Dry power transformers

Dry three-phase power transformers with geafol cast insulation with voltage up to 10.5 kV are designed for converting electricity in the networks of power systems and consumers of alternating current electricity with a nominal frequency of 50 Hz.

Transformers are equipped with windings from Siemens, the winding material is aluminum.

To insulate the windings, an epoxy compound with quartz filler (geafol) is used. Additionally, the windings are reinforced with fiberglass mesh, which eliminates the occurrence of cracks in the epoxy compound even when the transformers are overloaded. Geafol does not have a harmful effect on the environment and does not emit toxic gases even when exposed to arc discharges. Thanks to this insulation, the windings do not require maintenance.

To measure and control temperature, transformers are equipped with a TR-100 digital temperature relay with three RT100 type temperature sensors built into the LV windings. An additional sensor is installed on special transformers (for powering semiconductor converters, etc.), as well as at the customer’s request, to monitor the temperature of the magnetic core.

The temperature relay TR-100, equipped with an RS-485 MODBUS RTU interface, is connected to direct or alternating voltage from 24 to 260 V.

If the temperature rises dangerously, the output relay for controlling the warning circuits is activated. If the temperature rise continues and the temperature exceeds the maximum permissible value, the output relay for alarm control (emergency shutdown of the transformer) is activated.

At the customer's request, other types of temperature control devices can be installed.

Transformers TSGL, TSDGL (without protective casing) are equipped with temperature sensors with a cable length of ten meters, which allows you to transfer the thermal protection relay or fan control box for TSDGL to enclosing structures or other structural elements of the substation (at a distance of up to six meters) to ensure its safe and convenient service. At the customer's request, other types of thermal protection can be installed.

Transformers TSDGL, TSDZGL, TSDZGLF, TSDZGL11, TSDZGLF11 are equipped with a forced cooling system consisting of a control box and winding cooling fans. The use of forced ventilation makes it possible to increase the power of dry transformers by up to 40%.

TSGL, TSZGL, TSZGLF - dry transformers

Dry three-phase power transformers with geafol cast insulation of the TSGL, TSZGL series (with VN inputs inside the casing) and TSZGLF (with VN inputs brought out on a flange located on the end surface of the casing) produced by the Minsk Electrical Plant named after. IN AND. Kozlov with voltage up to 10 kV are designed for operation in electrical networks of alternating current electricity consumers with a nominal frequency of 50 Hz. Transformers are equipped with windings. The heat resistance class of the windings is F. An epoxy compound with quartz filler (geafol) is used to insulate the windings. Additionally, the windings are reinforced with fiberglass, which eliminates the occurrence of cracks in the epoxy compound even when the transformers are overloaded. Geafol does not have a harmful effect on the environment and does not emit toxic gases even when exposed to arc discharges. Thanks to this insulation, the windings do not require maintenance. Transformers can operate in networks subject to lightning and switching overvoltages, have a low noise level, and high resistance to short-circuit currents. Transformers are environmentally friendly and fireproof, can be installed in places requiring increased safety (metro, mines, cinemas, residential and public buildings), in places with increased requirements for environmental protection (water intake stations, sports facilities, resort areas), in industrial enterprises, metallurgical plants, chemical plants, power plants in close proximity to the load center, which avoids costs associated with the construction of substations, ensures savings in distribution busbars and low-voltage cables, and reduces electricity losses in them. Voltage regulation up to ±5% in steps of 2.5% is carried out on a completely disconnected transformer (PBV) by rearranging the jumpers. To protect against overheating, transformers are equipped with a thermal protection device controlled by thermistors built into the LV windings. Transformers are designed for indoor operation in temperate climates (from +40°C to -45°C). Relative humidity 75% at 15°C. The environment is non-explosive and does not contain dust in concentrations that deteriorate the parameters of products within unacceptable limits. The installation height above sea level is no more than 1000 m. TSGL transformers are manufactured with a degree of protection IP 00 (without casing), TSZGL and TSZGLF-1R 21 (with casing).

Technical characteristics of transformers of the TSGL, TSZGL, TSZGLF series

| Type | Rated power, kV*A | Power loss, W | Current XX, % | Short-circuit voltage at 75°С, %, (UK) | Corrected sound power level, dB(A) | Dimensions, mm | Weight, kg | |||

