Electricity is supplied to consumers over considerable distances. In this case, a certain voltage level is used, the value of which is brought to normal due to the operation of a TMG type power transformer. The technical decoding of the device indicates the type of device: T - three phases, M - oil and air cooling, G - tightness. In other words, TMG is a power three-phase oil sealed transformer for equalizing voltage in alternating current networks.

Transformer TMG

Principle of operation

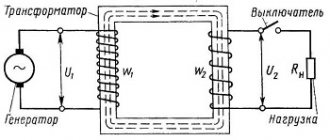

TMG power plants are irreplaceable and reliable devices. The principle of operation of the units is to bring the voltage value to an acceptable value in the process of induction of an alternating current electromagnetic field (leveling), avoiding surges and instability. This is achieved thanks to its design and technical characteristics.

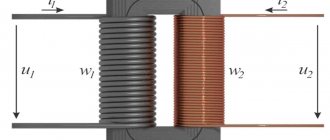

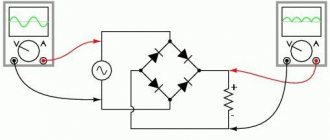

Transformer operating principle

A transformer is a static device that converts current and voltage through mutual induction. Layer windings of primary and secondary voltage are initially placed on a frame made of electrical steel. When the secondary winding opens, the primary winding receives voltage and creates a magnetic field with a flux that closes along the core. The magnetic flux meshes with the turns of the windings, due to which the electromotive force is brought back to normal, and the voltage in the network is 220 V.

In this case, the recommended winding connection is star. No-load losses are 15%, and the rated voltage reaches 0.4-0.35 kV. During operation, the unit is cooled by oil located in a sealed tank, the temperature of which is automatically regulated, preventing overheating.

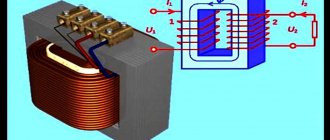

General structure and principle of operation

Each transformer is equipped with two or more windings inductively coupled to each other. They can be wire or tape, covered with an insulating layer. The windings are wound on a core, also known as a magnetic circuit, made of soft ferromagnetic materials. If there is one winding, such a device is called an autotransformer.

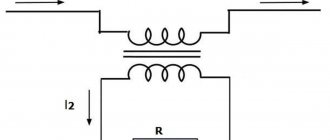

The operating principle of the transformer is quite simple and understandable. An alternating voltage is applied to the primary winding of the device, which leads to the flow of alternating current in it. This alternating current, in turn, causes the creation of an alternating magnetic flux in the magnetic circuit. Under its influence, an alternating electromotive force (EMF) is induced in the primary and secondary windings. When the secondary winding closes to the load, alternating current also begins to flow through it. This current in the secondary system differs in its own parameters. It has individual current and voltage indicators, number of phases, frequency and voltage waveform.

Energy systems that transmit and distribute electricity use power transformers. With the help of these devices, the values of alternating current and voltage are changed. However, the frequency, number of phases, current or voltage curve remain unchanged.

The design of the simplest power transformer includes a magnetic core made of ferromagnetic materials, mainly electrical steel sheets. The primary and secondary windings are located on the magnetic core rods. The primary winding is connected to the AC source, and the secondary winding is connected to the consumer.

In power transformers, when flowing through the turns of the winding, an alternating magnetic flux is also created, which arises in the magnetic core. Under its influence, an EMF is induced in both windings. The output voltage may be higher or lower than the original voltage, depending on whether a step-up or step-down transformer is used. The EMF value in each winding varies according to the number of turns. Thus, if you create a certain ratio of turns in the windings, you can create a transformer with the required ratio of input and output voltages.

Design

The TMG case is durable and sealed, withstanding long-distance transportation. The unit is small in size, has a reliable sealed housing to protect the magnetic circuit and a durable mechanism. The unit is capable of operating under temperature fluctuations from +40 to -60 degrees. In this case, a non-explosive environment and protection from dust must be ensured.

Also read: Single-phase cast current transformer - TSL

The design consists of the following components:

- Core made of special steel.

- Insulated metal winding, with high and low voltage inputs, magnetic circuit and high voltage switch.

- Coil with rated voltage.

- Corrugated sealed closed tank, with an oil filling level from 470 to 1570 ml and an oil level indicator.

- Thermometer for monitoring oil layer temperature.

- Safety valve and switch without excitation.

- Air dryer with expansion.

There is also a ground plate and drain plug at the bottom of the oil tank. The technical parameters of the TMG are indicated by the manufacturer on the outside of the unit in the form of a plate.

