General provisions

The electrical load of individual consumers, and therefore their total load, which determines the operating mode of power plants in the energy system, is constantly changing. It is customary to reflect this fact with a load graph, i.e. diagram of changes in power (current) of an electrical installation over time.

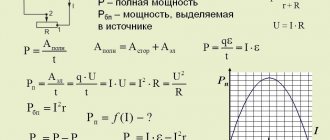

Based on the type of parameter being recorded, graphs of active P, reactive Q, total (apparent) S power and current I of the electrical installation are distinguished.

Typically, graphs reflect changes in load over a certain period of time. On this basis, they are divided into daily (24 hours), seasonal, annual, etc.

According to the place of study or the element of the energy system to which they relate, the graphs can be divided into the following groups:

- consumer load schedules determined on substation buses;

- network load diagrams - on the buses of district and hub substations;

- power system load graphs characterizing the resulting power system load;

- power plant load schedules.

Load graphs are used to analyze the operation of electrical installations, to design a power supply system, to make forecasts of power consumption, to plan equipment repairs, and also during operation to maintain normal operation.

Daily consumer load schedules

The actual load graph can be obtained using recording instruments that record changes in the corresponding parameter over time.

The long-term consumer load schedule is determined during the design process. To construct it, you must first of all have information about the installed power of electrical receivers, which is understood as their total rated power. For active load

(1)

Connected power on consumer substation buses

(2)

Where are, respectively, the average efficiency of electrical installations of consumers and the local network at rated load.

In operating practice, the actual load of consumers is usually less than the total installed capacity. This circumstance is taken into account by the simultaneity coefficients kо and load kз. Then the expression for the maximum load of the consumer will look like:

(3)

where kspr is the demand coefficient for the consumer group under consideration.

Demand coefficients are determined based on operating experience of similar consumers and are given in reference literature. The average values of demand coefficients for some industrial consumers are given in Table 1.

Table 1

Demand coefficient kspr

The maximum load value found from (3) is the largest in the year and usually corresponds to the period of winter maximum load.

In addition to Pmax, to construct a graph it is necessary to know the nature of the change in consumer load over time, which during design is usually determined using standard graphs.

A typical load schedule is constructed based on the results of a study of similar existing consumers and is given in the reference literature in the form shown in Fig. 1, a.

Fig.1. Daily graphs of the active load of the consumer a - typical b - in named units

For ease of calculations, the graph is performed in steps. The highest possible load per day is taken as 100%, and the remaining stages of the graph show the relative value of the load for a given time of day.

With Pmax known, it is possible to convert a typical schedule into a load schedule for a given consumer, using the relationship for each stage of the schedule:

(4)

where n% is the ordinate of the corresponding step of the standard graph, %.

Figure 1, b shows the graph of the electricity consumer, obtained from the standard one (Figure 1, a) at Pmax = 20 MW.

Typically, each consumer is given several daily schedules that characterize his work at different times of the year and on different days of the week. These are typical schedules of winter and summer days for working days, a weekend schedule, etc. The main one is usually the winter daily workday schedule. Its maximum load Pmax is taken as 100%, and the ordinates of all other graphs are given as a percentage of this particular value (Fig. 2).

Fig.2. Example of a typical schedule for a specific type of production (ferrous metallurgy) 1 - workday schedule 2 - weekend schedule

In addition to active load graphs, reactive load graphs are used. Typical reactive consumption graphs also have the ordinates of steps, %, of the absolute maximum:

(5)

where tgφmax is determined by the value of cosφmax, which must be set as the initial parameter for a given consumer.

The daily graph of total power can be obtained using known graphs of active and reactive loads. The power values by stages of the graph (Fig. 3) are determined by the expressions

(6)

where Pn and Qn are the active and reactive loads of a given stage in named units.

Fig.3. Daily graphs of active, reactive and apparent power of the consumer

Calculation and construction of an annual load schedule

⇐ PreviousPage 2 of 12Next ⇒The assignment for the course design indicates the enterprise for the supply of which it is necessary to design a substation. Using /2, 3/, a daily load schedule is selected, usually winter, drawn in relation to its task, taking the maximum load according to the schedule equal to the given full Smax

or active

Pmax

of the substation.

