Why do you need a vapor barrier?

Vapor barrier material is used for normal moisture circulation indoors. If you ignore the vapor barrier, then moisture in the air can enter the insulation and gradually destroy the material.

If the construction of buildings is carried out from a material that is already insulated, then the vapor barrier will serve as protection against the entry of harmful substances into the premises.

Insulation is a heat-insulating material. Depending on the origin of the feedstock, it is divided into:

What kind of vapor barrier is needed?

- organic thermal insulation - the basis is wood, plants, peat, animal hair;

- inorganic thermal insulation - mineral wool, fiberglass, concrete.

The installation of a vapor barrier layer is carried out to maintain a comfortable temperature inside the house, preventing air from penetrating through the cracks of the building.

When using insulation that absorbs moisture well, you cannot do without a vapor barrier. In its absence, moisture is absorbed into the structure of the insulation and there it turns into water. Over time, the thermal insulation characteristics of the insulating material will decrease. After a certain period, it will be possible to observe the appearance of fungus and mold. The use of a vapor barrier creates a kind of shield between the insulation and the internal air of the apartment.

Correct installation of the vapor barrier will allow the insulation to last a long time and effectively.

Types of vapor barriers

In modern construction, vapor barrier is successfully used to protect organic and inorganic thermal insulation materials. It comes in the following types:

- Film.

- Diffusion membrane.

- Energy saving membrane.

- Roll vapor barrier.

The film is a blind vapor barrier material that retains moisture and does not let it pass through. Due to its low cost and excellent waterproof characteristics, the film is used not only in the construction industry, but also for domestic needs. Films vary in thickness, number of layers, and surface quality. It can be smooth on the outside and rough on the inside. Water always remains on the surface of the film.

Summary table of vapor barrier film properties

Diffusion membrane . This type of vapor barrier material consists of a polymer film and polypropylene and has limited vapor permeability. Water vapor contained in the insulation immediately evaporates.

The energy-saving membrane is resistant to elevated ambient temperatures due to its metallized outer layer. Vapor barrier should be installed in rooms with high humidity and temperature. The material is capable of reflecting infrared radiation.

Rolled vapor barrier allows moisture to pass in two directions. Convenient to use when insulating large surface areas.

The thermal insulation and vapor barrier characteristics of a structure depend on the choice of material. A careful approach to the selection of the necessary products will ensure the comfort and coziness of the premises and will help extend the service life of the entire structure.

Types of materials

The modern vapor barrier market is replete with a variety of materials of various types. Typically, breathable membranes and films are used to vapor barrier a wooden floor. Obviously, there are other materials for creating vapor barriers, for example, liquid rubber, polymer and bitumen mastics, but they are more suitable for roofs, walls, concrete floors and foundations.

Polyethylene film

The use of polyethylene film requires special care, as it breaks easily during installation. This material is available due to its wide distribution. There are two types of polyethylene films used for vapor barriers - non-perforated and perforated, which is associated with the degree of vapor permeability caused by micro-holes in the film. For non-perforated film, this Sd indicator is 40-80 m, while for perforated film it is much higher than Sd – 1-2 m.

It is worth noting that for vapor barrier it is customary to use non-perforated film, while perforated film is used for waterproofing. If you take a closer look at perforated film, then in reality this figure will be slightly lower, which balances the difference between these types of films.

When installing vapor and waterproofing using polyethylene film, a ventilated gap should be provided. As a rule, they use the type of film that costs less.

Relatively recently, another type of polyethylene films with a reflective aluminum layer appeared on the construction markets. The use of this type of film makes it possible to provide a higher level of vapor barrier. This material is usually used in rooms with high levels of humidity and high temperature - bathhouse, sauna, steam room, bathroom, kitchen, swimming pool.

The main disadvantage of all types of polyethylene films is their low strength. Despite being equipped with reinforced mesh, the durability and strength of this material are quite low.

Polypropylene film

Polypropylene film is not only an easy-to-install vapor barrier material, but also has high strength and therefore durability. If we draw an analogy with polyethylene, then propylene is not only more durable, but also more resistant to atmospheric conditions.

Initially, it was made exclusively from propylene, but during operation, the appearance of condensation in the films from the insulation side was noted, which prompted manufacturers to reinforce the film by introducing an additional layer in the form of viscose fibers with cellulose. A distinctive feature of this layer is its ability to absorb and retain a significant amount of moisture, which prevents the formation of droplets. The accumulated moisture gradually dries out as the humidity decreases; this process is determined by the quality of the ventilation.

