Ways to decorate a house

Aerated concrete requires mandatory finishing, as over time it can begin to absorb moisture. Additional cladding helps retain heat and give the building an attractive appearance.

You can clad a building using facing bricks, which can be attached to the wall in different ways: this material not only has an attractive appearance, but will also reliably protect the aerated concrete from damage, cold and moisture.

Insulation can be placed between the cladding and the wall. Another advantage of brick is its ability to breathe: this will remove moisture from aerated concrete and give the facade the necessary ventilation. However, if the mortgages were not made initially, a problem may arise, since there is no fastening of the facing brick to the load-bearing wall. This can be solved; there are several ways to accomplish the task.

Flexible fiberglass ties for brickwork, facing bricks, aerated concrete. Galen

The main task of flexible connections is to provide a high-strength connection of facing layers and insulation with load-bearing walls. According to SNiP, flexible connections are made of “corrosion-protected steels, as well as polymer materials.” Composite flexible connections significantly reduce heat loss, are not subject to corrosion and the influence of aggressive environments, do not form dew on the surface during cold periods, exceed metal connections in tensile strength, are lighter and cheaper than metal. You can fill out the order form for flexible connections directly on our website.

- Energy saving

The use of composite elements significantly reduces heat loss by eliminating cold bridges.

- Resistance to aggressive environments

Flexible composite connections are not subject to corrosion.

- Lightness of elements

Flexible composite connections are more than 3 times lighter than metal ones.

- Material strength

The composite rod has a tensile strength 2 times greater than that of a metal rod.

- Economic expediency

The cost of composite flexible ties is 3 times lower than the cost of metal ones.

- Maximum grip

Composite flexible ties have a sand anchor along the entire length.

How is cladding done with aerated concrete?

Attaching facing bricks to load-bearing walls is one of the most important points, but before you get started, you need to understand the technology as a whole. An important point is the width of the foundation; if brick finishing is planned, it must be wide enough for this work. Usually there are no problems.

Attaching the facing brick to the wall can occur at different distances, it all depends on whether the installation of thermal insulation is planned or not. If there is insulation, then a gap of at least 3 and no more than 5 cm should be left between the aerated concrete blocks and the brick. The insulation should be moisture-resistant, for example, polystyrene foam or similar materials are suitable. Ventilation holes will need to be left in the walls. For finishing, either M-150 ceramic brick or finishing brick is used, the layer is laid in one brick, the installation method is similar to laying walls.

The facing brick can be attached to the insulation closely. If insulation is not planned, then the brick should not be pressed against aerated concrete, otherwise both materials will quickly collapse, since they have different indicators, and there should be an air gap between them.

Main types and markings of flexible connections

Flexible connections may vary by type of use:

- For perpendicularly adjacent internal walls. They have the form of a perforated strip, attached in a bent state to the load-bearing wall and laid in the inter-row spaces of the masonry of the adjacent wall. They are made primarily of stainless steel, since the specific nature of internal operation does not threaten the formation of cold bridges.

- For three-layer walls with insulation and an outer cladding layer. These are the anchor rods in question made of polymer materials with a sand-coated coating.

Marking of flexible connections fully reflects the parameters of the rod:

BPA - 300-6-2P

- where BPA is basalt-sand reinforcement.

- 300 is the length of the anchor rod.

- 6 - diameter.

- 2P - 2 sand anchors.

Sometimes the marking directly indicates the type of material of the load-bearing walls for which the anchor is intended, for example:

SPA -250-6-aerated concrete.

- SPA - fiberglass fittings.

- 250 is the length of the rod.

- 6 - diameter.

- Aerated concrete is a load-bearing wall material. The indication of the material usually indicates the presence of a plastic sleeve at one end, installed like a dowel into a load-bearing wall. Aerated concrete is a rather soft material, and conventional installation methods are not suitable for it.

Methods of fastening facing bricks

Screws are often used to fasten facing bricks, as this is the simplest and most inexpensive way to fix materials. Buy the longest wood screws on the market. The advantage of this method is the speed and reliability of the connection.

If the wall has a sufficiently large area, the use of additional fastenings is necessary, otherwise the foundation may fail or the wall itself may deform.

The use of mesh or rods every 3-5 rows in bandaging is mandatory in any case!

The use of long screws is perhaps the simplest and cheapest option for fastening to foam concrete

Is it necessary to reinforce the openings?

Aerated concrete is a rather fragile material; When working with openings, the fastening of facing bricks must be done in a special way, since they require reinforcement. If this is not done, the cladding will crack over time; to prevent this during construction, a small metal rod with a diameter of 5 mm is placed in the seams between the facing bricks. The distance may vary depending on the width of the masonry used. The elements are connected through spot welding and the use of a profiled rod with the same cross-section. It is important that after installing the rod, the seam is sealed tightly.