With known Smax

,

Pmax

a typical load schedule is converted into a load schedule for a specific consumer, using the following relationships for each stage of the schedule:

(2.1)

where Pi

– power at the i-th stage of the daily schedule, MW;

ni%

– ordinate of the corresponding stage of the daily standard schedule, %;

Pmax

– maximum load of the substation specified in the task, MW;

Then, according to the daily load schedule, the following is determined:

1) daily electricity consumption Wс

, MWh:

| (2.2) |

where ti

– duration of the i-th stage of the daily schedule, hour;

2) average daily load Psrs

, MW and show it on the daily load graph (Figure 2.1):

(2.3)

where tс

– length of day – 24 hours;

3) graph filling factor Kzg

, which shows the degree of unevenness of the installation schedule:

(2.4)

Then an annual graph of load by duration is constructed for a given industry. Typically, for each consumer, the reference literature provides several daily schedules that characterize the consumer’s work at different times of the year and on different days of the week. These are typical schedules for winter and summer days for working days, a weekend schedule, etc. The main one is the winter daily workday schedule. Its maximum load Pmax

is taken as 100% and the ordinates of all other graphs are given as a percentage relative to this value (Figure 2.1).

a) b)

a) – typical schedule, b) – load schedule for a specific consumer

Figure 2.1 - Daily load graphs

Power of each stage of the schedule, MW:

The annual load duration graph shows the duration of substation operation throughout the year with different loads. The ordinate axis shows loads on the appropriate scale, and the abscissa axis shows the hours of the year from 0 to 8760 hours. The loads on the graph are arranged in descending order from Pmax

to

Pmin

(Figure 2.2).

Figure 2.2 - Annual graph of load duration

The construction of an annual schedule of load duration is carried out on the basis of known daily schedules (in percentage or in named units). The schedule determines:

1) annual electricity consumption Wg

, MWh:

(2.5)

where Ti = tiз∙nз + til∙nл

;

tiz, til

– duration of steps on winter and summer load schedules, hour;

nz, nl

– the number of winter and summer days in a year;

2) duration of use of maximum load, Tmax

, hour:

(2.6)

For example, the duration of the stages of the annual load schedule (Figure 2.2), built according to the daily schedule (Figure 2.1):

T1 = t4

∙ 365 = 6 ∙ 365 = 2190;

T2 = t2

∙ 365 = 4 ∙ 365 = 1460;

T3 = (t3 + t5)

∙ 365 = (4 + 2) ∙ 365 = 2190;

T4 = (t1 + t6)

∙ 365 = (6 + 2) ∙ 365 = 2920;

It is assumed that the enterprise operates according to the same schedule in winter and summer.

3 Selecting the type, number and power of transformers

Power transformers installed in substations are designed to convert electricity from one voltage to another. Three-phase transformers are most widespread, since losses in them are 12-15% lower, and the consumption of active elements and cost are 20-25% less than in a group of three single-phase transformers of the same total power.

In course design assignments, two substation voltages are usually indicated - 110 (35) kV and 10 (6) kV, therefore, according to the number of windings, two-winding transformers should be used. If the power of the selected transformer is 25,000 kVA or more, then it is necessary to accept transformers with split windings on the lower side in order to limit short-circuit currents.

The choice of the number of transformers at the substation is determined by the category of the consumer (see task). It is advisable to make step-down substations with no more than two transformers. For consumers of the third and partially second category, it is possible to consider the option of installing one transformer in the presence of backup power from a neighboring transformer substation.

At substations with two transformers, it is advisable to keep the working sections of low-voltage busbars in operation separately. In this mode, the short circuit current is reduced and the operating conditions of low voltage devices are simplified /1/.

In power supply systems of industrial enterprises, the power of power transformers must provide power to all receivers under normal conditions. When choosing the power of transformers, one should achieve both an economically feasible operating mode and appropriate provision of power backup for receivers when one of the transformers is turned off. It should be remembered that at a single-transformer substation the determining mode is normal operation, at a two-transformer substation the determining mode is post-emergency.

