Failures of radio equipment can be repaired independently. This method involves quickly solving problems and saving money. Using the instructions below, it is easy to perform high-quality repairs of the motion sensor yourself.

Detailed comments will help you reproduce certain technological operations without errors.

How motion sensors work

Products in this category perform their functions using active or passive methods of examining the surrounding space. The first option involves scanning, supplemented by comparison of the obtained data with standard indicators. As a rule, radiation in the invisible spectrum is used to ensure secrecy of control.

Laser motion sensor

The picture shows an example with two functional components. The emitter (spotlight) generates a beam of light. When crossing the corresponding line, the beam will be interrupted. This moment is recorded using a sensitive photosensor. To form a protective zone from a complex “mesh”, additional reflective elements are used.

This publication discusses in detail passive modifications of devices that record changes in readings in the infrared range. This solution has the following advantages:

- secrecy;

- wide directional pattern of the working area;

- economical energy consumption;

- fairly simple circuit design;

- affordable cost;

- high resistance to interference.

Operating principle of the IR sensor

Photocells are located in the center of the printed circuit board. They, together with the receiving path, are tuned to a wavelength range of 8-11 microns, which corresponds to thermal radiation from human skin at normal body temperature of +36.6°C. A multicomponent lens is installed on top.

As shown in the diagram, the appearance of a person is detected by a change in the input signal. The complex shape of the lens ensures movement is recorded. By adjusting the mode of the built-in amplifier, the amplitude of the input signal (sensitivity) is changed.

How does an IR detector work?

The operating principle of an infrared motion sensor is based on recording changes in the density of thermal radiation in the controlled space using a Fresnel lens. As long as the infrared background of the room is stable, the sensor is in standby mode. As soon as a person enters the room, the level of thermal radiation changes the balance towards increasing the IR flux. This will cause a change in resistance in the lens, which will give a signal to the relay, which in turn will turn on the light. When the movements of people in the room stop, the reverse process will occur, and then the light in the room will go out.

Operating principle of the IR sensor:

Sensor location

DIY motion sensor

From the above information, several preliminary conclusions can be drawn:

- As you move away from the sensor, the ability to detect small movements deteriorates;

- Light from lamps (direct) should be excluded to prevent false alarms;

- partitions, furniture and other obstacles can impair the functionality of the device;

- glass does not transmit infrared waves.

For your information. To select the correct sensor (installation location), it is necessary to clarify the range and directional pattern.

Check the location of the sensor

When choosing a motion sensor, you should pay attention to its detection range and range. The same parameters must be taken into account when selecting the location of the device.

During installation, the device must be installed and focused so that these parameters optimally suit the characteristics of the selected room. The optimal location for the sensor corresponds to the following indicators:

- From this position, the sensor's detection zone monitors the entire required space. This takes into account different operating ranges for “working at a desk”, “moving straight towards the sensor” and “walking to the side of the sensor”.

- If possible, the sensor should be installed to the side of the direction of movement of people and vehicles.

- The minimum distance to the lamp being switched on is one meter.

- The light to be switched on must not be within the detection range of the sensor. The light cone of indirect luminaires should not hit the sensor directly.

If one of these parameters does not match, the motion sensor may malfunction. You can check this yourself, and to troubleshoot problems due to the incorrect position of the device, contact a specialist.

Typical motion sensor malfunctions

Connection diagram of the motion sensor to the spotlight

These devices are often used in combination with lighting fixtures. Such solutions provide good visibility in corridors, rooms without windows, and in entrance areas. Problems appear as follows:

- complete lack of performance;

- delays;

- spontaneous switching of modes regardless of movements in the working area.

Such malfunctions appear after voltage surges in the power supply network or mechanical damage. The reason may be moisture getting inside the case, creating a short circuit between the conductors of the electronic circuit. Typical problems and sensor repairs are discussed below. Consistent inspection will help localize the damage.

The sensor does not work due to incorrect settings

First you need to make sure that there is mains power. Replacement of fuses and switching on of switchboard circuit breakers is carried out according to standard algorithms. Restoring wiring is a topic for a separate publication.

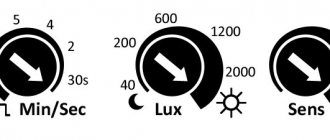

If the device stops turning off, check the settings. As a rule, such sensors are equipped with three smooth adjustments:

- photocell sensitivity;

- time interval before turning off the lamp;

- threshold level of background (natural light).

Regulators of main parameters

Users apply settings based on personal preferences. If necessary, you can use construction and sanitary standards for room illumination, depending on the intended purpose. So, for the kitchen area the standard value is at least 150 lux.

Incorrect installation location selected

At the next stage, compliance with the manufacturer’s instructions during installation work is checked. The following items are corrected:

- mounting height (as a rule, a range of 180-200 cm from the floor level is used);

- direction of photocells;

- the presence of batteries, incandescent lamps, and other heat sources nearby.

False inclusions

Arbitrary activations can provoke the following actions:

- convection currents;

- opening doors;

- rotating fan blades;

- movement of pets;

- movement of decorative elements.

If fine tuning does not help, change the direction of action. Some sensors can be equipped with different types of focusing lenses. In the most difficult situations, sets of several products are used, and another model with suitable characteristics is installed.

The sensor does not turn off the light

The constant light is on when there is heavy traffic in the corresponding area. They also check settings, external interference, and position. Sometimes it helps to disconnect the device from the power supply for a long time (10-15 minutes).

The light does not turn on when the sensor is working

The check is performed by analogy with the previous section. Before carrying out repair work, check the correctness of installation, established adjustments, and operating features.

