What causes the buzzing, and what to do in such a situation?

The fact is that alternating current flows in the network with a frequency of 50 Hz, which means that electrons move along the core in uniform waves occurring 50 times per second. Due to this movement, vibration of conductive parts occurs, the sound of which you hear.

The human ear detects any sound (air vibration) in the range from 20 Hz to 20,000 Hz. Microvibration at a frequency of 50 Hz is quite perceptible to our ears.

Oscillations occur due to poor contact of conductive parts. This problem often appears due to manufacturing defects or shocks and falls during transportation, careless storage, etc.

Usually, a long beep does not mean that the protection will fail at a critical moment, but still the characteristic sound indicates a malfunction. In this case, it is better to make a replacement, even if you checked the functionality yourself and an electrician you know said that “it’s okay, it’s normal.”

Any, even minor, malfunction often causes the release to fail in a critical situation.

Considering that a circuit breaker, even from a good German brand, is now easy to buy for just $5, it’s better to do so. You can easily verify this - on the website of the Axiom+ online electrical store there are always current prices for German Hager automatic machines. This is a small price to pay for protection against overloads and short circuits, which often cause fires.

Along with the humming, sometimes a slight shaking of the body is also felt.

The machine knocks out when you turn on the old machine

There may be several reasons:

- The machine is outdated and requires replacement.

- Problems with electrical wiring (frayed, condensation appeared). You can't do it without an electrician.

- The network is overloaded. If you turn on several high-power household appliances (electric stove, air conditioner, iron, electric kettle), the machine may work. Try to unload the network by turning off unnecessary devices. If it doesn't help, the problem is in the washing machine.

- The power filter in the machine, which evens out power surges during operation, has burned out. The filter can be replaced.

- The power button closes. When pressed, a short circuit occurs and the machine turns off. Needs renovation.

- The CM module (control board) is shorted. For example, the German brand Bosch is not designed for constantly unstable voltage in the network - electronics often fail. Need professional help.

We have listed the reasons why the machine knocks out at startup.

What to do if vibrations occur?

They often occur when current is applied to a coil or bimetallic strip, which creates an electromagnetic field that acts like an electric magnet on the metal parts inside. Electromagnetic influence provokes vibrations.

Even if the vibrations are almost imperceptible, this is also a malfunction. If you feel a slight tremor when you touch the body with your finger, it means the mechanism inside is defective, which is dangerous for further operation. In this case, it is highly recommended to make a replacement.

Purely theoretically, a circuit breaker can serve you for several more years, but there is no guarantee that the circuit will break during a short circuit. Moreover, constant vibration will over time weaken the connections more, causing the machine to jam, trigger falsely, or even fail. In any case, this is dangerous, so replace it with a new one as soon as possible. The only thing worse than vibrations is crackling. In this case, replacement is needed immediately .

If a machine cracks, why is it dangerous?

You probably already guess that the crackling sound is the sound of sparking inside the case. Most often, its main cause is weakened contact of current-carrying elements.

In most cases, cracking occurs due to breakdowns inside or insufficient tightening of the wires in the terminals. Because of this, the insulation of the wires often catches fire, and the melting transfers to the flammable plastic housing.

Read: Laying the antenna cable

If you hear crackling noises, replace them quickly. Do not delay, because there is a very high probability of a fire. Moreover, the shield often becomes the source of fire in an apartment.

The sparks gradually melt the plastic case, causing it to begin to smoke and ignite. Due to deformations, opposite contacts may come into contact, causing a short circuit and causing all the wiring to burn.

Cracking is the first sign of danger, and in this case the machine must be replaced.

In rare cases, a reinstallation will be sufficient. For example, if the terminals were cracking due to loose tightening, then the machine must be dismantled and reinstalled. After this, watch him carefully. If the cracking still occurs, replace it with a new one.

In addition to cracking, users often perceive case heating as a problem. But this does not always indicate a malfunction.

Circuit breaker hums

Let's look at the first fault, namely humming. If your machine makes a sound during operation like a starter or contactor, this indicates a defect or defect.

Do not look here for damage to electrical wiring, bad contacts, etc. A humming machine definitely needs to be changed.

Although this does not mean that his defense will not work as it should.

It can still shut down properly and operate during short circuits.

But how long it will work like this - a month or two, or it will burn out at any moment, you will never know in advance.