Laying of such films is carried out with a layer that prevents the formation of condensation, down. In this case, it is necessary to ensure the presence of a ventilation gap between the insulation and the laid polypropylene film.

The main advantage of installing a vapor barrier using polypropylene film is ease of installation, excellent strength and durability, as well as availability and reasonable price.

Diffusion membranes

One of the most expensive materials used to provide high-quality and durable vapor barrier are diffusion membranes, otherwise called “breathable”.

Regulation of the moisture level is carried out by the ability to pass air from both two and one side, so the membranes can be divided into double-sided and single-sided. When laying a one-sided membrane, you must not confuse the side with which it will be laid to the insulation; accordingly, this aspect is not relevant for a double-sided membrane.

The microstructure of the membrane, which is a non-woven material consisting of artificial fibers, provides a high coefficient of vapor permeability. Membranes can be classified by the number of layers - there can be from one to three, and an additional anti-condensation layer can be used, which is responsible for the accumulation of moisture and its subsequent evaporation.

One of the most versatile and popular breathable membranes are multilayer intelligent membranes that are capable of adjusting vapor exchange in accordance with the room temperature and humidity level; they have the qualities of heat, vapor and waterproofing.

Another undeniable advantage of breathable diffusion membranes is the absence of the need to create a gap between the insulation and the membrane, which makes it possible not only to simplify installation work, but also to save space.

The only disadvantage of diffusion membranes is their high cost. But if you pay attention to the simplicity of installation work, the reliability and durability of the vapor barrier, then you can not pay attention to the price, since the main task - protecting the floor from moisture and ensuring reliable and durable operation of the structure will be achieved.

Principles of installing vapor barriers to different surfaces

Manufacturers of vapor barrier films, focusing on consumer desires, produce their products in different directions:

Vapor barrier installation options

- for work on and under the roof;

- on vertical wall surfaces;

- on the floor.

Vapor barriers can be installed on any surface. When using a vapor barrier material on wooden structures, a film with a membrane is used. Polymer or bitumen mastic can be used for any type of surface. It is recommended to install a vapor barrier with a metal outer layer on concrete walls.

Its use will be much more effective if the working side is prepared in advance. Preliminary work depends on the characteristics of the material with which the building is built.

Breathable membranes

When building a wooden house, first, all wooden surfaces are impregnated with special products against insects and harmful bacteria. Only after completing a set of preparatory work are they started to install the vapor barrier layer.

The highest quality material for insulating wooden floors is breathable membranes. The body of the membrane consists of a layer of anti-condensation fibers that absorb and accumulate moisture. There are single-sided and double-sided membranes. In the latter option, moisture is absorbed from both sides at once, so the double-sided breathable membrane can be laid with either side to the floor.

When carrying out a major overhaul, all outdated insulating coatings are dismantled. Surfaces are thoroughly cleaned and impregnated with special disinfectants. Then you can lay the vapor barrier. Concrete surfaces do not require special treatment with special means; they just need to be cleaned.

Installation technology

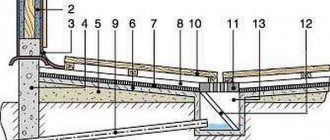

Installation of Izospan V involves a number of preparatory works. In general, the floor pie in a wooden house is the following design:

- rough base;

- wooden logs;

- thermal insulation layer;

- waterproofing;

- finishing floor;

- finishing coating.

You should not violate the technology for installing a wooden floor, because otherwise the structure will turn out to be unreliable. The entire pie should ideally rest on brick or concrete supports, with a small ventilated area between the soil and the wood floor. The vapor barrier should be installed immediately during the construction of the house; there is no need to postpone this stage “for later”.

Vapor barrier will reliably protect against moisture and condensation

Preparations before laying the vapor barrier membrane are as follows. To begin with, all wooden parts of the floor pie are treated with a special protective compound, which will allow the tree to acquire immunity to rot and fungus for the longest possible period. Particular attention should be paid to wooden joists and the rough floor, on which the membrane material will be laid.

Connecting tape (adhesive tape) Izospan FL

Vapor barrier of a wooden or concrete floor consists of three important stages: preparation of the surface before installation, installation of the material and its final fixation. There is no need to confuse the installation of vapor and waterproofing. The second is performed according to a similar algorithm, but its installation should be performed before installing the log.

