Concept of resistive heating cable

Externally, the heating cable does not differ from the conductive cable used for power supply of installations.

But its conductors are not made of aluminum or copper, but of a material with high ohmic resistance.

Design features

The cable consists of the following components:

- Several cores made of highly resistive material. They are enclosed in an electrically insulating shell with a high thermal conductivity coefficient.

- Metal braid (screen). Covers the conductors, serves as protection against mechanical damage and grounding, and shields electromagnetic radiation.

- Dense shell made of light-resistant polymer with high thermal permeability. It also serves as protection against mechanical stress and additional insulation.

There are models with double shell.

Operating principle

The operation of the heating cable is based on the Joule-Lenz law. According to it, as a result of the flow of current in a conductor, heat is released with a power proportional to the product of the electric field density and intensity.

Resistive cable design.

In integral form for thin conductors, the law sounds like this: the power of heat generated in a section of a conductor is equal to the product of the square of the current strength and the resistance of the material. Mathematical notation:

W=I²*R, where:

W—heat generation power;

I - current strength;

R - resistance.

The work done by the electric field when moving a charge is consumed to release heat.

The resistance of copper and aluminum conductors of current-carrying wires is low, they do not heat up. In a resistive cable, on the contrary, it is large, and when connected to a power source, it increases the temperature of the structure to which it is attached.

Main advantages of use

This type of heater has the following advantages:

- Elasticity. The product can be used to heat curved and broken surfaces.

- No noise. Unlike burners, steam generators and other devices, the cable does not make sounds.

- Easy to use. To bring the system into working condition, you only need to supply power.

- High reliability. The simple design means there is nothing to break, minimizing the risk of icing on the roof or other element due to a failure in the heating system.

- Efficiency. The efficiency of electric heating is 99%, almost all the energy expended is spent usefully.

- Low price. A resistive cable is cheaper than a self-regulating analogue with a semiconductor matrix.

- Compact and light weight. The thin cable does not load the structure and does not affect its dimensions.

- Lack of water, steam, antifreeze. When using heating cables, you do not have to deal with leaks, corrosion and other shortcomings of liquid systems.

- Uniform heating along the entire length. All areas of the structure receive high-quality heating, regardless of its duration.

Elasticity and uniform heating along the entire length are the advantages of the cable.

Working principle of resistive cable

Resistive cable is one of the types of heating cables, the main advantage of which is their small size and ease of installation. This is the simplest and most inexpensive cable to produce. Consists of a conductive core in insulation. The power of such a cable is static: it is made of a fixed length and power, so such a cable cannot be shortened during installation. Arbitrary cutting of such a cable leads to an increase in the resistance of the entire cable and to its further overheating and failure.

The constant heating cable ensures the same temperature along its entire length. This is its main difference from a self-regulating cable. The configurations of heating systems built on a resistive heating cable are varied: from simple ones (in which the cable is plugged into an outlet) to complex ones equipped with automatic equipment for measuring and regulating temperature.

Varieties

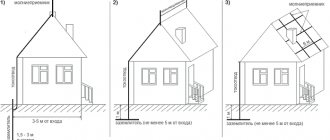

Single-core resistive cable has a nuance that should be taken into account when installing. The cable is connected from both ends to the electrical network, so during installation they try to lay the cable in such a way that both ends converge in one place.

The two-core resistive cable can be connected on one side, which simplifies installation.

The next type of resistive cables in the process of technology development were zonal heating cables . The design of the two-core resistive cable was improved by adding short sections of spiral heating conductors at a certain pitch. The zone cable can be cut into the required pieces with a certain pitch. Its disadvantage is possible local overheating and the likelihood of a cold zone appearing at the end and beginning of the circuit.

The advantages of resistive cables over self-regulating ones are their affordable price, constant characteristics throughout their entire service life, the absence of inrush currents, and high reliability of the heating circuit.

Resistive cables are most widely used in floor heating systems and for local heating of small-diameter water pipes, in heating roofs and greenhouses. Resistive cable produces constant power, so it is useful to use it with thermostats and heat sensors to measure the environment and start the system in a timely manner.

The nuances of selecting a resistive cable

Decide on the tasks, location and method of cable installation. Pay attention to the following tips:

- When installing a heating cable, avoid crossing the cable, this can cause overheating and failure of the entire section.

- Heating cables designed for underfloor heating systems should not be used in anti-icing systems, since such cables do not have proper insulation.

- Think in advance about what will be located in the heated space, since insufficient heat removal leads to overheating of the cable. (This can be avoided by using a more expensive zone cable.)

Areas of use

Cable heating systems are used in everyday life, industry, transport and other areas. When used outdoors, the product is covered with thermal insulation if possible.

