Home » Articles » Batteries

80077 5 Published April 26, 2017

Rechargeable batteries (AB), depending on their purpose, are assembled from a certain number of energy-storing elements. Connection diagram

batteries depends on what purpose is being pursued. This could be an increase in battery capacity, an increase in voltage, or a combination of both of these parametric characteristics of the device.

Basically, batteries are assembled in series-parallel, and the assemblies themselves are used for intermediate or backup storage of electricity

There are 3 known and widely used options for connecting individual batteries into a battery: serial, parallel and mixed or combined.

Increasing battery operating voltage

Electric energy batteries have different operating voltages. It can vary in a very wide range: from 0.5 to 48 Volts. At the same time, to ensure autonomous power supply of devices, starting internal combustion engines, and powering electric drive equipment, a different voltage range is required. You can increase the operating voltage of an autonomous current source by connecting several batteries in series into a battery.

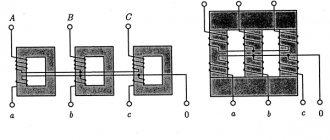

Schemes and formulas for series connection of batteries

In a series connection, the opposite polarity terminals of the battery are switched. The positive terminal of the previous device is connected to the negative terminal of the next one. The total operating voltage of the battery with this method will be equal to the sum of the operating voltages of the switched current sources. This means that to obtain a battery with an operating voltage of 12 V, it is necessary to connect 4 three-volt sources or 10 batteries with an operating voltage of 1.2 V in series. The capacity of the series-connected sources does not change and remains equal to the capacity of each battery included in the circuit.

An obvious and clear example of this method of assembling a battery is car batteries. In them, individual sources, called banks, are combined in a common housing and connected in series with lead busbars. The choice of lead as a material for the connecting bars is explained simply: battery electrodes are also made of lead. The buses, integrated into the communication circuit, are connected to the electrodes at the molecular level rather than mechanically. This will avoid the occurrence of electrochemical corrosion processes.

Increasing power supply capacity

There are often technical conditions when increased capacity is required from the power source while maintaining the operating voltage. In such cases, a parallel connection of batteries is used to complete the battery. This method of switching allows you to increase the total capacity of the power supply device several times, and in especially critical cases, tens of times.

Parallel connection of batteries with formulas

Parallel connection is carried out by switching single-pole terminals of current sources: the positive and negative terminals of the previous battery are connected to the same terminals of the next one. The total electrical capacitance of a battery switched in this way will be equal to the sum of the electrical capacitances of the individual sources included in the circuit. This means that when three batteries with a nominal capacity of 60 A*h are connected, the result is a device with an electrical capacity of 180 A*h.

As an example of connecting batteries using parallel switching, we can cite sources of uninterruptible or emergency power supply for devices and equipment. The batteries of heavy-duty vehicles and heavy special equipment with a large engine capacity are connected in parallel. Parallel switching has become widespread in the navy: here parallel-connected power devices are used to start auxiliary diesel engines, operate lighting, communication systems and life support in emergency situations.

Increasing voltage while simultaneously increasing battery capacity

A striking example of a mixed or combined connection of batteries in a complex with the necessary indicators of operating voltage and electrical capacity are power supplies for electrically driven machines.

IMPORTANT! As the battery capacity increases, the currents also increase. Select the correct wire cross-sections! Use non-flammable or self-extinguishing wires.

Traction batteries to ensure the operation of drive and control motors of electric drive machines and mechanisms are equipped exactly according to this scheme. The methods of connecting the battery are described in sufficient detail in this video:

A combined connection implies the use of both serial and parallel connection methods in the switching circuit. There are two options:

1. First, batteries with the required operating voltage are prepared using the method of series connection of sources. At the second stage, the required number of prepared assemblies are switched in parallel to provide the required electrical capacity.

2. In the second option, batteries with the required capacity are pre-charged by parallel switching. After this, the devices are connected in series until the required operating voltage is achieved.

The series-parallel connection circuit for batteries is the most commonly used, since modern batteries for autonomous power supply to homes have a nominal voltage of 3.4 V

Equipping batteries using a combined method allows you to create power sources, the voltage and electrical capacity of which are limited only by the workspace they occupy.

Series and parallel connection of batteries

Home > Theory > Series and parallel connection of batteries

Each battery cell has a certain structure, which affects its voltage and capacity, which are constant. In order to change the battery parameters, series and parallel battery connection schemes are used. Most chemical power supplies lend themselves to these types of connections.

Serial connection

If you need to increase the battery voltage, you need to connect the batteries in series, that is, combine the “plus” of each element with the “minus” of the other. With a series connection, there is no effect on the capacitance, but only on the voltage of the connected battery. For example, two 6V batteries with a capacity of 7.2Ah will create one 12V battery with the same capacity.

Important! Connecting batteries in series allows higher overall voltages to be generated. The disadvantage of this design is that the weakest element of the battery affects the performance of the series. A faulty battery will cause the entire line to fail.

The probability of failure increases with the number of connected elements. If one of the cells fails, it results in low voltage.

Batteries with identical capacity can be combined into a series circuit, since they must be discharged synchronously to avoid deep discharge of weaker elements.

Batteries connected in series

Certain conditions must be observed when charging series-connected batteries:

- identical capacity;

- one discharge level;

- general design.

If the batteries differ greatly in the named parameters, this can lead to exceeding the maximum current and charge voltage on individual elements, which will cause their damage.

