Do you need a voltage stabilizer for a refrigerator?

According to statistics, the No. 1 reason for the failure of refrigerators is the poor quality of the supplied electricity. If the network does not provide the required parameters, breakdowns of the electrical and electronic components of the devices are possible.

Possible breakdowns

Sensitive electronic components, elements of the NoFrost system, and the motor-compressor burn out due to network overvoltage. Low voltage is no less dangerous; it causes insulation breakdown or interturn short circuit of the motor windings. With long-term exposure to starting current, as a result of a complete stop, overheating occurs with subsequent combustion of the windings of the power unit. In case of voltage fluctuations, beating of the moving parts of the electric motor is observed, and errors occur in the operation of the controller.

According to paragraph 4.2.2 of the current GOST 32144-2013, the voltage value in the network should be in the range of 198-242 V. Deviation of the parameter from the limit values often leads to breakdown of the electrical appliance.

If the alternating voltage in the network is more than 242 V, the controller and sensitive electronic components of the refrigeration unit are likely to fail.

Devices for protecting the refrigerator from power surges

According to an engineer at the specialized online store for electrical goods "Axiom Plus", on whose page https://axiomplus.com.ua/odnofaznyie-rele-napryazheniya/ there are over a hundred different models of voltage relays and one and a half times more stabilizers for reliable protection For compressor equipment, it is advisable to use one of these devices. The specific choice depends on the pressing problems of your electrical network, since functionally these devices are categorically different.

Voltage control relay for “rare but accurate” cases

General recommendation: if the power supply is generally stable, and failures occur a couple of times a year, it is recommended to install a safety net in the form of a voltage control relay.

This is a device that can instantly de-energize a line when the actual voltage values exceed the upper or lower limit of the norm. These values are set by the factory settings of the relay or adjusted by you manually. Look for the recommended range for your refrigerator in its documents - in the operating instructions or warranty card.

And only after the network parameters are normalized will the power supply be resumed again

The relay may slowly continue to kill your refrigerator

A voltage relay without a switch-on delay, at a minimum, will not help. It is important to understand: automatic restarts without delay are very dangerous for compressor equipment. The fact is that the most vulnerable and expensive element is the compressor, which is driven by an electric motor when instantly restarted and is likely to fail, as in the absence of protection as such.

Perhaps not immediately, but in a repeating scenario it will happen fairly soon. The start delay after power supply is restored is necessary to ensure that the refrigerant pressure is equalized in all components of the system, after which it will be safe to restart the compressor.

How long should the restart delay be?

Most often, manufacturers recommend setting an interval of 5 minutes, and in general , the longer, the more reliable . But even 30 seconds is better than nothing and can save the situation.

Which is better – a surge protector or a stabilizer?

Simple network filters are built on inductive-capacitive single-link LC stages.

More complex designs are implemented using semiconductor varistors with auxiliary elements of the electrical circuit. They convert the energy of “parasitic” pulses into dissipated heat. Surge filters are “sharpened” to eliminate only low-power short-term (duration 10−6-10−9 s) industrial and lightning impulses on power lines entering the 220 V network. They are also able to cope with interference induced in the network wiring from a working power tool or, for example, an electric generator. Such protection is effective until “the thunder strikes.” “Networkers” are not able to prevent drops in incoming voltage that occur for any length of time. This is due to the use of energy stored by capacitors, whose electrical charge capacity is limited, for smoothing.

Stabilizers operate on a fundamentally different method of voltage equalization, continuously adjusting the mains voltage “plug” within the range of ~ 220 V ± 5%, 50 ± 0.2 Hz, due to changes in the current strength in the electrical receiver. Therefore, they are preferable for use in worn-out electrical networks with unbalanced loads and low-quality electricity.

How to make the right choice?

The correct choice of stabilizer will help eliminate this unfavorable scenario. Some models are ideal for overvoltage situations, while others are more effective at boosting voltage in the event of a voltage drop or coping with network interference.

At increased voltage

Relay voltage stabilizers are indispensable for equalizing high voltages that last for a long time. However, they are not able to quickly track changes with frequent and sudden changes in this parameter. A triac stabilizer can handle fast voltage surges.