Design features and operating principle of the motion sensor

The operating principle of the IR motion sensor is based on monitoring changes in the temperature field of the environment in the area of action. Such devices respond to the thermal field of a person, animal or other moving object, the temperature field of which differs from the background one. The sensitive sensor of the sensor registers IR waves, which are focused on it using a lens system. The voltage generated by the photosensor is amplified by an amplifier and supplied to a comparator, which transmits the signal through a transistor to the executive relay. In tracking mode, the system is in an equilibrium state in which the relay contacts are open. As soon as a moving element enters the sensitive area, the level of illumination of the sensitive element with infrared radiation will change, which will lead to the sensor’s functional circuit becoming unbalanced and triggering relay contacts that will connect an external load.

Motion sensor circuits

DIY drill repair

As an example, you can consider the typical design shown in the following figure. Further in the publication there will be links to this diagram. If the motion sensor for another type of lighting does not work, you should find the relevant information. It will help you repair the product without errors.

Electrical circuit of the motion sensor

Visual-tactile diagnostics

Repair of motion sensors may be limited to identifying damaged radio components and replacing them as a result of visual-tactile diagnostics of the infrared sensor. The device is disassembled and placed on the desktop under the light of a table lamp, armed with a magnifying glass: Check the integrity of the radio elements. There should be no swollen containers, darkened, cracked or loose elements. The smell of something burning will indicate the presence of burnt parts. They are clearly visible on the board.

The board track may burn out. Cracked, burned and broken grooves are restored by soldering jumpers. Analysis of the breakdown will help to avoid further malfunctions in the detector.

It is necessary to check the soldering of all radio elements. A tactile inspection reveals poorly secured elements on the board, and they are soldered again. All suspicious parts are replaced with new elements.

Common malfunctions and how to eliminate them For motion sensors for lighting, the most typical manifestations of operational failure can be characterized as follows:

- The lamp does not turn on.

- The sensor does not turn off the light.

- False alarm.

- Sensor orientation is incorrect.

Where to start repairs if the sensor does not work

After clarifying the possible causes, it is easier to establish the direction of diagnostic operations. If the mains power is OK, check the settings. Correct the position, eliminate external interference.

Open the sensor

At this stage, check for visible damage:

- wire breaks;

- breaks in printed circuit board tracks;

- soldering quality;

- thermal destruction of parts.

Test run

After eliminating the above faults, voltage is applied. Check operating modes. Trying to change the setting.

Checking the voltage at the lamp and detector

In order not to listen to the relay clicks, connect the load. You can turn on a regular 25-40 W incandescent lamp. It is advisable to add an automatic machine to the circuit to prevent the development of emergency situations.

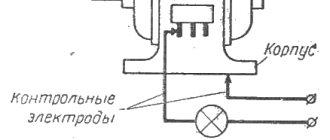

Checking the inside of the sensor

At this stage, the functionality of the built-in power supply is clarified. DC voltages (12, 24 V) and other values are checked at test points with a multimeter. Measurements are carried out sequentially using an electrical circuit.

Power circuits

In this part of the device, the main function is performed by a relay. Check the supply voltage, the integrity of the coil, and the passage of current when the contacts are closed. Check the functionality of the control switch on the power transistor.

Adjusting Sensor Settings

This procedure is performed according to a standard algorithm. Regulate:

- height and angle of inclination;

- sensitivity (Sens);

- illumination (threshold – LUX);

- light switch-off delay time (TIME).

A working detector does not turn off the circuit

In order to repair devices in this category correctly, you should correctly understand the basic principles of operation and the nuances of the functioning of a particular design. As noted in the title of this section, the photocell does not disable the control electronics. The signal received from it is used to form a delay interval. After a time determined by the setting, the relay interrupts the power supply to the lamp or other load.

Main signs of sensor malfunction, possible causes

There may be three signs:

- unauthorized activation, at any time without any reason;

- does not turn off the lighting lamp;

- does not turn on the lighting lamp or other terminal devices, and does not respond to obvious signs of movement in its field of view.

Sequence of troubleshooting and troubleshooting

In any case, you need to start by inspecting the appearance to see if there is any obvious mechanical damage to the optical system of the Fresnel lens, or a simple layer of dust and dirt. If necessary, clean the lens and check the functionality of the sensor. This is the most common and simplest cause of malfunction. If there is no positive result, you will have to perform more complex operations:

- Remove the housing and check that the connection is correct.

Motion Sensor Circuit Boards

- If, when simulating driving conditions, the relay is activated, a characteristic click is heard, and the lamp does not light up, it means that the circuit between the relay contacts and the lamp is faulty, ring it. The relay contacts may have oxidized; replace it or clean the contacts. I do not consider the lamp to be faulty; this needs to be checked first.

- Measure the DC voltage after the converter; depending on the sensor model, it can be from 8–24 V (see diagram and other documentation). The measurements are carried out relative to zero; it is convenient to take the “-” diode bridge on the boards.

- If there is no required voltage, ring the elements in the converter circuit, most often these are diodes of the rectifier bridge.

It happens that a short circuit in the circuit following the bridge or stabilizer extinguishes the incoming voltage. To verify this, disconnect the entire circuit after the stabilizer. If there is voltage, look for a short circuit, a faulty element after the stabilizer. This way you can ring the entire circuit up to the relay and lamp; if faulty elements are identified, replace them and check their functionality. If you follow this method, you will definitely find the cause of the malfunction; this method is good when a person has skills in working with electronic equipment, measuring instruments, and knows how to solder. When you don’t have such skills, you need to limit yourself to the first points: wiping, setting up, checking the power supply. If the elements on the board are faulty, contact a specialist.

Failures of radio equipment can be repaired independently. This method involves quickly solving problems and saving money. Using the instructions below, it is easy to perform high-quality repairs of the motion sensor yourself.