Inspection of substation equipment

INSTRUCTIONS

ON THE PROCEDURE FOR INSPECTIONS OF SUBSTATION EQUIPMENT

| I. Procedure for inspecting substation equipment. |

| 1. Inspection of power transformers. |

| 2. Inspection of open distribution devices. |

| 3. Inspection of closed distribution devices. |

| II. Actions of operational, operational and production personnel upon arrival at the substation to carry out planned operational switchings. |

| III. Actions of operational, operational and production personnel upon arrival at the substation to inspect equipment after an emergency shutdown. |

Knowledge of this manual is required for:

- chief, foreman of a group of substations;

- operational, operational and production personnel of the SPS.

Scheduled (monthly) inspection of substation equipment is carried out by two persons: an electrician and the head (foreman) of a group of substations. The electrician inspects the equipment in accordance with the operating personnel work schedule at least 3 times a month. The head (master) of a group of substations carries out an inspection in accordance with an annually approved schedule, but at least once a month at each substation of the group.

What frequency of inspections of switchgear equipment without disconnecting from the network is indicated incorrectly?

| A) At facilities with permanent staff duty at least once per shift. |

| B) At facilities with permanent staff duty - at least once a day. |

| C) At facilities without permanent staff on duty - at least once a month. |

| D) At transformer and distribution points - at least once every 6 months. |

| D) In the dark to detect discharges, corona - at least once a month. |

SO 153-34.20.501-2003

5.4.15. Inspection of switchgear equipment without disconnecting from the network must be organized:

at facilities with permanent staff duty: at least 1 time per day;

in the dark to identify discharges, corona - at least once a month;

External inspection of current conductors must be carried out at power plants daily.

In case of unfavorable weather (heavy fog, sleet, ice, etc.) or increased pollution at the outdoor switchgear, as well as after equipment shutdown due to a short circuit, extraordinary inspections must be organized.

All detected malfunctions must be recorded and higher operational dispatch and engineering personnel notified.

Malfunctions must be corrected as soon as possible.

When changing the color of the shell, the conductor must be disconnected.

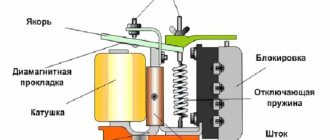

116. Which of the listed requirements for the operation of tanks of air circuit breakers and other high-voltage devices is incorrect?

| A) Reservoirs of air switches and other devices must comply with the provisions of the rules for the design and safety of operation of pressure vessels. |

| B) Hydraulic tests of air circuit breaker tanks should be carried out in cases where inspection reveals defects that cast doubt on the sufficient strength of the tanks. |

| C) Internal inspection of tanks of air switches and other devices must be carried out at least once every 2 years. |

| D) The internal surfaces of the tanks must have an anti-corrosion coating. |

SO 153-34.20.501-2003

5.4.23. Reservoirs of air switches and other devices, as well as air collectors and cylinders must comply with the provisions of the rules for the design and safe operation of pressure vessels established by state control and supervision authorities.

Reservoirs of air switches and other high-voltage devices are not subject to registration with state control and supervision authorities.

Internal inspection and hydraulic testing of air collectors and compressor pressure cylinders must be carried out in accordance with the rules of state control and supervision bodies. Internal inspection of tanks of air switches and other devices should be carried out during average repairs.

Hydraulic tests of air circuit breaker tanks should be carried out in cases where inspection reveals defects that cast doubt on the sufficient strength of the tanks.

The internal surfaces of the tanks must have an anti-corrosion coating.

117. Which of the listed requirements for operating a capacitor unit is incorrect?

| A) Operation of the capacitor unit is prohibited if the currents in the phases differ by more than 10%. |

| B) Inspection of the capacitor unit without shutting down must be carried out at least once every 3 months. |

| B) Restarting the capacitor unit is allowed no earlier than after 1 minute. After disconnecting. |

| D) Turning on a capacitor unit that has been turned off by protection is permitted after the cause of its shutdown has been identified and eliminated. |

SO 153-34.20.501-2003

5.6.5. It is not allowed to turn on the capacitor unit at a capacitor temperature below:

minus 40°C - for climate control capacitors U and T;

minus 60°C - for condensers of climatic version HL.