The transformer power at a two-transformer substation can be selected in two ways: according to the given power of the substation; according to the load schedule.

1) first method.

The power of the transformer at the substation in accordance with /1/ is determined by:

(3.1)

where Snom

– rated power of the transformer;

S'max

– maximum load of the substation taking into account compensating devices.

(3.2)

where Pmax

– maximum active power;

Qmax

— maximum reactive power of the substation;

Qku

– power of compensating devices;

(3.3)

tg φ

determined by a given

cos φ

;

(3.4)

where Qes

– reactive power that can be supplied by the power system to the network.

(3.5)

Basic value tg φb

= 0.4 when powering the substation at U = 220 – 230 kV;

tg φb

= 0.3 when powering the substation at U = 110 – 150 kV;

tg φb

= 0.25 when powering the substation at U = 35 kV, /4/.

The calculated power of transformers obtained using formula 3.1 is rounded to the nearest standard power Snom

) according to the GOST 11920-85, GOST 12965-85 scale. Then the selected transformer is checked for overload capacity according to GOST 14209-97

(3.6)

where k2

– emergency overload coefficient when one of the transformers is disconnected during an accident, determined from emergency overload tables /7/.

It depends on the initial load coefficient ( K1

), the temperature of the cooling medium during the accident (

θcool

), the duration of the overload (

h

), as well as from the cooling system of the transformer.

In accordance with /1, 5, 6/ k2

= 1.4, subject to the following conditions: in cases where the load of transformers (for cooling systems M, D, DC and C) before and after an emergency overload did not exceed 0.9 of its rated capacity, it can be overloaded for up to 5 days by 40% at a cooling air temperature

θcool

of no more than +300C, but the duration of the overload in each day should not exceed 6 hours (the total duration of the overload in a row or with breaks), at a temperature cooling air

θcool

more than +300C, the overload value is reduced to 30% and its duration is reduced to 4 hours a day.

Initial load factor K1

defined as:

(3.7)

where Srm.kv

– rms load;

n

– number of transformers.

It is possible to use the initial load factor in maximum mode.

(3.8)

If, when checking a transformer in emergency mode, condition (3.6) is not met, then it is necessary to provide for the disconnection of some consumers of category III, or to increase the power of the transformer by one step.

2) second method.

This calculation is based on the enterprise load schedule and the selection criterion is the wear of the transformer insulation. Based on the daily load schedule, the root mean square load Srm.sq

:

(3.9)

where T

– schedule duration, hour;

Si

– total power of the i-th stage of the schedule.

And then the rated power of the transformer will be determined as:

or

(3.10)

where S*rms

– root mean square load in relative units.

(3.11)

Based on the rms power, it is recommended to select the power of transformers that supply a sharply variable load.

The resulting power is rounded to the nearest standard. Then Snom

plotted on the daily chart as a straight line.

The selected transformer is tested for emergency overload. To do this, set the average temperature of the cooling air (for the Orenburg region θcool

= –13.4 º C) /7/ and the total number of hours of transformer overload above the rated power

h

.

Then the initial load ( K1

) from expression (3.7) or:

where Sm

– average power of the interval with duration

∆tm

.

According to table 11 GOST 14209-97 for known K1

and

h

, as well as the ambient temperature and the method of cooling the transformer, the permissible emergency load

k2

. Then condition (3.6) is checked; if it is not satisfied, proceed in the same way as in the previous case (see p. 19).

For example, the enterprise load schedule is given (Figure 3.1), for which S'max

= 23 MVA.

Figure 3.1

The rms power is determined:

S*rms

= 0.82

Snom

= 0.82∙

S'max

= 0.82∙23 = 18.9 MVA.

According to the reference book /10/, two transformers with power Snom

= 16 MVA. This value is plotted on the graph as a percentage of the maximum load of the substation

The load factor of transformers is checked in normal mode:

which corresponds to the economic load of transformers.

The systematic load of transformers is less than their rated power ( S'max

< 2·

Sn

), therefore the selected transformers are tested only for emergency overload.

