When they talk about lithium batteries or accumulators, most often they don’t even realize that almost a dozen varieties have appeared in the last couple of years, each of which is lithium with various additives of other chemical elements, which ultimately differ significantly from each other.

Let's look at their types and start with the classics:

Li-ion batteries

Lithium-ion batteries are classic rechargeable batteries in which lithium ions move from the negative electrode to the positive electrode during discharge and back again when charging. Lithium-ion batteries are widely used in consumer electronics. They are one of the most popular types of rechargeable batteries for portable electronics, with one of the best energy densities, no memory effect and slow loss of charge when not in use (low self-discharge).

This series covers cylindrical and prismatic battery sizes. Li-ion has the highest power density of any old type battery. Very light weight and long life cycle makes it an ideal product for many solutions.

Battery device

Almost any modern li lon battery has a special design that is absolutely impenetrable and airtight. Moreover, such a requirement for the production of batteries is dictated by the inadmissibility of leakage of the electrolyte, which is located inside, because it is this that ensures the stable operation of the device.

In addition, in lithium-ion batteries, aluminum acts as the negative electrode, while copper acts as the positive electrode. Moreover, anodes and cathodes can be made in almost any shape, although in practice they are most often found in the form of a cylinder or an oblong rectangle wrapped in foil. The battery has a simple device:

- The design of such batteries can be manufactured in two main versions: cylindrical and prismatic. In the cylindrical design, the separator package and electrodes of the device are rolled up and then placed in a special housing, which can be made of steel or aluminum. The housing is connected to the negative electrode, and the positive pole of the battery is brought out through the insulator directly to the cover of the device. As for the prismatic version of the battery, it is produced by stacking flat rectangular plates on top of each other.

- The copper foil contains the anode material, and the aluminum foil contains the cathode material. They are separated using a porous separator impregnated with electrolyte.

- The electrodes placed in the battery pack are installed in a durable and sealed housing, while the cathodes and anodes are tightly connected to special terminals designed to remove current and ensure reliable contact with parts of the electrical circuit (current collector).

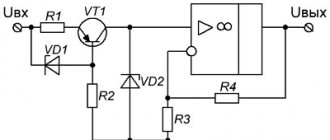

- Additional devices are located immediately under the cover of the device. For example, one is to regulate the increase in resistance, and the second is to break the electrical connection between the cathode and the terminal. In addition, a special fuse can be built into the battery, which allows you to relieve strong pressure in case of violation of the operating conditions of the device.

- To increase the level of safety when using the device, the li ion battery can be equipped with an external electronic protection system. Thanks to this element, the possibility of overheating the device, short-circuiting or overcharging the battery is eliminated.

Most often, batteries are produced in a prismatic design, since such devices are most suitable for modern gadgets such as mobile phones, tablets or laptops.

LTO batteries

Lithium titanate (lithium titanate) is a relatively new class of lithium-ion batteries (read more here). It is characterized by a very long life cycle, measured in thousands of cycles. Lithium lead titanate is also very safe and comparable in this regard to iron phosphate. The energy density is lower than other lithium-ion power sources and its rated voltage is 2.4V.

This technology features very fast charging, low internal resistance, very high life cycle and excellent endurance (also safety). LTO has found its application mainly in electric vehicles and wristwatches. Recently, it has begun to find application in mobile medical devices due to its high security. One of the features of the technology is that it uses nanocrystals on the anode instead of carbon, which provides a much more efficient surface area. Unfortunately, this battery has lower voltages than other types of lithium batteries.

Peculiarities:

- Specific energy: about 30-110Wh/kg

- Energy density: 177 W * h/l

- Specific power: 3,000-5,100 W/kg

- Discharge efficiency: approximately 85%; charging efficiency more than 95%

- Energy-price: 0.5 W/dollar

- Shelf life: >10 years

- Self-discharge: 2-5%/month

- Durability: 6000 cycles to 90% capacity

- Nominal voltage: 1.9 to 2.4 V

- Temperature: -40 to +55°C

- Charging method: Uses stable constant current, then constant voltage until it reaches the threshold.

Chemical formula: Li4Ti5O12 + 6LiCoO2 < > Li7Ti5O12 + 6Li0.5CoO2 (E=2.1 V)

Battery operation stages

Like every electronic device, power supplies have their own life path. In order for them to serve as long as possible without the need for replacement, you need to follow the rules of correct operation at each stage. There are several of them:

- Primary charge-discharge cycle.

- Everyday use.

- Storage.

- Disposal.