Parallel connection

Series connection of capacitors

If the car requires more starting power than the battery can provide, several batteries are connected in parallel.

Battery parallel connection diagram

For practical reasons (mainly weight and case size), batteries have a limited capacity. 12-volt batteries are produced with capacities up to several hundred Ah. A good 200 Ah battery weighs 60-70 kg. Because of this, batteries up to 250 Ah are mainly used. However, very often the demand exceeds this capacity. In such cases, you can use a parallel connection of batteries. Thanks to this solution, battery packs have no capacity limitations, and at the same time, their assembly, disassembly, and movement are possible without lifting equipment.

For example, to get a capacity of 400 Ah and 12 V, you need to connect the following batteries:

- two 200 Ah batteries (2 x 200 Ah = 400 Ah);

- five 80 Ah batteries (5 x 80 Ah = 400 Ah);

- two 100 Ah batteries and one 200 Ah battery (2 x 100 Ah + 200 Ah = 400 Ah).

Likewise any other combinations.

The capacity of the set created in this way is equal to the sum of the capacities of the individual batteries. In this case, it is necessary to connect the same poles of the batteries.

Battery connection

How to connect the battery to the load depends on the number of cells and load current:

- With a small number of batteries and low-current loads or charging, differences in the energy output of individual cells will be insignificant. You can connect the load and charging to the first battery;

- The connection method, when the “minus” to the load and charging is connected from the first battery, and the “plus” from the last, is recommended for balancing batteries under load during charging with a high current or when many elements are connected in parallel. This allows the voltage distribution to be optimized.

Preferred connection of parallel-connected elements

Important! The second method of connecting the battery is suitable for all cases.

Principles of parallel connection

The best results can be obtained by combining batteries with the same parameters:

- capacity;

- degree of wear;

- internal resistance.

Although the requirements for the similarity of parameters in this case are much lower than when a series connection of batteries is used. The main condition is an identical nominal voltage. But you can combine:

- batteries of various capacities;

- batteries from different manufacturers;

- even significantly different in degree of wear.

Important! In case of parallel connection, damaged batteries with low internal resistance should not be used. The use of damaged or heavily worn batteries is economically unjustified - they consume the energy of the remaining cells, which reduces the available power of the entire set.

Checking the connection

Before assembling multiple batteries, you should test each battery individually. This will avoid losses and even failure of elements.

- Using a battery with a very low capacity is not dangerous, but it does not make sense since it will not increase power, but the risk of future problems will increase;

- If a combination of parallel batteries is left connected, with one of them at low short circuit current and consuming a lot of power, maintaining this condition for a long time will cause the other batteries to discharge and limit efficiency;

- A battery with a low short circuit current but a significant capacity can only be useful if the energy is consumed within a short time after charging has finished. Such a set requires constant monitoring, since the load resistance can drop to dangerous levels;

- Tested batteries should be charged so that their voltage is the same. Connecting charged and discharged batteries in parallel results in sudden high current flow. A charged element will discharge quickly, and a discharged element will discharge even faster. The scale of this phenomenon depends on the difference in voltage and power.

For example, for a 200 Ah battery it will not be dangerous to connect a second 7 Ah battery, regardless of the discharge level. At the same time, with the difference in voltage during connection, a small battery will experience a significant loss of power, which can even lead to damage to its case.

Connection Tips

When using different connection schemes, you must connect the battery to the car in compliance with the following rules:

- Use batteries of the same manufacturer, type, service life;

- Since a parallel connection can increase the current consumption, you must ensure that the cross-section of the cables is sufficient to withstand it;

- Before installation, you must clean all contacts and use only reliable clamps;

- Check connections regularly.

Battery Installation Tips

- Check that the battery is properly secured in the car to prevent it from being dislodged or knocked;

- Accessories with high power consumption should only be connected to the top terminals, without using the side terminals;

- Replace cables and connections that have become corroded or mechanically damaged;

- Do not lift or move batteries using their output terminals.

Parallel connection of resistors

Combination of series and parallel connection

The combination of series and parallel battery connections provides greater flexibility in battery form. The required voltage and power are made possible using standard cells. High-voltage batteries require careful mating, especially under heavy loads or when operating in cold temperatures.

Video

Parallel connection of resistors

Features of battery packing

All three methods of connecting individual power sources into a complex are subject to simple, but important rules for effective and long-term operation.

Series-parallel connection diagram using the example of lithium-ion batteries

Prolonged battery operation and its economic feasibility can be ensured by observing the following rules:

- the electrical capacity of the sources included in the complex should not differ by an amount exceeding 5% of the nominal;

- the operating voltages of individual battery cells must be in a reasonable ratio;

- the operational technical condition of the elements included in the autonomous power supply complex must be as balanced as possible;

- the cross-section of switching lines and buses must be calculated taking into account current loads both inside the battery and in external electrical circuits.

The range of power sources offered by the market, with a competent approach, allows you to create batteries with all the characteristics necessary for reliable use.

Why combine batteries into one unit?

During operation of the systems, ohmic voltage losses are observed. This is the part of the expended energy that is converted into heat without producing useful work. By combining batteries in a certain way, you can reduce losses, increasing efficiency. There are cases when the capacity of one galvanic cell is not enough to operate the equipment. Buying a larger capacity battery is expensive and not always convenient (for example, placement problems). It is more practical to combine two similar chemical energy sources.

Requests for power specifications vary from area to area.