Fillers for lightweight concrete For the production of lightweight concrete, porous aggregates are used, which can be organic and inorganic, and ordinary and quick-hardening Portland cement or Portland slag cement are used as a binder. Just like dense, porous aggregates are divided into small and large. Coarse aggregate such as porous gravel or porous crushed stone have a particle size from 5 to 40 mm and are divided into fractions: 5-10, 10-20 and 20-40 mm. Fine porous aggregate has a particle size of less than 5 mm, such as porous sand. Fine aggregate , in particular porous sand, is divided into two fractions: from 1.2 to 5 mm is coarse sand, and less than 1.2 mm is fine sand.

Porous aggregates also divided into grades according to density, which can be from 250 to 1100 kg/cub.m.

Organic fillers.

Organic aggregates for concrete

When constructing thermal insulation structures and some structural and thermal insulation structures, organic aggregates for concrete . Such fillers can be wood, cotton, firewood and polystyrene foam granules for the preparation of styrofoam concrete .

Types of lightweight concrete and their application

In private and professional construction the following are used:

Porous concrete. Perlite concrete, expanded clay concrete, agloporite concrete. Cellular concrete. Aerated concrete and foam concrete. Concrete mixtures with organic aggregates. Bonfire concrete, polystyrene concrete and wood concrete.

Lightweight concrete with porous aggregates

They are widely used in private construction, including as the basis for the construction of one-story buildings.

Expanded clay concrete

A building material containing cement, sand and filler (expanded clay). Basic proportions:

1 part cement; 2 parts fine-grained filler; 3 parts coarse-grained filler.

Air-entraining additives (saponified tree resin) must be added to the mixture.

Expanded clay is a porous material, with a specific volumetric gravity of 300-600 kilograms per cubic meter. A distinctive feature is the ability to strongly absorb and store water. Specifics of preparing concrete mixture:

1 part cement, 1 part water and 2 parts sand are poured into a container or concrete mixer, after which the ingredients are thoroughly mixed. The mixture is supplemented with expanded clay - 3 parts of coarse filler.

During the re-mixing process, the finished solution should be wet. If expanded clay absorbs a lot of water, then it is necessary to additionally pour in liquid in portions of 5-7 liters without stopping mixing until the granules of the substance are covered with a cement “glaze” on all sides.

The above scheme is used to create brick blocks with a mass of 15-20 kilograms. If a screed is made on the basis of expanded clay concrete, then you need to add significantly more water so that the concrete mixture, when mixed, resembles a “sour cream-like” essence. The poured floor is isolated from rigid structures and other types of concrete using multilayer polyethylene film.

Currently reading: Concrete M100: main characteristics and composition

Advantages of the material:

High speed of construction work; Effective interaction with various finishing materials; No need to pour a heavy foundation for construction and expanded clay concrete blocks; Low coefficients of water absorption and thermal conductivity after hardening of the mixture; Lack of mold and low cost of blocks compared to similar materials of the same strength.

Perlite concrete

The density of such concrete mixtures in the hardened state is 600-1200 kilograms per cubic meter. The basis of the material is expanded perlite, which is a finely dispersed material obtained from crushed volcanic rocks by direct firing.

Features of perlite concrete:

Lightness and fire resistance; Easy to use and breathable; Environmentally friendly; High degree of water absorption.

In private construction, perlite concrete is used to lay out fireplaces, create “warm” plaster, and as a basis for decorative work.

Agloporite concrete

The basis of the concrete mixture is a combination of processed clay mixture and ash-cereal waste from coal enrichment.

The products have a low compressive strength class - B2.5-B7.5. In a dry state, the relative density is 1000-1500 kilograms per cubic meter. Thermal conductivity coefficient is 0.3-0.6.

Agloporite concrete is used in the construction of internal walls of low-rise structures or the foundations of outbuildings.

Concrete with lightweight organic aggregates

The filler of this type of concrete is a variety of organic matter.

Arbolit

Shredded wood in a splinter-like state is used as a filler. Mineralizer - calcium chloride, liquid glass, aluminum sulfate or other components that neutralize the negative effects of organic matter on cement.

The relative density of wood concrete is 400-850 kilograms per cubic meter. The hardened mixture has high bending strength, absorbs sounds, does not burn and is convenient for any type of processing. Other parameters:

Water absorption - 50-80 percent when mixing; Frost resistance - 40-50 freezing/thawing cycles; Shrinkage - 0.4-0.5 percent; Elasticity - 1000-2300 MPa.