| XX | short circuit | L | IN | N | ||||||

| TSGL | 100 | 0,6 | 1,3 | 2,0 | 4,0 | 59 | 1250 | 700 | 900 | 750 |

| TSZGL | 1600 | 1100 | 1400 | 900 | ||||||

| TSGL | 160 | 0,65 | 2,15 | 1,4 | 4,0 | 62 | 1300 | 710 | 1000 | 850 |

| TSZGL | 1650 | 1100 | 1500 | 1000 | ||||||

| TSGL | 250 | 0,9 | 3,0 | 65 | 1420 | 770 | 1150 | 1200 | ||

| TSZGL | 1850 | 1170 | 1745 | 1500 | ||||||

| TSGL | 2,5 | 1420 | 770 | 1300 | 1550 | |||||

| TSZGL | 400 | 1,2 | 3,9 | 5,5 | 68 | 2050 | 1170 | 1745 | 1705 | |

| TSZGLF | 2085 | 2185 | 1760 | |||||||

| TSGL | 1520 | 1000 | 1500 | 1950 | ||||||

| TSZGL | 630 | 1,65 | 5,73 | 2,0 | 71 | 2050 | 1250 | 1970 | 2180 | |

| TSZGLF | 2095 | 2170 | 2200 | |||||||

| TSGL | 1720 | 1000 | 1700 | 2900 | ||||||

| TSZGL | 1000 | 2,15 | 8,4 | 1,5 | 74 | 2245 | 1250 | 2170 | 3150 | |

| TSZGLF | 2295 | 3170 | ||||||||

| TSGL | 6,0; 8,0 | 1950 | 1000 | 1950 | 4600 | |||||

| TSZGL | 1600 | 2,6 | 11,8 | 1,0 | 76 | 2505 | 1250 | 2380 | 4900 | |

| TSZGLF | 2550 | 4920 | ||||||||

| TSGL | 2500 | 4,4 | 16,4 | 0,5 | 78 | 2000 | 1400 | 2150 | 5200 | |

| TSZGL | 2600 | 1600 | 2400 | 5500 | ||||||

TSGL, TSZGL - dry power transformers with Geafol insulation

Dry power transformers of the TSGL series (without a casing, unprotected version - degree of protection IP00), TSZGL (with a casing, protected version - degree of protection IP20, IP21) with windings with cast insulation of the "Geafol" type (epoxy compound with quartz filler) - power step-down three-phase two-winding general purpose, normal design, power from 100 to 2500 kVA, voltage up to 10 kV, used in many sectors of the national economy. Transformers are designed to convert electrical energy in three-phase alternating current power networks with a frequency of 50 Hz and are installed in industrial premises and public buildings, which are subject to increased requirements in terms of fire safety, explosion protection, and environmental cleanliness. Additional windings are reinforced with fiberglass, which eliminates the occurrence of cracks in the epoxy compound even when the transformers are overloaded. This material does not have a harmful effect on the environment and does not emit any toxic gases even when exposed to arc discharges. Thanks to this winding insulation, no maintenance is required.

Price list

Specifications

Power transformers of the TSZGL type with a power from 100 to 2500 kVA with a rated voltage of the primary winding (high voltage) up to 20 kV inclusive and secondary winding (low voltage) - 0.4 kV. Voltage regulation - non-excited jumper switching to ±5% or ±2.5% UH.

Terms of Use:

- ambient temperature: from -25 oC to +40 oC;

- relative air humidity ~ no more than 98% at a temperature of +25°C;

- installation height above sea level - no more than 1000m;

- The environment is non-explosive and does not contain conductive dust.

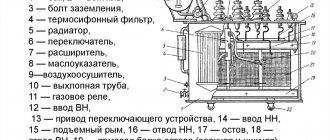

Transformer design

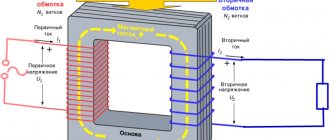

Transformers consist of the following main assembly units:

- magnetic circuit;

- windings placed on the magnetic core (active part);

- bends (inputs, LV and HV busbars);

- protective casing.

The magnetic core is made of high-quality electrical steel. LV windings are made of aluminum or copper foil and filled with epoxy resin. HV windings are manufactured as either coil or layer, depending on power and voltage. High technology of filling under deep vacuum, baking in electrical ovens according to a special temperature program guarantees stable quality of windings and high resistance to short circuit currents.

The heat resistance class of the windings is F, the windings are painted brown.

Transformers with a casing, upon customer request, are supplied in the following versions:

- with the ability to connect power cables through the bottom of the shell;

- with HV and LV bus terminals on the narrow sides of the transformer;

- with outputs of HV and LV buses through the transformer cover.

Containments provide access to the transformer through removable panels on the long side of the transformer. Transformers with these windings have advantages over other dry transformers:

- they can operate in networks subject to lightning and switching overvoltages;

- have a reduced noise level;

- have high resistance to mechanical forces arising in short circuit mode;

- When using transformers, complete environmental and fire safety is ensured.

