Crane electric motors of the MTF, MTN, DMTF, 4MTN, MTKF, MTKN, DMTKF series, as well as crane motors of other series, are designed to operate in electric drives of metallurgical units and lifting and transport mechanisms of all types and are supplied to complete towers, gantry, portal, bridge and others cranes

The main (basic) version is an asynchronous three-phase crane electric motor, designed for operating mode S3 PV = 40% according to GOST 183, powered by an alternating current network of 50 Hz with a voltage of 380V (220V, 660V). Climatic modification and placement category U1, degree of protection IP54, with standard technical characteristics that meet the requirements of the standards.

Crane electric motors with wound rotor

| Engine series | Type-size | Power kW | RPM | Engine series | Type-size | Power kW | RPM | Engine series | Type-size | Power kW | RPM |

| MTN, MTF, DMTF | 011-6 | 1,4 | 1000 | MTN, MTF | 411-6 | 22 | 1000 | 4MTM, 4MTN | 280 L6 | 110 | 1000 |

| MTN, MTF, DMTF | 012-6 | 2,2 | 1000 | MTN, MTF | 411-8 | 15 | 750 | 4MTM, 4MTN | 280 L8 | 90 | 750 |

| MTN, MTF, DMTF | 111-6 | 3,5 | 1000 | MTN, MTF | 412-6 | 30 | 1000 | 4MTM, 4MTN | 280 L10 | 75 | 600 |

| MTN, MTF, DMTF | 112-6 | 5,0 | 1000 | MTN, MTF | 412-8 | 22 | 750 | MTN, MTF | 611-6 | 75 | 1000 |

| AMTF | 132 M6 | 5,0 | 1000 | 4MTM, 4MTN | 225 M6 | 37 | 1000 | MTN, MTF | 611-10 | 45 | 600 |

| MTN, 4MTN | 132 LA6 | 5,5 | 1000 | 4MTM, 4MTN | 225 M8 | 30 | 750 | MTN, MTF | 612-10 | 60 | 600 |

| MTN, 4MTN, AMTF | 132LB6 | 7,5 | 1000 | 4MTM, 4MTH | 225 L6 | 55 | 1000 | MTN, MTF | 613-6 | 110 | 1000 |

| MTN | 211A-6 | 5,5 | 1000 | 4MTM, 4MTH | 225 L8 | 37 | 750 | MTN, MTF | 613-10 | 75 | 600 |

| MTN, MTF, AMTF | 211-6 | 7,5 | 1000 | MTN, MTF | 511-6 | 37 | 1000 | MTN, 4MTN(F) | 400 S8 | 132 | 750 |

| MTN, MTF, DMTF | 311-6 | 11 | 1000 | MTN, MTF | 511-8 | 30 | 750 | MTN, 4MTN(F) | 400 S10 | 110 | 600 |

| MTN, MTF | 311-8 | 7,5 | 750 | MTN, MTF | 512-6 | 55 | 1000 | MTN, 4MTN(F) | 400 M8 | 160 | 750 |

| MTN, MTF | 312-6 | 15 | 1000 | MTN, MTF | 512-8 | 37 | 750 | MTN, 4MTN(F) | 400 M10 | 132 | 600 |

| MTN, MTF | 312-8 | 11 | 750 | 4MTM, 4MTN | 280 S6 | 75 | 1000 | MTN, 4MTN(F) | 400 L8 | 200 | 750 |

| MTN, MTF, 4MT | 200 LA6 | 22 | 1000 | 4MTM, 4MTN | 280 S8 | 55 | 750 | MTN, 4MTN(F) | 400 L10 | 160 | 600 |

| MTN, MTF, 4MT | 200 LA8 | 15 | 750 | 4MTM, 4MTN | 280 S10 | 45 | 600 | MTN, MTF | 711-10 | 110 | 600 |

| MTN, MTF, 4MT | 200LB6 | 30 | 1000 | 4MTM, 4MTN | 280 M8 | 75 | 750 | MTN, MTF | 712-10 | 132 | 600 |

| MTN, MTF, 4MTM | 200LB8 | 22 | 750 | 4MTM, 4MTN | 280 M10 | 60 | 600 | MTN, MTF | 713-10 | 160 | 600 |

Crane electric motors, squirrel-cage and wound-rotor

View the price of crane electric motors

Crane electric motors of the MT series are designed to drive crane and other mechanisms operating in short-term and intermittent modes, including frequent starts and electrical braking. The engines can also be used for long-duty mechanisms.

Crane electric motors are designed for power supply from a 380 V, 50 Hz network with three output ends from the stator winding, and can also be manufactured for voltages of 220/380 and 380/660 V with six output ends for connecting the phases in a star or triangle. At the customer's request, crane electric motors are manufactured for other voltages and frequencies.

Crane electric motors MTF, MTH, MIT are manufactured with a wound rotor, MTKF, MTKH, MTKI motors are manufactured with a squirrel-cage rotor, one- and two-speed.

Crane electric motors MT(K)F are designed for moderate climates (version U1), motors MT(K)N are designed for work at elevated temperatures (version U1), for tropical climates (version T1) and for cold climates (version HL1).

Crane electric motors MT(K)I have a single climatic version 01 and, having certain heating reserves, allow operation in metallurgical production conditions

Cooling of electric motors - external airflow (IC 0141). The degree of protection of the motors is IP 44, the degree of protection of the terminal box and hatch of the motor slip rings is IP 54.

- Design according to installation method (1M):

- MT(K) 311, 312: IМ1001, IМ1002 - horizontal, with one and two cylindrical shaft ends;

- IM2001 - horizontal flanged with one cylindrical shaft end;

- IМ2011, IМ2012 - vertical flanged with one and two cylindrical shaft ends.

- IM1003, IM1004 - horizontal, with one or two conical shaft ends.

- IM2003 - horizontal flanged with feet, with one conical shaft end;

Crane electric motors MT(K)I 225 can be manufactured with cylindrical shaft ends in the design IM1001, IM1002, IM2001, IM2011, IM2012.

Crane electric motors MTF, MTKF, MTH, MTKH comply with GOST and the requirements of IEC regulatory documents. In terms of linking the power scale with the height of the rotation axis, MIT and MTKI engines comply with CENELEC and DIN standards.

Crane electric motors of the MT and MIT types have safety certificates of conformity with the Gosstandart of the Russian Federation and are produced under a license from the Gosgortekhnadzor of Russia.

Technical characteristics of crane squirrel-cage electric motors:

| engine's type | Power at duty cycle 40%, kW | Rotational speed, rpm | Weight for IM1001,1003, kg | Stator current at U=380V, A | Rel. Max. moment. to nominal | Efficiency, % | Power factor | Height of rotation axis, mm | Heat resistance class |