When delivered to the user, the battery should be subjected to several consecutive full discharges and charges.

This way you can configure the controller internally to optimal parameters and significantly extend the service life. To do this, without recharging, you need to completely lower the charge level to a value close to zero, and then charge it. It is better to repeat this process no more than three or four times. In subsequent cases, the battery will only be harmed. In everyday work, it is better not to allow the level to drop below fifteen to twenty percent. When charging, do not leave the device connected to the network overnight. Then the battery is under constant standby voltage, which reduces its life cycle time.

Using low-quality chargers can also greatly reduce the life of the battery. In their manufacture, low-quality electrical materials are used, which leads to a discrepancy between the specified characteristics and the real ones.

For example, if the voltage supplied by the charger exceeds the norm by at least 5%, a gradual loss of capacity is inevitable. The same applies to the current supplied to the modules. You can check these parameters with any multimeter. To do this, the charger is inserted into the socket, and the probes of the measuring device are applied to the positive and negative pins at its end.

The measuring device must be set to a mode of up to 20 volts with a switch on the body. If the result is within normal limits, then there is no need to worry. In other situations - for example, when the stated 5 volts produce 5.1-5.2, it is better not to use such a device. This will inevitably cause the battery to degrade its capacity.

There is no need to correctly determine the polarity of the pins on the charger connector: even if it is reversed, the value with a minus sign will simply appear on the screen. It is their search that can cause more problems. In order to accurately determine the two pins responsible for power supply, you need to switch to the “dialer” mode, that is, measuring resistance with a signal during a short circuit. You need to go through all the pins sequentially: the pair at which the multimeter makes a squeak is the desired contacts.

We recommend: Program for checking laptop battery

Li-Polymer batteries

Lithium polymer has a higher energy density in terms of weight than lithium-ion batteries. In very thin cells (up to 5 mm), lithium polymer provides high volumetric energy density. Excellent stability in overvoltage and high temperatures.

This series of batteries can be produced in the range from 30 to 23000 mAh, prismatic and cylindrical housing types. Lithium polymer batteries offer a number of advantages: greater energy density by volume, flexibility in cell sizes, and a wider margin of safety, with excellent voltage stability even at high temperatures. Main areas of application: portable players, Bluetooth, wireless devices, PDAs and digital cameras, electric bicycles, GPS navigators, laptops, e-readers.

Peculiarities:

- Rated voltage: 3.7V

- Charging voltage: 4.2±0.05V

- Charge current, speed: 0.2-10C

- Discharge voltage limit: 2.5 V

- Discharge speed: up to 50C

- Cycle endurance: 400 cycles

LiFePO4 batteries

Lithium iron phosphate has good safety characteristics, long service life (up to 2000 cycles), and low production cost. LiFePO4 batteries are well suited for high discharge current applications such as military equipment, power tools, electric bicycles, mobile computers, UPS and solar power systems.

As a new anode material for lithium-ion batteries, lifepo4 was first introduced in 1997 and has been continuously improved to date. It has attracted the attention of experts due to its reliable safety, durability, low environmental impact during disposal, and convenient charging and discharging characteristics. Many experts claim that lifepo4 batteries are by far the best option for autonomously powering electronics.

Types of Lithium Batteries

Speaking about the classifications of Li-batteries, first of all they try to divide them into classes depending on the main active substance. As a rule, each such category of development has its own formula and abbreviated name:

- Complex lithium-nickel-cobalt-aluminum-oxide batteries, also known as NCA, were initially popular with makers of medical equipment, powertrains, and industrial applications. Today, the creators of electric vehicles are actively including them in their developments. These batteries demonstrate high energy intensity along with impressive durability, but they have not yet become leaders due to their high cost and dubious safety.

- The lithium-manganese development (based on a lithium-ion cell, complemented by a cathode in the form of a Li-Mn overcoat) is a product of high

power, quite safe, but not characterized by too much capacity. They are most often supplied as components for electric bicycles: both mountain and folding. Such solutions are lightweight, demonstrate excellent charging speed, but are not very durable. However, more recently, scientists were able to combine lithium-manganese structures with lithium-nickel-manganese-cobalt, resulting in a more advanced battery with good energy capacity and an extended service life.

- Lithium-cobalt solutions are relevant for equipment that consumes low currents. These designs are based on a graphite-type anode and a cobalt oxide-based cathode. Among the advantages of such batteries are good specific energy intensity and excellent cost, while the disadvantages include a short operating period, instability to extreme temperatures, and modest specific power.