Emergency overload factor ( K2

), as stated above, depends on the transformer cooling system (TM, DC, etc.), the temperature of the cooling medium (

θcool

), the number of hours of emergency overload (

h

), the initial load factor (

K1

or

K1max

).

K2

=

f (θcool; h; K1max)

θcool

= –13.40C;

h

= 24 hours

According to table /27/ K2

= 1,5.

The selected transformer is checked for emergency overload:

Snom ∙ K2 ≥ S'max

; 16 ∙ 1.5 > 23 MVA.

The selected transformer meets the requirements of GOST 14209-97. All catalog data of the transformer are written out from reference books /2, 3/. For example: TDN-16000/110/10

Snom

= 16 MVA,

Uin

= 115 kW,

Unn

= 11 kV,

Iхх

= 0.7%,

Pxxx

= 18 kW,

Pkz

= 85 kW,

Ukz

= 10.5%.

Dimensions: length 6 m, width 3.5 m, height 5.5 m.

The choice of transformer power on a single-transformer GPP is made based on rms power:

Snom ≥ Srms

with checking the overload capacity of the transformer during peak hours

Snom ∙ K2 ≥ S'max

,

where K2

– coefficient of permissible systematic load.

Since the required power of an enterprise grows from year to year, when designing substations it is necessary to calculate the foundations and structures, as well as the substation busbar and input devices for transformers at a level higher than the design power, i.e., to provide for the possibility of increasing the power of the substation without significant redistribution /1/ .

Short circuit currents

⇐ Previous2Next ⇒

What will happen to the Earth if its axis shifts by 6666 km? What will happen to the Earth? - I asked myself...

What does the IS operation and maintenance department do? Responsible for the safety of data (copying schedules, copying, etc.)…

WHAT IS CONFIDENT BEHAVIOR IN INTERPERSONAL RELATIONSHIPS? Historically, there are three main patterns of differences that exist between...

What makes your dreams come true? One hundred percent, unshakable confidence in your...

Didn't find what you were looking for? Use Google search on the site:

Daily schedules of district substations

These graphs are determined taking into account losses of active and reactive power in lines and transformers during electricity distribution.

Power losses from current flow in line wires and in transformer windings are variable values depending on the load. The constant portion of power losses in the network is determined mainly by the no-load losses of transformers.

Constant distribution losses and variable losses for maximum mode in the i-th network element (line, transformer) are found using methods known from the course “Electrical Networks”. The total losses for any stage of the substation load graph can be found from the expressions

(7)

where Si is the load of the i-th network element, corresponding to the considered n-th stage of the total load graph; Si,max is the load of the element (line, transformer) at which the

The method for constructing an active load graph for a specific network is shown in Fig. 4.

Fig.4. To construct a graph of the active load of the electrical network (on the buses of a district substation): a - network diagram, b - load graphs of individual consumers, c - total load graph

Electrical load graphs

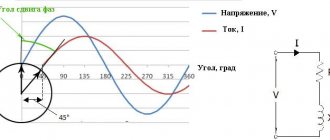

Electrical loads refer to the power consumed by the system or the current in the supply line.

The operating mode of electricity receivers changes throughout the day, weeks and months of the year. At the same time, the load on all links of the SES also changes. These changes are depicted in the form of graphs on which the values of loads in kW or as a percentage of the maximum load are plotted along the ordinate axis, and the time of action of these loads is plotted along the abscissa axis.

Definition:

Graphs of electrical loads are a graphical representation of changes over time in active and reactive power and power losses in solar power plants.

Electrical load graphs provide a visual representation of the nature of changes in electrical load in a line or system.

The value of electrical loads is determined by the choice of all elements of the solar power plant: the power of generators, power transformers of substations, the cross-section of conductors of the supply and distribution networks, the type and technical parameters of switching and protective equipment.

There are daily and annual load schedules. The annual schedule is constructed on the basis of the daily schedule based on the total duration of individual load values for the year in descending order.

Real graphs of electrical loads of existing systems can be obtained by installing power meters or recorders in the supply line. Real graphs look like a smooth curve. For ease of calculation, they are replaced by a stepped line with a minimum step duration of 30 or 60 minutes.