| DMTKF 011-6 | 1,4 | 875 | 47 | 5,2 | 2,8 | 70,5 | 0,67 | 112 | F |

| MTKN 011-6 | 1,4 | 920 | 45,5 | 4,5 | 2,8 | 70,5 | 0,67 | 112 | N |

| DMTKF 012-6 | 2,2 | 880 | 54 | 7,2 | 2,8 | 73,5 | 0,70 | 112 | F |

| MTKN 012-6 | 2,2 | 915 | 49,5 | 6,5 | 2,8 | 73,5 | 0,70 | 112 | N |

| MTKN 111-6 | 3,5 | 865 | 77 | 8,9 | 2,75 | 74,5 | 0,8 | 132 | H |

| MTKN 112-6 | 5 | 890 | 85 | 12,8 | 3,35 | 76 | 0,78 | 132 | H |

| DMTKF 111-6 | 3,5 | 900 | 78 | 9,9 | 2,7 | 72,0 | 0,79 | 132 | F |

| DMTKN 111-6 | 3,0 | 910 | 78 | 9,5 | 2,7 | 68,0 | 0,70 | 132 | H |

| DMTKF 112-6 | 5,0 | 910 | 92 | 14 | 3,2 | 74,0 | 0,74 | 132 | F |

| DMTKN 112-6 | 4,5 | 900 | 92 | 12,7 | 4,1 | 71,5 | 0,75 | 132 | H |

| AMTKF 132 M6 | 5,0 | 905 | 103 | 12,6 | 2,1 | 87,0 | — | 132 | F |

| AMTKN 132 M6 | 4,5 | 905 | 103 | 11,7 | 2,3 | 87,0 | — | 132 | H |

| AMTKF 132 L6 | 7,5 | 905 | 120 | 18,5 | 1,4 | 87,0 | — | 132 | F |

| AMTKN 132 L6 | 7,0 | 900 | 120 | 18,5 | 2,3 | 87,0 | — | 132 | H |

| MTKI 160 M6 | 7,0 | 905 | 131 | — | 3,5 | 78,0 | 0,77 | 160 | H |

| MTKI 160 M8 | 5,0 | 675 | 131 | — | 3,0 | 77,0 | 0,68 | 160 | H |

| MTKI 160 L6 | 10,0 | 915 | 159 | — | 4,0 | 83,0 | 0,76 | 160 | H |

| MTKI 160 L8 | 7,0 | 680 | 159 | — | 2,8 | 80,0 | 0,69 | 160 | H |

| MTKF 311-6 | 11,0 | 910 | 155 | 28,5 | 2,9 | 77,5 | 0,76 | 180 | F |

| MTKN 311-6 | 11,0 | 915 | 185 | 26,7 | 2,9 | 81,0 | 0,77 | 180 | H |

| MTKF 311-8 | 7,5 | 690 | 155 | 21,8 | 2,7 | 73,5 | 0,71 | 180 | F |

| MTKN 311-8 | 7,5 | 695 | 185 | 21 | 2,7 | 78,5 | 0,69 | 180 | H |

| MTKF 312-6 | 15,0 | 930 | 195 | 36 | 3,2 | 81,0 | 0,78 | 180 | F |

| MTKN 312-6 | 15,0 | 925 | 205 | 35 | 3,2 | 83,0 | 0,78 | 180 | H |

| MTKF 312-8 | 11,0 | 700 | 195 | 29 | 2,9 | 78,0 | 0,74 | 180 | F |

| MTKN 312-8 | 11,0 | 700 | 205 | 29,2 | 2,9 | 81,5 | 0,70 | 180 | H |

| MTKF 411-6 | 22,0 | 935 | 255 | 51 | 3,3 | 82,5 | 0,79 | 225 | F |

| MTKN 411-6 | 22,0 | 935 | 255 | 51 | 3,3 | 82,5 | 0,79 | 225 | H |

| MTKF 411-8 | 15,0 | 695 | 255 | 40 | 3,2 | 80,0 | 0,71 | 225 | F |

| MTKN 411-8 | 15,0 | 695 | 255 | 40 | 3,2 | 80,0 | 0,71 | 225 | H |

| MTKF 412-6 | 30,0 | 935 | 315 | 70 | 3,3 | 83,5 | 0,78 | 225 | F |

| MTKN 412-6 | 30,0 | 935 | 315 | 70 | 3,3 | 83,5 | 0,78 | 225 | H |

| MTKF 412-8 | 22,0 | 700 | 315 | 60 | 3,2 | 80,5 | 0,69 | 225 | F |

| MTKN 412-8 | 22,0 | 700 | 315 | 60 | 3,2 | 80,5 | 0,69 | 225 | H |

| 4MTKM 200 LA6 | 22,0 | 935 | 253 | 48 | 3,3 | 87,0 | 0,80 | 200 | H |

| 4MTKM 200 LA8 | 15,0 | 705 | 260 | 40 | 3,2 | 83,0 | 0,70 | 200 | H |

| 4MTKM 200 LB6 | 30,0 | 945 | 279 | 61 | 3,3 | 87,5 | 0,85 | 200 | H |

| 4MTKM 200 LB8 | 22,0 | 700 | 290 | 54 | 3,2 | 83,0 | 0,75 | 200 | H |

| 4MTKM 225 M6 | 37,0 | 930 | 360 | 77 | 3,0 | 85,0 | 0,86 | 225 | H |

| 4MTKM 225 M8 | 30,0 | 700 | 360 | 72 | 2,8 | 84,0 | 0,75 | 225 | H |

| 4MTKM 225 L6 | 55,0 | 925 | 460 | 112 | 3,4 | 86,0 | 0,87 | 225 | H |

| 4MTKM 225 L8 | 37,0 | 700 | 450 | 85 | 2,8 | 85,0 | 0,78 | 225 | H |

| MTKN 511-6 | 37,0 | 930 | 360 | 77 | 3,0 | 85,0 | 0,86 | 250 | H |

| MTKN 511-8 | 30,0 | 700 | 360 | 72 | 2,8 | 84,0 | 0,75 | 250 | H |

| MTKN 512-6 | 55,0 | 925 | 460 | 112 | 3,4 | 86,0 | 0,87 | 250 | H |

| MTKN 512-8 | 37,0 | 700 | 450 | 85 | 2,8 | 85,0 | 0,78 | 250 | H |

Technical characteristics of crane motors with wound rotor:

| engine's type | Power at duty cycle 40%, kW | Rotational speed, rpm | Weight for IM1001,1003, kg | Stator current at U=380V, A | Rotor current, A | Rel. Max. moment. to nominal | Efficiency, % | Power factor | Height of rotation axis, mm | Heat resistance class |

| DMTF 011-6 | 1,4 | 880 | 56 | 5,2 | 9,0 | 2,5 | 89,0 | 0,66 | 112 | F |

| DMTF 012-6 | 2,2 | 895 | 63 | 7,5 | 11,5 | 2,3 | 87,0 | 0,68 | 112 | F |

| DMTF 111-6 | 3,5 | 900 | 92 | 18,7 | 15,0 | 2,2 | 86,0 | — | 132 | F |

| MTH 011-6 | 1,4 | 890 | 60 | 4,9 | 8,8 | 2,6 | 65 | 0,67 | 112 | H |

| MTH 012-6 | 2,2 | 895 | 68 | 6,9 | 11 | 2,7 | 70 | 0,69 | 112 | H |

| MTH 111-6 | 3,5 | 900 | 91 | 9,7 | 14,3 | 2,3 | 75 | 0,73 | 132 | H |

| MTH 112-6 | 5 | 930 | 101 | 13,7 | 15,7 | 2,7 | 79 | 0,7 | 132 | H |

| DMTN 111-6 | 3,0 | 890 | 92 | 18,2 | 15,0 | 2,5 | 88,0 | — | 132 | H |

| DMTF 112-6 | 5,0 | 925 | 110 | 25,4 | 15,7 | 2,6 | 87,0 | — | 132 | F |

| DMTN 112-6 | 4,5 | 900 | 110 | 24,0 | 15,6 | 2,4 | 88,0 | — | 132 | H |

| AMTF 132 M6 | 5,0 | 905 | 120 | 11,0 | 15,2 | 2,2 | 87,0 | — | 132 | F |

| AMTN 132 M6 | 4,5 | 925 | 123 | 12,9 | 14,3 | 2,3 | 87,0 | — | 132 | H |

| AMTF 132 L6 | 7,5 | 900 | 140 | 16,0 | 18,8 | 2,2 | 87,0 | — | 132 | F |

| AMTN 132 L6 | 7,0 | 925 | 140 | 19,1 | 20,7 | 2,4 | 87,0 | — | 132 | H |

| MTI 160 M6 | 7,0 | 930 | 138 | — | 18,7 | 3,0 | 81,0 | 0,69 | 160 | H |

| MTI 160 M8 | 5,0 | 965 | 138 | — | 16,9 | 2,5 | 78,0 | 0,64 | 160 | H |

| MTI 160 L6 | 10,0 | 950 | 166 | — | 24,7 | 3,5 | 84,0 | 0,69 | 160 | H |

| MTI 160 L8 | 7,0 | 700 | 166 | — | 20,4 | 2,5 | 79,0 | 0,64 | 160 | H |

| MTN 211-6 | 7,0 | 945 | — | 16,0 | — | 2,7 | 87,0 | — | 160 | N |

| MTF 311-6 | 11 | 945 | 220 | 29,3 | 42 | 3,0 | 80,0 | 0,71 | 180 | F |

| MTN 311-6 | 11 | 940 | 220 | 29,3 | 41 | 3,0 | 80,0 | 0,71 | 180 | H |

| MTF 311-8 | 7,5 | 695 | 225 | 23,0 | 21 | 3,0 | 76,0 | 0,65 | 180 | F |

| MTN 311-8 | 7,5 | 700 | 225 | 23,0 | 21 | 3,0 | 76,0 | 0,65 | 180 | H |

| MTF 312-6 | 15 | 955 | 240 | 37,5 | 46 | 3,0 | 82,0 | 0,74 | 180 | F |

| MTN 312-6 | 15 | 950 | 240 | 37,5 | 46 | 3,0 | 82,0 | 0,74 | 180 | H |

| MTF 312-8 | 11 | 695 | 240 | 32,7 | 43 | 3,0 | 78,5 | 0,65 | 180 | F |

| MTN 312-8 | 11 | 705 | 240 | 32,7 | 43 | 3,0 | 78,5 | 0,65 | 180 | H |

| MTF 411-6 | 22 | 965 | 280 | 51 | 60 | 2,8 | 86,0 | 0,76 | 225 | F |

| MTN 411-6 | 22 | 965 | 280 | 51 | 59 | 2,8 | 86,0 | 0,76 | 225 | H |

| 4MTM 200 LA6 | 22 | 960 | 270 | 51 | 59 | 2,8 | 86,0 | 0,76 | 200 | N |

| MTF 411-8 | 15 | 710 | 280 | 44 | 48,8 | 3,2 | 83,0 | 0,62 | 225 | F |

| MTN 411-8 | 15 | 710 | 280 | 44 | 46 | 3,2 | 83,0 | 0,62 | 225 | H |

| 4MTM 200 LA8 | 15 | 720 | 275 | 44 | 46 | 3,2 | 83,0 | 0,62 | 200 | N |

| MTF 412-6 | 30 | 970 | 345 | 55 | 73 | 2,8 | 87,0 | 0,79 | 225 | F |

| MTN 412-6 | 30 | 970 | 345 | 55 | 72 | 2,8 | 87,0 | 0,79 | 225 | H |

| 4MTM 200 LB6 | 30 | 960 | 300 | 55 | 72 | 2,8 | 87,0 | 0,79 | 200 | N |

| MTF 412-8 | 22 | 720 | 315 | 58 | 57 | 3,0 | 83,0 | 0,70 | 225 | F |

| MTN 412-8 | 22 | 720 | 315 | 58 | 58 | 3,0 | 83,0 | 0,70 | 225 | H |

| 4MTM 200 LB8 | 22 | 715 | 305 | 58 | 58 | 3,0 | 83,0 | 0,70 | 200 | N |

| 4MTM 225 M6 | 37 | 955 | 390 | 80 | 80 | 3,0 | 87,0 | 0,81 | 225 | N |

| MTN 511-6 | 37 | 955 | 390 | 80 | 80 | 3,0 | 87,0 | 0,81 | 250 | N |

| 4MTM 225 L6 | 55 | 955 | 490 | 117 | 122 | 2,9 | 88,0 | 0,81 | 225 | N |

| MTN 512-6 | 55 | 955 | 490 | 117 | 122 | 2,9 | 88,0 | 0,81 | 250 | N |

| 4MTM 225 M8 | 30 | 715 | 390 | 74 | 70 | 2,9 | 85,0 | 0,72 | 225 | N |

| MTN 511-8 | 30 | 715 | 390 | 74 | 70 | 2,9 | 85,0 | 0,72 | 250 | N |

| 4MTM 225 L8 | 37 | 725 | 470 | 88 | 76 | 2,9 | 86,0 | 0,74 | 225 | N |

| MTN 512-8 | 37 | 725 | 470 | 88 | 76 | 2,9 | 86,0 | 0,74 | 250 | N |

| 4MTH 280 S6 | 75 | 955 | 740 | 149 | 180 | 3,2 | 89,0 | 0,86 | 280 | H |

| MTH 611-6 | 75 | 955 | 740 | 149 | 180 | 3,2 | 89,0 | 0,86 | 315 | H |

| 4MTH 280 L6 | 110 | 970 | 970 | 216 | 168 | 3,5 | 91,0 | 0,85 | 280 | H |

| MTH 612-6 | 110 | 970 | 970 | 216 | 168 | 3,5 | 91,0 | 0,85 | 315 | H |

| 4MTH 280 M8 | 75 | 720 | 820 | 156 | 188 | 3,0 | 90,0 | 0,81 | 280 | H |

| 4MTH 280 L8 | 90 | 725 | 980 | 190 | 171 | 3,2 | 91,0 | 0,79 | 280 | H |

| 4MTH 280 M10 | 60 | 575 | 825 | 140 | 162 | 3,2 | 88,0 | 0,74 | 280 | H |

| MTH 612-10 | 60 | 575 | 825 | 140 | 162 | 3,2 | 88,0 | 0,74 | 315 | H |

| 4MTH 280 L10 | 75 | 575 | 975 | 175 | 150 | 3,0 | 89,0 | 0,73 | 280 | H |

| MTH 613-10 | 75 | 575 | 975 | 175 | 150 | 3,0 | 89,0 | 0,73 | 315 | H |

| 4MTN 400 L8 | 200 | 750 | 1480 | 407 | 271 | — | 93,5 | 0,80 | 400 | H |

| 4MTH 400 M8 | 160 | 750 | 1380 | 330 | 266 | — | 93,3 | 0,79 | 400 | H |

| 4MTH 400 S8 | 132 | 750 | 1230 | 272 | 271 | — | 92,3 | 0,80 | 400 | H |

| 4MTH 400 L10 | 160 | 600 | 1580 | 355 | 242 | 2,55 | 91,3 | 0,73 | 400 | H |

| 4MTH 400 M10 | 132 | 600 | 1420 | 285 | 249 | 2,1 | 91,3 | 0,73 | 400 | H |

| 4MTH 400 S10 | 110 | 600 | 1255 | 240 | 251 | 1,75 | 90,5 | 0,73 | 400 | H |

Dimensions of crane squirrel cage motors:

| engine's type | l1 | l10 | l21 | l31 | l33 | b10 | b11 | H | H31 | D20 | D22 | D24 | D25 | d | b | h |

| DMTKF 011-6 | 60 | 140 | 5 | 70 | 407 | 140 | 188 | 112 | 320 | 265 | 15 | 230 | 300 | 28 | 8 | 31 |

| DMTKF 012-6 | 60 | 159 | 5 | 70 | 442 | 159 | 210 | 112 | 320 | 265 | 15 | 230 | 300 | 28 | 8 | 31 |

| DMTKF(N) 111-6 | 80 | 190 | 5 | 140 | 713 | 220 | 290 | 132 | 342 | 300 | 18 | 330 | 250 | 35 | 10 | 38 |

| DMTKF(N) 112-6 | 80 | 235 | 5 | 135 | 574 | 220 | 290 | 132 | 342 | 300 | 18 | 330 | 250 | 35 | 10 | 38 |

| AMTKF(N) 132 M6 | 110 | 203 | 5 | 89 | 536 | 216 | 270 | 132 | 350 | 300 | 19 | 250 | 350 | 42 | 12 | 45 |

| AMTKF(N) 132 L6 | 110 | 203 | 5 | 89 | 576 | 216 | 270 | 132 | 350 | 300 | 19 | 250 | 350 | 42 | 12 | 45 |

| MTKI 160 M | 140 | 210 | 5 | 108 | 845 | 254 | 320 | 160 | 410 | 300 | 19 | 250 | 350 | 60 | 12 | 45 |

| MTKI 160 L | 140 | 254 | 5 | 108 | 910 | 254 | 320 | 160 | 410 | 300 | 19 | 250 | 350 | 60 | 12 | 45 |

| MTKF(N) 311 | 110 | 260 | 5 | 155 | 637 | 280 | 350 | 180 | 444 | 300 | 19 | 250 | 350 | 50 | 14 | 53,5 |

| MTKF(N) 312 | 110 | 320 | 5 | 170 | 712 | 280 | 350 | 180 | 444 | 300 | 19 | 250 | 350 | 50 | 14 | 53,5 |

| MTKF(N) 411 | 140 | 335 | 5 | 175 | 749 | 330 | 440 | 225 | 527 | 350 | 19 | 300 | 400 | 65 | 16 | 66,4 |

| MTKF(N) 412 | 140 | 420 | 5 | 165 | 824 | 330 | 440 | 225 | 527 | 350 | 19 | 300 | 400 | 65 | 16 | 66,4 |

| 4MTKM 200 L | 140 | 305 | — | 133 | 910 | 318 | 400 | 200 | 500 | — | — | — | — | 65 | 16 | 66,4 |

| 4MTKM 225 M | 140 | 311 | — | 149 | 945 | 356 | 435 | 225 | 545 | — | — | — | — | 70 | 18 | 71,4 |

| 4MTKM 225 L | 140 | 356 | — | 149 | 1054 | 356 | 435 | 225 | 545 | — | — | — | — | 70 | 18 | 71,4 |

| MTKN 511 | 140 | 310 | — | 251 | 945 | 380 | 500 | 250 | 570 | — | — | — | — | 70 | 18 | 71,4 |

| MTKN 512 | 140 | 390 | — | 271 | 1054 | 380 | 500 | 250 | 570 | — | — | — | — | 70 | 18 | 71,4 |

Dimensions of crane motors with wound rotor:

| engine's type | L1 | L10 | L21 | L31 | L33 | B10 | B11 | H | H31 | D20 | D22 | D24 | D25 | d | b | h |

| DMTF 011-6 | 60 | 140 | 5 | 70 | 513 | 190 | 240 | 112 | 290 | 265 | 15 | 230 | 300 | 28 | 8 | 31 |

| DMTF 012-6 | 60 | 159 | 5 | 70 | 548 | 190 | 240 | 112 | 290 | 265 | 15 | 230 | 300 | 28 | 8 | 31 |

| DMTF(N) 111-6 | 80 | 190 | 5 | 140 | 673 | 220 | 290 | 132 | 342 | 300 | 15 | 330 | 250 | 35 | 10 | 38 |

| DMTF(N) 112-6 | 80 | 235 | 5 | 135 | 713 | 220 | 290 | 132 | 342 | 300 | 15 | 330 | 250 | 35 | 10 | 38 |

| AMTF(N) 132M6 | 110 | 203 | 5 | 89 | 660 | 216 | 270 | 132 | 350 | 300 | 19 | 350 | 250 | 42 | 12 | 45 |

| AMTF(N) 132L6 | 110 | 203 | 5 | 89 | 700 | 216 | 270 | 132 | 350 | 300 | 19 | 350 | 250 | 42 | 12 | 45 |

| MTI 160M | 110 | 210 | 5 | 108 | 845 | 254 | 320 | 160 | 410 | 300 | 19 | 250 | 350 | 42 | 12 | 45 |

| MTI 160L | 110 | 254 | 5 | 108 | 910 | 254 | 320 | 160 | 410 | 300 | 19 | 250 | 350 | 42 | 12 | 45 |

| MTN 211 | 110 | 243 | 5 | 150 | 731,5 | 245 | — | 160 | — | 300 | — | 250 | — | 40 | — | — |

| MTF(N) 311 | 110 | 260 | 5 | 155 | 859,5 | 280 | 350 | 180 | 444 | 300 | 19 | 250 | 350 | 50 | 14 | 53,5 |

| MTF(N) 312 | 110 | 320 | 5 | 170 | 834,5 | 280 | 350 | 180 | 444 | 300 | 19 | 250 | 350 | 50 | 14 | 53,5 |

| MTF(N) 411 | 140 | 335 | 5 | 175 | 1027 | 330 | 420 | 225 | 525 | 350 | 19 | 300 | 400 | 65 | 18 | 66,4 |

| MTF(N) 412 | 140 | 420 | 5 | 165 | 1102 | 330 | 420 | 225 | 525 | 350 | 19 | 300 | 400 | 65 | 18 | 66,4 |

| 4MTM 200L | 140 | 305 | — | 133 | 907 | 318 | 400 | 200 | 500 | — | — | — | — | 65 | 16 | 66,4 |

| 4MTM 225M | 140 | 311 | — | 149 | 960 | 356 | 435 | 225 | 545 | — | — | — | — | 70 | 18 | 71,4 |

| 4MTM 225L | 140 | 356 | — | 149 | 1070 | 356 | 435 | 225 | 545 | — | — | — | — | 70 | 18 | 71,4 |

| 4MTH 280S | 170 | 368 | — | 190 | 1090 | 457 | 540 | 280 | 740 | — | — | — | — | 90 | 22 | 91,8 |

| 4MTH 280M | 170 | 419 | — | 190 | 1170 | 457 | 540 | 280 | 740 | — | — | — | — | 90 | 22 | 91,8 |

| 4MTH 280L | 170 | 457 | — | 190 | 1260 | 457 | 540 | 280 | 740 | — | — | — | — | 90 | 22 | 91,8 |

| 4MTH 400S8 | 210 | 560 | — | 280 | 1472 | 686 | 790 | 400 | 880 | — | — | — | — | 110 | 25 | (106,8) |

| 4MTH 400M8 | 210 | 630 | — | 280 | 1552 | 686 | 790 | 400 | 880 | — | — | — | — | 110 | 25 | (106,8) |

| 4MTH 400L8 | 210 | 710 | — | 280 | 1622 | 686 | 790 | 400 | 880 | — | — | — | — | 110 | 25 | (106,8) |

| 4MTH 400S10 | 210 | 560 | — | 280 | 1402 | 686 | 790 | 400 | 880 | — | — | — | — | 110 | 25 | (106,8) |

| 4MTH 400M10 | 210 | 560 | — | 280 | 1473 | 686 | 790 | 400 | 880 | — | — | — | — | 110 | 25 | (106,8) |

| 4MTH 400L10 | 210 | 630 | — | 280 | 1553 | 686 | 790 | 400 | 880 | — | — | — | — | 110 | 25 | (106,8) |

| MTN 511 | 140 | 310 | — | 251 | 1110 | 380 | 500 | 250 | 570 | — | — | — | — | 70 | 18 | 71,4 |

| MTN 512 | 140 | 390 | — | 271 | 1220 | 380 | 500 | 250 | 570 | — | — | — | — | 70 | 18 | 71,4 |

| MTN 611 | 170 | 345 | — | 256 | 1265 | 520 | 650 | 315 | 775 | — | — | — | — | 90 | 22 | 91,8 |

| MTN 612 | 170 | 445 | — | 256 | 1345 | 520 | 650 | 315 | 775 | — | — | — | — | 90 | 22 | 91,8 |

| MTN 613 | 170 | 540 | — | 256 | 1439 | 520 | 650 | 315 | 775 | — | — | — | — | 90 | 22 | 91,8 |

Drawings of crane squirrel-cage electric motors:

Drawings of crane electric motors with a wound rotor:

Crane electric motors with squirrel-cage rotor

| Engine series | Type-size | Power kW | RPM | Engine series | Type-size | Power kW | RPM | Engine series | Type-size | Power kW | RPM |

| MTKN, MTKF, DMTKF | 011-6 | 1,4 | 1000 | MTKN, MTKF | 311-8 | 7,5 | 750 | MTKN, MTKF | 412-8 | 22 | 750 |

| MTKN, MTKF, DMTKF | 012-6 | 2,2 | 1000 | MTKN, MTKF | 312-6 | 15 | 1000 | 4MTKM | 225 M6 | 37 | 1000 |

| MTKN, MTKF, DMTKF | 111-6 | 3,5 | 1000 | MTKN, MTKF | 312-8 | 11 | 750 | 4MTKM | 225 M8 | 30 | 750 |

| MTKN, MTKF, DMTKF | 112-6 | 5,0 | 1000 | MTKN, 4MTK | 200 LA6 | 22 | 1000 | 4MTKM | 225 L6 | 55 | 1000 |

| AMTKF | 132 M6 | 5,0 | 1000 | MTKN, 4MTK | 200 LA8 | 15 | 750 | 4MTKM | 225 L8 | 37 | 750 |

| MTKN, 4MTKN | 132 LA6 | 5,5 | 1000 | MTKN, 4MTK | 200LB6 | 30 | 1000 | MTKN, MTKF | 511-6 | 37 | 1000 |

| MTKN, 4MTKN, AMTKF | 132LB6 | 7,5 | 1000 | MTKN, 4MTKM | 200LB8 | 22 | 750 | MTKN, MTKF | 511-8 | 30 | 750 |

| MTKN | 211A-6 | 5,5 | 1000 | MTKN, MTKF | 411-6 | 22 | 1000 | MTKN, MTKF | 512-6 | 55 | 1000 |

| MTKN, MTKF | 211-6 | 7,5 | 1000 | MTKN, MTKF | 411-8 | 15 | 750 | MTKN, MTKF | 512-8 | 37 | 750 |

| MTKN, MTKF | 311-6 | 11 | 1000 | MTKN, MTKF | 412-6 | 30 | 1000 | MTKN, MTKF | 612-10 | 75 | 600 |

Mounting version(IM….)