At low voltage

If low voltage is constantly observed at the facility, it is optimal to use an electromechanical type of stabilizer. It is also used in autonomous power supply systems with a large number of household appliances that cause a voltage drop when turned on at the same time.

High voltage interference

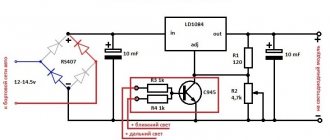

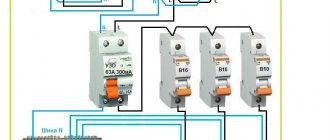

Each stabilizer by default contains circuits for filtering the input voltage from RF and LF interference with galvanic isolation. However, during a lightning strike or in an emergency, consumers may be supplied with increased voltage, which can damage the input circuits of the stabilizers. For example, if the “zero” in the line breaks, 380 V is supplied to consumers. Therefore, for reinsurance, a voltage relay is additionally installed on the electrical panel.

Recommendations for selection

All devices on the market differ from each other in design, operating principle and output results. In this regard, there are several types of voltage stabilizers. These are devices of relay, electromechanical and triac types.

Electromechanical models are equipped with an electronic board that controls voltage levels. The advantage is a high degree of accuracy, the disadvantage is the low speed of operation. Professionals recommend installing it when the refrigeration equipment operates in the mode of constant interruptions in the voltage supply.

Relay stabilizers, due to the built-in electronic unit and microcontroller, are capable of switching transformer windings using power relays. The system takes into account the time when the relay is activated and minimizes significant differences in voltage values.

The advantages of this type of device are its quick response to changes and the almost complete absence of delay in response.

Disadvantages include some noise when the relay operates (you can hear clicks) and wear on the contacts due to frequent power surges.

It is reasonable to use this device where a sudden change in the parameters of the electrical network is possible. However, it is worth remembering the service life of the device, which is reduced due to constant surges.

Triac-type stabilizers are capable of switching transformer windings thanks to power switches (triacs).

There are no contact switches in such devices, which makes them virtually silent devices. Pros: speed of operation, multiple switchings. Cons: high cost of the device and strict requirements for the quality of parts. If there are severe fluctuations in the network, installing a triac device will be the optimal solution.

Considering the above, it becomes clear what a refrigerator stabilizer can save from. Now it is necessary to clarify the question of how to calculate the required power of the device.

Kinds

Stabilizers, depending on the principle of operation and performance characteristics, are divided into several types.

Not any device is suitable as a voltage equalizer for a refrigerator, but only one designed to power SBT with electric motors. The electrical appliance must provide significant starting currents flowing through the windings of the compressor motor after being connected to the network. The high reliability of the instance is also important, since it will be used around the clock. Electromechanical, relay and system voltage stabilizers are highly resistant to overloads. They work perfectly both with a significant drop in the supply voltage and with a significant overvoltage in the network.

Electromechanical

Electromechanical devices use independent voltage regulation using an automatic power transformer. Stabilization occurs when the servo drive smoothly moves along the contact paths of the winding. The relatively quiet operation is explained by the silent movement of the current collector mechanism along the turns of the transformer. This type of device provides stabilization with an error of no more than 2.0–3.5%.

Relay

Relay stabilizers regulate the input voltage in case of deviation from the nominal values. If the measured parameter has a deviation, the relay for stepwise connection of the transformer windings is activated within 0.15 s. The accuracy of stabilization due to the intermittent connection of transformer taps usually does not exceed 5-8%, but it is noticeably lower in modern models with a large number of switching stages. Due to voltage surges and sine wave distortion, relay devices are not recommended for use in refrigerators with sensitive electronic components.

System

System stabilizers use triacs as a control element. They provide a quick response to voltage fluctuations in the network in 0.01-0.04 s with a stabilization accuracy of 1.5-4.0%. Switching of the transformer windings occurs without clicks, and thanks to the multi-stage protection system, the devices are practically invulnerable. The disadvantage of system stabilizers is the large dimensions required to accommodate radiators and fans.