Turning on the capacitor unit in accordance with the instructions for its operation is permitted only after the temperature of the capacitors (ambient air) has been raised to the values specified in the instructions and held at this temperature for the specified time.

5.6.6. If the currents in the phases differ by more than 10%, operation of the capacitor unit is not allowed.

5.6.7. Restarting the capacitor unit is allowed no earlier than after 1 minute. after shutdown.

5.6.8. Turning on a capacitor unit that has been turned off due to protection is permitted after the cause of its shutdown has been identified and eliminated.

5.6.9. Capacitors impregnated with trichlorobiphenyl must have a distinctive sign on the housing in the form of a yellow equilateral triangle with a side of 40 mm.

When servicing these capacitors, precautions must be taken to prevent the release of trichlorobiphenyl into the environment. Failed capacitors impregnated with trichlorobiphenyl should be stored in a sealed container, the design of which prevents trichlorobiphenyl from entering the environment.

Destruction of damaged capacitors impregnated with trichlorobiphenyl should be carried out centrally at a specially equipped landfill.

5.6.10. Inspection of the capacitor installation without shutting down must be carried out at least once a month.

The procedure for inspecting substation equipment.

When performing a scheduled (regular) inspection of substation equipment, the following is performed:

Inspection of power transformers:

The presence and operability (based on indirect evidence) of thermal alarms, oil indicators, gas and jet relays, the absence of signs of disruption of their functionality, the absence of gas (air) in the gas relay.

- Condition of the mechanical protective casing and control cable from the gas relay.

- Oil levels in the expanders of the main tank of the transformer and contactor, their correspondence to the air and oil temperatures of the transformer.

- Compliance of the position of process valves and bypass valves with the normal operating mode of the transformer.

- Completeness and sufficiency of measures to prevent theft of transformer oil, transformer parts and components.

- No oil leaks.

- Condition of the oil receiver, oil drains, oil collector, side guards of the oil receiver.

- Condition of air dryers (completeness, color of indicator silica gel, presence of oil in oil seals).

- Condition of oil-filled bushings and insulators (no cracks, chips, cleanliness of porcelain, oil pressure level, condition of bushing air dryers, absence of oil leaks).

- Condition of the transformer busbar (integrity, presence and position of temperature indicators, absence of heating of contact connections).

- The state of the on-load tap-changer devices - record the position of the switching device (compare with the pointer on the control panel), the number of switching operations, the completeness of the drive, its operability, the oil level in the contactor tank (for the on-load tap-changer type RNTA), the condition of the drive fittings.

- Condition of grounding disconnectors, short circuits, capacitors, arresters.

- Condition and performance of transformer blower fans. Operability of automatic blowing.

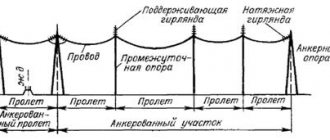

Inspection of open switchgears.

Absence of switchgear equipment malfunction signals on the protection panels.

- The condition of the cable duct floor slabs, no signs of cable ducts being opened by unauthorized persons.

- Oil levels in oil-filled equipment, integrity and performance of oil indicators, color of indicator silica gel, condition of air dryers.

- Compliance with oil and gas pressure standards in equipment operating under excess pressure (switch inputs, small-volume switches).

- The condition of the switchgear busbar is integrity, no signs of kinks, mechanical damage, surges, no signs of heating of contact connections (thermal indicators, color changes, sparking).

- Condition of suspended insulation (integrity of porcelain, glass, degree of wear of caps, insulator pestles, coupling fittings).

- Condition of the support insulators (contamination, absence of unacceptable chips, cracks).

- Condition of porcelain covers of current and voltage transformers, bushings, small-volume switches, capacitors.

- Condition of barriers, capacitors, filter connections, grounding disconnectors.

- The condition of disconnectors, short-circuiters, separators, their drives, the absence of bird nests, rodents, wasp nests in structures and drive cabinets, the condition of KSA and SBC. Serviceability and performance of canopies, locks, latches, box lids and drive boxes. The presence of protective visors over the jaws of the disconnectors.

- No oil leaks from oil-filled equipment.

- Levels and locations of corona insulation.

- Condition of terminal boxes, switch drive cabinets, protection cabinets (tight closure, serviceability and operability of locks, constipations, presence and operability of heating devices, state of switching, equipment, absence of wasp nests, nesting places of birds and rodents).

