Reinforced concrete structures are the basis of modern construction. However, they have significant flaws, associated primarily with insufficient load capacity and the formation of cracks in the stone under operational loads. Improvements in the technology of manufacturing concrete products and steel reinforcement have led to the creation of prestressed reinforced concrete, which has a number of advantages.

Definition

Prestressed reinforced concrete structures are building products, the concrete of which, at the creation stage, forcibly receives the initial design compressive stress. It is created due to the preliminary formation of tensile stress in working high-strength reinforcement and its compression of concrete in those areas that will experience tension (deflection) during operation. When compressed, the reinforcement does not slip, since it is adhered to the material or is held by anchoring the reinforcement at the ends of the products. Thus, the tensile stress, which the reinforced concrete composition acquires with the help of reinforcement, balances the tension of the pre-compression of the stone.

Return to contents

Advantages

Prestressed reinforced concrete long-term delays the time at which cracks begin to form in products working in deflection and reduces the depth of their opening. At the same time, the products acquire increased rigidity without reducing strength.

Prestressed reinforced concrete beams tend to work well in compression and deflection, having the same strength along the length, which allows increasing the width of the spans to be covered. In such structures, the cross-sectional dimensions are reduced, therefore, the volume and weight of the component elements are reduced (by 20–30%), as well as cement consumption. More rational use of the properties of steel makes it possible to reduce the consumption of reinforcement (rod and wire) by up to 50%, especially from high-strength grades (A-IV and higher), which have a significant tensile strength. The chemical neutrality of concrete to steel helps protect reinforcement from corrosion. At the same time, increased crack resistance protects stressed reinforcement from rusting in structures that are under constant pressure of water, other liquids, and gases.

The building construction methods used in frame construction are based on the technology of prestressing reinforced concrete structures during the construction process.

Stressed reinforcement that compresses the concrete of assembly units ensures their practical joining by significantly reducing the consumption of metal at the joints. Prefabricated and precast-monolithic products from reinforced concrete stressed structures can consist of abutting parts with the same cross-section, which at the edges are made of unstressed lightweight (heavy) concrete, and the loaded fragment is prestressed reinforced concrete. Such products have increased endurance, compensating for repeated dynamic impacts.

This property allows you to dampen changes in stress in concrete and reinforcement caused by fluctuations in external loads. The increased seismic resistance of buildings is increased due to the high structural stability of prestressed reinforced concrete, compressing their individual fragments. A prestressed structure provides greater safety, since its destruction is preceded by an extreme deflection, signaling that the structure has exhausted its strength.

Return to contents

Important advantages and disadvantages of prestressed concrete

Details Category: Building materials

Created: 04 November 2016

Prestressing concrete to increase its strength is a modern way to increase the strength of concrete structures. In this article, we will list the advantages and disadvantages of prestressed concrete.

Concrete is used in various types of construction. The name 'pre-cast' does not mean that the type of concrete has been stressed before the floor above it is built. However, instead of buckling under pressure, it manages to become stronger and is able to withstand much greater stresses than ordinary concrete.

But how to do that. What are the advantages and disadvantages of prestressed concrete? Let's find out the answers to these questions that will help us understand this better.

What is prestressed concrete?

Concrete in its normal state has an extremely high level of compressive strength. This makes it possible to use it to create structures that must bear compressive loads. For example, it is used to create columns and supports to support various structures in large buildings.

However, compared to its compressive strength, concrete has almost no integrity strength. Therefore, if ordinary concrete is used for the construction of floors, it will sag under the pressure of compression on it, and will eventually crack and crumble. To eliminate this drawback, the prestressing method is used. In its most basic form, prestressing is accomplished as follows.

A series of steel cables are tensioned by applying a pulling force at their ends, and placed in a concrete block. Then, the liquid concrete is poured into the molds and hardens, causing a bond between it and the steel cables inside. After this, the cables try to restore their original shape, they pull the concrete with them, creating compression. This stresses the internal particles of concrete, strengthening it and making it an excellent material for use in structures. Since the concrete is stressed before it is used, it is called prestressed concrete.

Prestressed concrete has a large amount of strength, both compressive and tensile. It is used to build long bridges, building slabs, etc.

Flaws

The state of prestress in the material is achieved by special equipment, precise calculations, labor-intensive design and costly production. Products require careful storage, transportation and installation that do not cause them to become unsafe even before use.

Concentrated loads can contribute to the formation of longitudinal cracks, which reduce the load-bearing capacity. Miscalculations in design and production technology can cause complete destruction of the reinforced concrete product being created on the slipway. Prestressed structures require metal-intensive formwork of increased strength and increased consumption of steel for embedded parts and reinforcement.

Large values of sound and thermal conductivity require the placement of compensating materials into the body of the stone. Such reinforced concrete structures provide a lower fire resistance threshold (due to the lower critical heating temperature of prestressed reinforcing steel) compared to conventional reinforced concrete. Prestressed concrete structures are critically affected by leaching, solutions of acids, sulfates, and salts, leading to corrosion of cement stone, opening of cracks and corrosion of reinforcement. This can lead to a sharp decrease in the load-bearing capacity of the steel and sudden brittle failure. Also, the disadvantages include the significant weight of the products.

