Engineering communications are an integral attribute of the bathroom. They make the room functional and provide the opportunity to take hygiene procedures. However, even in modern designs, water supply and sewerage networks are often far from aesthetics and violate the harmony of the interior. To hide pipe structures and make them completely invisible, you can use several methods. One of them is the construction of a box in the bathroom from plasterboard, which is easy to assemble with your own hands. You just need to purchase the material and follow the technology for installing the structure.

What type of material to choose

There is only one solution for improving communications - covering it with a decorative box. Occasionally, when the pipe distribution is dispersed over the surface of the wall, it is possible to use a false wall. In most apartments, the layouts are not particularly spacious. When the risers are located in the corners or in the case of compact localization of the wiring, the best solution would be to use a bathroom box. This way you can get the most compact arrangement, creating the illusion of a more spacious room.

Sewer and water pipes without a duct look unsightly

There are two more questions that need to be resolved before starting work - what can the bathtub box be made from and what size should it be. The main requirement for materials is resistance to high humidity:

- Moisture-resistant drywall;

- PVC wall panels;

- Plastic channel box.

Pipes hidden in a plasterboard box

Pipes are hidden under the frame for PVC panels

Pipes in a plastic channel box

As for the dimensions of the bathtub box, they should be determined by the principle of reasonable expediency. The pipes must be completely covered with decorative walls with a small margin. The size of the internal empty space should provide, if repairs are necessary, the possibility of access through a removable hatch to key components (audits, gasket installation locations, threaded pipeline connections).

Pipe box with inspection door

Disadvantages of drywall

A do-it-yourself bathroom box is most often made from moisture-resistant plasterboard. This is due to the low cost, availability and ease of processing of the material. To finish the assembled structure, moisture-resistant paints or tiles can be used.

When purchasing material, you should pay attention to the color of the sheet - moisture-resistant drywall has a green outer paper layer.

The main disadvantage that should be taken into account is the relatively low mechanical strength. When making a box for a bathroom, a sheet of drywall is quite easy to accidentally break. In addition, the resistance of the material to prolonged exposure to moisture is quite limited. Only the outer paper layer is impregnated with protective compounds. When cutting a large sheet, the resulting edges will be unprotected.

Appearance of moisture-resistant drywall

The most critical is the formation of puddles on the floor near the wall of the box under the bathtub. In this case, quite a long time may pass from the moment water appears to detection. Through micro-slits at the junction of the box wall and the floor, moisture can seep inside. When installing the box in the bathroom, you can protect the bottom edge of the drywall sheet from getting wet using a strip of silicone sealant.

Useful tips on the device

When arranging the structure, it is important to take into account the following recommendations from experts:

- If the box is intended to mask vertical pipes, markings should be made starting from the floor.

- Be sure to provide a door or hatch at the valve and water meter.

- Regardless of the material used to construct the system, an antifungal agent must be applied to its inner surface to protect against harmful microorganisms.

- In a bathroom with a high content of vapors, it is highly advisable to avoid wooden structures: in this case, preference should be given to a metal profile.

- To construct the box, it is not advisable to use various types of chipboard, including waterproof boards, since this material swells under the influence of water vapor.

- When attaching the structure to the ceiling, the transverse parts are located at a distance of 30 centimeters from each other to ensure proper rigidity of the structure.

- With closely spaced pipes, it is better not to build separate boxes around each of them, but to create a single structure for the entire communication system.

It is important to ensure that the box does not touch the communications: the minimum distance of the casing from the pipe should be 3 centimeters.

An alternative to a partition box can be roller shutters. They give the interior a stylish look and also provide full access to the pipes.

Options for masking pipes in the toilet are given in an article entirely devoted to this issue.

What tools and materials will be needed for the job?

Making a decorative box for a bathtub is not the most difficult, but still quite a labor-intensive process. In addition to the drywall itself, you will need a number of auxiliary materials:

- Galvanized metal profiles - the frame is assembled from them;

- Fasteners - self-tapping screws and dowel-nails for connecting elements of the supporting structure, fastening it to the surface of the floor and walls, fixing sheets of drywall;

- Silicone sealant - for treating joints with the floor;

- Serpyanka and putty - they are necessary for masking screw heads and sealing sheet joints (used when preparing the surface of a bathroom frame for painting);

- Inspection hatch – for performing maintenance.

Assembling a frame from a metal profile

The set of tools that will be needed to complete the work is not that large. It is quite possible to get by with the necessary minimum, consisting of a screwdriver with a set of bits, a hammer drill, a construction knife and metal scissors.