Moreover, if in the electrical panel it stands in one tight row with other intact circuit breakers, its sudden damage or ignition will lead to the failure of all neighboring switching devices.

Therefore, it is better not to delay the replacement and immediately buy another one. Do not listen to the advice of those who recommend simply knocking on the machine body with some blunt object.

For example, the back of a screwdriver. Apparently after this the sound disappears.

Replacing a machine is not such a difficult job, and many people do it even under voltage.

Also, do not try to repair or disassemble it yourself. Such modular devices are made disposable and cannot be restored at home.

They are assembled not with screws at all, but with rivets. These rivets can only be drilled out.

If you do this, you will see the following picture inside.

The only thing that can hum here is the trip coil or the electric magnetic release, which is triggered by short circuits.

Its core is constantly in a magnetic field, and if it is not tightened enough, it will actually make a similar sound. Under the influence of an electric magnetic field, the coil enters resonance and begins to vibrate.

Some people notice that when other devices are turned on, the sound disappears. But the point here is not in the device, but in the change in load and induction density. Following it, the vibration amplitude changes, and therefore the hum.

Although in exceptional cases, certain types of devices can actually have a similar effect on the machine and make it buzz.

For example, this may be caused by connecting consumers with a pulsed load to the network. Such as power supplies for computers or LED strips.

Turn off the fancy LED backlight and the noise disappears.

You cannot fix this, because some machines initially perceive such a load normally and operate without extraneous noise. Or at least you don't hear them.

And others will get on your nerves and hum like a transformer.

Therefore, we repeat once again, if the machine is buzzing, change it to another one.

Don't blame the electricians for this, they have nothing to do with it. You just received a defective product.

This could be a manufacturing defect, unknown transportation conditions (drops or impacts on the case), improper storage (in damp rooms), possible counterfeiting, and much more.

Therefore, even if you buy well-known brands (ABB, Hager, Schneider, Legrand), and not cheap IEK or TDM, you can still run into trouble.

Only pre-installation tests and loading the machines with a long-term primary current can save you from this. But 99.9% of users never do this.

Why does the machine heat up?

The fact is that all household series operate on a thermomagnetic release. Under load, it heats up and as soon as the temperature exceeds the permissible value, the contact plate is deformed and activates the release mechanism, breaking the circuit.

To be fair, it should be said that all machines heat up under load and this is a normal phenomenon. The higher the load, the more the release heats up and the faster the circuit breaks. For example, if a 20A machine starts to pass 23A, then after half an hour it will turn off the network, at 25A this will happen after 5 minutes, and so on. There are several reasons for strong heating:

- Poor condition of contacts - when the contact strip is loosened, the basic throughput deteriorates, causing it to become very hot;

- Wear of the release mechanism - over time, parts wear out, their basic characteristics, including throughput, decrease;

- Poor assembly - low-quality machines, as a rule, have characteristics lower than declared. They do not pass the maximum current for which they are designed, which is why they become very hot;

- High load - the thermal release reacts to the overload protection, and it takes time to heat up, and the plastic case also heats up with it.

Each manufacturer has its own standards for permissible heating temperature, but usually it is from +55°C to +70°C, which is safe for use. You can always check the heating limit in the technical data sheet.

If you notice that the heating level is noticeably higher than +70°C, and light traces of melting are visible on the body or the handle is stuck, then this is an emergency. In such a situation, it is better to replace the machine with a new one. If you ignore it, at best the shield will burn out, at worst there will be a fire in the apartment.

If any of the problems occur, replace the machine. Don't take risks and don't try to repair it.

The machine buzzes in the control panel under load

It happens that when you turn on a specific electrical appliance in the apartment, for example a multicooker or a lighting system using energy-saving lamps, or the power supply of a specific electrical appliance, the circuit breaker in the electrical panel begins to buzz. Moreover, this phenomenon is usually not associated either with the increased power of the connected consumer, or with the corresponding current approaching the nominal value of the machine. And it is associated with a certain power or with a certain household appliance.

In some cases, the hum disappears completely with increasing load power, and often the owner of the home has no complaints about the smell of burning... This means that it is not the arc that is humming inside the machine. And then what? Where does this hum come from? Is he dangerous? How to fight this phenomenon and is it worth fighting it at all? Let's think about this.