The most favorable from the point of view of operating the power supply system and rational use of electrical equipment is a uniform load schedule. Obtaining a uniform load schedule can be achieved by appropriate organization of the production process and the creation of integrated energy systems.

With a uniform graph, voltage fluctuations in the network will be minimal. Therefore, there is no need to take measures to maintain the voltage in the system within the limits established by power quality standards: switch the on-load tap-changer regulator of power transformers, regulate the power of the compensating device, switch the power of individual consumers to backup lines, etc.

In addition, a stable value of the electrical load allows you to select the types and parameters of all system elements with a minimum margin for all indicators, as a result of which they will operate with a load close to the rated one. This increases the efficiency of use of all electrical equipment. With a uniform load schedule, it becomes possible to more accurately determine the calculated currents in all areas of the system and the currents of the protection against abnormal operating conditions. At the same time, the number of unauthorized shutdowns in the system is reduced, i.e. reliability of power supply increases

Figure 8 . An example of a real (1) and ideal (2) daily active load schedule.

Figure 9. An example of a stepped daily (a) and annual (b) graph of active (P) and reactive (Q) load.

Graphs can be constructed both for the entire energy system and for its individual parts, down to production areas and specific supply lines.

To more fully characterize the operation of SES throughout the year, it is necessary to have winter and summer daily schedules of electrical loads for the busiest shift.

The greatest load according to the daily schedule is called the maximum daily load Pmax.

The area of the electrical load graph, limited by the coordinate axes and the load change curve, represents on a scale the amount of electricity per kWh generated or consumed by a given installation or system over the corresponding period of time.

For operating enterprises, knowing the electricity consumed, it is possible to calculate the average power over a certain period of time.

For example, the average daily and average annual load is determined by:

where Wday. – energy consumed per day;

Wg. – energy consumed per year;

8760 – number of hours of work per year on a three-shift schedule;

24 is the number of hours in a day.

Graphs can be constructed for active and reactive power and for power losses (DP, ?Q) in the system.

There are constant and variable electrical losses. Constant losses do not depend on the load size; These include heating losses of the cores of electrical machines and devices from eddy currents.

Variable losses depend on the load size; These include losses on active resistances of the windings of electrical machines and devices.

An important indicator characterizing the operation of SES is the time of use of the maximum electrical load.

.

Definition:

The time of use of the maximum electrical load Tm is the time during which the system, provided that it is constantly operating at maximum load, transmits or produces the same amount of electricity as when operating under a real variable load schedule.

[L2. §2.4; L3 §2.2; L16, §3.1; L17, ch.8]

Control questions:

1. What is meant by electrical loads?

2. What is an electrical load graph?

3. How to obtain a real graph of the electrical load of the existing power supply system?

4. What does the ideal electrical load schedule look like?

5. What are the ways to achieve uniformity of the electrical load schedule?

6. Why is a uniform schedule the most preferable?

7. Which parameter on a scale expresses the area of the electrical load graph?

8. By what principle is the annual electrical load schedule constructed?

9. Define the Tm parameter.

10. How to determine the average daily and annual power?

Daily power plant load schedules

By summing up the graphs of consumer loads and distribution losses in electrical networks as a whole throughout the power system, the resulting graph of the load of power plants of the power system is obtained

Fig.5. Power system active load graphs

The load graph of the power system generators is obtained from the graph of power supplied from the buses, taking into account additionally the consumption of electricity for auxiliary needs (Fig. 5). With significant fluctuations in the load of power plants, it is necessary to take into account the variable nature of auxiliary consumption.

(8)

where Pi is the power supplied from the station buses; Rust is the installed power of generators; Рс.н.max - maximum consumption for own needs; coefficients 0.4 and 0.6 approximately characterize the corresponding share of the constant and variable part of the expenditure for own needs Рс.н.max.

The load is distributed between individual power plants in such a way as to ensure maximum efficiency of operation of the entire power system. Based on these considerations, the power system dispatch service sets daily load schedules for power plants.