If you are laying a vapor barrier layer when installing the floor in a newly built building, then the preparatory measures are limited to treating the subfloor joists with a compound that prevents them from rotting. If you are renovating the home where you live, you will have to do a lot more work on preparation.

Vapor barrier is laid on the subfloor joists

To do this, it is necessary to repair the existing screed. Any large cracks and holes in it must be filled with cement mortar. If the screed cannot be repaired, then you need to make it again. If there are small cracks in the screed, then there is no need to fill them with mortar. Immediately apply a waterproofing mixture on top of it, after which you need to wait for it to dry completely.

The vapor barrier of the subfloor is laid along the joists, so there is no need to make markings. Thus, the subfloor design must include insulation, joists and vapor barrier material.

Usually, on the first floor of a wooden house, the floors are laid directly on the ground. As a rule, a rather primitive design is used, which involves laying a subfloor, joists, heat, hydro, vapor barriers, a finished floor and the floor covering itself. The entire structure rests on supporting pillars made of concrete, stone or brick.

The space between the ground and the wooden floor, otherwise called the underground, must be equipped with its own ventilation. As a rule, vapor barrier of the floor in a wooden house must be done during the construction process. Obviously, after long-term operation it is necessary to do a major overhaul, during which it will be necessary to rebuild the vapor barrier, the installation of which must begin with preparation.

When building a new house, there are much fewer problems due to the fact that the treatment of wooden boards with compounds against pests, fungi and rot can be done even before installation. This primarily applies to the subfloor, since it is located in close proximity to the ground. After processing the subfloor, you can begin laying vapor and thermal insulation, and then installing joists.

When installing insulation in the case of a finished wooden floor, proceed as follows. First of all, you will have to remove the covering, disassemble the finished floor and remove the remaining thermal insulation, then check the condition of the joists and subfloor, assessing the condition of the wood.

We suggest you familiarize yourself with what you need to build a bathhouse with your own hands

When laying a vapor barrier, no special skills or special tools are required, you just need to follow a certain procedure. Typically, film materials are used for vapor barriers, one of the most common of which is Izospan.

It should be laid on the supporting frame of the subfloor, at this point it is necessary to ensure that the laying is carried out with an overlap of at least 0.15-0.20 m wide. Galvanized nails can be used as fastening or a construction stapler can be used.

The main advantage of the tape is the creation of a solid coating without joints and cracks

A layer of insulation must be laid on top of the vapor barrier, which can be polystyrene foam, mineral wool, polystyrene foam or other heat-insulating material. It is necessary to ensure a good fit of the insulation to the joists; a layer of vapor barrier must again be laid on top of the insulation, ensuring overlapping laying. Upon completion of the work, the joints should be glued again, after which you can begin installing the finished floor, and then the floor covering.

Vapor barrier installation diagram: 1. Floor 2. Izospan vapor barrier 3. Insulation 4. Counter lath 5. Beam 6. Subfloor 7. Izospan D hydro-vapor barrier

For reliable and durable operation of a wooden floor, it is necessary to properly protect it from the effects of various negative factors. First of all, this relates to high levels of humidity, which is one of the main enemies of wood. Modern advanced technologies, as well as highly effective hydro and vapor barrier materials, make it possible to ensure the longevity of any wooden structure.

When using foil insulation, it should be noted that installation should be done with the metallized side facing up so that heat is reflected into the room. The flooring should not be overlapped, but joint to joint. Upon completion of work, all joints should be taped with aluminum tape.

Work begins with chalking the starting markings, according to the chosen direction of the stripes.

If the material is laid as a flooring, then special fastening screws are used, or the covering is not fixed to the floor at all

| Flooring | Permissible percentage of residual humidity for floors without heating | Permissible percentage of residual humidity for heated floors |

| Laminate, parquet, parquet board | Up to 2% | Up to 1.5% |

| Plastic panels, linoleum | Up to 3.4% | Up to 1.5% |

| Carpet on a moisture-proof basis | Until 3% | Up to 1.5% |

| Jute backed carpet | Up to 2.5% | Up to 1.5% |

When gluing waterproofing coatings to the floor, adhesive mixtures and mastics on a polymer-bitumen basis are used, although most often the sticky layer is already applied to one of the surfaces of the insulate, which significantly reduces the work time. If the manufacturer does not provide an adhesive layer on the coating, then the required area of the floor and the edges of the panel are treated with mastic heated to a temperature 20-25 °C higher than the room temperature, after which the material is laid on the base and rolled out with pressure rollers. The joints of adjacent strips are additionally glued with mastic.

