- 14.1. Electricity metering rules

- 14.2. Electric energy metering devices

CHAPTER 14

BASIC PRINCIPLES OF ELECTRIC ENERGY ACCOUNTING

14.1. Electricity metering rules

Payments for consumed electricity are one of the fundamental positions of the contractual relationship between the consumer and the energy supply organization, taking into account the interests of both parties.

The requirements for calculated electricity metering devices are multifaceted and include the reliability and accuracy of determining electricity consumption, taking into account its losses in electrical networks, openness and accessibility of measurement results at all stages of production, transmission, distribution and consumption of electricity.

These issues are the focus of attention at the highest government levels and are reflected in a number of government legislative documents, including:

in the Law of the Russian Federation “On Energy Saving” No. 28-FZ, adopted by the State Duma on March 13, 1996, which indicates the need to ensure mandatory instrumentation of the entire volume of produced and consumed energy resources;

in articles 541, 543 and 544 of the Civil Code, which emphasize that the amount of transmitted electrical energy is determined in accordance with the data from metering devices on its actual consumption, etc.;

in the Decree of the Government of the Russian Federation dated November 2, 1995 No. 1087 “On urgent measures for energy saving”, on the basis of which the Electricity Accounting Rules are in force [18];

in the Law of the Russian Federation “On Ensuring the Uniformity of Measurements”, which establishes the legal basis for ensuring the uniformity of measurements in the Russian Federation, regulates the relations of government bodies of the Russian Federation with legal entities and individuals on the issues of manufacturing, production, operation, repair, sale and import of measuring instruments and directed to protect the rights and legitimate interests of citizens, the established legal order and the economy of the Russian Federation from the negative consequences of unreliable measurement results;

in the Law of the Russian Federation “On state regulation of tariffs for electrical and thermal energy in the Russian Federation”, adopted by the State Duma on March 10, 1995, which defines the economic, organizational and legal basis for state regulation of tariffs for electrical and thermal energy in the Russian Federation;

in other legislative, legal and by-laws, as well as in state standards and a number of regulatory and technical documentation.

These Electricity Accounting Rules define the general requirements for the organization of its accounting and the relationship between the main regulatory and technical documents in force in this area.

It is allowed, on the basis of existing legal and regulatory technical documents, departments to develop and approve in the prescribed manner, within their competence, departmental regulatory and technical documents in the field of electricity metering that do not contradict the approved Rules for Electricity Accounting. If these documents contain requirements of an interdepartmental nature, they must be approved in accordance with the established procedure with Rostechnadzor.

Electric energy metering rules are mandatory when:

production, transmission, distribution and consumption of electrical energy;

performing design, installation, adjustment and repair work on organizing electrical energy metering;

ensuring the operation of electrical energy metering devices.

The main purpose of electricity metering is to obtain reliable information about its production, transmission, distribution and consumption in the wholesale and retail markets to solve the following main technical and economic problems:

financial settlements for electricity and capacity between energy supply organizations and electricity consumers, taking into account its quality;

determination and forecasting of technical and economic indicators of production, transmission and distribution of electricity in energy systems;

determination and forecasting of technical and economic indicators of electricity consumption at enterprises in industry, transport, agriculture, the public utility sector, etc.;

ensuring energy saving and power consumption management.

Accounting for active electricity should ensure the determination of the amount of electricity (and, if necessary, average power values):

generated by power plant generators;

consumed for the own and economic needs (separately) of power plants and substations, as well as for the production needs of the energy system;

supplied to consumers via lines extending from power plant buses directly to consumers;

transmitted on the network of other owners or received from them;

released to consumers from the electrical network;

transferred for export and received for import.

The organization of active electricity metering should provide the ability to:

determining the flow of electricity into electrical networks of various voltage classes of power systems;

compilation of electricity balances for self-supporting units of energy systems and consumers;

monitoring compliance by consumers with their prescribed consumption regimes and electricity balances;

consumer payments for electricity at current tariffs, including multi-rate and differentiated tariffs;

power management.

Accounting for reactive electricity should provide the ability to determine the amount of reactive electricity received by the consumer from the power supply organization or transferred to it, if these data are used to make calculations or monitor compliance with the specified operating mode of compensating devices.

Electricity metering is carried out on the basis of measurements using electricity meters and information-measuring systems.

For electricity metering, measuring instruments must be used, the types of which are approved by the State Standard of Russia and included in the State Register of Measuring Instruments.