Fastening facing bricks to the wall can be done using metal corners, which are attached to anchors or self-tapping screws designed for aerated concrete. In order to make it possible to lay the element, special consoles are attached to the foam blocks. After such framing, stirrups are placed above the window and door openings to create a frame of the necessary rigidity. This is the most modern method; previously a wide concrete beam was used, which was installed above the opening.

Attaching a metal corner for rigidity

Fastening with pins

Quite often, facing bricks are fastened to aerated concrete using reinforcement pins. They need to be installed every 5 rows of brickwork.

Pin mounting

You can do the reinforcement more often, but it is not recommended to do it less often; the pins should be 1 meter apart from each other. In addition, metal rods are laid between the blocks, which should protrude 10 cm from the blocks.

Fastening facing bricks into aerated concrete using reinforcing pins should begin with the first row of bricks. Make a hole with a small drill, then drive in the ribbed reinforcement.

To make the structure hold up better, we make a slight horizontal slope. After this, the next rows are overlapped and thus create a reliable harness of reinforcement. This method is inexpensive but requires a lot of physical effort.

Flexible connections for facing bricks from TM Bever

Facing brick or clinker brick is a high-quality and reliable material that is used for cladding buildings, houses, garages and other types of structures. In terms of its characteristics, not many materials for exterior finishing can be compared to it. Walls built from the above types of bricks can last a very long time. But for such flawless operation of the brick, appropriate support from related materials is required. One such material is flexible stainless steel connections from the Bever brand.

Advantages of flexible connections from TM Bever

The problem of reliable connection of brick-lined walls arose quite a long time ago, when the popularity of brick-clad walls reached its apogee. Due to the great demand for such products, the Bever TM was founded in Germany, which specializes in the production of flexible connections for well masonry.

The company has its own production and testing laboratory, on the basis of which manufactured products are tested, and new options for flexible connections are being developed.

Having won the trust and respect of German consumers, the company began to actively explore new markets, which also included Ukraine. Thanks to excellent performance and mechanical properties that meet strict German standards, Bever TM products easily increase their army of admirers in our country.

Thus, the first confident steps are being taken in the confrontation with the traditional material - masonry mesh, which, by inertia, is used for this type of masonry.

Assortment of flexible connections TM Bever

The market for materials for the construction of external load-bearing walls is very large today. But the company’s specialists have developed flexible connections for various types of bases for connection with clinker or facing bricks. We offer a brief overview of the main items from the product line.

- Flexible connection, type L

- wave is used for masonry with the principle of anchoring seam to seam, or, in simple terms, when the masonry seams coincide. This is the simplest type of anchor from the line of flexible ties; it can be 3 or 4 millimeters in diameter. Consumption depends on the size of the air gap and ranges from 5 to 9 pieces per 1 m2. - A universal and universal plus

is flexible connections that can be used in standard or thin joints (for example, aerated concrete). Universal communication is established with an air gap of up to 170 millimeters. Universal plus if the distance is up to 200 millimeters. Consumption from 5 to 9 pcs. per 1 m2. - GB - wave

, is an anchor that is used to connect brick and aerated concrete. It comes complete with a special dowel designed for such a base. Available in diameter 4 mm. Consumption from 5 to 9 pcs. per 1 m2. - WK – wave

, flexible connection designed for connection to a wooden base. Installs using a screw-in adapter. Consumption is about 5 or 9 pieces per 1 m2. Can be produced with a diameter of 3 or 4 mm. - To fasten various types of insulation,

Iso Clip clamps with a diameter of 60 millimeters are used.

Using flexible links

Another reliable way to attach facing bricks to aerated concrete walls is to use flexible connections. There are different options and manufacturers. There are several types of these materials: fiberglass, basalt plastic. True, their cost ranges from 10 to 60 rubles. per piece, and it is not always possible to purchase.

The strength of flexible connections is one of the key characteristics that is looked at when choosing such consumables. Craftsmen are aware of the fact that the street part of the wall, under the influence of moisture and temperature changes, can change size and deform, “walking” relative to the stationary load-bearing masonry. Strong balsat fibers allow the outer cladding to change size and move without creating mechanical stress in the wall itself.

Connections from Armplast

The flexible connection is a rod made of basalt plastic with a sand coating. The sand coating serves as anchors when connecting the walls of concrete panels. Sand anchors provide adhesion to mortar and also protect against corrosion in alkaline concrete environments.

