Complete set of electric hoists

The most popular and easiest to install and operate device for lifting loads is the electric hoist. Let's look at its design using the example of modern hoists of the MH series produced by Balkankarpodem. The general diagram of the hoist is shown in the picture above.

Schematic electrical diagrams of the hoist can be found here

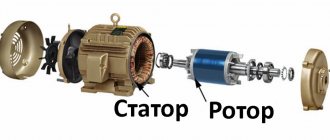

The mechanical equipment of the MH electric hoist includes such important structural elements and assembly units as a lifting drum, gearbox, coupling, hook suspension, trolley, and load rope.

Lifting motor

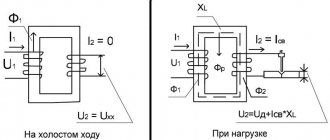

Asynchronous two-speed electric motor with cone rotor and stator and built-in asbestos-free cone brake. The rotor has the ability to move with less resistance in the axial direction. In the event of a power failure, the brake is activated by the force of the coil spring.

A wide range of possible combinations between motors and gearboxes with different technical characteristics expand the range of lifting loads and lifting speeds. Additionally, hoists are supplied with two-speed motors - having two stator windings (for operating speed and for precise positioning of the load).

Another delivery option is with frequency converters for the smoothest possible starting and braking of drives.

Gearbox

Two-stage planetary gearbox installed on the opposite side of the electric motor. This design is preferred due to the need to ensure compactness of the hoist in the radial direction. Three stages of the gearbox provide reduction (reduction) of engine speed, as well as smooth starting and braking.

High-quality materials are used for the manufacture of gears and other gear elements. The surfaces of the gear teeth are carburized and hardened, followed by grinding, which ensures a long service life and silent operation of the gears with high gear efficiency.

An extended kinematic chain for transmitting engine torque to the drum reduces dynamic loads when operating an electric hoist.

Frame

The new body is box-shaped. It is a tightly welded flange-type connection between the engine and the gearbox. The rope output in all possible radial directions along the periphery of the housing ensures the operation of the electric hoist in a variety of mounting options and positions.

Elastic coupling

A special gearbox coupling is used, located inside the drum between the motor shaft and the gearbox shaft. The elastic package absorbs peak torque components. The design of the coupling ensures unhindered axial movement of the electric motor shaft. At the same time, it protects the shafts from any radial or tangential movements.

This specificity is due to the fact that the rotor of the lifting electric motor is conical. When the drive is turned on, such a rotor extends along the axis, disengaging from the stator, and when turned off, it retracts back. Thus, the engine itself is able to brake the drive during a stop, that is, it has a built-in brake.

The kinematic connection between the gearbox and the electric motor is unbreakable.

Drum

The lifting drum is a cylindrical hollow structure designed for winding a cargo rope. The surface of the drum is covered with special grooves - “streams”, thanks to which the cargo rope is wound in even rows, without overlaps or creases. Along with the rope, the rope layer also moves on the drum - a device necessary not so much for laying the rope in streams, but for turning on and off the limit switches for over-lifting and over-lowering.

Screw channels for the rope are made along the surface of the drum. A special rope wrap moves in these channels and ensures correct winding and unwinding of the rope, regardless of the size of the suspended load. The drum has two diaphragms. One of them is mounted on the front flange of the electric motor using a roller bearing. The torque from the outgoing hollow shaft of the gearbox is transmitted to the second diaphragm through a splined connection.

Rope wrap

New design. To replace the rope wrap, you do not need any special tools. The limits of rope deflection towards the engine or gearbox are ±4°. The rope tie operates the switch for the extreme upper and lower position of the hook.

Rope

The MH electric hoist uses a Bulgarian-made metal cable as a load rope. The most common rope reeving involves rigidly tying one end to the hoist body and clamping the second end to one edge of the lifting drum. In this case, the cargo rope itself is thrown through the hook suspension block.

This reeving avoids damage to the rope and extends its service life. One end of the rope is fixed to the drum using rope ties. The other end is attached to the hoist body, or to the hook body, or to the drum first, depending on the method of hanging the load.