Arbolite is used in the construction of low-rise buildings for commercial and residential purposes, and the creation of external enclosing structures.

Kostrobeton

The organic filler of the concrete mixture is woody parts of the stems of cultivated hemp. A mandatory additive is calcium chloride, alumina sulfate or lime, which helps to avoid deterioration of the adhesive properties of cement.

Bonfire concrete is not subject to rotting and is unattractive to rodents and insects. Volumetric mass – 400-700 kilograms per cubic meter. The product has low thermal conductivity and sound conductivity, and is easy to machine. It is used for secondary work in private construction - thermal and sound insulation, internal partitions of residential premises.

Polystyrene concrete

A common composite material. Porous filler - foamed polystyrene granules, which are the main product of polymerization of vinylbenzenes.

Advantages:

Good sound insulation and heat insulation properties, comparable to the identical characteristics of mineral wool, foam glass and polystyrene. Cost-effectiveness and low load on the foundation. Environmental friendliness and low water absorption. High coefficient of frost resistance. Minimum level of shrinkage and balanced adhesion to the plaster mixture. Low vapor permeability.

The relative density of polystyrene concrete is 200-600 kilograms per cubic meter.

Scope of use:

Monolithic and classic private housing construction. Filling the space inside critical and secondary structures - load-bearing walls, fences, concrete grillages. Alternative insulation of premises. Comprehensive measures to reduce the load weight on various structures - swimming pools, profiled decking, watercraft.

Cellular concrete

The basis of concrete mixtures of this type is siliceous aggregates, which form spherical or oval voids as a result of reactions.

Foam concrete

This type of concrete mixture is created on the basis of cement-sand mortar, water and foaming agent. The latter forms small, medium and large pores, acting as a substitute for classical aggregates.

Depending on the specific composition, the lightweight type of foam concrete can be thermal insulating, structural-thermal insulating, or structural. The main feature of the material is its long-term strength gain. It reaches nominal parameters within 20-40 days after filling (depending on climatic conditions) and over the course of 2-3 years its characteristics gradually improve.

The relative strength of foam concrete is 10-90 kilograms per square centimeter. The material is used in monolithic and classical construction of houses, as complex thermal and sound insulation of ceilings, floors, walls, and roofs. Thanks to simple production technology, foam concrete products are cheaper than conventional concrete. Low weight and ease of processing make it possible not only to reduce transportation costs, but also to use the products in any type of construction.

Disadvantages of foam concrete:

bends, gives significant shrinkage, mechanically fragile.

Aerated concrete

Classic cellular concrete is made from quartz sand, cement and gas-forming agents.

The gas-forming agent is finely dispersed aluminum. Once it is combined with lime mortar or highly alkaline cement, a chemical reaction is formed to form calcium aluminates and hydrogen gas. The latter foams the solution, creates closed spores of spherical or oval shape communicating with each other, reaching a diameter of 4 mm.

Gas-forming additives are represented by aluminum pastes and suspensions, since in dry bulk form the substance generates a lot of dust.

The scope of application of aerated concrete is commercial, residential and industrial construction. The material is used to make wall partition blocks, internal floor slabs, lintels, including reinforced ones. The advantages and disadvantages of the material are identical to foam concrete.

Inorganic fillers.

Porous aggregates of inorganic origin are divided into natural and artificial. Natural aggregates are obtained by simple sieving or sieving with crushing of rocks such as limestone, tuff, pumice.

Artificial porous aggregates are products made from mineral raw materials that have been subjected to heat treatment, which in turn are divided into specially manufactured and by-products of the fuel and metallurgical industries.

Types of lightweight concrete

The weight of concrete is reduced due to the formation of pores and the use of lightweight aggregates instead of traditional gravel, and sometimes sand. Sometimes pores are formed when various processes are used. Depending on the method of production, lightweight concrete is divided into three groups:

- Cellular or porous concrete. It is obtained by a mixture of binder, water, sand (some brands do not contain sand) and additives that form foam or promote gas formation. When using foam, foam concrete is obtained; when using gas-forming additives, aerated concrete is obtained. If the majority of the binder in aerated concrete is lime, gas silicate is obtained. The main difference between cellular materials is the absence of coarse aggregate.

Cellular concrete is characterized by small pores and a uniform structure - Ordinary lightweight concrete. It is obtained from a mixture of binder, coarse and fine aggregate, and water. They differ from ordinary concrete by the presence of light porous aggregate instead of crushed stone. Almost all the voids between the filler particles are filled; there are few air cavities in such material - no more than 6%.