Necessary tools for making a box

Installation of profiles

You need to start by installing a vertical frame from profiles according to the following plan:

- install the profile, cut along the length of the line using metal scissors, and secure with dowel nails;

- a similar action is performed on the second side;

- then the profile is installed on the ceiling;

It is important: that all profiles are installed strictly along the line, otherwise there will be a skew and the tiles will not lie flat.

- then the rack profiles are installed with their ends in the guides, screwed to the floor and ceiling;

- the profile must be screwed to the walls on both sides using dowel nails. The fastening step should not be more than 20 centimeters, otherwise the structure will be unstable;

- check the level of the profiles, but before doing this, check the building level;

Execution of the frame

Work begins with marking the walls, floor, and, if necessary, the ceiling. The size and location of the lines will indicate the position of the walls of the box. To prevent frame distortions, the markings must be checked with a level. Situations should be avoided where the walls of the plasterboard box in the bathroom will interfere with the opening of the furniture door or the entrance door.

Frame components are mounted level

If all the rules are followed and the markings are done correctly, you can begin assembling the frame of the box for the bathtub. Metal profiles are cut to the required size using metal scissors. First, the sections are attached to the floor and walls - they create reference points for attaching the frame. Then, the vertical posts of the supporting frame of the box under the bathtub are installed. The assembly is completed by installing the top guide, which combines all the elements into a single rigid structure. To service metering devices and sewer inspection, auxiliary guides are installed. In the future, they will serve as the basis on which the inspection hatch will be attached.

The frame is assembled from metal guides

The profiles are connected to each other using self-tapping screws (“seeds”). There is a notch on the surface of the metal that prevents the tip of the screw from slipping. Resting against these recesses, you can easily install the fasteners.

Assembling the frame

The frame is assembled around pipes laid on the floor

It is necessary to provide places for passing pipes in the frame

Plasterboard box in the bathroom

Let's start with drywall, as a more popular and versatile option. Working with this material is a pleasure. It is easy to process and allows you to assemble structures of almost any configuration.

Tools

To work we need the following set of tools:

Table 1. Tools for work.

| Tool, photo: | Description, purpose: |

| Drywall is attached to a frame, which in turn is attached to the walls, floor and ceiling. The connection is made using dowel screws or anchor wedges, which are inserted into holes made in concrete and brick walls with a hammer drill. The tool itself does not require a professional, since the amount of work will not be very large. |

| A screwdriver will help us connect frame parts to each other, secure plasterboard sheets, screw screws into dowels when attaching profiles, and even completely replace a hammer drill if the work is done in a wooden house. It is better to choose a cordless tool, as it is especially convenient to work with at heights. It must have a high engine speed in order to quickly and effortlessly screw hardware into a metal profile. |

| This profile will have to be cut to the size of the box. Professionals on large objects do this with an electric tool, but for us, metal scissors will be enough, since there will not be so many components. |

| When cutting drywall, uneven edges are obtained, which can protrude beyond the plane of the box and interfere with the laying of tiles in the future. The easiest way to correct the situation is with a rasp like this, which can be purchased for no more than 100 rubles. |

| You can cut drywall very easily and quickly with a utility knife. It is used only for straight cuts. For a curly one, you will additionally need a hacksaw. |

| You will need a tape measure and a marker. For the drywall itself, you can also use a pencil - it is not suitable for profiles, since it will not draw on a galvanized coating. |

| It is very important to set the frame strictly level, as it can serve as an excellent basis for supporting wall tiles during finishing. To determine the horizon, it is best to use a water level or a laser level. As a last resort, we use a bubble level, but be careful, as it may cause an error in measurements. |

Prices for popular hammer drill models

Hammers

Of course, we did not name the entire set, since the need for various small things constantly arises. For example, dowel-screws can be hammered in rather than tightened, in which case a hammer will be useful, or profiles can be connected with a cutter, and so on. If we missed something important, it will emerge as we describe the work.

Materials for work

The easiest way to assemble a box is from the following components:

Table 2. Material for work.

| Materials, photos: | Description: |

| There are many varieties of profiles, but the most convenient for our purposes is the ceiling 27*28 mm. It has a U-shape without stiffeners. The strength of the element will depend entirely on the thickness of the metal - it is best to take the 0.6 mm option. |

| We will only use moisture-resistant drywall. It has a green shell color. Both wall and ceiling options are suitable, since the structure will subsequently be reinforced with ceramic tiles glued on top. |

| Plastic dowel screws will securely connect the frame and walls. Buy the version with a mushroom cap. The photo shows a secret one - it can also be used, but the first option will hold better. Fastener dimensions 6*40 mm. The same type of drill is used for the hammer drill. |

| These 9 mm shorts are used to connect the profiles together. You can replace them with a model with a press washer, but screwing them into the metal is somewhat harder. |

| You can tell the salesperson in the store about self-tapping screws for drywall, and he will show you such hardened hardware with rapid threads. Due to this, they are held qualitatively on thin-walled profiles. This fastener is used for installing plasterboard sheets. A length of 25 mm will be sufficient. |

Prices for drywall and sheet materials

Drywall and sheet materials

Now let's say a few words about how to calculate the amount of material. It is clear that we will not calculate the fasteners individually, so we take them “by eye”, with a small margin - they are inexpensive and will always come in handy when necessary on the farm.

