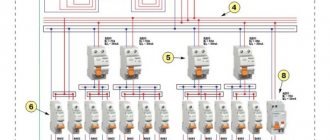

There are also so-called modular contactors - these are compact contactors designed for installation on a DIN rail, otherwise their design and operating principle are the same as those of conventional contactors.

Now, having understood the concepts of contactor and starter, let’s begin to study the principle of their operation.

Design and principle of operation of the contactor

As can be seen in the picture above, an electromagnetic contactor consists of the following main elements: a magnetic circuit consisting, in turn, of moving and stationary parts, an electric coil, power contacts designed to turn on and off the load, which include moving contacts that are attached to the moving parts of the magnetic circuit and fixed contacts that are attached to the upper part of the contactor body, block contacts intended for use in control circuits, as well as a spring that ensures that the power contacts are maintained in an open state.

The contactor is controlled by applying voltage to an electric coil; when an electric current passes through it, an electromagnetic field is created flowing through the magnetic circuit, while the stationary part of the magnetic circuit together with the electric coil work as an electromagnet which, as can be seen in Fig. 2 above, overcoming the resistance of the spring, attracts the upper moving part of the magnetic circuit with moving contacts attached to it, thus closing the power contacts; when the voltage is removed from the contactor coil, the electromagnetic field disappears, ceasing to attract the moving part of the magnetic circuit, which, under the influence of a spring, returns to its original position, opening the power contacts.