In ordinary lightweight concrete, lightweight aggregates are used instead of crushed stone - Large-porous lightweight concrete. Instead of sand and crushed stone, large porous aggregate is used, which is mixed with a binder diluted with water. There is no sand, which is why this material is also called sandless concrete. Fragments of filler stick together only in those places where they touch, leaving voids unfilled. Air voids can be up to 25%.

There is no sand in coarse concrete and aggregate fragments are connected only at points of contact

But each group can have many varieties and compositions. Different aggregates and different binders are used. Traditionally, cements are used as a binder (Portland cement materials have better strength characteristics). The second most popular binder is lime; gypsum is used less frequently. Sometimes they can use mixtures of binders and use liquid glass.

Hardening technologies

There are three technologies for producing cellular concrete:

- Natural hardening. The composition poured into the molds is left in the formwork for an indefinite period of time. After a certain time (depending on the composition and type), the formwork is removed. This technology produces the cheapest material, but its characteristics are at the very bottom of the acceptable range, and sometimes even lower.

- Processing in heat and humidity chambers at atmospheric pressure. Quality indicators are higher, but costs and prices are also higher.

- Autoclave curing. The material acquires excellent characteristics, but is also more expensive due to expensive equipment and energy costs (to maintain temperature and pressure in the chamber).

Plant for the production of autoclaved aerated concrete

Fillers

Based on their origin, aggregates for lightweight concrete can be divided into two groups: natural (natural) and artificial. Natural ones are obtained by grinding natural porous materials: shell rock, pumice, lava, turf, limestone, etc. The best of them are pumice and volcanic turf. Their pore structure is closed, which reduces the amount of moisture absorbed by the material.

Fillers can be different not only in “origin” but also in size, and often also in shape

Artificial fillers for lightweight concrete are waste from certain technological processes (slag) or materials specially created from natural components (expanded clay, vermiculite, perlite, etc.) as well as some chemical fillers (polystyrene).

Inorganic aggregates of artificial origin.

Expanded clay gravel.

This is a specially manufactured aggregate , which is obtained after firing granular intumescent clay. This filler has two positive characteristics at once: it is light and durable at the same time, its density can vary from 250 to 800 kg/cub.m.

After firing, the granules are covered with a durable shell, which gives it high strength. In cross section, expanded clay granules have a porous structure, which gives them lightness. Thanks to these two important characteristics, expanded clay gravel is the most common aggregate for porous concrete .

In addition to expanded clay itself, expanded clay sand is also used as a filler, which is obtained at the time of preparation of expanded clay gravel, but in small quantities and has a grain size of up to 5 mm.

Expanded clay sand can also be obtained by firing granules in suspension, or by crushing the expanded clay gravel itself.

Slag pumice.

This is also a specially manufactured filler , which is obtained after sharp cooling of molten metallurgical blast furnace slag, which subsequently leads to their swelling. After crushing and dispersing slag pumice, porous crushed stone is obtained.

In those areas where the metallurgical industry is well developed, the production of slag pumice is common, since its production is much cheaper than the production of expanded clay.

Expanded perlite.

Expanded perlite

Perlites, as well as obsidians, are water-containing volcanic glassy rocks, which, after firing at temperatures from 950 to 1200 ° C, increase in volume by approximately 10-20 times due to the release of water, after which expanded perlite is obtained. .

Expanded perlite is used to produce not only lightweight concrete, but also thermal insulation materials.

Expanded vermiculite.

According to the production method and application, expanded vermiculite is similar to the previous filler , only vermiculite is obtained by firing water-containing micas.

Metallurgical granulated slag.

This aggregate is a by-product of the metallurgical industry, which is formed through metallurgical processes in production and looks like sand with large grains of about 5-7 mm, and some can reach up to 10 mm.

Fuel waste and slag.

These are porous materials in the form of small pieces that were obtained by sintering inorganic substances contained in coal. Fuel slag is also only a by-product that is obtained in the furnace as a by-product when burning solid fuels, such as: hard and brown coal, anthracite, peat, shale, wood and others.

After receiving the slag, it is subjected to light crushing and sieving to remove impurities harmful to concrete , such as unburned coal.

Ash is also used to prepare ash and alumina gravel.

Lightweight concrete with porous aggregates

Concrete is called lightweight if its density does not exceed 1800 kg/cub.m. The basis of such concrete is Portland cement or Portland slag cement.