Ruberoid is the most common waterproofing option

When laying panels using the fusing method, you should try to maintain a burner flame temperature of about 145-160 °C, which ensures optimal adhesion of the coating to the base. Deviation from the recommended range by even a few degrees can subsequently lead to detachment. When installing the covering using a gas burner, the unrolled material and the floor are gradually heated, and the canvas itself is fixed to the floor. Upon completion of installation, the joints are heated with a burner and pressed to the base.

Fusing waterproofing

The waterproofing is rolled out along the “circle”, extending 5-7 cm onto the wall.

If during rolling the roll “goes to the side”, forming waves, then it needs to be cut and, having aligned the direction, continue working with an interception of 25 cm along the cutting line.

Experts recommend rolling out at least two layers of waterproofing coating on the floor, preferably changing the direction of placement of the sheets (one layer perpendicular to the other), waiting for the previous one to be completely fixed.

Laying a layer of vapor barrier in a private wooden house is a very simple process. The installation of protective material can be done by hand, the main thing is to follow the correct procedure and take into account all the nuances. The vapor barrier is installed on the subfloor in one layer. All joints that are formed during the process must be covered with a special construction tape, this will ensure a high level of reliability and, accordingly, quality. You can overlap the material.

To make the fastening even more reliable, in addition to tape, experts recommend using nails or a stapler with medium staples. Correctly installing a vapor barrier means following this procedure:

- be sure to prepare the subfloor - to do this, treat all the material with an antiseptic;

- lay the vapor barrier layer - the roll is laid on the frame, individual sheets are mounted overlapping;

- secure the material around the perimeter, carefully close all joints and gaps;

- then we move on to installing insulation;

- after the insulation has been laid, it is better to install another layer of vapor barrier;

- at the end the finishing floor is laid.

Features of installation on various surfaces

Installing a vapor barrier layer is not particularly difficult; you need to carefully carry out the preparatory work and know the main stages of installation.

Laying on the floor

Film is the best option for insulating floors from moisture. On the ground floor, the insulation layer below is protected by a waterproofing device, and closer to the premises - by a roll of insulating film, which is laid overlapping. The joints are taped with metallized tape or tape.

If this is an interfloor or attic floor, then the film is unfolded with the smooth side down to protect against water vapor coming from the slab or floor logs.

Laying vapor barrier on the floor

Ceiling insulation

Used in rooms with high moisture content in the air. These can be bathrooms, showers, baths, saunas. The vapor barrier is securely overlapped and the joints are sealed. The reflective side of the material is directed indoors. Particular attention is paid to the corners of the room, the insulation should be slightly overlapping the walls around the entire perimeter of the room.

Ceiling insulation with vapor barrier

Vertical surfaces

For such surfaces, diffusion membranes are used, which allow air to pass through rather than moisture. The walls must “breathe”, so impermeable film is not used. In case of external work, the product is laid with the smooth side facing the insulation. When installing, the film is slightly stretched.

Wall insulation

Roof mounting

The purpose of the vapor barrier is to protect the rafters from mold and prevent the formation of condensation in the insulating layer. Installation is carried out with an overlap and sealing of the seams. The main condition is to ensure the tightness of the roof in conjunction with the vertical elements of the building.

Roof vapor barrier - device

Basements, balconies and underground structures

Balconies, basements and underground rooms are in contact with cold outside air. For balconies, dense foamed polyethylene is used, the reflective side of which is directed indoors. For other structures, membrane film is used.

Insulation of underground structures

How to distinguish the vapor barrier side

When working with vapor barrier materials, it is necessary to find out which side the product should be laid in relation to the insulation. The location of the vapor barrier will determine the degree of moisture absorption by the insulation and its service life. The instructions for the product indicate how to install it correctly. But what if there are no instructions? In this case, the installation method is determined independently, taking into account the following points:

- if there are sides of different colors on the vapor barrier material, the lighter one is placed next to the insulation;

- the outer side of the product has a rough surface;

- If in doubt, take a glass of hot water and place it on the vapor barrier area. Condensation forms on the waterproof side.

The polyethylene film is laid with either side facing the insulation, while the diffusion film has one smooth surface, which should lie towards the insulation. By preventing the insulating layer from getting wet, it allows moisture to pass through the smooth side without hindrance.

Types of vapor barrier materials

For a high-quality vapor barrier layer, the most modern materials available on the market are currently used. In wooden buildings, the following materials can be used to protect floor coverings from steam:

- polyethylene film;

- polypropylene film;

- diffuse membrane;

- liquid rubber.