Accounting means include a set of devices that provide measurement and metering of electricity (current and voltage measuring transformers, electrical energy meters, telemetry sensors, information-measuring systems and their communication lines) and are interconnected according to an established scheme.

The organization of electricity metering at existing, newly constructed, and reconstructed electrical installations must be carried out in accordance with the requirements of the current normative and technical documentation in terms of:

installation locations and volumes of electricity metering devices at power plants, substations and consumers;

accuracy classes of meters and instrument transformers;

placement of meters and electrical wiring to them.

Accounting for active and reactive energy and power, as well as monitoring the quality of electricity for settlements between the energy supply organization and the consumer, is carried out, as a rule, at the border of the balance sheet of the electrical network.

To increase the efficiency of electricity metering in electrical installations, it is recommended to use automated electricity metering and control systems created on the basis of electricity meters and information-measuring systems.

Persons performing installation and adjustment of electricity metering equipment must have a license to carry out these types of work, i.e. a document certifying the right to engage in these types of activities, issued to legal entities and individuals by the state metrological service.

Means for metering electrical energy and monitoring its quality must be protected from unauthorized access to eliminate the possibility of distortion of measurement results.

The organization of operation of electricity metering devices must be carried out in accordance with the requirements of current normative and technical documentation and instructions of manufacturers.

Operational maintenance of electricity metering devices must be carried out by specially trained personnel.

When servicing electricity metering equipment, organizational and technical measures must be taken to ensure the safety of work in accordance with current rules.

Based on current legal and regulatory technical documents, departments can develop and approve, within their competence, departmental normative and technical documentation in the field of electricity metering that do not contradict these rules.

Within the time limits established by the State Standard of Russia, it is necessary to periodically check the measuring instruments used to account for electrical energy and control its quality. Rearrangement, replacement or change of metering switching schemes is carried out with the consent of the energy supplying organization.

In addition to the Electricity Accounting Rules, there is a Standard Instruction for Electricity Accounting during its Production, Transmission and Distribution (RD 34.09.101-94), which contains the basic provisions for electricity metering during its production, transmission and distribution, establishes requirements for the organization, composition and rules operation of electricity and power metering systems. The standard instructions are intended for personnel of joint-stock companies of energy systems, design organizations and electricity consumers.

Representatives of Rostechnadzor have the right of access to electricity metering devices, measuring systems and the metering system as a whole at all power plants, substations and enterprises located in the service area to carry out inspection and routine work with the participation of personnel of the corresponding power facility (electrical installation).

Each electricity metering system installed according to the normal or temporary arrangement of calculation and technical electricity metering devices must have a technical passport-protocol of the following form.

PASSPORT-PROTOCOL

measuring complex

These Electrical Energy Accounting Rules have been agreed upon with the State Standard of Russia, Glavgosenergonadzor of Russia and RAO UES of Russia and approved by the Ministry of Fuel and Energy of the Russian Federation and the Ministry of Construction of the Russian Federation.

14.2. Electric energy metering devices

Single- and three-phase electricity meters, mainly of two types: induction and electronic (1-, 2- and multi-tariff), which are increasingly used, are used as calculation and technical (control) accounting tools at enterprises (organizations).

Induction three-phase active and reactive energy meters used as calculated metering devices must have an accuracy class of at least 2.5 (0.5; 1.0; 2.0 and 2.5) for active and not below 3 (1. 5; 2.0 and 3.0) for reactive energy.

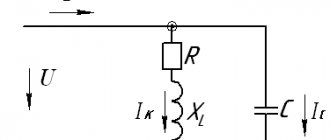

An induction meter is a counter in which the magnetic field of stationary current-carrying coils affects a movable element made of conductive material. This is usually a disk through which currents flow, induced by the magnetic field of the coils.

In accordance with GOST 6570-75, meters are characterized by:

counter constant C, i.e. the number of watt-seconds, watt-hours or kilowatt-hours per revolution of the device disk;

gear ratio A, i.e. the number of revolutions of the disk that it must make in order for the meter reading to change by 1 kWh;

coefficient K of the meter, i.e. the number by which you need to multiply the meter readings to get the actual electricity consumption, kWh.

Counter constant C

can be calculated using the markings on its shield, using the formulas given in table. 6.