Dry transformers TSZGL series with power 160 to 2500 kVA

| Power, kVA | No-load losses, W | Short circuit loss, W | Short circuit voltage, % | Dimensions, mm | Weight, kg | ||

| L | IN | N | |||||

| 160 | 850 | 2300 | 4 | 1380 | 925 | 1380 | 1310 |

| 250 | 1000 | 2890 | 4 | 1700 | 1050 | 1580 | 1670 |

| 400 | 1150 | 3790 | 6 | 1760 | 1050 | 1640 | 1700 |

| 630 | 1600 | 5800 | 6 | 1820 | 1188 | 1850 | 2500 |

| 1000 | 2100 | 7900 | 6 | 1980 | 1224 | 1950 | 3050 |

| 1600 | 3100 | 11500 | 6 | 1980 | 1298 | 2320 | 4100 |

| 2500 | 4800 | 12000 | 6 | 2850 | 1455 | 2735 | 6900 |

Power transformers TSGL, TSZGL, TSZGLF

Power dry three-phase transformers TSGL, TSZGL with geafol cast insulation (with HV inputs inside the casing) and TSZGLF (with HV inputs brought out on a flange located on the end surface of the casing) with voltage up to 10 kV are intended for converting electricity in power supply networks and AC electricity consumers current rated frequency 50 Hz. Power transformers SGL, TSZGL, TSZGLF are designed for indoor operation in moderate climate conditions (from plus 40°C to minus 45°C). Relative air humidity 75% at 15°C.

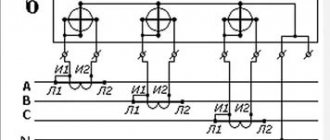

The environment is non-explosive and does not contain dust in concentrations that reduce the parameters of products within unacceptable limits. Installation height above sea level is no more than 1000 m. Transformers are equipped with windings. The heat resistance class of the windings is F. An epoxy compound with quartz filler (geafol) is used to insulate the windings. Additionally, the windings are reinforced with fiberglass, which eliminates the occurrence of cracks in the epoxy compound even when the transformers are overloaded. Geafol does not have a harmful effect on the environment and does not emit toxic gases even when exposed to arc discharges. Thanks to this insulation, the windings do not require maintenance. Power transformers can operate in networks subject to lightning and switching overvoltages, have a low noise level, and are highly resistant to short circuit currents. Transformers provide complete environmental and fire safety, can be installed in places requiring increased safety (metro, mines, cinemas, residential and public buildings), in places with increased requirements for environmental protection (water intake stations, sports facilities, resort areas), in industrial enterprises, metallurgical plants, chemical plants, power plants in the immediate vicinity of the load center, which avoids costs associated with the construction of substations, ensures savings in distribution busbars and low-voltage cables, and reduces electricity losses in them. Voltage regulation up to ±5% in steps of 2.5% is carried out on a completely disconnected transformer (PBV) by rearranging the jumpers. To protect against overheating, upon customer request, transformers are equipped with a thermal protection device controlled by thermistors built into the LV windings. Vibration damping pads can be supplied upon customer request. The degree of protection of transformers TSGL - IP 00, TSZGL and TSZGLF - IP 21. Diagram and group of winding connections - D/Un-11, U/Un-0, rated voltage LV - 400V. Dry power transformers TP 1- and 3-phase from 0.1 to 200 kVA enclosed with varying numbers of secondary windings

Characteristics of dry power transformers TP

| Name | Number of phases | In. U | Exit U | Weight, kg |

| TP1-(0.1-0.63) | 1 | 127-1000 | 5-1000 | 10 |

| TP1-(1.0-1.6) | 1 | 10-1000 | 27 | |

| TP1-(2.0-2.5) | 1 | 30 | ||

| TP1-(3.0-4.0) | 1 | 40 | ||

| TP1-(5.0-6.3) | 1 | 50 | ||

| TP1-(7.0-8.0) | 1 | 85 | ||

| TP1-(9.0-10.0) | 1 | 100 | ||

| TP3-(1.0-1.6) | 3 | 37 | ||

| TP3-(2.0-2.5) | 3 | 127-1000 | 10-1000 | 40 |

| TP3-(3.0-3.5) | 3 | 50 | ||

| TP3-(4.0-6.3) | 3 | 60 | ||

| TP3-(7.0-8.0) | 3 | 90 | ||

| TP3-(10.0) | 3 | 110 | ||

| TP3-(16.0) | 3 | 20-1000 | 160 | |

| TP3-(20.0) | 3 | 20-1000 | 180 | |

| TP3-(25.0) | 3 | 36-1000 | 190 | |

| TP3-(30.0) | 3 | 36-1000 | 200 | |

| TP3-(35.0) | 3 | 36-1000 | 220 | |

| TP3-(40.0) | 3 | 50-1000 | 240 | |

| TP3-(63.0) | 3 | 50-1000 | 260 | |

| TP3-(100.0) | 3 | 220-1000 | 100-1000 | 400 |

| TP3-(160.0) | 3 | 220-1000 | 150-1000 | 750 |

| TP3-(200.0) | 3 | 220-1000 | 200-1000 | 800 |

| TP3-(250.0) | 3 | 220-1000 | 200-1000 | 900 |