How strong and dense concrete is depends on its binder and water content, as well as the density of the grain composition and the method used to compact the mixture.

Lightweight concrete with porous aggregates has found wide application in the modern construction industry, so we decided to take a closer look at the characteristics of this material.

Types of lightweight concrete aggregates

Various porous materials serve as concrete fillers, they can be:

- 1. Organic, made from wood chips, polystyrene foam granules, cotton stalks, etc. They are not used very often.

- 2. Inorganic, which, in turn, are divided into:

- - natural, for the production of which it is necessary to partially crush and disperse or only disperse rocks (pumice, volcanic tuff, limestone-shell rocks, etc.);

- - artificial, which are products of heat treatment of mineral raw materials (fuel ash, slag, etc.).

To obtain expanded clay gravel, granules prepared from intumescent clays are fired. The density of this aggregate ranges from 250 to 800 kg/cub.m. At the point where the expanded clay granule breaks, you can see that it has a foam structure.

Thanks to the sintered shell covering the granule, it has high strength. Expanded clay sand is obtained from expanded clay gravel; for this purpose, the method of firing granulated clay in suspension or the crushing method is used.

To obtain slag pumice, you need to quickly cool the molten metallurgical slag, which will lead to swelling. The lump slag pumice must then go through a crushing and dispersion stage, resulting in porous crushed stone.

To obtain expanded perlite, it is necessary to burn water-containing volcanic glassy rocks. When the temperature increases to 950–1200 degrees, water is released, as a result of which the volume of perlite increases ten to twenty times. Lightweight concrete and thermal insulation products are produced from expanded perlite.

Fuel slag can be obtained by sintering and swelling of inorganic impurities that coal contains. The slag is then partially crushed, dispersed and enriched to remove ash, coal residues, etc.

Specifications

Lightweight concrete with porous aggregates has the following properties:

- 1. Durability.

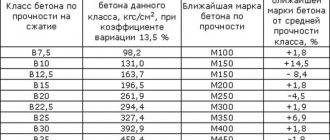

Characterized by strength class. Lightweight concrete, which has a dense structure, is represented by the following classes in terms of compressive strength: B2.5-B40; in terms of axial tensile strength - from B0.8 to B3.2.

Thermal insulating concrete has three classes: B0.35, B0.75 and B1. To obtain lightweight concrete of increased strength, porous aggregate, which has greater strength, is used, and instead of porous sand, dense sand is used.

- 2. Density.

Depending on this indicator, dry lightweight concrete can have grades from D200 to D2000. Lightweight concrete (GOST 25820–83) is divided into three groups:

- — thermal insulation — density up to 500 kg/cub.m;

- — structural and thermal insulation — density from 500 to 1400 kg/cub.m;

- — structural — density from 1400 to 1800 kg/cub.m.

To reduce the density of lightweight concrete, it is necessary to form small closed pores in the cement stone; this can be achieved by adding a little foam or gas-forming substances to it.

- 3. Thermal conductivity.

This indicator is directly influenced by the density of concrete and its moisture content. If the volumetric humidity of lightweight concrete increases by 1%, then its thermal conductivity will increase by 0.016–0.035 W/m*deg. The thermal conductivity of lightweight concrete affects the thickness of the outer wall, which can vary from 20 to 40 centimeters.

- 4. Frost resistance.

External enclosing structures made of lightweight concrete are constantly exposed to sub-zero temperatures, as a result of which they either freeze, then defrost, then moisten, then dry out.

As a result, lightweight concrete should have a certain frost resistance. Depending on this indicator, lightweight concrete with porous aggregates can be of the following grades: from F25 to F500.

For the production process of external walls, as a rule, concrete is suitable that has a frost resistance of 15 to 25 cycles of alternate freezing and thawing.

- 5. Waterproof.

Depending on water resistance, lightweight concrete is divided into classes from W0.2 to W1.2. A high degree of water resistance is characteristic of dense structural lightweight concrete. For example, expanded clay concrete, which has a cement consumption of 300 to 350 kg/cubic meter, is not capable of passing water even at a pressure of 2 MPa.

Thus, thanks to the universal properties of lightweight concrete based on porous aggregates, especially high values of water resistance and frost resistance, the scope of their application is significantly expanding.

This building material is successfully used in the construction of various buildings and structures, as well as in hydraulic engineering.

Stressed reinforced concrete is used to build bridges, and lightweight concrete with a low thermal conductivity coefficient is used for the manufacture of wall panels and panels for floors of heated rooms