- Batteries with iron phosphate, expectedly called lithium iron phosphate, demonstrate excellent electrochemical properties, high current, low internal resistance, and thermal stability. They do not deteriorate due to improper use, which provides them with a long service life. LiFePo modules are found mainly in installations where extreme equipment endurance and the ability to withstand high currents are required. In particular, they have proven themselves as an element of powerful electric bicycles. These batteries work for a very long time and can withstand loads perfectly, providing the user with the required power at a relatively low weight.

- Lithium titanate structures have an anode made of lithium titanate nanocrystals, plus a cathode made of graphite. This device differs from analogues in its increased safety and ability to operate at critical temperatures. It can be charged extremely quickly and used slightly longer than classic Li-Ion. Some electric vehicle manufacturers have already set their sights on these batteries. Lithium titanate is relevant for transport used in countries with cold climates or in cold/hot seasons. These batteries can be charged and discharged both at -50 and +50 degrees Celsius.

Lithium polymer batteries use polymer material as the electrolyte. Today they can very often be found in the designs of scooters, unicycles and bicycles with electric motors, as well as in individual electric vehicles! This type of battery is considered one of the revolutionary ones, since it delivers tens of times more current compared to the value of its capacity in ampere-hours. Light weight and the ability to operate in a wide temperature range are the main advantages of the development. Its service life is about 500 cycles.

Today, lithium-oxygen batteries stand apart, as opposed to lithium-air batteries. They are called an innovation in the market of universal batteries. These are devices with low weight but high performance, which are based on the use of nanoparticles containing Li and O2. This development, in one of its latest modifications, was freed from the disadvantage of rapid energy loss, protected from overcharging, and also demonstrated good resistance to moisture and external influences.

Li-SO2 batteries

Lithium sulfur dioxide (Li and SO2 battery) - These batteries have high energy density and good resistance to high power discharge. Such elements are used mainly in military science, meteorology and astronautics.

Lithium sulfur dioxide batteries with a lithium metal anode (the lightest of all metals) and a liquid cathode containing a porous carbon current collector filled with sulfur dioxide (SO2) produce a voltage of 2.9 V and are cylindrical in shape.

Peculiarities:

- High operating voltage, stable throughout most of the discharge

- Extremely low self-discharge

- Performance in extreme conditions

- Wide operating temperature range (-55°C to +65°C)

Li-MnO2 batteries

Lithium manganese dioxide (Li-MnO2 battery) - These batteries have a lightweight lithium metal anode and a solid manganese dioxide cathode immersed in a non-corrosive, non-toxic organic electrolyte. This type of battery is EU RoHS compliant and is characterized by large capacity, high discharge capacity and long service life.

Li-MnO2 is widely used in backup power supplies, emergency beacons, fire alarms, electronic access control systems, digital cameras, medical equipment.

Peculiarities:

- High energy density

- Very stable discharge voltage

- More than 10 year shelf life

- Operating temperature: -40 to +60°C

Further development

Numerous problems arose when working with the anode, since the charging and deposition of lithium created a surface with high activity.

In this case, the chemical element remained on the surface of the cathode, turning into dendrites. Ultimately, a passive film appeared, enveloping the lithium particles and disrupting the interaction with the main element. Soon this process was even given a name - encapsulation. Due to this reaction, after a certain number of cycles, the electrodes lost their performance characteristics and lost the optimal temperature balance inside the battery. At the same time, within a certain period of time, the element acquired the melting point of lithium, and the reaction became uncontrollable.

Because of this, in the early 90s of the last century, most of the produced models were returned back to the manufacturer. We are talking about the very first power sources that were equipped with mobile devices. In those days, the incidence of telephone explosions during a conversation was very high. Facts about burning a person's face and more serious consequences are mentioned. In addition to the increased fire hazard, such elements caused a short circuit.

Given the current situation, researchers began to look for more optimal solutions and tried to find a way out of the situation. Initially, they began to develop a method for treating the cathode surface, trying to avoid the formation of dendrites by introducing various additives into the electrolyte. Scientists have made great strides, but have not been able to completely solve the problem - until today.

Li-SOCL2 batteries

Lithium thionyl chloride (lithium-SOCl2) batteries have a lightweight lithium metal anode and a liquid cathode containing a porous carbon current collector filled with thionyl chloride (SOCl2). Li-SOCL2 batteries are ideal for automotive devices, medical devices, and military and aerospace applications. They have the widest operating temperature range from -60 to + 150°C.

Peculiarities:

- High energy density

- Long shelf life

- Wide temperature range

- Good sealing

- Stable discharge voltage