The technical characteristics of the rope provide the necessary reliability and minimal wear on the rope itself and the drum channels.

Hook - set

Hook included: a new design that, together with the chain hoist, meets modern technical safety requirements. Operation is facilitated by the minimal dead weight of the hook.

There is reliable protection against the arbitrary release of the rope from the channels of the rope rollers. The hook suspension contains a freely rotating rope block in a metal casing that prevents the rope from falling off.

The cargo hook itself also rotates freely in both directions for the convenience of slinging work.

Trolleys

Three types of trolleys are available: N type, K type and D type . The bodies of electric hoists are attached to them in such a way that optimal distribution of the load on all wheels is ensured. The wheels are designed to move the hoist along the flanges of the I-beam. The trolleys can also be electric (EK), manually operated (RK) or free-wheeling (SK).

The electric trolley has a motor mechanism of the same type as the load lifting mechanism. A normal motor mechanism with an electromagnetic brake is also available. The range of trolley speeds is very wide. Installation and adjustment of bogies in relation to the profile of the monorail are carried out smoothly. In case of ordering a double-rail trolley, the track width and dimensions of the rails are specified by the customer.

Some electric hoists, which are large in the axial direction, are equipped with two running trolleys.

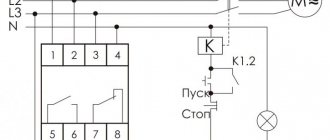

Electrical equipment

The electrical equipment of the hoists includes lifting motors, travel motors, a pendant control panel, a starting cabinet, a limit switch block, a brake coil and a load limiter. The coil and limiter, depending on the configuration, may be missing. The design of the electrical equipment of the hoist can be special, for example, for operation in a chemically aggressive environment or in a tropical climate.

The voltage and frequency of the electrical network are given by the customer. Operating voltage to the relay coil and contactors is 42 V, frequency -50 Hz. For the most part, the electrical equipment is located in a command box attached primarily to the hoist body. The limit switch for lifting and lowering the load is placed in the motor terminal block.

The push-button pendant control panel has a degree of protection of IP65 and can be four-button or six-button for operation as part of an overhead crane.

The remote control includes a key mark to prevent unauthorized access to the control of the mechanism, as well as a mushroom button for emergency shutdown of the drives. For hoists with two-speed electric drives, the remote control may have two-position buttons (pushers) or a larger number of buttons - up to 12 pieces.

Electric hoists: design features, application

A telpher in its classical representation is an electric hoist equipped with a carriage (trolley) for movement. Translated from Greek, the word “telfer” is a combination of two words – “far” and “carrying”, which, in fact, explains all its functionality. The telpher provides not only vertical lifting of the load, but also its movement in the horizontal plane using special guides (I-beams).

Sometimes there are stationary hoists (without a moving trolley), but such modifications are not very popular.

Where are hoists used?

Electric hoists are widely used in various fields of industry, construction, warehousing, and production for lifting heavy loads. It is not allowed to use hoists for lifting people, for transporting hot and liquid metal, toxic substances, in warehouses of explosive and flammable substances, in explosion- and fire-proof places (except for special explosion-proof modifications).

Electric hoists can be used both independently and as a lifting element of more complex lifting mechanisms, mainly cranes (bridge, gantry, cantilever, jib).

The use of an electric hoist allows you to very quickly and safely lift even the most complex, heavy and inconvenient loads. Unlike manual lifting mechanisms, the hoist provides a very high speed of work and can significantly increase its efficiency and staff productivity.

Telpher design

An electric hoist is a block mechanism, the main element of which is an electric motor with a conical rotor. Important design elements are also a cone rotor, a winding element - a drum in rope hoists and a sprocket in chain hoists, a brake, a load-handling device (brake) and a load-lifting element - a steel rope or chain. Some models are equipped with built-in motor protection.