We suggest you familiarize yourself with How to choose a suitable bench for a wooden sauna A complete description of the types of wooden benches

Often, when creating a vapor barrier, polyethylene film is used. Speaking about this material, we note that it is produced in several varieties. Most often used:

- film with perforated side;

- film with non-perforated side;

- material with a reflective coating on one side.

When it is necessary to perform high-quality waterproofing work, perforated film is used. The remaining two types are used to create a vapor barrier layer. Polyethylene film has several advantages. Let us identify the two most important ones: low price and availability of material.

This polyethylene film also has its disadvantages. When used indoors, a greenhouse effect is achieved. Therefore, to avoid this, when creating a vapor barrier using this material, a ventilation gap is created. Working with this film, a vapor barrier layer is created without connecting seams.

Another vapor barrier material, polypropylene film, is more modern among the materials in this group. It is highly durable. It contains viscose-cellulose fibers, which prevents the penetration of steam into the floor covering, thereby preventing the formation of condensation.

Polypropylene film reacts quite quickly to changes in the level of humidity in the room, removing all trapped vapors. The main advantages of this material are:

- affordable price;

- ease of installation;

- long service life.

Diffuse membranes

A vapor barrier membrane is a coating that has the ability to allow air to pass through. One of the characteristic features of diffuse membranes is a high degree of vapor permeability. In addition, such material is able to regulate the microclimate in the room based on air temperature. To create a vapor barrier for the floor, both one-sided and two-sided varieties of material can be used.

Liquid rubber

The material is mainly used for waterproofing and vapor barrier work on concrete-based coatings. Bitumen-polymer compounds are the main component in the production of this material. Liquid rubber is characterized by high heat, hydro and vapor barrier properties.

Next comes the installation of vapor barrier. In truth, both layers of the membrane will serve as both a hydro- and vapor barrier. This layer serves as a barrier to the penetration of moisture from the soil into the subsequent insulation. Here you can use Izospan V.

But how to put Izospan? Film from rolls is overlapped by 15-20 centimeters. Vapor barrier installations on floors must be securely connected using adhesive tape or double-sided tape. This helps avoid cracks and gaps where moisture can penetrate.

This film should be attached to the joists using a stapler or galvanized nails.

When laying Izospan vapor barrier, the question arises: which side to lay the insulator on. To prevent condensed moisture from penetrating into the insulation and possibly evaporating over time, you need to lay the material with the smooth side facing it.

Laying insulation

The heat-protective layer is laid between the joists. The thickness of the material should be at least 5 cm, but it is clear that the larger it is, the better. The most commonly used are polystyrene foam or mineral wool.

When laying the material, you must ensure that it fits snugly against the wooden joists and insulator.

This layer, just like the first one, should overlap by 15-20 centimeters. Izospan S is used for this insulation layer.

We recommend that all joints need to be glued. If the manufacturer says that the connection must be made using tape, then there is no need to look for an alternative. This can lead to poor-quality gluing of joints. It is better to spend a little on materials than to later discover that excessive savings have led to moisture and vapors penetrating through the cracks.

It’s good if, when attaching a vapor barrier to the joists or counter-batten, the film sags a little, and there is also a small gap between it and the insulation. This will be the ventilation gap.

In addition, you need to slightly (several centimeters) wrap the film on top and attach it to the wall with adhesive tape.

When laying Izospan, you need to correctly determine which side to lay it towards the insulation. Incorrect placement of the film can lead to it simply not performing its functions.

A finished floor is laid on top of the second insulating layer. Then you can install laminate, parquet or any other floor covering on it.

Having carried out all the work on insulating the floor efficiently, you don’t have to worry that excessive dampness will very soon damage the floor covering.

Advice from installation experts

Some recommendations:

Installation of vapor barrier

- By placing the barrier with its smooth side facing the thermal insulation, the influx of steam and the formation of rotting processes in wooden structures are eliminated;

- when installing a thermal insulation layer outside the building, the insulating layer is placed outside the room;

- the film should fit tightly to the insulating layer;

- When sealing joints, wide adhesive tapes and tapes are used;

- when working with window and door openings, it is necessary to leave a small supply of vapor barrier film;

- The film should be protected from direct sunlight;

- Before starting work, the most critical places are determined - areas of interaction between warm and cold air.

When performing work on installing a vapor barrier film, it is important that the product is attached correctly. Otherwise, the error will lead to ineffective thermal insulation.