Coating features

Cold asphalt is produced and sold in the form of asphalt concrete mixture, packaged in 50 or 15 kg. For large volumes of work, packaging weighing up to a ton is provided.

The finished material includes:

Composition of cold asphalt

- bitumen;

- polymer and elastic additives;

- plasticizers;

- fine crushed stone.

All components are mixed and at the last stage of production undergo heat treatment. The special additives included in the mixture form a protective film on the surface. A special manufacturing technology allows the material to retain its properties and not set until it leaves the packaging in an open environment. Upon contact with air, the protective properties are lost, and the bitumen begins to harden.

Thanks to these characteristics, cold asphalt can be used in the most unfavorable conditions and at any time of the year.

It is advisable to use the material for minor road repairs. This is a very convenient tool for filling holes - there is no need to transport heavy equipment and prepare hot asphalt mixtures.

What is unique about cold asphalt?

This technology has taken a strong position in its niche and is consistently used by both private owners and city services. This is due, first of all, to ease of use. The mixture allows you to work without having special knowledge and without the use of heavy equipment.

This is interesting: Prom styling for medium hair 2019

The material is not picky about weather conditions. This justifies the high price. Unlike classical technology, there are practically no restrictions on air humidity and temperature.

Advantages

The cold method of laying asphalt is incredibly simple. It can easily be used for road repairs or landscaping in the yard. Moreover, this can be done not only by a utility worker, but also by an ordinary site owner.

Advantages of modern material:

The advantage of cold asphalt is its ease of installation.

- quick installation. Fill, level and compact - the whole process takes no more than an hour;

- ready-to-use material;

- no need for special equipment for installation;

- can be used in winter at temperatures down to -25 degrees;

- transportation and storage in any conditions, shelf life in original packaging - from 2 to 10 years.

There is no need to fear that the cold asphalt coating will be fragile and short-lived. It can be used immediately after installation, while maintaining high strength for a long time.

Scope of application

The main purpose of the material is rapid partial repair of roads and restoration of their technical functions. There are several areas of its application:

Application of cold asphalt

- elimination of holes and potholes on the road surface;

- creating a blind area;

- arrangement of garden paths;

- paving the entrance to a house or cottage;

- preventive measures for road improvement.

All these activities can be carried out regardless of the weather - in severe frost, if it rains or snows.

Most often, laying dry asphalt is carried out on those sections of roads where urgent repairs are required, and it is not possible to stop or limit the traffic flow. It is also advisable to use it in areas where it is difficult to deliver heavy special equipment. This also includes hard-to-reach areas, hatches, recreation areas and courtyards of high-rise buildings. They can restore parts of the foundation.

For owners of suburban areas and private houses, laying cold asphalt can be useful for making a parking lot or driveway to a garage. They lay out the floors in gazebos and verandas. Summer residents also find a use for it and use it to lay paths in their gardens.

Although its price is high, this is compensated by the convenience and durability of the coating - it will last for a long time without heavy loads. This is an excellent option for minor repairs and landscaping.

Laying asphalt mixture

It is most convenient to order ready-made asphalt mixture. Making it yourself is difficult and expensive. It is cheaper to buy from a company that specializes in the production of asphalt mixtures. It will meet all standards. There are two types of asphalt: coarse and fine grain. Coarse-grained grades are KZ-7 (ideal for paths) and KZ-10 (for driveways). Fine asphalt is poured on top of the coarse fraction. This way the coating will look perfect. Dirt will not settle in it. The asphalt mixture is delivered hot. When laying it, the temperature must be at least 105 degrees Celsius. If the asphalt is colder, then you need to spend more time compacting or rolling it.

This is interesting: Laying asphalt in Novosibirsk 2021

Therefore, start laying asphalt immediately after it is delivered. If the paths are narrow, throw with a shovel. And immediately compact them with a vibrating foot. If the area is large, order an asphalt paver and an asphalt roller. The roller must move smoothly and steadily across all paving strips. If the surface is inclined, then the roller moves only from bottom to top!

Don't forget these important tips:

- First, coarse asphalt is laid. Compact. Then – fine-grained. In fine-grained asphalt mixtures, a vibrating screed can be used. If you need little asphalt - only for paths, then take completely fine-grained asphalt. It will be denser.

- The vibrating leg, the vibrating plate, the vibrating screed and the roller - all working surfaces should be moistened with water. Otherwise, the asphalt will quickly stick and work will stall.

- Do not leave joining seams unrolled. They occur when passing a roller and with a large vibrating plate. Immediately tamp the seams at the junction of the strips so that they do not have time to harden.