The cone brake, built into the internal structure of the hoist, operates by axial displacement of the rotor under the influence of a spring, which guarantees the operation of the braking mechanism even in the event of a sharp drop in voltage or even a complete power outage.

For greater reliability and safety, the hoist can be equipped with an additional electromagnetic shoe brake. The electric hoist can be equipped with a planetary or helical gearbox.

The planetary gearbox is more convenient because it is located outside the drum and is easier to install and dismantle.

Optionally, the design of electric hoists can include limit switches that are activated when the hook reaches the maximum upper and lower limits, and load limiters that block lifting when the recommended load weight is exceeded.

The hoist is controlled using a push-button remote control, which can be either wired (suspended on a flexible cable) or remote.

How can electric hoists differ?

In addition to the main parameters - lifting height and load capacity - hoist models can also differ in design features:

Possibility of movement.

Telphers can be stationary or mobile. Stationary hoists are suspended on loops or a hook and only allow you to lift the load vertically, without moving it to another place.

Mobile hoists are mounted on carriages (trolleys), which move in a horizontal plane along special guides (I-beams). Mobile electric hoists provide maximum efficiency and are the most popular type.

Depending on the parameters of the hoist (load capacity and lifting height), it can be equipped with one or two electric (driven) trolleys, or one driven and one idle trolley.

Load-lifting element.

There are chain and rope hoists: in chain hoists, a round-link calibrated chain is used to lift the load, in rope hoists, high-strength steel rope is used. Both varieties have their pros and cons. The rope hoist can be used to make pulley hoists (the hoist pulley can be double, quadruple or double double).

The design of the rope telpher includes a drum with threads for winding the rope. Optionally, the drum can be equipped with a rope laying machine, which ensures correct winding and unwinding of the rope.

The chain hoist can be equipped with two load chains that lift the load synchronously; This is very convenient for lifting and transporting long loads, especially in construction.

Number of lifting speeds.

Depending on the number of speeds of the lifting mechanism, electric hoists can be single-speed or two-speed. The design of the two-speed hoist includes a microdrive unit, which allows the use of an electric hoist at low speeds for lifting and lowering loads. This is convenient when working with fragile loads, as well as in cases where precise and accurate positioning is required.

Drum axis location.

Electric hoists are available in longitudinal design (the drum axis is located in the direction of movement) or transverse design (the drum axis is located perpendicular to the direction of movement). Hoists with a transverse design have a smaller height, which can be especially important when working in rooms with low ceilings. Electric hoists can be of low construction height and such hoists are mounted not directly under the I-beam, but on the side of it.

Additional options.

Our catalog presents hoists with both basic configuration and with additional options: for example, the maximum configuration of the CD1 hoist includes thermal protection for all motors, an improved rope handler, an electronic load limiter, and a modern high-quality control box with Shneider starters.

Requirements for the operation of the telpher

It is not allowed to operate an electric hoist for transporting people, explosives and flammable substances. A protective screen can be installed to transport molten metal. The use of the hoist in chemically aggressive environments is prohibited.

Optimal conditions for operating the hoist: indoors or under a canopy, at an ambient temperature from -40° to +40° C, with a humidity of no more than 80% (except for waterproof modifications of hoists).

It is very undesirable to use the hoist in very dusty rooms, as dust accelerates wear of the electric motor. If such operation is necessary, then frequent inspection, cleaning and maintenance of all mechanisms and electrical equipment should be carried out.

Catalog of electric hoists

Source: https://gortorgsnab.ru/articles/telfery-osobennosti-konstrukcii-primenenie/

Construction of hoists

A hoist is a lifting device with a manual, electric or pneumatic drive, suspended from beams or special trolleys moving along a suspended monorail track. Hoists are designed for lifting, lowering and horizontal movement of cargo suspended on a hook suspension. A distinctive feature of the hoist is its compactness.

The industry produces electric hoists with a lifting capacity of 0.25 to 16 tons and manual hoists with a lifting capacity of: 1; 3.2; 5 and 8 tons. The height and speed of lifting the hoist load, respectively, is no more than 30 m and 0.05–0.15 m/s .