Table 6

Formulas for determining the counter constant C

One of the disadvantages of induction meters is that they have self-propelling, which is the movement of the meter disk under the influence of voltage applied to the terminals of the voltage circuit, in the absence of current in the shock circuit of the meter.

In accordance with GOST 6570-75, the meter disk should not make more than one full revolution in the absence of current in the series (current) circuit and at any voltage from 80 to 110% of the rated voltage.

Induction meters belong to repairable products that cannot be restored on site, which must have an average time to failure of at least:

25,000 h – for three-phase meters of accuracy class 0.5;

33,300 h – for single-phase meters cl. 2.0; for three-phase active energy meters cl. 1.0 and cl. 2.0;

37,500 h – for single-phase meters cl. 2.5 and three-phase reactive energy meters cl. 1.5 and cl. 2.0;

50,000 h – for single-phase meters cl. 2.0 and three-phase reactive energy meters cl. 3.0.

The average service life before the first major overhaul must be at least:

30 years – for single-phase meters CL. 2.0; for three-phase meters cl. 2.0 and cl. 3.0 at customer's request;

27 years – for three-phase meters CL. 2.0 and cl. 3.0;

25 years – for single-phase meters CL. 2.5;

22 years – for three-phase meters CL. 0.5, cl. 1.0 and cl. 1.5.

Induction meters can be used in three or four-wire networks, in networks with an isolated or solidly grounded neutral, which can be determined by the designation of the meter, namely:

CA3 – three-phase direct connection or transformer three-wire active energy;

CA4 – the same, four-wire;

CP4 – three-phase direct connection or transformer three- and four-wire reactive energy;

SA3U – three-phase transformer universal (with a secondary or mixed counting mechanism) three-wire active energy;

SA4U – the same, four-wire;

SR4U – three-phase transformer universal (with a secondary or biased mechanism) three- and four-wire reactive energy.

A transformer is a meter designed to be switched on through one or more instrument transformers.

Single- and three-phase electronic meters of the latest design are promising in the conditions of the sales market and electricity consumption, as a result of which they are increasingly replacing induction metering devices. These meters can be connected to the network directly or through instrument transformers.

In accordance with GOST 30207-94 for electronic (static) meters, a transformer is a meter designed to be switched on through measuring transformers with predetermined transformation ratios. The meter readings in this case must correspond to the value of the energy passed through the primary circuit.

A transformer universal meter is a meter designed to be switched on through instrument transformers having any transformation ratio. To determine the energy passed through the primary circuit, it is necessary to multiply the meter readings by the product of the transformation coefficients.

The main advantage of electronic meters is a differentiated electricity metering tariff (one-, two- and more tariffs), which is provided using an external tariff switching device (for example, UPT 12-100 in an electric meter of the SET4-2 type). The load capacity of such a tariff switching device ranges from 1 to 30 meters.

A multi-tariff meter is an electric energy meter equipped with a set of counting mechanisms, each of which operates at set time intervals corresponding to different tariffs.

The electronic meter can be used as an incremental sensor of electricity consumption for remote information-measuring systems and electricity metering and distribution systems.

In accordance with GOST 30207-94, electronic type meters have a standardized name - a static meter, i.e. a meter in which current and voltage act on solid-state (electronic) elements to create output pulses, the number of which is proportional to the measured active energy. This standard specifies electronic meters according to their accuracy class designation, i.e. 1 and 2.

The constant of a static (electronic) meter is a value that expresses the relationship between the energy taken into account by the meter and the number of pulses on the test bench.

The meter constant is expressed either in pulses per kilowatt-hour [imp/(kWh)] or in watt-hours per pulse [(Wh)/imp].

In table 7 and 8 show standard (according to GOST 30207-94) values of rated voltages and currents, i.e. those values that are the initial values when establishing requirements for meters.

Table 7

Standard voltage ratings

Table 8

Standard current ratings

The maximum current for direct-connection meters, i.e. the highest current value at which the meter satisfies the accuracy requirements established in GOST 30207-94, is preferably an integer multiple of the rated current (for example, 4 times the rated current).

If the meter is powered by a current transformer(s), the current range of the meter must be selected to match the secondary current range of the current transformer(s). The maximum current in this case is 1.2Inom; 1.5Inom or 2Inom.

The meter terminals must provide connection to up to two copper or aluminum wires with a total cross-section of up to 5 mm. All terminals intended for connection to voltage measuring transformers must be separate and have holes with a diameter of at least 4.2 mm.