Sizes 0, 1, 2, 3 and motors with axis height 132:

- 1001 - on feet with one cylindrical shaft end.

- 1002 - on feet with two cylindrical shaft ends.

- 2001 - on feet with a flange with one cylindrical shaft end.

- 2002 - on feet with a flange with two cylindrical shaft ends.

Dimensions 4, 5, 6 and motors with axis height 200, 225, 280, 400:

- 1003 - on paws with one conical shaft end.

- 1004 - on paws with two conical shaft ends.

- 2003 - on feet with a flange with one conical shaft end.

- 2004 - on feet with a flange with two conical shaft ends.

- 2008 - foot-mounted with a flange with one conical shaft end and one cylindrical end.

Marking of crane electric motors type 1:

MTKH112—6У11234567891. Series name: MT, AMT, DMT

2. Rotor type: K – squirrel cage rotor

absence of letter – wound rotor

3. Heat resistance class of insulation: H or F

4. Dimensions of the outer diameter of the stator sheets: 0…7

5. Engine upgrade: 0…1

6. Motor stator core length size: 1…3

7. Number of poles: 6, 8, 10

8. Climatic version: U, T, UHL

9. Accommodation category: 1, 2

Application of crane electric motors

Asynchronous AC crane electric motors are designed for heavy-duty operation of repeated starts-stops-reverses, with control of the rotor speed in conditions of severe shaking and vibration. Crane electric motors with a wound rotor also operate in metallurgical shops at ambient temperatures up to 700 ºC, in an atmosphere of high gas pollution and vapor formation.

Electric motors with a wound rotor operate on portal, bridge, tower, gantry cranes and intra-shop telpher systems in heavy and very heavy duty. Asynchronous motors with a phase rotor of the MTF and MTN brands are used as crane electric motors, where the letters “F” and “N” indicate the heat resistance class.

Marking of crane electric motors type 2:

| AMT | K | F | 132 | L | A | — | 6 | U | 2 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

1. Series name: MT, AMT, DMT, 4MTM

2. Rotor type: K – squirrel cage rotor

absence of letter – wound rotor

3. Heat resistance class of insulation: H or F

4. Rotation axis height: 132…400

5. Installation dimension along the length of the bed: S, M, L

6. Core length designation: A, B or without letter

7. Number of poles: 6, 8, 10

8. Climatic version: U, T, UHL

9. Accommodation category: 1, 2

In addition to the main marking, additional characteristics are also indicated:

Mounting design IMхххх

Crane electric motors up to size 3 inclusive and with a rotation axis height up to 180 inclusive are usually made with cylindrical shaft ends.

Crane electric motors of size 4 and above, as well as with a rotation axis height of 200 and above, are usually made with conical shaft ends.

Protection degree IPxx (GOST 17494-87)

Typically, crane electric motors are made with a degree of protection IP54 and IP44 according to GOST 17494 (IEC 60034-5). At the request of consumers, electric motors can be manufactured with a degree of protection IP55.

Heat resistance class of insulation

Crane electric motors, as a rule, have an insulation heat resistance class of “F” (temperature index 155°C) or “H” (temperature index 180°C) according to GOST 8865-93.

Nominal operating mode

(for which a number of capacities are given) : intermittent S3 - PV40% according to GOST 183-74 (IEC 60034-1). Crane electric motors can also operate in other modes: S3 - PV15, 25, 60, 100%, short-term S2 - 30 and 60 minutes.

Crane electric motors of the ENERAL fully comply with all technical standards of the Russian Federation. Their installation and connection dimensions fully correspond to engines manufactured by Sibelektromotor OJSC, Tomsk.>

Dimensions may vary among different manufacturers.

Rice. 1 — Version IM1001 (1002, 1003, 1004)

Rice. 2 - Version IM2001 (2002, 2003, 2004)

Overall, installation and connection dimensions are given in the tables. The installation and connecting dimensions of electric motors of the MT and 4MT series are the same for the corresponding heights of the rotation axes.

The overall dimensions of crane electric motors may vary slightly among different manufacturers.

Types of crane electric motors

Due to the use of various principles for rotating the rotor in an electric motor, many of them have found wide application in the operation of crane installations. Among electric motors for general industrial use, there are AC and DC machines, asynchronous motors, both with phase and squirrel-cage rotors. Next, we will consider each of the types used for crane equipment.

Alternating current

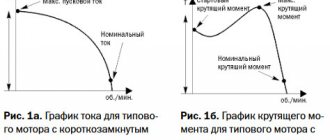

For domestic cranes, asynchronous AC electric machines are used. A distinctive feature of such installations is good traction characteristics, but the disadvantages include the need to connect three phases at once and large starting currents. Most models are manufactured for a standard network frequency of 50Hz; such options are capable of constantly withstanding overloads of 10 - 15%.

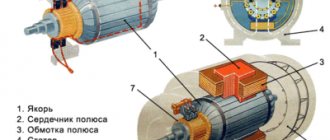

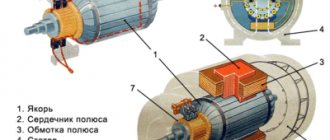

Rice. 1. Example of an AC motor

The most common models in the AC network are MTF and MTKF electric motors, which have a wound rotor and a squirrel-cage rotor, respectively. And in metallurgical production, the model range consists of electric machines MTH and MTKH with the same design features. In practice, alternating voltage with a frequency of 50 and 60 Hz can be used to power both. The possibility of rotor rotation for them ranges from 600 to 1000 rpm for a supply electrical quantity with a frequency of 50 Hz. Or from 700 to 1200 at frequencies of 60Hz. Electric drives of mechanisms in most cases can have several speeds at once.

Direct current

DC electric motors are used to equip crane installations that require frequent switching over the course of an hour or an entire work shift. In addition, they allow you to adjust the frequency range over a fairly wide range. Of course, in our time, three-phase asynchronous machines can become closer to DC motors through the introduction of frequency conversion systems. Regulation is performed by either weakening the stator magnetic field or increasing the voltage of the rotor windings.

Rice. 2. DC motor example

Structurally, they are produced for power from 2 to 190 kW, depending on the value of the supply voltage, groups of excitation windings can have a serial or parallel connection. In this type of crane electric motors, control is carried out by changing the currents in the excitation winding.

Crane and metallurgical asynchronous electric motors of the 4MT series

The metallurgical industry is characterized by significant volumes of materials moved and the specific gravity of the metal. Therefore, crane electric motors of the MT series must provide the declared power, regardless of the rotation speed. The yoke of an electric machine is made with four or eight poles to transmit magnetic flux; the material for the magnetic core is cold-rolled steel. To insulate crane electric motors, polymer films, impregnated fabrics or paper are used as a dielectric.

Rice. 3. Crane-metallurgical electric motors

In electric drives of metallurgical cranes, greater reliability is built into the manufacturing stage - up to 0.98, while all others can have a coefficient of 0.96. The service life declared by the manufacturer must also be at least 20 years.

With wound rotor

Crane electric motors with a wound rotor are distinguished by the presence of a separate winding on the rotating part. The rotor coil is powered by a collector unit, which collects current and takes power through a sliding contact. However, the brush mechanism in them is the most wearable element; after the graphite contacts wear out, they must be replaced.

Rice. 4. Design of an electric motor with a wound rotor

This type of three-phase asynchronous electrical machines is characterized by smooth start-up and high load capacity. Due to this, they are installed on medium and heavy cranes that move heavy loads. Allows you to adjust the torque force on the shaft in three and four-step modes, proportionally increasing the impact power.

With squirrel-cage rotor

Structurally, the rotating part is a steel structure of cast or stacked type. Unlike the previous version, crane electric motors with a squirrel-cage rotor are lighter and have lower cost. However, the main disadvantage is the small torque created on the shaft, and this, in turn, leads to a lack of force. Therefore, squirrel-cage motors are installed on low-power crane installations designed to move light weight loads at low speed.

Rice. 5. Electric motor with squirrel-cage rotor

Specifications

Like any electrical installations, electrical machines are manufactured in accordance with the requirements and conditions in which they will be operated. When choosing a specific crane motor model, you are guided by its parameters. The main characteristics include:

- Power consumption – characterizes the amount of consumed electrical energy required to operate the electric motor. May be expressed in kilowatts or kilovolt-amperes.

- Efficiency – shows the ratio of useful work performed by an electric machine in relation to the electricity consumed from the network. In crane installations, this parameter can vary from 60 to 90%.

- Rotation frequency - shows the number of shaft revolutions that it can make per unit of time. As a rule, the value per minute is used. For each model, the speed may vary, so the parameter will have a range value.

- Shaft power – determines the force created by the crane electric motor directly on the working body.

- Rated operating voltage - indicates the potential difference that must be supplied to the input of an electrical machine to set it in motion.

- Weight and overall dimensions are the physical parameters required for installation in the overall crane structure.

- The degree of dust and moisture protection is indicated by the Latin letters IP and two numbers indicating the possibility of particles penetrating into the housing.