When designing the electrical part of a power plant, it is necessary to know the load schedule of transformers and autotransformers connected to the power system. The method for constructing such a graph for transformers connecting a thermal power plant with the power system is shown in Fig. 6.

Rice. 6. Graphs of active load for a thermal power plant operating in the power system a - explanatory diagram 6 - graphs of power generation and consumption at generator voltage c - graph of the load of communication transformers

The required schedule Рт is obtained by subtracting from the generator load schedule Рg the local load consumption schedule and electricity consumption for own needs Рс.н.

Daily load schedule for residential buildings

May 9, 2015 k-igor When choosing transformers, it is important to understand the daily load schedule.

With industrial facilities, everything is much more complicated, but residential buildings have a fairly constant daily schedule of electricity consumption. The daily load schedule influences the choice of transformer. I know many of you follow my blog. I recently talked about choosing a transformer for a cottage village. In that article, I tried to somehow justify a 100 kVA transformer for 31 houses, because... RES wanted this, but with the initial data everything was quite complicated. According to calculations, it turned out that for this number of houses and a transformer of 63 kVA is quite enough.

After that article, I was hit like a roller, that I was fundamentally wrong and that I needed almost 160 kVA. To be honest, I still didn’t understand what and where I was wrong. The main thing is that those comments prompted me to write another article that will help us justify and make the right choice of transformer.

Understanding the daily load schedule will be useful when calculating the loads of an existing transformer substation. Nowadays we are very fond of writing such a clause in the technical specifications for power supply.

On the Internet, on one of the sites, I found a real daily load schedule for a 62-apartment building with gas stoves. I hope this information is reliable, at least the graph is very similar to the real one.

Daily load schedule (62-apartment building with gas stoves)

With the red line on the graph, I brought our graph to a two-stage one, as is customary in power supply. When choosing transformers, use the values of K1 and K2, which exactly correspond to the lower and upper values.

As we can see from the graph, the evening maximum load consumption lasts about 4 hours, the rest of the time the load on the transformer will be 3 times less than in the evening.

If we turn to our regulatory documents, the specific load per apartment would be slightly less than 1.4 kW or Рр=86.8 kW. What do we actually see? 15kW By the way, who knows the definition and physical meaning of the design load?

Do you think the graph is wrong? Let's find the average consumption per apartment.

20*5+4*15=160 kWh/day - consumed by the whole house.

160*30/62=77.4 kWh/month - consumed by one apartment.

I think the result obtained is questionable, although my average consumption in the apartment is about 40 kWh, although I have neither a TV, nor a washing machine, nor a microwave oven, I use LED lamps instead of incandescent lamps

Let's analyze another house with 501 apartments with gas stoves:

Daily load schedule (501-apartment building with gas stoves)

Here the ratio of the consumed load in the evening maximum is 2 times greater than in the daytime and at night.

Per month for one apartment it turns out: (20*80+4*160)*30/501=134 kWh.

The results differ by almost 2 times. Perhaps the first house has only one-room apartments.

Now let's return to our cottage village.

I'm more inclined to think that the K2/K1 ratio will be around 3.

Let us assume that each house will consume 600 kW per month. In fact, I very much doubt that their average consumption will be more than 300 kW. We are not talking about any mansions that have swimming pools, saunas, etc. My parents’ private house in the village consumes about 300 kW/month, which is what they don’t use there.

Let's find Pmax - the consumed load at the evening maximum. We'll have to remember school math.

31 houses, 31 days in a month, then:

Pmax=56 kW or S=60 kVA

Those. K1=20 kVA, and K2=60 kVA

Still, am I wrong that a 63 kVA transformer is enough for our load of 31 houses? This transformer will not have to work even with an overload, and if you look at the overload capacity of the transformer in our operating mode, then it will have a power reserve of about 30%.

Transformer overload capacity

It is worth noting that the daily schedule of apartments and houses with electric stoves is slightly different. There are additional peaks in the morning and afternoon, but they are smaller compared to the evening maximum.

Now on the blog (in the left column) there is a survey on just this topic. Don't be lazy to answer just one question.