Most likely, one sheet of drywall will be enough if the length of the pipes is not very long. In general, the sheet has dimensions of 120*250 cm . Use this data in your calculations.

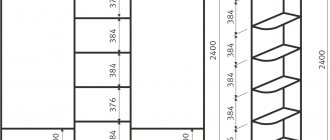

The profile is also easy to calculate. You need to measure the length of the future box. Let's say it turns out to be 2.5 m . We multiply this number by three, since there will be three belts. In our case it turns out 7.5 m . The length of one profile is 3 m , which means we need to buy 3 pieces - the trimmings will be used to form stops on the sides. To do this you need to know the depth and width of the box.

Advice! If the sides of the box are close to 50 cm , then it is better to install additional jumpers from the PN 27*60 for reliability. We also increase the number of belts to 4 .

The last point that is worth calculating is the perimeter of the inspection hatch. It will also have a rigid base. You will see everything in detail further.

Having trouble making the box? More detailed information in our special article! All about the types of boxes, the pros and cons of designs. Also detailed instructions on making a frame and installing drywall.

Assembling a plasterboard box for pipes

Riser - sewer and water pipes

So, before us is an ordinary bathroom of a high-rise building, through which a sewer riser and water pipes pass. We are required to cover it all up nicely and leave access to the audit and water meters. We will act in the following order:

Step 1. Marking the contour of the box.

Marking the contours of the box

- Everything, as usual, starts with markings. For this we need a plumb line, a pencil, a dye thread, a square and a tape measure (not always).

- We find the most protruding parts on the pipes. This could be connections, taps, meters, sewer inspections, and so on. Using a square, we transfer their level with marks to the walls. Then we add 3 cm to the sides from the riser to the points. As you understand, we are now marking both planes at once. If some obstacles prevent you from making the required indentation, then attach the PNP profile and see its most optimal position, taking into account the thickness of the drywall used and the tiles that will then lie on it - 2.5 cm , so as not to make a mistake.

- Then we take a plumb line or laser level and place marks at the bottom and top of the wall, focusing on the marks obtained taking into account 3 cm . Using a dye thread, we connect the dots and get a straight line from the ceiling to the floor.

- Next you need to mark the ceiling. This part is the hardest. We apply a square to the walls one by one and draw two intersecting lines. What's so complicated about that, you ask? And the fact is that next we need to check the angles that we got. Naturally, the walls will be exactly 90 degrees . We check the outer corner, which ideally should be the same. For this we use the same square or protractor. If large differences are detected, the lines should be redrawn so that the least noticeable difference is obtained.

The floor can be marked after attaching the guides to the walls and ceiling

- Next, we take a plumb line and apply it with a thread to the point of intersection of the lines in order to project it onto the floor. This work can be done with a laser level, but a bubble level can deceive. This is the only way we do it. It is impossible to measure separately using a square and a tape measure, since in the end the outer corner may turn out to be blocked.

- Having found the desired point, we connect it with the lines on the walls.

Step 2. Profile installation.

We mount the profiles

- Using metal scissors, we cut two profiles slightly less than the height of the room so that we do not run into the ceiling when installing them. We take a hammer drill in our hands, align the outer edge of the profile along the line on the wall and carefully begin to drill, trying not to move anything. You should start from the ceiling, retreating 50 centimeters from it . Then insert the dowel screw into the resulting hole and tighten it.

- We go to the bottom and repeat the procedure exactly. We make sure that the profile is exactly along the line, after which we begin to fasten it along the entire length, in increments of 40-50 cm .

- We attach two sections of the profile, as shown in the photo, to the floor and ceiling.

Advice! Even the shortest profile must be secured with at least 2 dowel screws so that it does not rotate.

Life hack from the master

In situations where the crossbars need to be attached to the guides in a hard-to-reach place, it is better to install them immediately, and only then attach the profile to the wall.

Step 3. Installation of the corner post.

Installing a corner post

- Next you need to secure the corner post. This is not difficult to do, but it is worth remembering that the element can bend for various reasons, so before fixing it, be sure to check its position according to the level.