The use of balsat rods for masonry significantly increases the service life of the structure.

- Basalt flexible connections from the Armplast company have a number of advantages:

- Low level of thermal conductivity;

- High levels of flexibility and strength;

- Not subject to corrosion or any other negative effects in an alkaline cement environment;

- Not subject to deformation.

Company website https://arm-plast.ru

Options from Glen

If you are going to carry out work on cladding the facade with clinker bricks later, then there is no need to lay flexible connections during the construction of the load-bearing wall, but use special flexible connections for working on the finished base.

This basalt flexible connection GALEN 6-AGERATED CONCRETE is intended for installation in a load-bearing base made of a material with increased porosity: aerated concrete blocks or foam concrete blocks

Glen connection

Material: basalt plastic

- Diameter – 6 mm;

- Minimum anchoring depth – 90 mm;

- Tensile modulus of elasticity - 51000 MPa;

- Modulus of elasticity in compression - 30,000 MPa;

- Breaking tensile stress, not less than 1000 MPa;

- Breaking stress during bending - not less than 1000 MPa;

- The pullout force value, not less than N for aerated concrete D400 - not less than 2500 N; for aerated concrete D500 – no less than 3000 N; for aerated concrete D600 - no less than 4000 N.

- Relative deformation at break - not less than 3%;

- Thermal conductivity coefficient is 0.46 W/m*0С.

- Consumption: depending on the distance between the walls (5-9 pcs/m2). **See below for flexible connection consumption calculation table.

- To fix the thermal insulation, additional thermal insulation clamps are purchased

- Length options: 180 – 400 mm.

Video:

Flexible connection ZV-Welle

The flexible connection ZV-Welle is made of stainless steel and is intended for connecting facing brickwork and a load-bearing wall made of dense building material, such as concrete or solid building brick, and setting a ventilation gap between them.

Flexible connection Bever ZV-Welle

The flexible Bever ZV-Welle connection is used when a load-bearing structure made of dense material has already been erected and it is not possible to use a less expensive flexible connection for installation in the seams of the load-bearing masonry. When using this flexible connection for porous bases (aerated concrete, foam block) only for buildings with low height (up to 4 meters), in other cases for porous bases use the Bever PB 10 Flexible Connection with an enlarged capsule. The Bever ZV Welle flexible tie is supplied with a stainless steel spacer and tie element and a nylon dowel.

Flexible connection Bever ZV-Welle

It is installed as follows: first, a hole with a diameter of 8 mm and a depth of 60 mm is drilled in the load-bearing wall. Then the dowel is driven in. Then, using a special casing element (found in each package) and a hammer, a flexible connection spacer element is installed into the installed dowel. Thus, in double brickwork systems (the inner layer is a load-bearing layer made of dense monolithic concrete or solid building bricks and the outer layer is made of facing bricks), the flexible Bever ZV-Welle connection is used in the sequential construction of double brickwork walls (first the load-bearing base is built, then the facing masonry).

- Material: stainless steel (link) and polyamide (dowel).

- Depth of penetration into the seam of the load-bearing wall: 50 mm.

- Depth of penetration into the facing masonry seam: 50 mm.

- Consumption: depending on the width of the ventilation gap (5-9 pcs/m2).

- To fix the thermal insulation, Iso Clip fasteners are additionally purchased.

- Length options: 160 – 320 mm.

Recommendations for use

Using, for example, connections, the facing brick is attached to the load-bearing wall; for this, it is necessary to select the right products that must meet the following requirements:

- The products are applicable if the house is already ready, they can be inserted by drilling holes in the wall at any time.

- One of the ends of the anchor should have a wavy profile, the other should have a shape that will meet your needs, for example, for attaching a plate.

- If the seams are tight, you will need an anchor with a curved end.

- With a spiral tip are used for driving into the material.

- If a dowel is used, screw-tip anchors are required.

- Preference should be given to stainless materials, for example galvanized.

- The diameter of the product should not be more than 4-5 mm.

- In order to secure the anchor, the load-bearing wall is drilled, plastic dowels are inserted into it, and then the connection itself is installed.

Fastening facing bricks with ties is the simplest and most affordable method. The anchors should be positioned in such a way that there are no more than five of them per square meter of wall; they should be placed in a checkerboard pattern: the most convenient is 50 cm horizontally and 40 cm vertically.

If it is necessary to create a frame for openings, the step is 30 cm; in this case, the most durable fastening of facing bricks and aerated concrete occurs, without reducing the load-bearing capacity of the wall. If the distance is measured from the corner of the building, you should not deviate from them by less than 150 mm; ideally, the deviation should be 250.