The terminals of three-phase meters intended for connection with current transformers must ensure separate connection of voltage and current circuits; The diameter of the clamp holes for these chains must be at least 3.5 mm.

The average service life before the first major overhaul and the average time to failure for static meters are approximately the same as for induction meters. For example, for an electronic meter of direct switching type SET4-1 (5-60)A, these values are respectively 24 years and 55,000 hours.

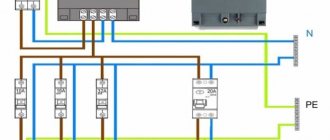

In Fig. 8, a

As an example, a diagram of the direct connection of a SET type meter to a four-pass three-phase network is shown.

In single-tariff meters of the SET4-1 type, the control circuit for the state of the counting mechanisms (tariff switching circuit) is not used and clamp 14 in the diagram in Fig. 8, a

not installed.

The output stages of the main and verification outputs of the meter are implemented on transistors with “open” collectors.

Output devices of electronic meters include:

test output - a device that can be used to test the meter;

operation indicator – a device that produces a visually observable signal of the meter’s operation;

storage device – an element designed to store digital information;

non-volatile storage device - a storage device that can retain information when the power source is turned off.

To ensure the functioning of the output stages, it is necessary to apply voltage according to the diagram in Fig. 8, b to clamps 2 and 13

Rice. 8.

Scheme of direct connection of a SET type meter to a four-wire three-phase network:

a –

connection diagram; b – connection diagram for the tariff switching device

to the meter

main output (transmitting device) and terminals 1 and 13 of the testing output.

Unlike induction meters, electronic meters have a light indication on the panel, namely:

NETWORK indicator, signaling that the meter is connected to the network (when 220 V phase voltage meter is supplied to the meter circuit, the NETWORK indicator should be constantly lit);

indicators A and B, signaling the switching on of the load, which should blink with a frequency proportional to the consumer power in the loads (in the absence of load current, indicators A

and

B

are in an arbitrary state, i.e. they can glow or not glow);

TARIFF II indicator (night time tariff) at a two-tariff meter, indicating the presence of 14

control signal counter, which must transfer the counting mechanism of the second tariff (TARIF II) to the “active” state, and the counting mechanism of the first tariff to the “passive” state.

Electricity consumption is taken into account directly in kilowatt-hours using the six digits of the drums located in the dashboard window.

In table 9 shows the technical characteristics of three-phase electronic meters, serially produced by OJSC Mytishchi Electrotechnical Plant (No. 1-8) and ABB VEI Metronika, Moscow (No. 9-12).

In adj. Figure 7 shows the markings of electronic meter panels (according to GOST 30207-94).

Table 9

Three-phase electronic meters

At enterprises (organizations), there is often a need to determine the connected power (load) at different periods of the day, usually during the hours of maximum or minimum load on the power system. Unfortunately, in these cases, sometimes the electrical engineering personnel of enterprises (organizations) experience certain difficulties, to the point that they use electrical clamp meters for this purpose with subsequent calculation of power, despite the fact that the energy supply contract states that for this purpose it is necessary to use an active meter. energy.

Load measurement can be carried out using an active energy meter and a stopwatch as follows.

At the moment a fixed line appears on the counter disk, the stopwatch should be turned on and after a certain number n full revolutions of the counter disk, the stopwatch should be stopped. Then, depending on the values of the meter constant C and its gear ratio A, the power is calculated using the formulas indicated in the table. 10.

Table 10

Formulas for calculating power on a meter using a stopwatch

Note.

In the table

t is

the time shown by the stopwatch, s.

Example.

The enterprise has two feeders installed with metering devices powered by transformers:

1st feeder.

Transformer with a power of 630 kVA with measuring CTs 100/5 A and VT 10,000/100 V. A transformer meter is installed, calibrated at CT 75/5 A and VT 6000/100 V, on the panel of which 1 kWh = 25 revolutions is indicated disk.

2nd feeder.

Transformer with a power of 400 kVA with measuring CTs 50/5 A and VT 6000/100 V. A universal meter is installed, on the panel of which it is written 3 × 5 A 6000/100 V, 1 revolution of the disk = 10 Wh.

Determine the load on each feeder and the total load of the enterprise.

Solution.

1. We measure time t

full revolutions

n

of the 1st counter disk. Let's assume that the measurements showed:

t

= 5 s at

n

= 6 full disk revolutions.