Currently reading: Do-it-yourself deep concrete vibrator based on a drill and a hammer drill

Return to contents

Methods for tensioning reinforcement in prestressed structures

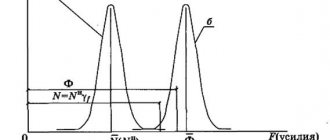

In structures subject to bending (slabs, beams, purlins, crossbars), tensile stresses appear under load. To perceive them, a large amount of reinforcement must be placed in the stretched zone. In addition, the tensile strength of steel is not sufficiently used, since cracks appear in the concrete in the tensile zone, although the stress in the reinforcement does not yet exceed the yield strength, and it is not allowed to operate such a reinforced concrete structure with a crack opening width greater than the permissible one.

These disadvantages are largely eliminated in prestressed structures. In such structures, even before installing it in the structure and transferring operational loads to it, the supposed tensile zone is already subject to compression. And before the concrete in the structure, accepting the operational load, begins to work in tension, it is necessary to first extinguish the pre-created compression.

Prestressing allows you to increase the load on the structure or, with the same load, reduce the dimensions of the structure.

Advantages of prestressed structures:

the use of reinforcement of smaller diameters made of high-strength steel makes it possible to reduce the size of the structure, and therefore the volume of prefabricated elements, by 20...30%, which leads to savings in materials, in particular cement;

thanks to better use of the properties of reinforcing steel, compared to conventional reinforced concrete structures, and when using steels with high tensile strength, metal savings of up to 40% are achieved;

structures with prestressed reinforcement are characterized by high crack resistance, which protects the reinforcement from corrosion; this is important for structures under constant pressure of water, other liquids and gases (pipes, dams, tanks).

Prestressing of reinforcement is carried out mainly in two ways:

tensioning the reinforcement before laying the concrete mixture into the structure;

laying and tensioning reinforcement after laying concrete and acquiring a strength of at least 70% of the design.

The first method is a factory method, it is called tension on forms and stops, the second is used in construction conditions at pre-assembly sites and is called tension on concrete.

Tension on forms and stops. When reinforcing using this method, the reinforcing bars are tensioned before laying the concrete mixture. Tensile forces, reaching several tens and hundreds of tons, are perceived by the structure of the steel mold in which the product is manufactured (molded), or by special stops of the stand. The product is concreted with tensioned reinforcement. When the tension devices are removed after the concrete has hardened and reached the required strength, compression of the concrete is achieved due to the adhesion between the tending to compress reinforcing bars or strands and the hardened concrete surrounding them. With this method, the tension of the reinforcement is controlled before the concrete is compressed.

The bench tensioning method is used in the manufacture of long (12 m or more in length), large and heavy structures - rafters and sub-rafters, roofing and crane beams. The structure is reinforced, tensioned, concreting is carried out, and the concrete acquires the necessary strength in a stationary position on the stand. The stops absorb the tension forces and transfer them to the massive foundation of the stand.

When tensioning the forms, there are no stops, and the forces are perceived by the form itself, which is a force. In such forms, slabs and panels of floors and coverings are concreted. The advantage of the forms is that they have modular dimensions, so when changing the concrete structure, it can be easily reconfigured for the production of new products.

Tension of reinforcement on concrete. Prestressing in monolithic and prefabricated monolithic structures can be created by the method of tensioning reinforcement on hardened concrete. With this method, the tensile force is perceived not by the shape or stops, but by the concrete that has already hardened and gained the necessary strength. This method is used mainly for reinforcing structures assembled from individual blocks.

According to the method of laying prestressed reinforcement, there are two types - linear and continuous. With the linear method, open or closed channels are left in prestressed structures during concreting. When concrete acquires a given strength, reinforcement is placed in the channels and tensioned, transferring force to the prestressed structure. The linear method is used to create stress in beams, columns, frames, pipes, silos and many other linear structures. The continuous method involves winding endless reinforcing wire with a given tension along the contour of a concreted structure. This method is used for prestressing the walls of cylindrical tanks and prestressed pipes.

In linear reinforcement, prestressing elements are used in the form of individual rods, strands, ropes and wire bundles. Linear reinforcement includes: preparation of prestressing reinforcement elements; formation of channels for laying prestressed reinforcement elements; installation of reinforcing elements with anchor devices in channels; tension of reinforcement followed by injection of closed channels or concreting of open channels.

For rod reinforcement, hot-rolled steel of periodic profile and high-strength wire are used. Preparation of rod elements consists of straightening, cleaning, cutting, butt welding and installation of anchors by welding steel shorts to the ends of the rods. The shorts have a thread onto which nuts are screwed, transmitting tensile loads through washers to the concrete.

