What requirements must the building material meet?

Compared to the installation of strip reinforced concrete structures, swimming pools require a higher quality mixture.

Preference should be given to material created in industrial production in compliance with technical standards.

Pool concrete must contain:

- additional pressure of the mass of water on the walls and base of the structure;

- constant exposure to groundwater and water inside the pool;

- sudden daily temperature changes.

At large factories, special attention is paid to the process of creating the mixture itself. For concrete, sand made from large granules about 2 mm without silt and foreign impurities is suitable.

Crushed stone of medium-sized fractions should be made only from strong natural rocks, such as granite or basalt. The cement must be of a grade not lower than M400 with a shelf life of up to 3 months.

Concrete pools - digging a pit, backfilling the drainage layer and pouring

Many of those who live in the private sector or have summer cottages dream of creating an artificial reservoir, but believe that this design is too expensive and labor-intensive. But if you set a goal and carefully follow all the recommendations, then you can carry out the work yourself, although this will actually take a lot of effort and money. We will consider concrete pools, since this option is the cheapest and does not require the involvement of specialists and construction equipment.

You can create pools of absolutely any size and shape from concrete, which is an undoubted advantage

Why concrete

Let's look at why building concrete pools is the most popular option. To better understand the issue, you should consider the main advantages and disadvantages of concrete structures.

| Advantages | Flaws |

| Monolithic construction is much more durable than prefabricated options. | As already noted, work on preparing the pit and pouring the foundation will require a lot of labor. |

| Despite the fairly large amount of work and materials, the price of this solution is much lower than when purchasing composite options. | The concrete bowl of the pool requires constant care and attention, otherwise mold will begin to form on the walls. |

| After hardening, the concrete surface can be finished in almost any way: lined with tiles or mosaics, covered with a decorative protective composition, polyurethane compositions, or covered with a special film. | All work must be carried out in accordance with the technology: the proportions of the components must be observed, and the preparation of the adhesive composition for cladding must be carried out as required by the instructions on the packaging. |

| In terms of strength and wear resistance, concrete is significantly superior to other analogues. A properly poured structure can last for decades. | If the drainage system is not properly planned and installed, the alteration will take a long time and will require reworking the entire structure, which is associated with enormous labor costs. |

| This type of pool can be built both outdoors and indoors. | Any violations of the technological process and the use of low-quality materials lead to cracks and leaks. |

To build a concrete pool with your own hands, you need to have at least minimal skills in the construction field. An inexperienced person is unlikely to be able to make such a structure, so at least one of those involved in the work should be well versed in concrete work.

Of course, it is better to fill using automated methods; doing everything manually is quite difficult

Of course, the question very often arises, which pool is better - concrete or composite? It all depends on your preferences and financial capabilities; the composite eliminates the labor-intensive work of pouring the solution, but the cost of this option is disproportionately higher.

Main stages of work

To understand this process in more detail, we will break it down into stages and look at them in more detail. It is important to remember that each type of work is very important, and violations at any stage can have the most negative consequences.

Preparatory stage

Like any other process, installing a swimming pool requires careful preparation, which includes the following activities:

- First of all, planning is carried out: you need to decide where the structure will be located and what its dimensions will be. It is important to take into account that as the size increases, the volume of work also increases, so you should not plan a huge structure, since the work on its construction may be beyond your strength.

The location of the pool is very important

- Next comes another important stage - planning the location of communications; it is important to clearly know in advance how the water will be supplied and where the drain hole will be located. There are cases when work on laying communications takes up almost the majority of the time, and this is all precisely because of illiterate planning.

In the photo - correct markings are important, so pay appropriate attention to them

- After all the necessary planning work has been carried out, you can begin to calculate the required amount of materials. Naturally, there should always be a reserve, since it is unknown how accurate the calculations were and what the actual thickness of the concrete layer will be, because every extra centimeter means an increase in concrete consumption.

- When determining the depth, it is worth considering that the minimum depth at which an adult can swim comfortably is one and a half meters, and this value should be used as a guide. In addition, a drainage layer is required, so the pit must be 40-50 centimeters larger in depth, width and length.

Advice! Protrusions can be made on one or both sides so that they are located 30-40 centimeters below the water level; they can be used as seats, which significantly increases comfort.