What's buzzing there?

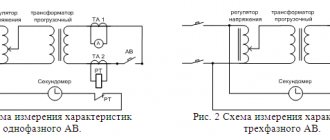

Anyone who is familiar with the design of a circuit breaker knows that two protective tripping mechanisms are simultaneously implemented inside it: thermal and electromagnetic.

The thermal release mechanism is based on the gradual deformation of a bimetallic plate, which, heated by the overload current passing through it, bends; this process is relatively inertial, however, if the current is equal to the nominal value of the machine, then after a few seconds the deformed plate will press on the trigger mechanism, and the charged spring of the switch will open the circuit .

The electromagnetic release mechanism is designed for the event of a short circuit; it is designed to instantly open the circuit when, during a short circuit, the current through the electromagnetic coil reaches such a value that a spring-pressed iron core is sharply retracted into this coil, which, when retracted, presses on the same spring-loaded switch - the circuit again it suddenly opens.

So, since the bimetallic plate cannot hum, it does not participate in magnetization, but is only heated by the current passing through it, therefore the hum of the machine is associated with the coil.

Indeed, the iron core of the coil is always in the magnetic field acting in the protected alternating current circuit. If the core is not pressed securely enough by the spring, if there is some play inside the circuit breaker body, then under certain conditions this core will indeed emit a rather noticeable hum.

Why is it buzzing? What are these conditions?

Firstly, if the shape of the current in the coil surrounding the core is distorted by a pulsed load connected to the network, producing pronounced peaks from transient processes, then the magnetostrictive effect of such peaks will inevitably generate noise from the iron core of the machine’s coil.

Secondly, if the core, even in the cocked machine mode, falls into the saturation region, then it will also hum.

Thirdly, if the core still has a strong backlash, it can transmit vibration to the plastic body of the machine and to other elements of your shield.

Thus, when three conditions are combined: core saturation, strong backlash, and the presence of impulse noise, we will theoretically hear maximum noise.

Who is to blame and what to do?

The answer to the question about the cause of the hum is logical: the manufacturers and developers of the humming machine did not provide for all the possible nuances associated with how the core will behave when the machine is cocked. And there is only one way out here. If you don’t want to put up with noise, then you need to purchase a machine whose coil core does not hum from interference, backlash, or possible saturation, and if it hums, it’s not very loud. If the hum does not bother you too much, you can leave the humming machine alone.

Very often we are faced with such a problem as the sudden appearance of an abnormal operating sound from a circuit breaker in the panel room.

A slight hum from an electromagnetic starter surprises few people, and some even consider this effect to be its usual mode of operation, although this is not the case for new devices. So what should you do when your machine buzzes like this or buzzes?

First of all, remember that all machines installed in a panel under normal operating conditions should never make any sounds.

If this sound appears, then first of all decide what it sounds like:

- hum

- buzz

All your further actions will largely depend on this.

Such sounds appear when the machine is energized and under load. That is, current flows through it. Moreover, the greater the load, the louder the machine can make noise.

Let's look at the first fault, namely humming. If your machine makes a sound during operation like a starter or contactor, this indicates a defect or defect.

Do not look here for damage to electrical wiring, bad contacts, etc. A humming machine definitely needs to be changed.

Although this does not mean that his defense will not work as it should.

It can still shut down properly and operate during short circuits.

But how long it will work like this - a month or two, or it will burn out at any moment, you will never know in advance.

Moreover, if in the electrical panel it stands in one tight row with other intact circuit breakers, its sudden damage or ignition will lead to the failure of all neighboring switching devices.

Therefore, it is better not to delay the replacement and immediately buy another one. Do not listen to the advice of those who recommend simply knocking on the machine body with some blunt object.

For example, the back of a screwdriver. Apparently after this the sound disappears.

Replacing a machine is not such a difficult job, and many people do it even under voltage.

Also, do not try to repair or disassemble it yourself. Such modular devices are made disposable and cannot be restored at home.

They are assembled not with screws at all, but with rivets. These rivets can only be drilled out.

If you do this, you will see the following picture inside.

Why you can’t repair a machine yourself

The fact is that no household machine is designed for repair at all. Based on the relatively low cost, manufacturers simply do not consider this option as it is not economically feasible.