A manual hoist (with a manual drive) lifts the load using load plate or welded combined chains, driven manually using sprockets.

Often the load chain forms a chain hoist with a multiple of 2; 3 and less often 4 . There are worm and gear manual hoists.

In Fig. Figure 1 shows the lifting mechanism of a manual worm hoist. The lifting mechanism includes a traction sprocket 7 mounted on the high-speed shaft 2 of the worm gearbox. The load is lifted using a welded traction chain (not shown in Fig. 1). Drums 4 are located on both sides of the low-speed shaft 3. Usually in this case a double pulley block is used (section A–A, Fig. 1), the equalizing block 5 of which is fixed to the gearbox housing 6 using a bracket 7 with screws 8.

Manual hoist lifting mechanism

A manual hoist (with a mechanical drive principle) operates solely under the influence of the operator’s muscular force and is associated with a gear or worm gear. The hoist moves loads vertically; a special trolley is used for horizontal movement. The operating principle and design of a manual hoist are as follows: the operator stands below and moves the chain with his hands, raising or lowering the load. The device contains a drive arm and a hanging hook that allows for 360° rotation.

Electric hoists: operating principle and which ones are more preferable

04/23/2015 13:24 | Category: General tips

It would be strange not to use high-tech equipment in the 21st century in industries where heavy loads, large parts and assemblies constantly have to be moved.

There is a demand for such mechanisms in the construction industry, energy, logistics, and industrial production. The range of lifting devices is quite wide, but to move medium and heavy loads, consumers often prefer to rent or purchase hoists.

What is a waist

These are suspended lifting mechanisms operating on the basis of a winch. Structurally, two types of equipment are classified: manual hoists, equipped with a manual drive, and electric devices, equipped with an electric drive. According to the method of operation in each type, stationary and mobile devices are distinguished.

Stationary mechanisms are fixed on the ceilings, and mobile ones are attached to trolleys moving on suspended rails. Their functionality is to ensure smooth lifting of the load to the desired height.

The criterion for choosing equipment is most often the frequency of use of the mechanism. For example, if moving loads is required only once a day, then it is better to use a hoist with a manual drive. With more frequent use of a lifting device, it is advisable to have a hoist, stationary or mobile.

What are the features of telphers

Telphers are electric hoists that move along a monorail track and are equipped with a special carriage. They can move loads horizontally, straight or radially.

The design of the mechanisms is quite simple: an electric motor and a gearbox are mounted on the body, the movement of loads is carried out using a cable or chain on a drum.

The lift gearbox and trolley are driven by an electric motor controlled by a remote control on the rope. Some higher-class hoists are equipped with radio control devices.

Such equipment is often part of complex lifting equipment, such as overhead and jib cranes. Hoists have larger dimensions than manual hoists or compact chain hoists. Therefore, when choosing equipment, you should always take into account not only production characteristics, but also the possibility of operation in a certain space.

What types are there?

There are two types of electric hoists - chain and rope. The first version of the equipment is used as an auxiliary device for a working jib crane. Electric rope hoists are used if the technological process involves overhead cranes and monorails.

The stationary one moves loads vertically, so it is used as a drive to lifting mechanisms. The mobile cable car has a horizontal trajectory, and it is possible to use two trolleys at once. This type of device turns out to be more productive, especially if a faucet cannot be installed in the room.

Principle of operation

Despite the differences in design, all electric hoists have a brake, upper and lower hook position switches and an emergency switch. They are equipped with magnetic reversing starters with electrical interlocking. This function is carried out by simultaneously pressing several buttons, thus eliminating the possibility of opposite movements being triggered in the same mechanism.

That is, the locking function ensures that movement is combined with lifting or lowering the load. The engines of all hoists are equipped with built-in thermal protection. Some industries use lifting mechanisms with options that support special operating modes. They have a second brake that works for lifting.

Various speeds are provided, including minimum ones, ensuring smooth movement of the load. There is a frequency converter. In conditions of increased explosion hazard, special hoists equipped with explosion-proof devices are used.