The ledge as a seat will allow you to relax while sitting in the water

Digging a pit and backfilling the drainage layer

When the location has been determined and all marking work has been completed, you can begin constructing the pit; work should be carried out in accordance with the following recommendations:

- If the pool is large, it is best to use the services of an excavator; in other cases, you can do it yourself; this is of course difficult, but quite doable on your own. Another important note: even if you dig with an excavator, finishing and leveling will still have to be done manually.

An excavator cannot make a perfectly level pit, so manual labor will still be needed

- To prevent the walls from crumbling, they must be made with a slight slope (about 5-7 degrees). This is very important, as sliding layers of soil can ruin your work.

- When the hole is ready, you can begin constructing a drainage pad. It is made from sand and crushed stone in the following way: first, 15-20 centimeters of sand are poured and leveled, after which medium or fine-grained crushed stone is filled with the same layer. After this, the surface must be leveled and compacted using a tamper or improvised means.

The drainage pad serves as a kind of buffer between the soil and the pool, preventing its damage when the ground freezes

- The last type of work that should be performed is laying roofing felt in 2-3 layers, and it is laid with an overlap of 20-30 centimeters on the vertical walls.

Concrete works

The most important factor is the composition of the concrete for the pool; its grade should be at least M400.

The solution is prepared as follows:

- It is necessary to take high-quality construction sand without inclusions of soil and silt, crushed stone of medium fractions and M500 cement, preferably it was made no more than 3 months ago.

- To make high-quality concrete for a swimming pool, you must first mix sand and cement in a ratio of 3 parts sand to one part cement. Then water is added until a mass is obtained, the consistency of which resembles sour cream, and lastly 5 parts of crushed stone are added. Also, a reasonable solution would be to use an additive that increases the resistance of concrete to moisture.

Additives increase the properties of ready-made concrete

- Do not forget that high-quality reinforcement is necessary, it is carried out with reinforcement 10-12 mm thick, the elements are connected with wire, and the ends of the rods along the perimeter are bent upward for subsequent connection with a vertical reinforced belt.

- Next, you can start pouring the base, but do not forget that there should be a slight slope at the bottom towards the drain hole.

- After this, you need to wait 6-8 days until the concrete gains strength; if the air temperature is high, the surface must be wetted twice a day.

Advice! In order not to waste time while the concrete hardens, you can start laying all the necessary communications: supply water, drain into a cesspool.

- Next, vertical formwork is installed, a reinforcing belt is laid and pouring is performed. After the concrete has hardened, the formwork is removed and the joints are additionally finished, although it is better to treat the entire surface with a waterproofing compound.

- The last stage is decorative finishing; it is no different from ordinary facing work.

Cladding work can begin no earlier than 14 days after pouring

The main thing to remember is that the grade of concrete for the pool should not be lower than M400. If you need to cut reinforced concrete with diamond wheels or diamond drill holes in concrete, then all seams and joints must be very carefully waterproofed with special compounds or mastics.

Conclusion

The video in this article will clearly show some of the features of the work process. Concrete pools have been and remain the most popular option for creating an artificial reservoir on a personal plot or summer cottage.

masterabetona.ru

What indicators should be used to choose a concrete mixture?

The most important indicators when choosing a concrete mixture:

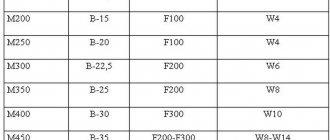

Brand of concrete.

Consists of the letter M and numbers indicating the strength of the finished mixture. M300 speaks of the ability to withstand pressure of 300 MPa without loss of performance characteristics. For the base and walls of the pool, use a grade of concrete not lower than M350.- Waterproof. It is designated by the letter W and a number in the range from 2 to 12. The higher the number, the more resistant the mixture is to water, and the more expensive its price. Given the constant contact with groundwater, it is better to use concrete with a water resistance of W6 and higher.

- Frost resistance. This indicator guarantees the preservation of characteristics over several cycles of freezing and defrosting. It is denoted by the letter F and a number that indicates the guaranteed number of such cycles. In practice, the F50 is guaranteed to last for many years, but it is recommended to play it safe and give preference to a brand no lower than F

- There is another indicator of concrete, which is designated as P with a number from 1 to 5. This marking indicates the mobility of the finished mixture. It is regulated by the amount of water in the finished solution. For ease of installation, it is recommended to give preference to concrete P2 or P3.

Often, instead of marking P1-P6, the water-cement ratio parameter is used. In this case, it is worth purchasing a mixture with an index close to 0.5.