For water supply

Sections of the water supply system that, for technical reasons, cannot be buried in the ground, are equipped with a resistive cable to prevent freezing of the transported medium in winter. There are 2 heating methods:

- Outer. The line is laid over the pipe using a spiral or snake.

- Interior. The cable is inserted into the pipeline through special pipes.

The wire is laid over the water pipes.

In the second option, products are used in a food-grade polymer shell. Small diameter pipes are heated using this method.

For floors

Heating cables are used in the construction of “warm floors”. This type of heating is characterized by low heat loss, which is explained by the following:

- it operates in low temperature mode (heat leaks are proportional to the temperature difference);

- the heated air does not touch the external walls.

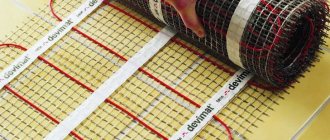

In concrete floors, the resistive conductor is filled with screed. They produce cable mats. These are panels made of fiberglass mesh with a heater attached to it, already laid in a “snake”. The system is easy to install - you only need to unroll the mats.

Resistive cable is used in “warm floor” construction.

In wooden floors, aluminum plates are laid on top of the cable to distribute heat evenly.

For roofing

Roof heaters are distinguished by a light-resistant shell of increased strength. They are laid in areas prone to icing:

- eaves of roofs and adjacent areas;

- in gutters and drainage pipes.

Thanks to the use of a heating system, people are prevented from being injured by falling icicles and labor costs for clearing snow from the roof are reduced.

High strength wires are used for the roof.

For tanks

Cables are used to maintain positive temperatures in outdoor containers containing petroleum products, raw materials for chemical production and other liquids. Heaters are laid along the entire surface of the tank. If the liquid contained in the container is non-aggressive, they are placed inside.

Main types

There are 3 types of resistive cables:

- 1-wire;

- 2-wire;

- zonal.

The last type is significantly different from the other 2. It consists of 2 conductive cores and sections of a heating coil connected to them in a parallel circuit.

Zone cable has 2 important advantages:

- It can be cut and extended without changing the specific heat output. In the second case, the current consumption increases; this must be taken into account when choosing the supply line and switches.

- If the spiral burns out, other areas remain operational. Other types are completely out of order due to such breakdowns.

Main types of resistive cable.

1-2-wire cables cannot be cut - this will lead to a decrease in resistance and, as a result, an increase in specific heat generation and current consumption. Increasing, on the contrary, will reduce the heating power.

Single-core

The heater consists of 1 resistive core. The advantage of this solution is low cost.

Flaws:

- Both ends are connected to the power source. You have to lay the product so that they converge at one point.

- Strong electromagnetic radiation. Such heaters cannot be used in “warm floors” and other structures near which people are constantly present.

Two-core

The product consists of 2 resistive wires connected in series using a coupling at one end. Advantages of the cable:

- Only 1 end is connected to the power source. The heating engineer has more freedom in choosing the installation scheme.

- There is no electromagnetic radiation. The currents in the veins have the opposite direction, so the fields they induce cancel each other out.

Due to the absence of electromagnetic background, 2-core cables are suitable for heating floors and other structures in the vicinity of which people are constantly located.

The disadvantage of products of this type is their higher cost compared to 1-core ones.

Heating cable: performance properties and main types

With the arrival of winter and the onset of cold weather, every zealous owner has an irresistible desire to provide his home with the necessary warmth, comfort and coziness. And a modern “warm floor” room heating system can help you with this! If you live in your own country house, then you need to pay attention to the anti-icing and snow-melting systems that are installed on the roof. These systems provide not only aesthetic functionality, clearing the roof of ice and the facade of icicles, they prevent leaks, prevent snow and ice from falling from the roof, etc.

The main element, one might say the working body of such systems, is the heating cable. And this article is dedicated to him.

The operating principle of the heating cable is based on the Joule-Lenz law, known to us from our school desks. If physics is not your thing, or it was studied a long time ago, let’s try to remember the main points together.

In this case, we have a conductor - a heating cable through which electric current flows. According to the law, a conductor under the influence of electric current necessarily heats up. The strength of heating directly depends on the magnitude of the electric current and the resistance of the conductor. In fact, this effect is extremely undesirable for wires and cables of power supply systems, but in the case of a heating cable, on the contrary, it is welcomed and developed.

Modern heating cables can be structurally divided into two types: self-regulating and resistive.

Resistive heating cable

Resistive type heating cables have a constant output power along their entire length, which depends on the length of the cable, the applied voltage, and the resistivity of the material.