Source

Annual schedule of load duration

This graph shows the duration of operation of the installation during the year at various loads. The ordinate axis shows the loads on the appropriate scale, the abscissa axis shows the hours of the year from 0 to 8760. The loads on the graph are arranged in descending order from Pmax to Pmin (Fig. 7).

Fig.7. Annual schedule of load duration

The construction of an annual schedule of load duration is carried out on the basis of known daily schedules. Figure 8 shows the method for constructing a graph in the presence of two daily load schedules - winter (183 days) and summer (182 days).

Fig.8. Method for constructing an annual load duration graph

For the most common consumers of electricity, the reference books provide typical schedules of active and reactive loads by duration.

The load duration schedule is used in calculations of technical and economic indicators of an installation, calculations of electricity losses, when assessing the use of equipment during the year, etc.

CONSTRUCTION OF ELECTRICAL LOAD CHARTS.

1.1. Based on the known number and power of consumers P

at a given voltage, we determine the total maximum load of consumers of TP

Pmax TP

= 3 MW and RP

Pmax RP

= 1.8 MW.

1.2. Pmax TP value

we take it as 100% of the typical graph, and in accordance with this we determine the actual power values at each stage of the TP load graph (see Table 1.2 and Fig. 1.2).

Table 1.2

Winter and summer daily load of TP, MW from Pmax TP

| TP | Watch | 0-1 | 1-2 | 2-3 | 3-4 | 4-5 | 5-6 | 6-7 | 7-8 | 8-9 | 9-10 | 10-11 | 11-12 | 12-13 |

| Winter | RZ, % | |||||||||||||

| RZ, MW | 4,8 | 4,8 | 4,8 | 4,8 | 4,8 | 4,8 | 4,8 | 7,2 | ||||||

| Summer | RL, % | |||||||||||||

| RL, MW | 3,2 | 3,2 | 3,2 | 3,2 | 3,2 | 3,2 | 3,2 | 3,2 | 3,2 | 3,2 | 5,6 | 5,6 | 4,8 |

| 13-14 | 14-15 | 15-16 | 16-17 | 17-18 | 18-19 | 19-20 | 20-21 | 21-22 | 22-23 | 23-24 | 24-0 |

| 7,2 | 7,2 | 7,2 | 7,2 | 7,2 | 4,8 | 4,8 | 4,8 | 4,8 | 4,8 | ||

| 4,8 | 5,6 | 5,6 | 6,4 | 6,4 | 3,2 |

Rice. 1.2 Daily winter and summer schedule of electrical loads of transformer substations

1.3. Pmax RP value

we take it as 100% of the typical graph, and in accordance with this we determine the actual power values at each stage of the RP load graph (see Table 1.3 and Fig. 1.3).

Table 1.3

Winter and summer daily load of TP, MW from Pmax RP

| RP | Watch | 0-1 | 1-2 | 2-3 | 3-4 | 4-5 | 5-6 | 6-7 | 7-8 | 8-9 | 9-10 | 10-11 | 11-12 | 12-13 |

| Winter | RZ, % | |||||||||||||

| RZ, MW | 1,44 | 1,44 | 1,44 | 1,44 | 1,44 | 1,44 | 3,36 | 3,36 | 4,32 | 4,32 | 2,88 | 2,88 | 2,88 | |

| Summer | RL, % | |||||||||||||

| RL, MW | 0,96 | 0,96 | 0,96 | 0,96 | 0,96 | 0,96 | 0,96 | 0,96 | 0,96 | 0,96 | 2,40 | 2,40 | 1,44 |

| 13-14 | 14-15 | 15-16 | 16-17 | 17-18 | 18-19 | 19-20 | 20-21 | 21-22 | 22-23 | 23-24 | 24-0 |

| 2,88 | 3,84 | 3,84 | 4,8 | 4,8 | 4,8 | 3,36 | 1,92 | 1,92 | 1,92 | 1,92 | 1,44 |

| 1,44 | 1,44 | 1,44 | 1,44 | 1,44 | 1,44 | 1,44 | 2,88 | 2,88 | 1,44 | 1,44 | 0,96 |

Rice. 1.3 Daily winter and summer schedule of electrical loads of the RP

1.4. Total daily load schedule of substation P

determined by summing the load graphs of TP and RP (see Table 1.4 and Fig. 1.4).