2. Since the meter is a transformer, connected to measuring CTs and VTs with other values of transformation ratios, it is necessary to determine the recalculation coefficient Kpr, which will be equal to the product of two ratios: the coefficients of the current transformers of the actually installed and the meter, and the coefficients of the voltage transformers of the actually installed and the meter, i.e.

In our case

3. Since the meter label indicates 1 kWh = 25 disk revolutions, then using formula (56) we determine the power shown by the meter:

4. Taking into account the conversion coefficient Kpr, the actual power for the 1st feeder will be:

5. We determine the power shown by the meter for the 2nd feeder, using formula (58) for our problem conditions:

where measured values by stopwatch n =

full revolution of the disk at t = 50 s.

6. The actual load on the 2nd feeder, taking into account the coefficients of the measuring CTs and VTs, will be:

7. Thus, in a given period of the day, the enterprise’s load on the 1st feeder is 384 kW, on the 2nd feeder – 216 kW, and the total load will be equal to:

?P = P l

+ P 2

= 384 + 216 = 600 kW

Correct calculation of power (load) and the ability to use the calculated coefficients of metering devices (electricity meters and instrument transformers) will not allow you to overpay for consumed electricity and will ensure reliable control over the contractual values of connected power.

In accordance with the requirements of PTEEP, monitoring of the operation of electrical energy metering devices at electrical substations (in switchgears) must be carried out by operational or operational-repair personnel.

Responsibility for the safety and cleanliness of measuring and metering instruments for electrical energy lies with the personnel servicing the equipment on which they are installed.

The installation and replacement of current and voltage measuring transformers, to the secondary circuits of which the metering meters are connected, is carried out by the personnel of the consumer operating it with the permission of the energy supply organization.

Replacement and verification of settlement meters, according to which settlements with the energy supplying organization are carried out, are carried out by the owner of the metering devices in agreement with the energy supplying organization.

The personnel of the power facility, in accordance with the requirements of PTEEP, is responsible for the safety of the settlement meter, its seals and for the compliance of electricity metering circuits with the established requirements. Breaking the seal on the billing meter, unless caused by force majeure, invalidates the electricity metering carried out by that billing meter.

To protect against unauthorized access to electrical measuring instruments, switching devices and detachable connections of electrical circuits, they must be marked in metering circuits with special visual control signs in accordance with established requirements.

In the era of market relations, increased attention has been paid to the issues of accounting for electricity consumption, since the reliability and accuracy of information on the production and consumption of electricity solves a whole range of pressing problems in the electricity industry, including issues of energy saving, reducing payments for consumed electricity, choosing rational operating modes for electrical installations, reliability of determination of electricity losses in networks and other important issues.

Table of contents

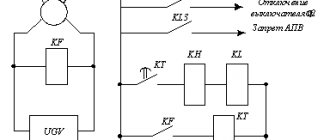

Commercial energy metering using automated systems

Commercial electricity metering using ASKUE and AIIS KUE is used at enterprises generating and distributing electricity to ensure automated remote control of produced, transported and released energy with maximum measurement accuracy. At the same time, the improvement of technology, the emergence of new metering devices and new data exchange interfaces have made it possible to significantly simplify such systems, reduce their cost and make them accessible to consumers of any level. Thanks to this, today ASKUE and AIIS KUE systems are increasingly being introduced and effectively used both in industry and in the public sector.

The implementation of ASKUE and AIIS KUE systems today is actually a necessity for many industrial enterprises with a branched structure or energy-intensive production. Automated electronic metering provides the maximum level of measurement accuracy and allows you to obtain a large amount of additional information necessary to optimize energy consumption. The implementation of such systems reduces labor costs for accounting to almost zero, even with a large number of primary accounting devices and a complex enterprise structure.

The automated commercial electricity metering system performs the following functions and has the following capabilities:

- automatic collection of data from primary meters and their periodic transmission to the server;

- long-term data storage;

- performing analytical functions (data analysis in order to optimize the consumption or transmission of electrical energy);

- identification of unauthorized electricity consumption;

- remote connection and disconnection from the network of end consumers, etc.

Unlike ASKUE, the AIIS KUE system is an automated measurement tool that allows access to the wholesale electricity market. Such systems must comply with the requirements of GOST R 8.596-2002. Therefore, for their implementation, a mandatory requirement is the registration of the system as a measuring instrument in the State Register, as well as its certification by a regulatory authority.