Overall, installation and connection dimensions of crane electric motors with a wound rotor

| Series | Type | I.M. | b1 | b10 | b11 | d1, d2 | d5 | d10 | d20 | d22 | d24 | d25 | h | h1 | h5 | h10 | h31 | l1, l2 | l3 | l10 | l11 | l20 | l30 | l31 | l33 |

| MTH | 011*** | 1001, 1002 | 8 | 180 | 230 | 28 | — | 12 | — | — | — | — | 112 | 7 | 31 | 20 | 320 | 60 | — | 150 | 250 | — | 585 | 132* | 648 |

| 2001, 2002 | 8 | 180 | 230 | 28 | — | 12 | 255 | 4x14 | 280 | 215 | 112 | 7 | 31 | 20 | 320 | 60 | — | 150 | 250 | 4 | 612 | 132 | 678 | ||

| DMTF | 011 | 1001, 1002 | 8 | 190 | 240 | 28 | — | 12 | — | — | — | — | 112 | 7 | 31 | 15 | 290 | 60 | — | 140 | 220 | — | 513 | 70 | 577 |

| 2001, 2002 | 8 | 190 | 240 | 28 | — | 12 | 265 | 4x15 | 300 | 230 | 112 | 7 | 31 | 15 | 350 | 60 | — | 140 | 220 | 5 | 513 | 65 | 577 | ||

| MTH | 012*** | 1001, 1002 | 8 | 180 | 230 | 28 | — | 12 | — | — | — | — | 112 | 7 | 31 | 20 | 320 | 60 | — | 190 | 250 | — | 616 | 127* | 678 |

| 2001, 2002 | 8 | 180 | 230 | 28 | — | 12 | 255 | 4x14 | 280 | 215 | 112 | 7 | 31 | 20 | 320 | 60 | — | 190 | 250 | 4 | 612 | 127 | 678 | ||

| DMTF | 012 | 1001, 1002 | 8 | 190 | 240 | 28 | — | 12 | — | — | — | — | 112 | 7 | 31 | 15 | 290 | 60 | — | 159 | 220 | — | 548 | 70 | 612 |

| 2001, 2002 | 8 | 190 | 240 | 28 | — | 12 | 265 | 4x15 | 300 | 230 | 112 | 7 | 31 | 15 | 350 | 60 | — | 159 | 220 | 5 | 548 | 65 | 612 | ||

| MTH | 111*** | 1001, 1002 | 10 | 220 | 280 | 35 | — | 15 | — | — | — | — | 132 | 8 | 38 | 25 | 350 | 80 | — | 190 | 305 | — | 650 | 140* | 733 |

| 2001, 2002 | 10 | 220 | 280 | 35 | — | 15 | 300 | 4x18 | 330 | 250 | 132 | 8 | 38 | 25 | 350 | 80 | — | 190 | 305 | 4 | 690 | 140 | 773 | ||

| DMTF(H) | 111 | 1001, 1002 | 10 | 220 | 290 | 35 | — | 19 | — | — | — | — | 132 | 8 | 38 | 20 | 342 | 80 | — | 190 | 240 | — | 586 | 140* | 673 |

| 2001, 2002 | 10 | 220 | 290 | 35 | — | 19 | 300 | 4x18 | 330 | 250 | 132 | 8 | 38 | 20 | 342 | 80 | — | 190 | 240 | 5 | 586 | 140 | 673 | ||

| MTH | 112*** | 1001, 1002 | 10 | 220 | 280 | 35 | — | 19 | — | — | — | — | 132 | 8 | 38 | 25 | 350 | 80 | — | 235 | 305 | — | 690 | 135* | 773 |

| 2001, 2002 | 10 | 220 | 280 | 35 | — | 19 | 300 | 4x18 | 330 | 250 | 132 | 8 | 38 | 25 | 350 | 80 | — | 235 | 305 | 4 | 690 | 135 | 773 | ||

| DMTF(H) | 112 | 1001, 1002 | 10 | 220 | 290 | 35 | — | 19 | — | — | — | — | 132 | 8 | 38 | 20 | 342 | 80 | — | 235 | 285 | — | 626 | 135* | 713 |

| 2001, 2002 | 10 | 220 | 290 | 35 | — | 19 | 300 | 4x18 | 330 | 250 | 132 | 8 | 38 | 20 | 342 | 80 | — | 235 | 285 | 5 | 626 | 135 | 713 | ||

| AMTF(H) | 132M | 1001, 1002 | 12 | 216 | 270 | 42 | — | 12 | — | — | — | — | 132 | 8 | 45 | 15 | 350 | 110 | — | 203 | 300 | — | 660 | 89 | 772 |

| 2001, 2002 | 12 | 216 | 270 | 42 | — | 12 | 300 | 4x19 | 350 | 250 | 132 | 8 | 45 | 15 | 350 | 110 | — | 203 | 300 | 5 | 660 | 90 | 772 | ||

| MTH | 132L*** | 1001, 1002 | 12 | 216 | 260 | 42 | — | 12 | — | — | — | — | 132 | 8 | 45 | 25 | 350 | 110 | — | 203 | 255 | — | 675 | 89* | 788 |

| 2001, 2002 | 12 | 216 | 280 | 42 | — | 12 | 300 | 4x19 | 350 | 250 | 132 | 8 | 45 | 25 | 350 | 110 | — | 203 | 370 | 4 | 675 | 89 | 788 | ||

| AMTF(H) | 132L | 1001, 1002 | 12 | 216 | 270 | 42 | — | 12 | — | — | — | — | 132 | 8 | 45 | 15 | 350 | 110 | — | 203 | 300 | — | 700 | 89 | 812 |

| 2001, 2002 | 12 | 216 | 270 | 42 | — | 12 | 300 | 4x19 | 350 | 250 | 132 | 8 | 45 | 15 | 350 | 110 | — | 203 | 300 | 5 | 700 | 90 | 812 | ||

| MTH | 211*** | 1001, 1002 | 12 | 245 | 305 | 40 | — | 15 | — | — | — | — | 160 | 8 | 43 | 25 | 415 | 110 | — | 243 | 345 | — | 763 | 150* | 875 |

| 2001, 2002 | 12 | 245 | 305 | 40 | — | 15 | 300 | 4x18 | 330 | 250 | 160 | 8 | 43 | 25 | 415 | 110 | — | 243 | 345 | 5 | 755 | 150 | 875 | ||

| AMTF(H) | 211 | 1001 | 12 | 245 | 300 | 40 | — | 24 | — | — | — | — | 160 | 8 | 43 | 20 | 378 | 110 | — | 243 | 300 | — | 700 | 150 | — |

| DMTF(H) | 311-6 | 1001 | 14 | 280 | 350 | 50 | — | 24 | — | — | — | — | 180 | 9 | 53,8 | 23 | 472 | 110 | — | 260 | 310 | — | 764 | 160 | — |

| MTH | 311** | 1001, 1002 | 14 | 280 | 355 | 50 | — | 24 | — | — | — | — | 180 | 9 | 53.5 | 30 | 450 | 110 | — | 260 | 335 | — | 772 | 155* | 885 |

| 2001, 2002 | 14 | 280 | 355 | 50 | — | 24 | 300 | 4x18 | 350 | 250 | 180 | 9 | 53.5 | 30 | 450 | 110 | — | 260 | 412 | 5 | 772 | 155 | 885 | ||

| MTH | 311 | 1001, 1002 | 14 | 280 | 350 | 50 | — | 24 | — | — | — | — | 180 | 9 | 53,5 | 21,5 | 480 | 110 | — | 260 | 320 | — | 765 | 155* | 885 |

| 2001, 2002 | 14 | 280 | 350 | 50 | — | 24 | 300 | 4x18 | 350 | 250 | 180 | 9 | 53,5 | 25 | 480 | 110 | — | 260 | 320 | 5 | 795 | 270 | 906 | ||

| MTH | 312** | 1001, 1002 | 14 | 280 | 355 | 50 | — | 24 | — | — | — | — | 180 | 9 | 53.5 | 30 | 450 | 110 | — | 320 | 400 | — | 837 | 170* | 950 |

| 2001, 2002 | 14 | 280 | 355 | 50 | — | 24 | 300 | 4x18 | 350 | 250 | 180 | 9 | 53.5 | 30 | 450 | 110 | — | 320 | 412 | 5 | 837 | 170 | 950 | ||

| MTH | 312 | 1001, 1002 | 14 | 280 | 350 | 50 | — | 24 | — | — | — | — | 180 | 9 | 53,5 | 21,5 | 480 | 110 | — | 320 | 380 | — | 830 | 170* | 950 |

| 2001, 2002 | 14 | 280 | 350 | 50 | — | 24 | 300 | 4x18 | 350 | 250 | 180 | 9 | 53,5 | 21,5 | 480 | 110 | — | 320 | 380 | 5 | 860 | 260 | 971 | ||

| MTH | 200L** | 1003, 1004 | 16 | 318 | 400 | 65 | M42x3 | 19 | — | — | — | — | 200 | 10 | — | 25 | 500 | 140 | 105 | 305 | 400 | — | 975 | 133* | 1118 |

| 4MT(M) | 200L | 1003, 1004 | 16 | 318 | 400 | 65 | M42x3 | 19 | — | — | — | — | 200 | 10 | — | 24 | 500 | 140 | 105 | 305 | 350 | — | 907 | 133* | 1053 |

| 4MTM(N) | 225M** | 1003, 1004 | 18 | 356 | 442 | 70 | M48x3 | 19 | — | — | — | — | 225 | 11 | — | 28 | 540 | 140 | 105 | 311 | 410 | — | 1050 | 149* | 1190 |

| 2003, 2004 | 18 | 356 | 442 | 70 | M48x3 | 19 | 400 | 8x18 | 450 | 350 | 225 | 11 | — | 28 | 540 | 140 | 105 | 311 | 410 | 5 | 1050 | 149* | 1193 | ||

| 4MTM(N) | 225M | 1003, 1004 | 18 | 356 | 435 | 70 | M48x3 | 19 | — | — | — | — | 225 | 11 | — | 24 | 545 | 140 | 105 | 311 | 370 | — | 960 | 149* | 1110 |

| 4MTM(N) | 225L** | 1003, 1004 | 18 | 356 | 442 | 70 | M48x3 | 19 | — | — | — | — | 225 | 11 | — | 28 | 540 | 140 | 105 | 356 | 442 | — | 1200 | 149* | 1340 |

| 2003, 2004 | 18 | 356 | 442 | 70 | M48x3 | 19 | 400 | 8x18 | 450 | 350 | 225 | 11 | — | 28 | 540 | 140 | 105 | 356 | 442 | 5 | 1200 | 149 | 1343 | ||

| 4MTM(N) | 225L | 1003, 1004 | 18 | 356 | 435 | 70 | M48x3 | 19 | — | — | — | — | 225 | 11 | — | 24 | 545 | 140 | 105 | 356 | 410 | — | 1070 | 149* | 1220 |

| MTH | 411** | 1003, 1004 | 16 | 330 | 412 | 65 | M42x3 | 28 | — | — | — | — | 225 | 10 | — | 28 | 540 | 140 | 105 | 335 | 425 | — | 927 | 175* | 1062 |

| 2003, 2004 | 16 | 330 | 412 | 65 | M42x3 | 28 | 350 | 8x18 | 400 | 300 | 225 | 10 | — | 28 | 540 | 140 | 105 | 335 | 529 | 5 | 925 | 175 | 1070 | ||

| MTH | 411 | 1003, 1004 | 16 | 330 | 440 | 65 | M42x3 | 28 | — | — | — | — | 225 | 10 | — | 25 | 525 | 140 | 105 | 335 | 435 | — | 907 | 175* | 1053 |

| 2003, 2004 | 16 | 330 | 440 | 65 | M42x3 | 28 | 350 | 8x18 | 400 | 300 | 225 | 10 | — | 25 | 525 | 140 | 105 | 335 | 435 | 5 | 917 | 175 | 1062 | ||

| MTH | 412** | 1003, 1004 | 16 | 330 | 412 | 65 | M42x3 | 28 | — | — | — | — | 225 | 10 | — | 28 | 540 | 140 | 105 | 420 | 529 | — | 1047 | 165* | 1190 |