- 1 ton of asphalt will cover 10 square meters of area well. The layer will be 10 cm thick.

- Lay asphalt yourself in good weather. Not in frost or rain. Dry and sunny weather is best.

By following these simple technologies, you can install excellent asphalt at home. There is no need to hire contractors - you can do it yourself. Your asphalt will last a long time and look well-maintained and durable.

Laying technology

The process is similar to laying regular hot asphalt, but with some nuances. Laying cold asphalt includes several stages. They are simple and take little time, but all are required. When all stages are completed correctly, vehicles can immediately move on the new surface. Here is an example of road repair, but for use in a country house or in the yard of a private house, you should follow the same algorithm.

Cold asphalt laying technology

Preparatory

At this stage, markings are carried out, the old road surface is removed, and seams are cut. The area to be treated is marked with lines around the perimeter, with a margin of 5 cm on each side. If there are several pits nearby, they should be combined.

Dismantling of the old canvas is carried out with a jackhammer or cutter. The seams are cut with a grinder or a special cutting tool along the entire depth. It is necessary to ensure that the sides of the pit are maintained vertically.

Preparing a road hole for laying cold asphalt

Cleaning

It is necessary to get rid of large parts of the old coating and remove asphalt chips. All small debris and moisture are also removed. This is a very important stage - if, when laying cold asphalt, foreign inclusions get into it, this will complicate the process of setting the two materials.

Treating a prepared pothole with bitumen emulsion. This procedure is not mandatory, but it is highly advisable to perform it to increase the service life of the restored area. The product can be purchased at a hardware store. This is a sticky liquid that consists of bitumen, water and other components.

Laying

The asphalt is poured onto the prepared surface and leveled. If there are stuck together lumps in the mixture, they must be broken up with any convenient tool.

The layer should not exceed 5 cm. If this thickness is not enough and the depth of the base is greater, you can add the required amount of crushed stone to the bottom. But this will reduce the quality of adhesion to the surface. Therefore, it is better to carry out the laying procedure in several layers, compacting each of them well.

The new coating should protrude 2 cm from the main surface - cold asphalt tends to compact and sag under the influence of passing cars.

Technological scheme for laying cold asphalt

Tamping

You can use the manual method for this, but a vibrating plate is more suitable. Compaction is carried out in a spiral. You need to work out the joints especially carefully.

Before use, fresh coating should be sprinkled with sand or cement - this way it will not stick to the wheels of cars.

Compacting cold asphalt

Laying cold asphalt concrete

If you follow the requirements of the installation technology, the process looks like this:

- removal of the previous coating;

- cleaning the surface from various debris;

- heating the “walls” of the treated surface with a gas burner (recommended);

- applying bitumen emulsion to the bottom and “walls” (acts as a kind of primer, also recommended);

- laying the mixture;

- leveling and compacting the mixture with a manual roller (vibrating plate).

This is interesting: Hair styling tools 2021

It should be noted: despite the possibility of using the mixture in a fairly cold environment, it is not recommended to use cold asphalt at an ambient temperature of -10 and below. Otherwise, the durability and reliability of the coating is significantly reduced.

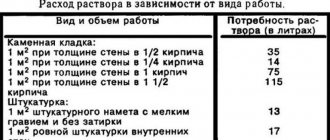

As for consumption. According to the accompanying instructions from the manufacturers, the consumption of non-hot substance is within 50 kg/1m2 with a laying layer thickness of around 50 mm. An important point: if, for example, a hole that needs to be filled requires laying a layer of more than 50 mm, then the hole should be partially filled with small crushed stone.

As a supplement, I attach a video about the process of laying such asphalt:

Disadvantages of cold asphalt

Even such modern and easy-to-use materials have their drawbacks:

Cold asphalt

- the price of this foreign innovation is 3 times higher than that of ordinary asphalt;

- laying cold asphalt is not suitable for highways, highways and other areas with heavy traffic - it will not withstand such loads and will quickly collapse;

- moisture resistance is lower than that of its traditional counterpart;

- the surface must be thoroughly cleaned, otherwise if any dust gets into the asphalt mixture, its properties will be impaired.

In terms of cost, in practice it is not that expensive, considering that they only carry out minor repairs and fill holes. In addition, it requires less labor and does not require the use of technology.

It is not used for complete laying of the road surface, not only because of its high cost. The point is in its properties - the material must be placed in a recess. Otherwise, under the weight of the cars, it will simply crawl apart, and it will certainly not withstand a loaded truck.

Related video: Cold asphalt laying technology

Publications on the topic

How to properly lay asphalt in your yard

Technology for laying paving slabs on concrete

DIY paving guide