Refrigerator compressor starting current

Peak electricity consumption of the refrigerator occurs precisely at the moment the compressor starts, because it contains an electric motor, which at the moment of start-up, for a short time, can consume 3-5 times more current, respectively, and power that is the same number of times more than declared.

Unfortunately, manufacturers usually do not indicate the starting current of the compressor, showing the maximum only the amount of electricity consumed by the refrigerator for a certain period of time, for example, the number of kWh/year is the amount of energy consumed by the refrigerator for a whole year if it is constantly turned on.

In fact, the power consumption of any household refrigerator most often does not exceed 150-250W and, as practice shows, the starting currents of the compressor motor rarely reach even 6A - which corresponds to 1.32 kW in a single-phase network, but more often they are much less.

The optimal solution would be to find out the brand of the compressor or compressors installed in the refrigerator, if there are several of them, and then find out the starting current parameters on the manufacturer’s website or by calling its technical service. support.

Further, it would seem, knowing this indicator, you can safely go to the store and buy the appropriate stabilizer, but not everything is so simple.

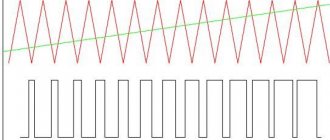

As you remember, the performance of any stabilizer depends on the incoming voltage; usually, in the technical documentation for each model, a graph of the drop in output power by the stabilizer is attached, depending on the incoming voltage, it looks something like this :

RESANT stabilizers , as you can see, the minimum voltage at which they will operate is 140 Volts, if it is lower, they will turn off, the upper threshold is 260V.

The maximum power of the Resanta stabilizer at 140V, judging by the graph, will be no more than 50% of the nominal.

Thus, if you have only 140V in your outlet, instead of the required 220V, when using the RESANTA ACH-2000/1-C stabilizer - for 2000 VA power, you will receive only half of this at its output, i.e. only 1000 VA. There is no guarantee that your refrigerator will start and operate correctly, because, as we found out, some models may require approximately 1.32 kW of power.

If the voltage in the outlet is at least 160 Volts, the output power of this stabilizer will already be 70% of the nominal, i.e. 1400 kVA - which is quite enough to operate almost any refrigerator.

Characteristics of the right choice

The passport for the device contains the main technical characteristics. When choosing an instance, you should pay attention to the following parameters:

- the power of the stabilizer, which should be several times greater than the power of the refrigerator being serviced;

- the operating range of the incoming voltage necessarily covers the voltage deviation;

- The response speed must be sufficient to prevent damage to sensitive electronics during voltage surges.

Taking into account the cost of the product and the popularity of the brand, you can choose a stabilizer model with an optimal price-quality ratio.

Power

Typically, manufacturers indicate the power of the stabilizer (total) in volt-amperes (V∙A), and the power of the refrigerator (active) in watts (W). To correctly make calculations, you need to divide the power value in watts by the correction factor Cos φ; for a refrigerator it is taken as 0.65. As a result, we get the total power of the refrigerator in VA. Since it contains an electric motor in the compressor, it is also necessary to take into account large starting currents when starting the unit. Therefore, the resulting total power must be increased at least 3 times.

Operating range

The operating range of the input voltage is one of the most important characteristics of the purchased models. It must be stated in the passport or other accompanying documentation for the product item. Typically, stabilizers with an operating range of 130-270 V are installed in private houses, country cottages and dachas.

Safety

In cheap models that have not been certified, manufacturers usually skimp on safety. The functionality of the stabilizers does not include elementary stages of protection against overvoltage, overcurrent or overheating. This can lead to premature failure of refrigeration equipment, electrical shock and fire.

Performance

The low response time of the stabilizer will help protect sensitive electrical components from electrical breakdown and burnout. A response time of 10-20 ms is considered acceptable. Such performance is ensured by modern stabilizers, with the exception of old electromechanical models based on LATRs.

Price

Relay models on the stabilizer market are distinguished by the “democratic” price of the products. In the low-cost product segment there are also many electromechanical stabilizers. System models are more expensive than relay models, which is justified by the use of various protection elements. Frankly “Chinese” will cost 2000-4000 Ᵽ, the cost of certified models starts from 6000 Ᵽ.