| 2003, 2004 | 16 | 330 | 412 | 65 | M42x3 | 28 | 350 | 8x18 | 400 | 300 | 225 | 10 | — | 28 | 540 | 140 | 105 | 420 | 529 | 5 | 1047 | 165 | 1190 | ||

| MTH | 412 | 1003, 1004 | 16 | 330 | 440 | 65 | M42x3 | 28 | — | — | — | — | 225 | 10 | — | 25 | 525 | 140 | 105 | 420 | 510 | — | 907 | 165* | 1053 |

| 2003, 2004 | 16 | 330 | 440 | 65 | M42x3 | 28 | 350 | 8x18 | 400 | 300 | 225 | 10 | — | 25 | 525 | 140 | 105 | 420 | 510 | — | 917 | 165 | 1062 | ||

| MTH | 511** | 1003, 1004 | 18 | 380 | 480 | 70 | M48x3 | 35 | — | — | — | — | 250 | 11 | — | 30 | 585 | 140 | 105 | 310 | 530 | — | 1195 | 251* | 1337 |

| 2003, 2004 | 18 | 380 | 480 | 70 | M48x3 | 35 | 400 | 8x18 | 450 | 350 | 250 | 11 | — | 30 | 585 | 140 | 105 | 310 | 530 | 5 | 1170 | 251 | 1315 | ||

| MTH | 511 | 1003, 1004 | 18 | 380 | 500 | 70 | M48x3 | 35 | — | — | — | — | 250 | 11 | — | 25 | 570 | 140 | 105 | 310 | 480 | — | 961 | 251* | 1110 |

| 2003, 2004 | 18 | 380 | 500 | 70 | M48x3 | 35 | 400 | 8x18 | 450 | 350 | 250 | 11 | — | 25 | 570 | 140 | 105 | 310 | 480 | — | 961 | 251 | 1106 | ||

| MTH | 512** | 1003, 1004 | 18 | 380 | 480 | 70 | M48x3 | 35 | — | — | — | — | 250 | 11 | — | 30 | 585 | 140 | 105 | 390 | 530 | — | 1215 | 271* | 1357 |

| 2003, 2004 | 18 | 380 | 480 | 70 | M48x3 | 35 | 400 | 8x18 | 450 | 350 | 250 | 11 | — | 30 | 585 | 140 | 105 | 390 | 530 | 5 | 1190 | 271 | 1335 | ||

| MTH | 512 | 1003, 1004 | 18 | 380 | 500 | 70 | M48x3 | 35 | — | — | — | — | 250 | 11 | — | 25 | 570 | 140 | 105 | 390 | 600 | — | 1071 | 271* | 1220 |

| 2003, 2004 | 18 | 380 | 500 | 70 | M48x3 | 35 | 400 | 8x18 | 450 | 350 | 250 | 11 | — | 25 | 570 | 140 | 105 | 390 | 600 | — | 1071 | 271 | 1216 | ||

| 4MTM(N) | 280S** | 1003, 1004 | 22 | 457 | 565 | 90 | M64x4 | 24 | — | — | — | — | 280 | 14 | — | 32 | 635 | 170 | 130 | 368 | 525 | — | 1259 | 190* | 1438 |

| 4MTM(N) | 280S | 1003, 1004 | 22 | 457 | 540 | 90 | M64x4 | 24 | — | — | — | — | 280 | 14 | — | 40 | 740 | 170 | 130 | 368 | 430 | — | 1090 | 190* | 1265 |

| 4MTM(N) | 280M** | 1003, 1004 | 22 | 457 | 565 | 90 | M64x4 | 24 | — | — | — | — | 280 | 14 | — | 32 | 635 | 170 | 130 | 419 | 575 | — | 1305 | 190* | 1489 |

| 4MTM(N) | 280M | 1003, 1004 | 22 | 457 | 540 | 90 | M64x4 | 24 | — | — | — | — | 280 | 14 | — | 40 | 740 | 170 | 130 | 419 | 480 | — | 1170 | 190* | 1345 |

| 4MTM(N) | 280L6** | 1003, 1004 | 22 | 457 | 565 | 90 | M64x4 | 24 | — | — | — | — | 280 | 14 | — | 32 | 635 | 170 | 130 | 457 | 575 | — | 1305 | 190* | 1489 |

| 4MTM(N) | 280L10** | 1003, 1004 | 22 | 457 | 565 | 90 | M64x4 | 24 | — | — | — | — | 280 | 14 | — | 40 | 635 | 170 | 130 | 457 | 590 | — | 1395 | 190* | 1579 |

| 4MTM(N) | 280L | 1003, 1004 | 22 | 457 | 540 | 90 | M64x4 | 24 | — | — | — | — | 280 | 14 | — | 40 | 740 | 170 | 130 | 457 | 520 | — | 1260 | 190* | 1439 |

| MTH | 611** | 1003, 1004 | 22 | 520 | 640 | 90 | M64x4 | 42 | — | — | — | — | 315 | 14 | — | 40 | 665 | 170 | 130 | 345 | 510 | — | 1265 | 256 | 1438 |

| MTH | 611 | 1003, 1004 | 22 | 520 | 650 | 90 | M64x4 | 42 | — | — | — | — | 315 | 14 | — | 35 | 775 | 170 | 130 | 345 | 575 | — | 1090 | 256 | 1335 |

| MTH | 612** | 1003, 1004 | 22 | 520 | 640 | 90 | M64x4 | 42 | — | — | — | — | 315 | 14 | — | 40 | 665 | 170 | 130 | 445 | 600 | — | 1315 | 256 | 1489 |

| MTH | 612 | 1003, 1004 | 22 | 520 | 650 | 90 | M64x4 | 42 | — | — | — | — | 315 | 14 | — | 35 | 775 | 170 | 130 | 445 | 645 | — | 1170 | 256 | 1435 |

| MTH | 613 | 1003, 1004 | 22 | 520 | 650 | 90 | M64x4 | 42 | — | — | — | — | 315 | 14 | — | 35 | 775 | 170 | 130 | 540 | 735 | — | 1260 | 256 | 1530 |

| MTH | 711** | 1003, 1004 | 25 | 640 | 750 | 110 | M80x4 | 48 | — | — | — | — | 400 | 14 | — | 55 | 1025 | 210 | 165 | 440 | 590 | — | 1423 | 323 | 1645 |

* electric motors, size l31 of which is marked *, in versions 1001 and 1003 have a shaft on the fan side; the rest - from the side of the brush-contact mechanism ** electric motors of the ENERAL brand *** electric motors of the ENERAL brand of self-cooling design

Overall and connecting dimensions of crane electric motors

| Type | d30 | l33 | h31 | b1 | b10 | b12 | d1 | d5 | d10 | l1 | l3 | l10 | l31 | h | h1 | h8 | b11 | l11 | h10 | Weight, kg | volume, m3 |

| 4MT 200LA6, 4MTM 200LA6 | 422 | 1053 | 500 | 16 | 318 | 80 | 65 | M42x3 | 19 | 140 | 105 | 335 | 133 | 200 | 10 | 33,9 | 400 | 350 | 24 | 270 | 0,22 |

| 4MT 200LB6, 4MTM 200LB6 | 422 | 1053 | 500 | 16 | 318 | 80 | 65 | M42x3 | 19 | 140 | 105 | 335 | 133 | 200 | 10 | 33,9 | 400 | 350 | 24 | 300 | 0,22 |

| 4MT 200LA8, 4MTM 200LA8 | 422 | 1053 | 500 | 16 | 318 | 80 | 65 | M42x3 | 19 | 140 | 105 | 335 | 133 | 200 | 10 | 33,9 | 400 | 350 | 24 | 275 | 0,22 |

| 4MT 200LB8, 4MTM 200LB8 | 422 | 1053 | 500 | 16 | 318 | 80 | 65 | M42x3 | 19 | 140 | 105 | 335 | 133 | 200 | 10 | 33,9 | 400 | 350 | 24 | 305 | 0,22 |

| MTF 411-6, MTH 411-6, 5MTF 411-6, 5MTH 411-6 | 422 | 1053 | 525 | 16 | 330 | 65 | M42x3 | 28 | 140 | 105 | 335 | 175 | 225 | 10 | 33,9 | 440 | 435 | 25 | 290 | 0,23 | |

| MTF 411-8, MTH 411-8, 5MTF 411-8, 5MTH 411-8 | 422 | 1053 | 525 | 16 | 330 | 65 | M42x3 | 28 | 140 | 105 | 335 | 175 | 225 | 10 | 33,9 | 440 | 435 | 25 | 296 | 0,23 | |

| MTF 412-6, MTH 412-6, 5MTF 412-6, 5MTH 412-6 | 422 | 1053 | 525 | 16 | 330 | 65 | M42x3 | 28 | 140 | 105 | 420 | 165 | 225 | 10 | 33,9 | 440 | 510 | 25 | 322 | 0,23 | |

| MTF 412-8, MTH 412-8, 5MTF 412-8, 5MTH 412-8 | 422 | 1053 | 525 | 16 | 330 | 65 | M42x3 | 28 | 140 | 105 | 420 | 165 | 225 | 10 | 33,9 | 440 | 510 | 25 | 328 | 0,23 | |

| 4MTM 225L6 | 465 | 1220 | 545 | 18 | 356 | 95 | 70 | M48x3 | 19 | 140 | 105 | 356 | 149 | 225 | 11 | 36,4 | 435 | 410 | 24 | 490 | 0,31 |

| 4MTM 225M6 | 465 | 1110 | 545 | 18 | 356 | 95 | 70 | M48x3 | 19 | 140 | 105 | 311 | 149 | 225 | 11 | 36,4 | 435 | 370 | 24 | 390 | 0,28 |

| 4MTM 225L8 | 465 | 1220 | 545 | 18 | 356 | 95 | 70 | M48x3 | 19 | 140 | 105 | 356 | 149 | 225 | 11 | 36,4 | 435 | 410 | 24 | 470 | 0,31 |

| 4MTM 225M8 | 465 | 1110 | 545 | 18 | 356 | 95 | 70 | M48x3 | 19 | 140 | 105 | 311 | 149 | 225 | 11 | 36,4 | 435 | 370 | 24 | 390 | 0,28 |

| MTH 511-6 | 465 | 1110 | 570 | 18 | 380 | 70 | M48x3 | 35 | 140 | 105 | 310 | 251 | 250 | 11 | 36,4 | 500 | 480 | 25 | 415 | 0,29 | |

| MTH 511-8 | 465 | 1110 | 570 | 18 | 380 | 70 | M48x3 | 35 | 140 | 105 | 310 | 251 | 250 | 11 | 36,4 | 500 | 480 | 25 | 415 | 0,29 | |

| MTH 512-6 | 465 | 1220 | 570 | 18 | 380 | 70 | M48x3 | 35 | 140 | 105 | 390 | 271 | 250 | 11 | 36,4 | 500 | 600 | 25 | 520 | 0,32 | |