Read: Selecting wire type and core cross-sections

Premium series of popular 16-amp single-phase Hager or Eaton in everyday life cost less than $10. Even with a slight breakdown, it will be cheaper to throw it away and replace it with a new one than to repair it. No service center does this, and don’t try it.

After self-repair, the consequences may be worse than before. You will have to open the case, which means compromising the integrity of the structure. The likelihood that the release mechanism will work properly after this is negligible. Moreover, after disassembly, nothing will hold securely there, which means an accident can happen at any moment.

Even such a minor (at first glance) breakdown as a dropped handle indicates mechanical defects. They often occur due to damage during transportation. There is no guarantee that everything else inside is working properly, so it is dangerous to put such protection in your shield.

Sometimes the main cause of breakdown is a manufacturing defect, which is often found among Chinese manufacturers.

The main problems with automatic machines

The machine has only three main faults:

- Knocks it out.

- Doesn't turn off.

- Doesn't cock.

The machine knocks out - this means that either suddenly, without obvious reasons, the voltage disappears, or when you turn on the load in one of the circuits, the power supply network is turned off. The machine may also not turn on in different ways:

- When the lever is cocked, it immediately goes down, the voltage appears briefly or does not appear at all.

- The lever is jammed and does not cock and does not work at all.

- If you hear a burning smell or the wires are burnt out from the circuit breaker, you need to turn it off before starting the repair, but the lever simply does not budge, as described in the previous paragraph, only in the on position.

The machine kicks out for no apparent reason

Periodic tripping of a circuit breaker is associated with the operation of a thermal disconnector or voltage surges in the supply network. There is nothing you can do about the last reason, except perhaps install a voltage stabilizer at the input to the machine, but this is expensive. But shutdown via a thermal disconnector is associated with a long-term but insignificant excess of the rated current.

More often than not, this is not a faulty circuit breaker, but rather a misuse of the circuit breaker. First of all, you should find out what current it is designed for, this is written on the front panel. Then calculate the total current consumed by electrical appliances that are powered through it. If the current is not indicated on the devices, the power consumption should appear on them; in this case, divide the number of W by 220 V, then you will find out the number of Amperes through the machine.

If the result obtained exceeds the nominal value of the machine, it will open. If the machine hums or crackles, this is a sign that it is overloaded.

Solution:

Reduce power line consumption, turn on powerful devices one at a time.

If the rating of the circuit breaker is selected correctly, the matter is different. The thermal disconnector is also thermal, so that it opens when overheated, and the source of heat can be burnt power contacts (as in the photo below) or wires that are not tightened in the terminal blocks. Both lead to an increase in contact resistance and heating, since the case is closed, there is nowhere for the heat to go, the thermal protection plate gradually heats up, and over time it will open.

Solution:

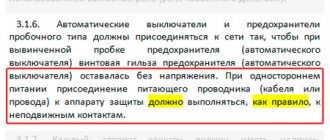

Check the tightness of the wires, remove them, if necessary, clean them from oxidation and carbon deposits, and then retighten them. The contacts cannot be cleaned without disassembling the machine; it is better not to “treat” this malfunction, but to replace the circuit breaker. To disassemble it, you can drill out the rivets and open the body, but you risk not assembling it or assembling it with errors, with distortion and mechanical defects, which will complicate correct operation.

Overheating can also occur from heat sources located near the AV in the shield itself. Check the temperatures of the surrounding devices with your hand; something nearby may be heating up.

Trigger when load is turned on

If a malfunction occurs when one of the circuits is turned on, for example a light, the fault is most likely in the lamp or the wiring leading to it. A short circuit has occurred due to the integrity of the cable insulation or connections being damaged.

Solution:

Diagnostics and repair consists of disconnecting the main line cable and replacing it with a temporary one; if it helps, then you have to inspect and repair the wiring.

Instant shutdown of the machine is associated with the operation of electromagnetic protection. It does not lock in the on position due to internal problems with the same electromagnetic protection. You can check the serviceability of the machine by replacing it with a known good one, with the same rated current and sensitivity - if everything works properly, this is the reason. If the circuit breaker does not reset without voltage, and there is no short circuit, it needs to be replaced.