What are flexible connections for facing bricks and aerated concrete? fastening technology

At the same time, it cannot be used as the main material, which creates certain difficulties when laying it on an insulated wall with the formation of a ventilation gap.

There is a need for a mechanical connection of the facing layer, otherwise there will simply be a free-standing half-brick wall.

note

If construction is carried out without external insulation, the outer layer is bandaged with interlocking bricks, periodically laid through a certain number of rows.

The situation with an insulated wall is more complicated.

The design of the bundle in such cases is a rod passing through the insulation into the wall, the other end of which is laid between the rows of cladding.

Flexible materials: What is flexible brick and how to use it?

Before you start installing flexible connections (which means before you start facing the house with bricks), you should decide on their size and quantity.

L = 90 T 40 90= 220 T

- where L is the length of the anchor.

- T is the thickness of the insulation.

- 90 and 40 are the depth of anchoring (filling) and the size of the ventilation gap, respectively. With an insulation thickness of 50 mm, anchors 270 mm long will be required.

The number of elements can be found in the design documentation, but if you do not have access to it (for example, at the time of purchase), you can simply calculate the area of the walls and purchase material with some reserve.

The procedure for installing flexible connections in aerated concrete walls is as follows:

- According to the established pattern, the centers of the holes are marked, corresponding in height to the inter-row spaces of the facing brick.

- Using a drill or drill bit from a hammer drill with a diameter of 10 mm, make a hole with a depth of at least 90 mm (usually 100 mm).

- Dust from the hole should be removed using a special blower supplied with the set of flexible fittings along with a key for screwing in the anchors.

- The anchor is inserted into the hole along the entire length of the sleeve and screwed with a special key until it stops.

- The insulation is pressed using a plastic retaining washer.

- The free end of the flexible connection is laid between the rows of facing bricks.

- Around door or window openings, at parapets and expansion joints, as well as at the corners of the building, additional flexible connections are installed in increments of 300 mm. The distance to the opening vertically is 160 mm, horizontally - 120 mm.

IMPORTANT!

Installation of insulation can be done before laying flexible connections or after that.

In the first case, it becomes possible to more firmly connect the anchor to the wall and seal the holes with mortar. At the same time, installation of insulation is complicated by the need to pierce the material with rods protruding from the wall, which can cause distortion or the formation of cracks.

The second option is simpler, but requires careful selection of a drill to install the anchors into the wall as tightly as possible, since sealing the connection with mortar in this case is very problematic.

When constructing walls with non-vapor-permeable insulation (foam plastic, polyurethane foam) with simultaneous cladding, the recommended sequence of actions changes:

- A flexible connection is established.

- The outer facing layer is erected to the height of installation of the next anchor.

- Insulation is being installed.

- The main wall is being laid.

- The next anchor is installed.

- The process then continues in the same order.

This technique is used due to the absence of a ventilation gap, which allows you to simultaneously build all layers of the wall.

If flexible connections are installed in walls with a ventilation gap, it is also recommended to carry out the masonry ahead of the facing layer:

- A connection is established.

- The outer wall is built up to the level of the next anchor.

- An internal wall is built up to the level of the next anchor.

- Insulation is installed between them.

- A flexible connection is laid, the insulation is pressed against the load-bearing wall using a locking washer.

- The process repeats again.

Application of masonry mesh

Fastening facing bricks to a load-bearing wall is often done using a masonry mesh. This is a fairly old but reliable method. The mesh is inexpensive and does not require complicated installation, but it must be laid at the time of construction of the aerated concrete wall; it will not be possible to attach the mesh to the finished structure. The mesh is needed so that when the building shrinks, the load is distributed evenly and cracks do not appear on the facade. You can use a metal product or galvanized mesh.

Attaching the mesh to the foam block

An option for attaching the mesh to the wall using pieces of cut mounting tape and wood screws

Attaching facing bricks to the walls using a mesh should occur every three rows. If a masonry of 2 blocks is used, then you can lay a grid every 4 rows. If not very strong blocks are used, more frequent laying of the mesh is acceptable, but in no case less frequent. It is necessary to reinforce the row from scratch: this will help firmly secure the cladding and avoid damage in the future.

Another option for attaching the construction mesh

This type of fastening for facing bricks can be made of different materials, for example, steel, fiberglass. When choosing a mesh, you need to pay attention to its rigidity; for example, fiberglass is not suitable for areas of the wall that are subject to heavy loads. Metal mesh is considered the most reliable; it can be used for any type of building.

Steel springs well, is not afraid of strong physical impacts, is tensile strength, and is lightweight and does not overload the structure. This is one of the simplest and most practical fastenings for facing bricks. The metal mesh is sharp, so there is a high risk of injury. Basalt in this regard is much safer, moreover, it does not rust, and can withstand the same loads.