When purchasing a concrete mixture for a swimming pool, you should pay attention to the instructions about the content of plasticizers and air-entraining components in its composition. These connections not only improve the quality of the finished monolithic structure, but also protect it from temperature changes and the negative effects of groundwater.

Composition of the mixture for filling an artificial reservoir

Having decided to mix the concrete mixture for a swimming pool or other artificial reservoir yourself, you need to become more familiar with the optimal composition of the solution. The latter has strict requirements:

- Sand. The suitable granule size is 1.5-2 mm. The presence of impurities - clay, debris and other inclusions - is not allowed.

- Gravel and/or crushed stone. Here you need to give preference to materials made from durable rocks. The size of the fractions should be small - from 1 to 2 cm. Impurities are undesirable.

- Cement. Only fresh material with a maximum shelf life of 3 months is suitable. Acceptable brands are M100-M400, which are selected depending on the stage of work.

- Water. The use of a technical, but pre-cleaned type is allowed. The water should have a soft structure.

When mixing the solution, it is important to maintain the correct proportions of ingredients. For one weight fraction of cement there should be three - sand and five - crushed stone. The volume of water depends on the total mass of the resulting mixture. Hydraulic additives are introduced at the last stage of mixing. Their quantity is 4 kg per 1 m3 of concrete.

Based on materials from the site https://betonchehovstroy.ru/

Several suitable options

Minimum acceptable characteristics of concrete to be purchased for the purpose of constructing a swimming pool bowl:

- brand - M350;

- class - B25;

- frost resistance - F200;

- water resistance - W6;

- the ratio of water to cement is 0.5.

When constructing large bowls, preference is given to higher quality and more expensive brands of concrete. Ideal indicators for capital construction would be M400 with class B30, frost resistance F300 and water resistance not lower than W8.

To reduce the cost, you can use a construction trick. With a base height of 30 cm and low groundwater, the lower part of the bottom can be filled with concrete grade M100 or M150, and the rest with a more expensive composition.

What kind of concrete is needed for a swimming pool?

We set up the formwork and get ready to accept the concrete. To pour a concrete pool bowl, we require class B25 concrete (concrete grade M350). It is necessary to add an air-entraining and plasticizing additive.

It is better to refuse to prepare concrete yourself and order it from a concrete plant. The characteristics of hand-prepared concrete are almost impossible to control, which will certainly affect the quality of the future pool. Be sure to call a concrete pump for the convenience of laying concrete, otherwise the finishing treatment at the pool will not include grinding the shells, but full-fledged plaster.

It is important to fill the pool with concrete in 1 stage (In case of a technical break between pouring the bottom and walls of the bowl for more than 12 hours, lay a Mapei “Idrostop” cord into the joint between the bottom and the walls of the bowl.). In order to avoid the appearance of cold seams. This way we protect the pool from groundwater.

Where and approximately at what cost is it sold?

Ready-made mixtures are purchased from a manufacturer of ready-mixed concrete and cement mortar.

Similar enterprises are found in almost every city with a population of 100 thousand or more.

In larger cities, you can find several manufacturers - this increases natural competition and reduces the final price for the consumer.

The average cost of ready-mixed concrete for swimming pools today is:

- M350 B25 - from 4000 to 6000 per 1 cubic meter. m;

- M400 B30 – from 4150 to 6500 per 1 cubic meter. m.

The price difference is due to the filler used. Cheaper concrete options are supplemented with ordinary quartzite, while the expensive mixture is completed with granite or basalt crushed stone.

Considering the high loads on the final structure, it is not recommended to buy the cheapest option from unverified manufacturers and private carriers.

How to prepare the solution yourself?

Before you save money and start making your own concrete mixture for a swimming pool, it is worth remembering that this process is complicated due to the impossibility of accurately controlling the finished result.

Even if the proportions are observed correctly, there is a risk of obtaining different quality of the mixture during two successive batches . Remains of the mixture in the concrete mixer may be the reason that the first time you get concrete of grade M350, and the next time you get grade M330 or M360.

Concrete mixtures of different brands do not guarantee equal strength around the entire perimeter of the pool bowl.

To create home-made ready-mix concrete grade M400, one 50-kilogram bag of cement will require 4 10-liter buckets of clean mountain sand, 7.5 buckets of granite or quartzite crushed stone.

Add 25 liters of water to the mixture and stir until smooth. The resulting concrete is used both for the bottom of the pool and for its support posts.