The hoists are powered from a three-phase alternating current network, the voltage must be at least 380 volts. Lifting mechanisms differ in electrical circuits, number of speeds, load class and use (duration of operation). These indicators determine the individual production characteristics of each type of equipment. But no matter how reliable the hoists are, it is strictly forbidden to move people without exception.

Which hoists are more preferable?

On the market today you can choose various modifications of domestically produced hoists, as well as those made in France, Germany, Bulgaria and China. Of course, you have to pay a lot more for European quality. In this case, the most optimal option, taking into account the cost of equipment and quality, are Balkan hoists.

They use new technologies; the technical characteristics of the mechanisms correspond to Russian GOST standards. They are productive, move significant loads, operate in temperatures from -40 to +40 degrees, in conditions of high humidity. In addition, in Russia there are service departments for repairing Bulgarian equipment; there are no problems with purchasing spare parts.

The main advantage of domestic hoists is their low cost. In terms of technical characteristics, they are practically in no way inferior to the Bulgarian ones. Russian electric hoists are also reliable in operation and fire resistant. But they can only work in temperature conditions from -20 to +40 degrees.

What should you consider when choosing an electric hoist? First of all, the tasks for which lifting equipment is purchased. It is necessary to take into account the maximum weight of the goods being moved, the height and speed of lifting, as well as the speed of horizontal movement.

All operating conditions of the electric hoist should be provided to ensure the reliability of its operation and protection from overloads and external influences.

And then the equipment will not let you down and will last a long time, significantly facilitating work processes associated with moving heavy loads.

Purpose and scope of electric hoists

An electric hoist is a special device designed for lifting, lowering and moving (horizontally) loads of various tonnage and dimensions. The competitive advantages of this type of equipment are obvious:

- Light weight - easy to transport and install. Also, there will be no need for additional reinforcement of the load-bearing/supporting structures on which the hoist will be attached (the mass of the goods being moved is pre-calculated).

- Compactness. The small size of the hoist allows it to be used in confined spaces.

- Low price. This lifting equipment is sold at an affordable price, which allows small construction firms and manufacturing companies with a limited budget to purchase it.

- Easy to maintain and use.

- Reliability and long service life.

- A wide range of models - it’s easy to choose an option based on the parameters of load capacity, engine power, and design features. For example: chain hoist or electric rope hoist, stationary or mobile, etc.

Operating principle of the telpher

The engine transmits torque through a gearbox to a sprocket or drum (depending on the model), to wind a chain or cable that lifts the load. The hoist design also includes an electric brake that holds the load suspended. If the hoist is mobile, i.e. capable of moving along the beam in the horizontal direction, the device is complemented by a running (drive) trolley. Torque is also transmitted to its wheels by a gearbox from the engine.

Scope of use

The scope of hoists covers production, industrial, agricultural, and construction sectors. In many cases, the use of electric hoists is the only alternative and the only correct (from an economic point of view) option. Examples of the main areas of application of lifting devices include:

- Construction. An electric chain hoist will help out when carrying out work indoors where it is not possible to use cranes. For example: installation of a steel flight of stairs, columns. Often used to lift building materials or structural components to a height

- Manufacturing: metallurgical, textile industry, assembly plants (automotive, shipbuilding, aviation), etc. For industrial purposes, an electric hoist can be used as an element of a crane (attached to a load trolley) or independently.

- Petrochemical, processing, mining plants and other industries with special operating modes. In this case, you can only use explosion-proof hoists that have a special protective shell. It prevents the possibility of sparking and fire.

- In open areas, an electric hoist with protection from moisture, precipitation, dust, and low temperatures is used.

In addition to the above, the hoist is actively used for unloading and loading operations on railways, ships, airports, warehouses, service stations and repair shops. This is a truly universal lifting mechanism.

Sales of lifting equipment is the main activity of TekhKranMontazh. We offer a huge selection of hoists made in Russia and abroad.