Reinforcing non-unwinding strands and ropes are made from high-strength wire with a diameter of 1.5...5 mm. The wire is produced into strands formed from three, seven or nineteen wires twisted together. If necessary, the finished strands are further wound into ropes. Strands and ropes come from factories wound onto spools. They are unwound from reels, passed through correct devices, at the same time cleaned of oil dirt, and cut into pieces of the required length. Sleeve tips are used for anchoring strands and ropes. The sleeve is put on the prepared end of a strand or rope, pressed in with a press or jack, and then on its surface the threads necessary to transmit concrete tension forces through the washers to the fastening nuts are cut or rolled.

Wire bundles are made from high-strength wire. The wire in the bundle is placed either with it filling the entire section, or along the circumference of the reinforcing bar. In the first case, the beam is equipped with a sleeve anchor, and in the second - with a sleeve-rod anchor.

The method of tensioning concrete makes it possible to assemble large-sized structures up to 30 m long or more at the site of their installation from separate, easily transportable smaller parts. When reinforcing structures assembled from individual blocks, channels or grooves are left in advance in prefabricated reinforced concrete elements during factory production to accommodate prestressing reinforcement. The prestressing reinforcement is laid (pulled) into these pre-left channels, the diameter of which is usually made 10...15 mm larger than the diameter of the reinforcing beam or rod.

Materials for structures

Reinforced concrete is a multicomponent material, the main components of which are concrete and steel reinforcement. Their quality parameters are determined by special design requirements for structural elements at the site of application.

Return to contents

Concrete

Forms for pouring concrete with rods to transfer prestress.

Prestressing in reinforced concrete is ensured by the use of heavy compositions of medium density from 2200 to 2500 kg/m3, which have axial tensile strength classes higher than Bt0.8, strength classes from B20 and higher, water resistance grades from W2 and higher, frost resistance classes from F50 . Product requirements guarantee concrete a standard strength not lower than the established one with a probability of 0.95 (in 95% of cases). The mixture must age for at least 28 days before the material receives prestresses. In the early stages of operation, concrete stone can partially lose its tensile quality due to a general decrease in the tensile strength of the steel (up to 16%). The material reliability coefficient for tension and compression in limit states is set for serviceability to be no lower than 1.0.

Return to contents

Armature

The steel filling must remain stressed in the reinforced concrete product throughout the entire service interval, withstanding long-term applied loads without stretching. Prestressed concrete products use high-strength steel with negligible fluidity, corresponding to the creep parameters of concrete.

In order to compensate for the operational loss of a certain amount of prestress during manufacturing, its value is set slightly higher than that provided for by the construction requirements for the structural element. The products use hot-rolled strengthened, cold-deformed reinforcement, reinforcing wire (bundles, packages, strands), ropes, welded frames, etc. The cross-section of the reinforcement can be smooth, periodic, and the laying of wire and ropes can be sickle-shaped or ring-shaped.

The steel must be guaranteed to comply with the established class regarding prestressed tensile strength (the fluidity of the metal must be within 0.2% of the relative elongation) with a probability of 0.95 or higher. The reinforcement must be plastic, cold-resistant, weldable, etc. Reliable adhesion to the concrete mixture is ensured by the formation of complex spatial surfaces by the reinforcement.

Return to contents

Production process

There are several ways to tension reinforcement:

The production of the material can be carried out using an electrothermal method.

- mechanical (screw or hydraulic jacks);

- electrothermomechanical (combination of the first and second methods).

electrothermal (steel rod is extended to the required values using electric current;

Tools and materials

Requirements are applied to prestressed concrete materials in accordance with existing regulatory documents:

Prestressed concrete structures are reinforced with the following materials:

- periodic profile reinforcement of class A-Shv, hot-rolled with drawing in its cold state;

- hot rolled sheet steel class At-V;

- reinforcing wire strands made of twisted wires.

Kawabanga! Tactile paving slabs

To carry out the process, it is necessary to prepare the following materials and tools:

For this work you will need mounting rods.

- rods (mounting, distribution);

- knitting wire;

- rod cutting tool;

- formwork panels for pouring concrete mixture.

Prestressing and work stages

With this production method, the prepared reinforcement must be stretched at the ends.

Reinforcing stress is produced mechanically, electrothermally, combined and physico-chemically.

Areas of use of structures

Prestressed concrete can reduce the consumption of reinforcing steel by up to 50%.

Prestressed products are used when the use of conventional reinforced concrete is impractical (overconsumption of materials, increase in weight and cost, inability to provide load-bearing strength, etc.). The areas of their use are civil, industrial, special and hydraulic construction. Objects - frames and bridges with wide spans, pressure pipelines, dams, waterproof containers, etc.

They are also used to create retaining walls, enclosing panels, flights of stairs, crane beams, foundations, columns, power line poles, tunnel frames, interfloor ceilings, etc. Such products are also indispensable when constructing buildings in conditions of explosion and seismic hazard. It is especially effective in the formation of prefabricated monolithic structures, when individual prestressed precast elements are connected in the design position by reinforcement so that they work as one whole.

Return to contents