- The installed stand will dangle as it is practically not secured. Start installing crossbars, and this effect will gradually fade away. Jumpers are installed in increments of 60 cm . The exception is the installation location of the inspection hatch - there we focus on its position and dimensions, and the place where the drywall sheets are joined.

- The crossbars are connected using self-tapping screws. On the side where it is not possible to insert a profile, mounting tabs are made on the parts, or you can attach another profile to the corner post, which needs to be turned towards the second wall.

Jumpers on the second side of the frame

If your box is small in size, then you don’t need to install jumpers. They will be replaced by drywall itself, screwed on both sides. The inspection window edging is also attached only to the drywall.

Step 4 . Fastening drywall.

We fix the drywall

- At the last stage, we cut the drywall into strips of the required width and attach it to the frame. The easiest way to cut is this way. We attach the sheet to the frame and grab it at several points, lifting it from the floor by 5 mm . We take a stationery knife and cut through a layer of cardboard along the corner post, as if along a guide. We break the sheet and bend it. We cut the paper on the other side and remove the excess piece.

- We clean up any unevenness on the edge with a utility knife or rasp.

- The first side that we will sew up will be the one where the hole for the hatch will be. We also cut it in place with a saw, and feel free to close the box completely. Self-tapping screws must be screwed into guide profiles and jumpers; their pitch is 20-25 cm . In this case, there is no need to monitor the caps that are precisely sunk into the material, since the tiles are installed on glue, which is not afraid of such small errors.

Prices for metal profiles

Metal profile

This completes the installation, all that remains is the finishing, which you can read about in other articles on our website.

Using a box to hide a pipeline

Video - How to make a plasterboard box for pipes

Installation of a plastic box

Plastic is even easier to install than drywall

PVC is good because it is not afraid of water, and it does not require finishing, except for covering the edges. A plastic box is assembled almost exactly the same way as a plasterboard box. In principle, this material can be attached to the same metal frame.

Video - Secrets of installing a plastic box in the toilet

However, instead of metal, it is better to use a wooden strip or beam. Plastic is a fairly fragile material and any self-tapping screw that slips through the metal can damage its surface.

This is what a wooden frame looks like

Let's quickly look at the assembly process and clarify the main differences.

- So, it all starts with exactly the same markings - we need straight lines along the walls, on the ceiling and floor.

- 25 mm thick strip and nail it to the walls using 6*60 mm dowel screws.

Attention! The slats can be bent, so bend them as needed, following the markings.

Fastening the slats to the wall with dowel screws

- The same rail is mounted on the floor and ceiling.

- An external rack made of timber with a cross section of 35*35 mm or larger . It is attached to the rail using steel furniture corners.

- We also build a frame at the location of the hatch. If the box is more than 37.55 cm wide , we install crossbars.

The parts are connected with self-tapping screws and steel corners

It’s worth making a small digression here. The width is indicated with the expectation that good durable plastic that has similar dimensions can be used. If you bought a narrower version, you will need docking, which means you won’t be able to do without jumpers that go every 50 cm .

The next step is to install the start

- An L-shaped profile, or simply a starter, is cut to the length of the box, applied to the rail and attached to it with self-tapping screws or with a stapler to staples. In this case, the part is pressed against the walls so that there are no unsightly gaps.

Cutting PVC panels with a utility knife

- Then a plastic panel is taken and also cut to length. This can be done with a fine-toothed hacksaw or a utility knife. To do this, lay the panel so that the unnecessary end hangs over the edge of a plane, for example, a table or stool. Make markings with a pencil and a square. Cut through the top layer of plastic, break it and cut through the second one.

- If nothing will cover the edges of the panel (baguettes, baseboards), put a starter profile on them. Insert the plastic into the starter on the wall and attach it to the external stand with self-tapping screws. Install the second side in a similar way, having previously cut out a hole for the hatch - there is no need to refine it, since inspection hatches have their own edging that will hide the edges.

Assortment of external corners for glue

- Next, you will need an external corner profile for glue, as shown in the photo above. We will attach it with “liquid nails”. After installation, the part must be secured with masking tape and left to dry.

Prices for different types of liquid nails

Liquid Nails

This is where the work actually ends. As you can see, there is nothing complicated, it’s enough to have the right tool and know how to work with materials. We also recommend watching the videos attached to the article, where you can see another interesting variation of the plastic box.

Find out how to install a plastic wire box, and also familiarize yourself with its purpose, types, sizes, in a special article on our portal.