Fastening a wall made of facing bricks to aerated concrete using a mesh has the following features:

- Withstands loads up to 50 kN/m.

- Has high strength.

- The small mass of the product does not act on the structure as an additional load.

- It can stretch, so it has a certain plasticity.

- If you use a metal mesh, cold bridges may form inside the walls; the basalt option eliminates this problem.

- It is worth noting that the basalt mesh is stronger in tension.

- Not afraid of environmental influences. If the mesh is made of basalt or stainless steel, ordinary steel can oxidize under the influence of moisture and oxygen, which causes rust to appear and the product loses its quality over time.

Conclusion: fastening facing bricks to aerated concrete is possible in a variety of ways, the choice of which depends not only on the cost of the products, but also on the stage of construction.

Video:

Video:

Video:

Rules for cladding the walls of a house made of aerated concrete with bricks

Aerated concrete is a building material that is becoming increasingly relevant in the construction of residential premises. It became so popular due to its increased heat capacity, low weight and the absence of the need to pour a powerful foundation. However, the material is porous and afraid of moisture, so to protect against the negative effects of the environment, facing materials should be used. Cladding a house made of aerated concrete with brick is a more suitable method for those who have not yet chosen the type of finishing for the facade.

- Pros and cons of aerated concrete walls lined with bricks

- Methods of facing walls with bricks

- Close to the wall

- With air gap without ventilation

- Three-layer wall with ventilated space

- Insulation of gas blocks with facing brick lining

- Cladding technology

- During the construction of a new building

- Fastening aerated concrete and brick when cladding a new building

- Cladding the external walls of an existing building

- Recommendations for cladding

- Laying the foundation

- Brick selection

- Brick laying

How to lay facing bricks above a window

When facing a built house with clinker bricks, the question often arises of how to get around the window and connect to the window since there is a gap between the wall and the masonry. Of course, there are sophisticated ready-made solutions for fixing bricks around a window, but I take into account their cost and the number of windows turns out to be expensive.

It was easy to solve the issue of connecting the window and the brickwork using a metal corner 120x120x9 mm and a custom-made bent sheet of metal. This method allowed us to immediately obtain the finished result. Perhaps this turned out to be the simplest solution for installing an upper slope to frame a window when facing an already built house with brick

The result was a ready-made street upper slope, which made it possible to hide a corner to close the gap in the brickwork

Installing a corner above a window, installing a slope simultaneously with brickwork

Curved street slope for connecting to a window

If you have your own ways of covering a window opening, share it in the comments. With that I say goodbye, good luck with the construction!

Video:

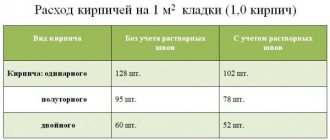

Dimensions of reinforcing products for masonry

Different types of mesh are used for different types of masonry. For example, basalt allows you to connect two-layer masonry. In this case, the walls can be made of foam blocks, but they are additionally lined with brick. Before laying the material, it is necessary to calculate the amount that will be required to complete the reinforced layer efficiently.

It is necessary to cut the material, correlating its dimensions with the parameters of the walls on which the mesh must be laid. To cut it, special metal scissors are used. Next, you need to decide on the presence or absence of a thermal insulation layer.

Reinforcement of masonry from aerated concrete blocks should be done by two people. The joints of the material should be laid with an overlap equal to 3-4 cells. When the reinforcing material is already fixed on the wall, gas blocks are placed on top of it. When performing work, do not allow gross displacement or deformation of the material. As a result, load-bearing capacities are reduced.

Reinforcement of aerated concrete, foam concrete or cinder blocks must be made with a high-quality product manufactured in accordance with the standard GOST RF 23279-85. It regulates only the quality of welded mesh made of metal. The quality of polymers containing basalt and fiberglass fibers must comply with STO 29424809.

In order to properly reinforce walls made of aerated concrete, you should decide on the size of the cells of the product. The requirements of GOST 23279 regulate the production of metal masonry products of the following sizes:

- 10x10 mm;

- 16x16 mm;

- 25x12.5 mm;

- 25x25 mm;

- 75x25 mm;

- 75x50 mm.

To make meshes of this size, you should use wire of class Vr-1 and V-1 in accordance with GOST 6727. When buying a metal product for aerated concrete, it is important to pay attention to the weight of 1 m² of material. Its differences from the reference weight of more than 5% are not allowed. If the difference is more than 5%, it means that the mesh was made from wire that does not meet the requirements of the standard.