Circuit breaker does not turn on

If you lift the lever up, but the circuit breaker does not turn on, and the lever instantly falls down, this is due to either mechanical wear of the machine components or the presence of a short circuit. You can check this by ringing the supply phase to zero with a low-resistance tester, for example, a test light, or an ohmmeter. High-impedance continuity testing (for example, LED control) can mislead you and the circuit can ring through the load (light bulbs, heating elements or electric motors). If the circuit is closed, then there is a breakdown of the cable insulation.

Solution:

Troubleshooting should be done by replacing the cable or restoring the insulation. If there is no short circuit, then replace the machine.

The lever is jammed

It’s another matter when you cannot move the machine lever from the lower position, which means the contact drive mechanism is jammed. This malfunction can occur when switching off under load, if a strong arc occurs and its splashes jam the movable contact, or rather its components, or it is soldered into the housing.

Solution:

Grasp the lever closer to the base and lift it firmly but smoothly, in this case there is a possibility of breaking it off. In the future, you will not be able to use such a machine. It is also possible that jamming will occur in the future, then the machine should be replaced. The probability of success in this procedure is 50%; in practice, the lever often breaks off, especially if this happens in the cold.

The machine does not turn off during a short circuit

There may be two reasons for the lack of response to short circuit. The first is that the contacts are stuck. Due to heating and arcing when opening, the contacts stuck to each other. The second is that the electromagnetic disconnector mechanism is jammed.

Solution:

If the machine does not operate during short circuits, try to forcefully break the contacts; if that does not work, then replace the machine.

Why are Chinese machines so unreliable?

Everyone understands that the only advantage of the “Chinese” is low cost. But it is achieved precisely by saving on materials. Budget Chinese models have cheap everything: plastic, metal, release mechanisms.

The most “trash” models often lack an arc chute. So, under high loads they do not spark, but immediately burn.

All these reductions in price will sooner or later come out sideways. For example, even due to elementary savings on rivets, the strength of the entire structure is lost. As a result, some parts fall off over time and the cocking mechanism weakens. This causes the problems listed above and will require replacement soon.

Electricians often swear at the “Chinese”. In fact, if you take the cheapest ones and take them apart to see what's inside, you'll be surprised how they even work. They usually have a lightweight design, thin springs, power contacts that barely hold, and other obvious problems. This doesn't inspire confidence.

Even worse are Chinese counterfeits of well-known brands, sold below the cost of the originals. Unfortunately, there are a lot of them on the CIS market. It is quite natural that the most popular brand, ABB, has the most counterfeits. This is a Swedish-Swiss manufacturer that produces fairly high-quality machines. Accordingly, you yourself must understand that they will not be too cheap.

To achieve high reliability and quality of releases, more expensive metals are needed: sputtering of silver, gold, etc. In addition, Europeans usually do not skimp on materials. There will definitely be an arc chute there and a heat sink will be made. And all this increases the cost, so there are no good machines cheaper than $3 .

How to choose a good circuit breaker

You probably already realized that first of all you should pay attention to European manufacturers. Everyone knows them: Hager, Schneider, ABB, Eaton and others. Even their budget series are head and shoulders above their Chinese counterparts.

Cheaper means worse?

One point is important here: the concept of “budget” is different between Europeans and Chinese. If the Chinese save on materials in order to reduce costs, then their European colleagues have a different approach:

- Instead of two self-clamping terminals, use one. Because of this, installation is more difficult, but the performance is not reduced;

- Remove color indicators. They are not always necessary at home, but the cost of production is cheaper;

- Inability to connect accessories. Without additional connectors, the price will be lower.

It turns out that in the end the “filling” becomes simpler, but no less high-quality. Therefore, if you buy a budget one, try not to buy “China”.

Don’t the “top” manufacturers have any defects?

Among “Europeans” it is very rare, but marriage also occurs. Therefore, before purchasing, do a visual inspection:

- The case must be intact, all fastenings are in place, and the terminals are not loose. If everything is not in order, it means it has probably been dropped or, even worse, taken apart. Then, take something else;

- All markings and the brand logo are applied with a laser, so they should not be erased. If the paint is a little smeared or worn out, then it is most likely a fake;

- A good machine gun should not be too light. The greater the weight, the more metal the manufacturer used in the mechanism, which means higher reliability;

- Click the handle. It should change position with medium pressure . If it sticks or moves too easily, this indicates defects in the design.

Also be sure to look at the technical data sheet to look at the breaking capacity. This is the main indicator of reliability.