Manufacturer

In the segment of Russian voltage stabilizers, competing on equal terms with Chinese-made products (“Resanta” with production in China), domestic ones, Tensi-Techno CJSC, Tula, were noted;

The products of SSK (Energy Technologies, Moscow) have an optimal price-quality ratio.

Types of stabilizers for refrigerators

Devices designed to stabilize voltage differ in both design, output power, and operating principle. Based on these characteristics, there are three types of refrigerator stabilizers: electromechanical, also known as servo drive, relay, triac or electronic.

The photo shows all three types of stabilizers: servo drive - the cheapest, relay, electronic - the most reliable, stable, but also expensive

Stabilizers are also divided by type of electrical network. They can be single- and three-phase. The first ones have compact dimensions, and since There is no cooling fan in their design; they make almost no noise during operation. The output voltage is monitored continuously, but the level of response to the input voltage is quite low.

For houses powered by a 380 V power supply, three-phase stabilizers have been developed that are designed for heavy loads, but when one of the phases fails, the protective mode does not work. Depending on the type of voltage in the network, devices are divided into those operating with low, high and intermittent voltage.

Electromechanical type devices

Servo-drive devices control the pantograph drive and monitor voltage parameters via an electronic board. High accuracy is their main advantage; the error is only 2-4%. The disadvantage is the speed caused by the inertia of 10-20 volts.

Electromechanical stabilizer - view from the inside. The slider, moving along the turns of the winding, changes the output voltage. A large number of nodes makes such devices short-lived

Such a stabilizer works well under conditions of either slowly changing voltage, or consistently low, or high voltage. If there are strong abrupt changes, the device will quickly become unusable. Such conditions are most often observed in dachas and country cottages, so this option is not suitable here.

Relay type stabilizer

A simple relay type stabilizer control system can withstand significant differences. On its electronic unit, as well as on the controller, there are power relays, which are responsible for switching the transformer windings. The transition occurs extremely quickly - in just 0.5 seconds.

The photo shows a relay type stabilizer. This equipment is the most common in everyday life. Often consumers are attracted by its relatively low cost

The weak link is the microcontroller. It can burn out if it cannot withstand the excessive mobility of the input voltage.

The work of switching transformer stages is accompanied by clicking noises, which does not add comfort to the home. Such models are intended for use in networks where rapid voltage reboot occurs constantly.

System models of devices

There is no such element as a relay in the electronic stabilizer; the control is managed by semistors, which quickly respond to the slightest changes in the network. The absence of mechanical contacts makes it possible to carry out multiple switching noiselessly during power outages.

Thyristor stabilizer SKAT ST-12345. It covers a wide range of input voltages, is characterized by high power and stabilization speed, and complies with all domestic and international standards

They can withstand voltage overloads of up to 20% for 12 hours, and up to 100% for one minute. Manufacturers of system stabilizers place high demands on the quality of parts and assembly accuracy, so both the durability and cost of the devices are appropriate.

Features of installation and connection of the stabilizer

Installation can be wall or floor. The stabilizer should not come into contact with heating devices, flammable substances, and be protected from drops of water. A cabinet or niche in the wall with a door is not suitable for placing the device, as this interferes with natural air circulation.

Also, do not connect the stabilizer to a consumer outlet with a different type of signal (computer, router). These electrical receivers will create interference in one line, which will provoke unauthorized operation of the stabilizer.

Exploitation

The operating rules allow the device to be used at t ≤ 40ºC and humidity specified in the product instructions (usually ≤ 80%).

It is not allowed to cover the stabilizer with cloth or paper, or plug the ventilation holes with foreign objects. Do not use the device with the top cover folded down. Failures of the refrigerator due to voltage surges are not considered service cases, therefore, if the refrigerator fails, the owner is forced to carry out repairs at his own expense. You should measure the voltage in the outlet with a multimeter 5-6 times a day. If the parameter goes beyond the range of 198-242 V, it triggers a response.

The optimal solution would be to connect it to the network through a voltage stabilizer. A correctly selected model will improve the quality of the power supply and significantly extend the life of the refrigerator.