Table 1.4

Winter and summer daily load of TP and RP, MW from Pmax

| ∑ | Watch | 0-1 | 1-2 | 2-3 | 3-4 | 4-5 | 5-6 | 6-7 | 7-8 | 8-9 | 9-10 | 10-11 | 11-12 | 12-13 |

| Winter | RZ, MW | 6,24 | 6,24 | 6,24 | 6,24 | 6,24 | 6,24 | 8,16 | 11,36 | 12,32 | 12,32 | 10,88 | 10,88 | 10,08 |

| Summer | RL, MW | 4,16 | 4,16 | 4,16 | 4,16 | 4,16 | 4,16 | 4,16 | 4,16 | 4,16 | 4,16 | 8,00 | 8,00 | 6,24 |

| 13-14 | 14-15 | 15-16 | 16-17 | 17-18 | 18-19 | 19-20 | 20-21 | 21-22 | 22-23 | 23-24 | 24-0 |

| 10,08 | 11,04 | 11,04 | 12,00 | 12,00 | 12,80 | 11,36 | 6,72 | 6,72 | 6,72 | 6,72 | 6,24 |

| 6,24 | 5,44 | 5,44 | 5,44 | 5,44 | 7,04 | 7,04 | 9,28 | 9,28 | 5,44 | 5,44 | 4,16 |

Rice. 1.4 Total daily winter and summer schedule of electrical loads of the RP

1.5. We construct an annual load graph by duration based on known graphs for summer and winter days (see Fig. 1.4). Let's construct an annual graph of active load by duration (see Table 1.5 and Fig. 1.5).

Table 1.4

Winter and summer daily load of TP and RP, MW from Pmax

| P, MW | 12,8 | 12,32 | 11,3 | 11,04 | 10,88 | 10,08 | 9,28 | 8,16 | 7,04 | 6,72 | 6,24 | 5,44 | 4,16 |

| Watch |

Rice. 1.5 Annual graph of electrical loads by duration

1.6. We determine the maximum power of the substation without taking into account and taking into account consumers of the third category. Consumers of the third category are assigned only to TPs as a percentage of the total load.

Maximum active, reactive and apparent power of the substation, taking into account consumers of category III:

Pmax = RTP max + Rkl1 max + Rkl2 max = 4 2.0 + 2.4 + 2.4 = 12.8 MW;

Qmax = RTP max·tgφTP + (Rkl1 max + Rkl2 max) tgφRP = 4·2.0·0.35 + (2.4 + +2.4)·0.3= 4.24 Mvar;

Maximum active, reactive and total power of the substation without taking into account consumers of category III (25% of RTP max):

Pmax 1, 2 = RTP max 0.75 + Rkl1 max + Rkl2 max = 4 2.0 0.75 + 2.4 + 2.4 = 10.8 MW.

Qmax1, 2 = RTP max 0.75 tgφTP + (Rkl1 max + Rkl2 max) tgφRP = 4 2.0 0.75 0.35 + + (2.4 +2.4) 0, 3= 3.54 Mvar;

Maximum active power for category III consumers:

Рmax 3 = RTP max·0.2 = 4·2.0·0.25 = 2 MW.

DETERMINATION OF MAIN INDICATORS AND COEFFICIENTS CHARACTERIZING LOAD SCHEDULES

Here it is necessary to determine the following indicators and coefficients: annual active energy consumption W

, average active power

Pav

, annual number of hours of use of maximum active power

Tmax

, time of maximum losses

tmax

, fill factor of the

KZP

.

Annual active energy consumption, MWh,

66907.2 MWh,

where Pi

– power of

the i

-th stage of the schedule, MW;

Ti

– duration of

the i

-th stage of the schedule, hours.

Average active power per day, MW,

where Wday

– active energy per day, MWh, determined by the relation:

Annual number of hours of use of maximum active power P

max load, h,

Time of maximum losses, h,

Chart fill factor