Such cables are used for heating a wide range of different objects that can be operated in a wide variety of climatic and environmental conditions. For the manufacture of cores of such cables, special alloys are used, which are characterized by an insignificant temperature coefficient of electrical resistance. Thanks to this property, it is possible to produce a cable that, at different temperatures, has an almost constant thermal linear power, i.e. The heat dissipation is constant along the entire length of the cable.

Resistive cables are divided into three groups depending on the operating temperature range:

- low temperature – up to 100 ºС,

- medium temperature – 100-250 ºС,

- high temperature – 250-1000 ºС.

High-temperature cables are characterized by significant heat release up to 250 W/m and, as a rule, are used primarily for heating various production process equipment, as well as large pipelines. To heat roofs, rooms, and garden paths, medium- and low-temperature cables are used, having an operating temperature of no more than 250 ºС and a heat release of 10...30 W/m.

By design, resistive cables are also divided into two groups: parallel (zonal) or serial.

Resistive serial cable

Such a cable, as a heating element in its design, has a solid core stretching along its entire length. The total resistance of the entire cable is the total resistance of individual sections, i.e. The resistance directly depends on the length of the cable section connected to the electrical supply. Consequently, a change in the cable length leads to a change in the linear thermal power. Serial resistive cables used in various heating systems may include one or two insulated cores in their design.

Most often, single-core resistive cables are connected to the electrical supply at both ends. The most budget version of such a cable has only an insulating layer and an outer protective sheath. A more expensive and safer version involves the presence of a special protective screen that protects a person from electric shock. In addition, the screen is used to reduce the voltage of the electromagnetic field to acceptable sanitary standards. According to the laws of physics, such a voltage arises around any conductor when electric current flows through it.

In some cases, a serial single-core cable can also be a single-jack cable. Those. one of its ends inside the end coupling is connected to the screen, which plays the role of a second conductor. In turn, the screen must be connected to “zero” to perform security functions.

Two-core resistive cables are connected to an electrical source at one end only. At the second end of the cable there is a coupling that connects the heating and return cores. In this heating system, the coupling is one of the most vulnerable elements, so special attention is paid to their development. As a rule, the manufacturing technology of couplings is secret among all manufacturers.

In the case of using a two-core resistive cable, we have two conductors located in parallel. Electric current moves through conductors in directions opposite to each other, which contributes to the effect of mutual compensation of the strength of electromagnetic fields. That is why a two-core cable is safer for human health during operation.

Nichrome is most often used for the manufacture of heating cores that are used in high-resistance cables. Nichrome is an alloy of nickel (55...78%) with chromium (15...23%) with the addition of iron, manganese, aluminum and silicon as alloying additives. To produce low resistance cables, either galvanized steel or nickel-plated copper conductors are most often used.

The insulation of two-core cables can be either single-layer or multi-layer. Consequently, multilayer insulation provides a higher quality of dielectric strength, but at the same time such a cable is slightly more expensive. A wide range of materials are used to produce insulation: polyethylene, fluoropolymer, polyvinyl chloride, etc.

The insulated heating core is placed in a special protective screen, which is a braid of tinned or nickel-plated wire. A solid metal tube made of aluminum or lead foil can also act as a protective screen.

The final layer of the entire structure is a shell made of high-strength polymers.

As a rule, resistive serial cables are supplied for sale in ready-made heating sections. Those. This is a section of heating cable that is completely ready for connection to a power source with pre-installed couplings at the ends. The length of one section can range from several tens to hundreds of meters and is selected in such a way that the applied voltage reaches a complete drop without overheating.

Currently, the market is replete with offers from various resistive cable manufacturers. The STEM Energy brand offers the best price solution for heating cables.

Criteria for choosing a resistive heating cable: tips and tricks

The product is selected according to the following parameters:

- Length. It depends on the size of the heated structure and the laying pattern (“snake”, “spiral”, etc.).

- Specific power. The parameter shows how much heat a linear meter of the product generates; selected based on the coldest 5-day period in January.

- Current consumption. In accordance with this value, the power cable, circuit breaker, thermostat and other system components are selected.

- Voltage. For use in post-Soviet countries, the product must be designed for a voltage of 220 V.

- Shell material. For installation inside the water supply, a food-grade plastic coating is required; for outdoor use without thermal insulation, for example, on the roof - light-resistant, especially durable.

The cable system is equipped with an automatic switch with a remote temperature sensor. When it warms up, it blocks power, preventing overheating of the product with subsequent burnout.

If there is a risk of local deterioration of heat dissipation, for example, they can put something on a resistive cable, it is better to buy a self-regulating analogue. This product is capable of independently turning off overheated areas, while the rest continue to work.