| MTH 512-8 | 465 | 1220 | 570 | 18 | 380 | 70 | M48x3 | 35 | 140 | 105 | 390 | 271 | 250 | 11 | 36,4 | 500 | 600 | 25 | 500 | 0,32 | |

| 4MTH 280S6, 4MTM 280S6 | 605 | 1265 | 740 | 22 | 457 | 125 | 90 | M64x4 | 24 | 170 | 130 | 368 | 190 | 280 | 14 | 46,8 | 540 | 430 | 40 | 740 | 0,57 |

| 4MTH 280L6, 4MTM 280L6 | 605 | 1439 | 740 | 22 | 457 | 125 | 90 | M64x4 | 24 | 170 | 130 | 457 | 190 | 280 | 14 | 46,8 | 540 | 520 | 40 | 970 | 0,64 |

| 4MTH 280S8, 4MTM 280S8 | 605 | 1265 | 740 | 22 | 457 | 125 | 90 | M64x4 | 24 | 170 | 130 | 368 | 190 | 280 | 14 | 46,8 | 540 | 430 | 40 | 740 | 0,57 |

| 4MTH 280M8, 4MTM 280M8 | 605 | 1345 | 740 | 22 | 457 | 125 | 90 | M64x4 | 24 | 170 | 130 | 419 | 190 | 280 | 14 | 46,8 | 540 | 480 | 40 | 820 | 0,6 |

| 4MTH 280S10, 4MTM 280S10, 5MTH 280S10 | 605 | 1265 | 740 | 22 | 457 | 125 | 90 | M64x4 | 24 | 170 | 130 | 368 | 190 | 280 | 14 | 46,8 | 540 | 430 | 40 | 715 | 0,57 |

| 4MTH 280M10, 4MTM 280M10, 5MTH 280M10 | 605 | 1345 | 740 | 22 | 457 | 125 | 90 | M64x4 | 24 | 170 | 130 | 419 | 190 | 280 | 14 | 46,8 | 540 | 480 | 40 | 825 | 0,6 |

| 4MTH 280L10, 4MTM 280L10, 5MTH 280L10 | 605 | 1439 | 740 | 22 | 457 | 125 | 90 | M64x4 | 24 | 170 | 130 | 457 | 190 | 280 | 14 | 46,8 | 540 | 520 | 40 | 975 | 0,64 |

| MTH 611-6 | 605 | 1335 | 775 | 22 | 520 | 90 | M64x4 | 42 | 170 | 130 | 345 | 256 | 315 | 14 | 46,8 | 650 | 575 | 35 | 805 | 0,63 | |

| MTH 611-10 | 605 | 1335 | 775 | 22 | 520 | 90 | M64x4 | 42 | 170 | 130 | 345 | 256 | 315 | 14 | 46,8 | 650 | 575 | 35 | 780 | 0,63 | |

| MTH 612-10 | 605 | 1435 | 775 | 22 | 520 | 90 | M64x4 | 42 | 170 | 130 | 445 | 256 | 315 | 14 | 46,8 | 650 | 645 | 35 | 890 | 0,67 | |

| MTH 613-6 | 605 | 1530 | 775 | 22 | 520 | 90 | M64x4 | 42 | 170 | 130 | 540 | 256 | 315 | 14 | 46,8 | 650 | 735 | 35 | 1045 | 0,72 | |

| MTH 613-10 | 605 | 1530 | 775 | 22 | 520 | 90 | M64x4 | 42 | 170 | 130 | 540 | 256 | 315 | 14 | 46,8 | 650 | 735 | 35 | 1050 | 0,72 | |

| MTH 711-10 | 790 | 1710 | 862 | 640 | 110 | 210 | 440 | 323 | 400 | 790 | 650 | ||||||||||

| MTH 712-10 | 790 | 1710 | 862 | 640 | 110 | 210 | 510 | 323 | 400 | 790 | 650 | ||||||||||

| MTH 713-10 | 790 | 1710 | 862 | 640 | 110 | 210 | 590 | 323 | 400 | 790 | 650 | ||||||||||

| 4MTH 400S8, 4MTNF 400S8 | 790 | 1735 | 880 | 25 | 686 | 110 | 35 | 210 | 165 | 560 | 280 | 400 | 790 | 710 | 1255 | 1,21 | |||||

| 4MTH 400M8, 4MTNF 400M8 | 790 | 1815 | 880 | 25 | 686 | 110 | 35 | 210 | 165 | 630 | 280 | 400 | 790 | 790 | 1405 | 1,26 | |||||

| 4MTH 400L8, 4MTNF 400L8 | 790 | 1885 | 880 | 25 | 686 | 110 | 35 | 210 | 165 | 710 | 280 | 400 | 790 | 860 | 1545 | 1,31 | |||||

| 4MTH 400S10, 4MTNF 400S10, 5MTH 400S10 | 790 | 1665 | 880 | 25 | 686 | 110 | 35 | 210 | 165 | 560 | 280 | 400 | 790 | 670 | 1280 | 1,16 | |||||

| 4MTH 400M10, 4MTNF 400M10, 5MTH 400M10 | 790 | 1736 | 880 | 25 | 686 | 110 | 35 | 210 | 165 | 560 | 280 | 400 | 790 | 710 | 1445 | 1,21 | |||||

| 4MTH 400L10, 4MTNF 400L10, 5MTH400L10 | 790 | 1816 | 880 | 25 | 686 | 110 | 35 | 210 | 165 | 630 | 280 | 400 | 790 | 790 | 1445 | 1,26 |

Crane electric motors - electrical parameters

Weight, kgR, kW Nominal rotation speed, rpm Efficiency, %In stator, AMoment of inertia, kg*m2Mmax/MnMTN011-61.4890658.80.0212.660MTN012-62.28957011.00.0262.768MTN111-63.59157518.2 /10.50.062.3105MTN112-65.09157723.4/13.50.082.3125MTN211-67.59407932/18.50.152.5160MTNZ11-6119458444.6/25.80.392.8200MTN312-6159 628458.5/33.80.392.8230MTN311-87 ,56907435/20.30.392.5230MTN312-8117008146.7/270.392.5230MTN411-6229608687/50.40.392.8320MTN412-63096088107.2/620.392.8398MTN411 -8157158361/350,392,8320MTN412-8227158681/46,90,392,8390MTKN011-61,492070 ,54.50.0162.846MTKN012-62.291573.56.50.0212.850MTKN111-63.592079.09.00.0562.580MTKN112-65.092079.012.80.0782.8100MTKN211-67.588 078.518 ,10.07633120MTKH311-6119408124.50.2752.8185MTKN312-6159408332.50.3082.8190MTKH311-87.57008121.00,2302.8160MTKN312-8117008126.00 ,3522.8205MTKN411-6229358448.00.5602.8262MTKN412-6309358561.00 ,7503.0322MTKN411-8157008240.00.5602.8262MTKN412-8227008354.00.7502.8322X

Design IM2001, 2002, 2003, 2004

Crane electric motors MTH, MTKH, 4МТН, 4МТКН with adapter plates

MTH111

| Type | d24 | L30 | L33 | h31 | b1 | b10 | d1 | d10 | d20 | d22 | d25 | L1 | L10 | L20 | L21 | L28 | L39 | L31 | h | h1 | h5 | L11 | h10 | b11 |

| MTN011 | 280 | 584 | 646 | 275 | 8 | 180 | 28 | 12 | 255 | 14 | 215 | 60 | 150 | 4 | 12 | 146 | 0 | 231 | 112 | 7 | 31 | 230 | 14 | 230 |

| MTN012 | 280 | 584 | 646 | 275 | 8 | 180 | 28 | 12 | 255 | 14 | 215 | 60 | 190 | 4 | 12 | 141 | 0 | 192 | 112 | 7 | 31 | 230 | 14 | 230 |

| 330 | 645 | 728 | 318 | 10 | 220 | 35 | 15 | 300 | 18 | 250 | 80 | 190 | 5 | 14 | 154 | 0 | 224 | 132 | 8 | 38 | 280 | 16 | 290 | |

| MTH112 | 330 | 645 | 728 | 318 | 10 | 220 | 35 | 15 | 300 | 18 | 250 | 80 | 235 | 5 | 14 | 149 | 0 | 184 | 132 | 8 | 38 | 280 | 16 | 290 |

| 4МТН132 LA(B) | 350 | 715 | 829 | 318 | 12 | 216 | 42 | 12 | 300 | 19 | 250 | 110 | 203 | 5 | 14 | 89 | 0 | 318 | 132 | 8 | 45 | 250 | 16 | 270 |

| MTH211 A(B) | 330 | 730 | 843 | 346 | 12 | 245 | 40 | 12 | 300 | 18 | 250 | 110 | 243 | 5 | 14 | 150 | 0 | 230 | 160 | 8 | 43 | 355 | 28 | 320 |

| MTH311 | 350 | 795 | 906 | 480 | 14 | 280 | 50 | 24 | 300 | 18 | 250 | 110 | 260 | 5 | 18 | 270 | 0 | 155 | 180 | 9 | 53,5 | 320 | 21,5 | 350 |

| MTN312 | 350 | 860 | 971 | 480 | 14 | 280 | 50 | 24 | 300 | 18 | 250 | 110 | 320 | 5 | 18 | 260 | 0 | 170 | 180 | 9 | 53,5 | 380 | 21,5 | 350 |

| MTKN011 | 280 | 430 | 492 | 275 | 8 | 180 | 28 | 12 | 255 | 14 | 215 | 60 | 150 | 4 | 12 | 89 | 13 | 132 | 112 | 8 | 31 | 230 | 14 | 230 |

| MTKN012 | 280 | 430 | 492 | 275 | 8 | 180 | 28 | 12 | 255 | 14 | 215 | 60 | 190 | 4 | 12 | 54 | 13 | 127 | 112 | 8 | 31 | 230 | 14 | 230 |

| MTKN111 | 330 | 508 | 590 | 318 | 10 | 220 | 35 | 15 | 300 | 18 | 250 | 80 | 190 | 5 | 14 | 98,5 | 14 | 140 | 132 | 8 | 38 | 280 | 16 | 290 |

| MTKN112 | 330 | 508 | 590 | 318 | 10 | 220 | 35 | 15 | 300 | 18 | 250 | 80 | 235 | 5 | 14 | 58,5 | 14 | 135 | 132 | 8 | 38 | 280 | 16 | 290 |

| 4MTKN132 LA(B) | 350 | 578 | 692 | 318 | 12 | 216 | 42 | 12 | 300 | 19 | 250 | 110 | 203 | 5 | 14 | 89 | 0 | 181 | 132 | 8 | 45 | 250 | 16 | 270 |

| MTKN211 A(B) | 330 | 583 | 695 | 346 | 12 | 245 | 40 | 12 | 300 | 18 | 250 | 110 | 243 | 5 | 14 | 153 | 11 | 80 | 160 | 8 | 43 | 355 | 28 | 320 |

| MTKN311 | 350 | 650 | 762 | 480 | 14 | 280 | 50 | 24 | 300 | 18 | 250 | 110 | 260 | 5 | 18 | 132 | 5 | 155 | 180 | 9 | 53,5 | 320 | 21,5 | 350 |

| MTKN312 | 350 | 715 | 827 | 480 | 14 | 280 | 50 | 24 | 300 | 18 | 250 | 110 | 320 | 5 | 18 | 122 | 5 | 170 | 180 | 9 | 53,5 | 380 | 21,5 | 350 |

| Type | d24 | L30 | L33 | h31 | b1 | b10 | d1 | d10 | d20 | d22 | d25 | L1 | L10 | L20 | L21 | L28 | L39 | L31 | h | h1 | h5 | L11 | h10 | b11 |

Note:

- The dimensional drawing does not reflect the design features of crane electric motors.