- Condition of electromagnetic and mechanical interlocks (presence of seals on EMB locks, locks on the drives of working and grounding knives). There are no signs of violation of the mechanical interlocks of the disconnectors.

- Correspondence of the position of the switchgear equipment to the normal mode diagram. There are no signs of outside interference in the reactor plant equipment.

- Condition of metal structures, concrete pillars of portals, equipment, condition of foundations. The condition of the components and parts for fastening the cross-arms to the portal posts, the condition of the metal embedded parts of the concrete cross-arms of the portals, the condition of the parts for fastening the garlands to the cross-arms of the portals.

- There is no possibility of water accumulation in pipes that protect cables from mechanical damage.

- Checking the functionality of security alarm devices.

- Availability, condition and compliance of dispatch inscriptions with equipment names, numbers and heights of lightning rods, presence of signs indicating the grounding location of fire trucks and trunks.

- The condition of the switchgear fencing, constipations, locks, the closed position of doors, wickets, gates. Lack of possibility of open access to the reactor plant equipment.

- Condition of oil receivers under multi-volume oil switches.

Inspection of closed switchgears.

External inspection of the indoor switchgear building, KRUN cabinets.

- The condition of doors, locks, their reliability and sufficiency. Condition and performance of security alarm devices.

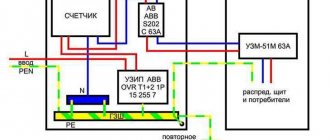

- Inspection of equipment in switch chambers, auxiliary transformer chambers, voltage transformer chambers, line disconnector compartments. Correct and complete switching on of switching devices, condition of current transformers, insulators, absence of heating of contact connections. State of phasing and inscriptions of dispatcher names. The inspection is carried out by opening the doors of the control switchgear and KRUN cameras. With the doors closed, inspection is carried out through the inspection windows on the side of the control compartment. The presence of mesh fences, their locking devices, barriers. For KRUN cabinets, the presence and functionality of mechanical interlocks.

- Inspection of equipment in the control corridor (for switchgear from the control compartments): insulation condition, absence of heating of contact connections; correct and complete switching on of switching devices; availability and compliance with the requirements of the ODS instructions of inscriptions of dispatcher names, phasing. Correct and complete sealing of electricity metering circuits. Condition and performance of electricity meters. The condition of the secondary switching circuits, the absence of signs of damage and outside interference in the switching and equipment. The condition and operability of relay protection devices, compliance of the position of the overlays of relay protection devices with the diagram and mode of their operation. Condition and performance of mechanical and electromagnetic locks, presence, performance, sufficiency of mechanical locks. Condition of lighting, space heating, equipment, KRUN cabinets.

- Inspection of bus floor equipment, systems, bus sections: correct and complete activation (disconnection) of switching devices. The presence and condition of mesh fences, the presence and serviceability of locks, constipations. Condition of insulation, contact connections, temperature indicators, absence of heating of contact connections. Availability and compliance with the requirements of the ODS instructions of inscriptions of dispatcher names, phasing. The condition of the closed switchgear roof, the roof of the switchgear, no leaks, no water ingress, no sources of insulation contamination.

Frequency of inspections of switchgears

How often should switchgear inspections be carried out in transformer substations without permanent personnel on duty?

Inspection of the reactor plant without shutdown should be carried out:

— at facilities with permanent personnel on duty - at least 1 time per 1 day; in the dark to identify discharges, corona - at least once a month;

- at facilities without permanent personnel duty - at least once a month, and at transformer and distribution points - at least once every 6 months. (2.2.39 PTEEP)

- Home page

- TOE

- Electric cars

- Physics

- Physics Krivchenko

- Tender

- As-built documentation

- Acceptance documentation

- How to download?

- To the Chief Power Engineer

- PPR system

- Responsible for electrical equipment

- Responsible for elevators

- Industrial Safety

- Occupational Safety and Health

- Accident

- Fire safety

- Rules and GOSTs

- Forms and protocols

- Equipment catalogs

- Counters

- Articles

- Email safety

- Contractor services

- For advertisers

- Earn money

- Labor protection at industrial enterprises

- Tickets by email security with answers

Page updated: 02/05/2018

Feedback and suggestions can be sent to [email protected]

The information is provided for informational purposes only and is not an official source.

Source