Frame covering

Standard sheets of drywall are cut to the required, pre-calculated size. It's a fairly simple process:

- The sheet is laid on a flat surface (in extreme cases, cutting in a vertical or slightly inclined position is allowed);

- Using a tape measure, the required size is measured and small marks are made on the surface with a knife;

- A metal ruler or a flat, long wooden strip is applied to the resulting marks;

- A construction knife is used to make a cut along the guide;

- The drywall breaks off along the resulting line;

- The resulting edge is trimmed with a knife if necessary.

The frame is covered with plasterboard

Cut sheets of drywall are attached to the frame using self-tapping screws. The sheet is pressed tightly, the screw is screwed first into the sheet and then into the metal profile. As a result, the entire area of the frame (except for the space provided for the hatch) must be sewn up. To facilitate puttying, the fastener heads must be recessed when screwing. To avoid cracking at the edges, fastening must be done with a slight indentation (2-3 cm).

We check all elements for evenness

We use mineral wool for sound insulation

Ready frame

Preparation for finishing

In order to protect the material of the bathroom box from exposure to water, all joints and junctions are treated with sealant. It is best to use silicone with fungicide additives that prevent the development of mold. The junctions should be sealed especially carefully for the box under the bathtub, where access will be difficult.

Surface preparation before tiling is limited to treatment with a primer solution. The entire area of the box under the bathtub and along the walls in an open space is covered with the working composition using a brush or roller. Perforated corners are fixed into the internal and external corners, and then the tiles are glued using specialized compounds. These can be either dry mixtures that need to be diluted with water, or ready-to-use mastics. Sometimes, to save consumables, the box under the bathtub is coated with paint instead of tiles. Preparation for this type of work involves gluing the joints of individual sheets with sickle tape. A leveling layer of putty is applied over the reinforcing tape and recessed fastener heads.

At the end of the finishing process, an inspection hatch is installed. Its installation is carried out using standard mounting lugs. It is necessary that the hatch dimensions coincide with the hole left for it, and its size is sufficient for servicing.

Tiled plasterboard box with hatch

Application of finished polymer products

The pipe box in the bathroom can be assembled using plastic materials - finishing wall panels and channels. In the first case, the sequence of work is almost identical to that already discussed - the frame is assembled and its sheathing is performed. Installation of plastic panels is carried out using construction adhesives “liquid nails”. To make the entire structure look neat, the joints and corners are masked with decorative strips. The inspection hatch is installed in its seat in the bathroom box, secured with fastening tabs to the surface of the panel profiles.

A good solution is to use standard plastic channels to make a bathroom box in which you can hide the pipework. For this purpose, both specialized products and air duct elements are used. The advantage of this method is that there is no need to perform additional operations (assembling the frame, cutting the material, finishing). It is enough to choose a plastic box for the bathroom that is suitable in color for pipes of the required dimensions and fix them on the wall using a hammer drill.

Difficulties arise when it is necessary to cover the sewer riser. Finding shaped parts from which you can make a bathtub box for pipes of the required size can be quite difficult. Another point to consider is the installation of metering devices. It will have to be done either open or using a plastic box.

Regardless of what material is chosen for the manufacture of the box, all operations (cutting, installation, finishing) must be performed carefully. Otherwise, there is no point in undertaking the work; the best option would be to invite a hired craftsman.

The pipes are hidden in a box made of PVC panels

Advantages of a plastic box

The structure for masking pipes can be made of plastic or plasterboard. Each of these options is good in its own way, but in terms of practicality, the plastic box is the leader. It has many undeniable advantages:

- Possibility of quick disassembly without damaging the material. This property of plastic construction is especially important for pipes joined using fittings and threaded connections that are not immune to leaks. After repairing a breakdown or scheduled maintenance of pipes, the box is easily reassembled.

- No need for further finishing. Plastic panels themselves are already a finishing decorative material, unlike drywall, which requires final processing.

- Resistance to deformation and ease of repair. The plastic used to make the panels is strong and flexible, so it is less likely to be damaged than tiles, which can be accidentally broken. Even if one panel is damaged, it can be easily replaced with a new one without damaging the entire structure.

- Moisture resistance. PVC is not afraid of water, does not rot, nothing will happen to the box, even if it is installed close to the bathtub or gets wet due to condensation forming on the pipes.

- Easy to install. Installation of the box will take only a few hours and will not require the use of expensive or specific tools.

- Affordable price. Plastic panels for bathrooms are one of the most inexpensive finishing materials.

- Spacious and compact. Thanks to the small thickness of the panels, the plastic structure is very roomy and will not take up much extra space in the bathroom, which is especially important for a small room.

The plastic box is very practical: it can be disassembled and assembled as many times as necessary.