- Crane electric motors MTN (MTKN) 411, 412, 511, 512 have 8 d22 holes, MTN211, MTKN211 - 4 d22 holes.

- Crane electric motors MT(K)N 411, 412 have foot heights h10=25mm on the terminal box side and h10=49mm on the fan side.

Design:

- IM2001 is a flanged crane motor with one cylindrical shaft end.

- IM2002 is a flanged crane motor with two cylindrical shaft ends.

- IM2003 is a crane motor with a flange and one tapered shaft end.

- IM2004 is a flanged crane motor with two tapered shaft ends.

↑ to top of page

Crane electric motors of the MTN MTKN 4MT 4MTM 4MTKM 4MTKN 4MTM series for operation from an industrial network

The motors are manufactured with phase-wound and squirrel-cage rotors in single-speed and two-speed versions in accordance with technical specifications TU16-2013.

Single-speed and two-speed motors are manufactured for a voltage of 380V and a frequency of 50 and 60Hz when the winding is connected in a star with three output ends, and for a voltage of 200/380V when the stator windings are connected in a triangle-star (Δ/Y) with six output ends. Motors can be manufactured for other standard voltages from 220 to 660V.

The degree of protection of the motors is IP54, the insulated brush assembly of the motors 4MTN225,280 is IP23; fan casing - IP20 according to GOST IEC60034-5. Engine cooling method - self-ventilation - IC411 according to GOST RMEC60034-6. Insulation class - N according to GOST 8865.

Depending on the installation method, motors can be manufactured in design versions: on feet, combined - flange and feet, with one or two output working ends of the shaft. The main nominal operating mode of single-speed motors is intermittent S3-PV40% according to GOST P52776.

Crane electric motors – asynchronous three-phase

Crane electric motors of the MT, 4MT, AMT and DMT series are designed to operate in electric drives of metallurgical units and hoisting and transport mechanisms of all types and are supplied to complete tower, gantry, portal, bridge and other cranes.

The basic version is an asynchronous three-phase crane electric motor, designed for operating mode S3, powered by a 50 Hz AC mains voltage of 380V (220V, 660V). Climatic modification and placement category - U1, degree of protection - IP54.

Crane electric motors have insulation heat resistance class “F” (temperature index 155°C) or “H” (temperature index 180°C), according to GOST 8865-93.

Nominal operating mode of crane electric motors:

- intermittent short-term S3 - PV40% according to GOST 183-74 (IEC 60034-1);

- other modes: S3 - PV15, 25, 60, 100%;

- short-term S2 - 30 and 60 minutes.

Symbol for crane electric motors - type 1: MT... [1] [2] [3] [4] [5] [6] [7] [8], where MT - Series of electric motors ( AMT, DMT) [1] - Type rotor: K – squirrel-cage rotor; absence of letter - phase rotor [2] - Insulation heat resistance class: H or F [3] - Dimensions of the outer diameter of the stator sheets: 0...7 [4] - Motor modernization: 0...1 [5] - Motor stator core length size: 1 …3 [6] — Number of poles: 6, 8, 10 [7] — Climatic version: U, T, UHL [8] — Placement category: 1, 2

Symbol for crane electric motors type 2: 4MT... [1] [2] [3] [4] [5] [6] [7] [8], where 4MT - Series name ( AMT, DMT) [1] - Rotor type : K – squirrel-cage rotor; absence of letter – wound rotor [2] — Insulation heat resistance class: H or F [3] — Rotation axis height: 112…400 [4] — Installation dimension along the length of the frame: S, M, L [5] — Core length designation: A, B, or absence of letter [6] — Number of poles: 6, 8, 10 [7] — Climatic version: U, T, UHL [8] — Placement category: 1, 2

additional characteristics

- Installation design. Crane electric motors up to size 3 inclusive and with a rotation axis height up to 180 inclusive, as a rule, are manufactured with cylindrical shaft ends. Crane electric motors of size 4 and above, as well as with a rotation axis height of 200 and above, are usually manufactured with conical shaft ends.

- Degree of protection (GOST 17494-87) . Wound electric motors are manufactured with a degree of protection IP54 and IP44 according to GOST 17494 (IEC 60034-5). At the request of consumers, electric motors can be manufactured with a degree of protection IP55.

Storage and transportation of crane engines

Crane motors MTF, MTH, MTKF, MTKH should be stored in closed rooms with natural ventilation, where there is no dust and harmful gases. Air temperature is allowed from +40°C to -50°C and humidity not exceeding 98% at a temperature of 25°C or at a lower temperature without moisture condensation. During storage, engines must be protected from moisture; close the terminal box cover; Coat the ends of the shafts with anti-corrosion lubricant and wrap them in paper. During storage, crane electric motors must be inspected at least once a year and, if necessary, re-preserved. All unpainted engine parts (shaft ends, machined paw surfaces, shield and frame locks) and spare parts are subject to conservation. For preservation, use AMS-3 lubricant. When transporting over short distances, take measures to prevent moisture from getting inside and damaging the shaft ends and other parts of the engine. For long distances el. crane motors must be transported in packaging and secured against movement. Secure the rope or cable only to the eye bolt.

crane electric motors in stock in a warehouse in St. Petersburg, however, it is better to check the availability of these products with the company’s managers. In order to find out prices and buy a motor for a crane, you can call: (812) 449-85-50 .

TECHNICAL DATA motor type power, kW rotation speed, rpm stator voltage, V rotor voltage, V stator current, A rotor current, A cos ϕ Efficiency % protection class, IP operating mode, S3 % version weight, kg with wound rotor 5MTN-111-6 3.5 912 220/380 177 16.6/9.6 14.7 0.73 75 54 40 U1 108 5MTN- 112-6 5 924 220/380 205 22.3/12.9 17.5 0.75 77.9 54 40 U1 117 5MTN-211-6 7.5 937 220/380 235 30.6/17.7 22 ,4 0.79 80 54 40 U1 160 5MTN-311-6 11 950 220/380 168 44.5/25.7 44.8 0.78 82 54 40 U1 215 5MTN-311-8 7.5 701 220/ 380 250 32.5/18.8 21.3 0.76 78 54 40 U1 215 5MTN-312-6 15 957 220/380 216 57.6/33.3 46.5 0.81 84 54 40 U1 230 5MTN -312-8 11 707 220/380 173 45.7/26.4 43.9 0.77 81 54 40 U1 230 5MTN-411-6 22 966 220/380 232 79.6/46 61.1 0.82 87 54 40 U1 347 5MTN-411-8 15 712 220/380 208 61.8/35.7 48 0.75 84 54 40 U1 345 5MTN-412-6 30 970 220/380 252 107/61.8 76, 3 0.82 88 54 40 U1 380 5MTN-412-8 22 718 220/380 233 84.3/48.7 61.4 0.79 86 54 40 U1 380 with squirrel cage rotor 5MTKN-311-6 11 942 220/ 380 42/24.3 0.84 81 54 40 U1 187 5MTKN-311-8 7.5 695 220/380 32/18.6 0.78 77 54 40 U1 187 5MTKN-312-6 15 940 220/380 55 /32.2 0.85 82 54 40 U1 206 5MTKN-312-8 11 691 220/380 45.7/26.4 0.79 79 54 40 U1 206

Design of crane electric motors with phase and squirrel-cage rotor

The crane motor is usually supplied with:

- crane brushes (spare set) – 6 pcs. (for electric motors with wound rotor MTF, MTH);

- passport - 1 pc.;

- instruction manual and technical description - 1 pc. (upon client's request).

Crane electric motors are produced with squirrel cage and wound rotor: MTF, MTH, MTKF, MTKH. According to the method of cooling and protection from external influences. engines are manufactured in a closed, i.e. blown design.

In a wound rotor motor, the main wear materials are electric brushes and brush holders for crane electric motors.

The crane motor with wound rotor (MTF, MTH) consists of:

- hatch cover for removing dust from the brush unit,

- bearing cap,

- bearing shield,

- inner bearing cover,

- slip ring,

- brush holder rod,

- brush holder,

- collector panel,

- manifold hatch cover,

- terminal box housing,

- terminal box cover,

- stator,

- rotor,

- eye bolt,

- frame,

- inner bearing cover,

- bearing shield,

- fan casing,

- fan,

- bearing,

- bearing cap,

- key,

- crane motor shaft.

The motor for cranes with squirrel-cage rotor (MTKF, MTKH) does not have the following positions: 1, 5, 6, 7, 8, 9. To protect crane motors from corrosion, special paint and varnish and galvanic coatings are used. In terms of heat resistance, the insulating materials of the stator and rotor windings correspond to class H.

Safety measures, installation and preparation for operation of crane engines

When operating crane electric motors MTF, MTH, MTKF, MTKH, access to its rotating and live parts must be prevented. Do not turn on the engine if the commutator and fan casing is removed, with the terminal box open. An electric motor mounted for operation must be grounded. In case of carrying out preventive and routine maintenance, the crane electric motor must be disconnected from the power supply.

Before installing it, you need to clean all unpainted metal parts from anti-corrosion lubricant with a cloth soaked in kerosene or gasoline. Corrosion (if it appears) must be removed with sandpaper with a grain size of 50-N. After completely cleaning the corrosion areas, remove any remaining metal and emery dust. Before installing the crane motor, you need to measure the insulation resistance of the stator and rotor windings, which should not be less than 0.5 MOhm. Electric motors with lower insulation resistance must be dried. Drying can be carried out using short circuit current from low voltage or external heating. During drying, the permissible highest temperature of the winding should not exceed 145°C, subject to insulation class H. During drying, rapid heating of the electrical circuit must not be allowed. crane motor, since in this case intense steam may occur, which in turn has a harmful effect on the insulation. Drying can be considered complete if the insulation resistance (measured with a megohmmeter) is not less than 0.5 MOhm when hot. The electric motor can only be installed on a horizontal plane with its feet down, aligning the axis of the electric motor with the axis of the mechanism. The power cable must be supplied through rubber seals, if necessary, in a metal pipe, in a flexible metal hose or through a metal pipe.