The net weight of the transformer is 280-920 kg, and with oil - 320-980 kg. The average dimensions of the unit are 1000x500mm.

Composition and design of the TMG-630 transformer.

The TMG-630 transformer consists of: a tank with radiators, a tank cover, and an active part.

The tank is equipped with a plug for taking an oil sample and a plate for grounding the transformer. The outer surface of the tank is painted with weather-resistant gray, light gray or dark gray paints (the color tone may vary). All transformer seals are made of oil-resistant rubber.

The transformer tank consists of:

- walls made of steel sheet with a thickness of 2.5 mm to 4 mm. (depending on the power of the transformer);

- top frame;

- radiators;

- loops for lifting the transformer

- bottom with support legs (channels).

The following are installed on the cover of transformers TM and TMG:

- HV and LV inputs

- switch drive;

- loops for lifting the transformer

- safety valve (on transformers type TMG and TMGF),

- membrane safety device

- pressure-vacuum gauge

Classification

TMG is divided into the following main types:

- Regarding appointments:

- intermediate

- measuring;

- protective;

- laboratory

- According to the installation method:

- external;

- internal;

- portable;

- stationary;

- tire;

- supporting

- By number of steps:

- single stage;

- cascading.

- By voltage rating:

- high voltage;

- low voltage.

- For winding insulation:

- dry;

- paper-oil;

- compound.

The power transformer is measured in kW units, and is used as a transformer substation kit.

Specifications

TMG power oil transformers are characterized by stable operation and high power. All this is achieved thanks to the technical indicators of the unit with GOST - 11677-85.

Technical characteristics of the TMG type transformer (to enlarge the table, click on it)

Table with characteristics for the TMG-1600 transformer

More detailed characteristics and dimensions can be found in the file: Open file

Transformers TMGF

TMGF transformers (flange) are a modification of TMG transformers for installation inside industrial premises.

The high and low voltage inputs on transformers of the TMGF series are shifted to the ends of the transformer housing and are equipped with boxes, which provides the possibility of flange coupling with the corresponding switchgears.

When installed indoors, the high and low voltage busbars must be located in such a way that they are not accessible to maintenance personnel. To do this, use metal boxes that protect the tires. The boxes on the transformer are attached to the flanges.

Installation of the TMGF transformer indoors

Device price

The cost of the unit depends on the type, area of its purpose and dimensions. Household transformers in the Russian Federation can be purchased from 14,000 to 21,000 rubles - the price depends on the region. For example, production amounts in 2021 in rubles:

- TMG-25 11 – 69 500;

- TMG-40 11 – 78 500;

- TMG-100 11 – 103 700;

- TMG-1000 11 – 413,500.

Also read: Peak transformer

It is best to purchase devices from domestic manufacturers. At the moment they are the best.

Marking

The alphanumeric designation of a transformer characterizes its quality characteristics, voltage class and power. There are different types of markings.

All TMG symbols are divided by 1/2/3/4.5, where:

- Amount of power.

- Nominal HV.

- Nominal NN.

- Climatic version, category according to GOST.

Decoding the TMG transformer markings

Main operational characteristics of TMG-630

The guaranteed service life of the TMG-630 transformer is 3 years from the date of commissioning of the transformer.

The established mean time between failures is at least 25,000 hours.

The full service life of TMG-630 is at least 30 years.

Mains frequency – 50Hz.

Voltage on the HV side – 6; 6.3; 10; 10.5; 27.5; 35 kV.

Voltage on the LV side – 0.4; 0.23 and 0.69 kV.

At your request, we can produce TMG-630 transformers on the HV and LV side with other voltage values, as well as non-standard transformers

Purpose and scope

TMGs are used in various conditions, but the purpose depends on the placement category, determined by the parameters: 2, 3, 4 and the installation altitude above sea level, which should not be higher than 1000 m.

Units with a power from 1000 to 2500 kVA, with pressure gauge signaling thermometers, are intended for use under a canopy and indoors at temperatures from -40 to +60 degrees.

The devices cannot be used in conditions of strong vibration, possible mechanical shock, chemically active or explosive environments. It is recommended to install dry transformers or devices with built-in protection relays near flammable objects, as well as in hot climates.

Experienced craftsmen for production needs advise using models like SESH, which equalize the voltage and at the same time save energy.

Features of operation

Installations of the presented category are operated strictly in accordance with generally recognized standards. Commissioning and monitoring of equipment condition is carried out by trained, experienced employees.

The presented equipment is installed in areas with moderate and cold climates. It is prohibited to store fire hazardous, explosive, chemical substances, gases, or liquids nearby.

The unit is installed at an altitude of no more than 1 km above sea level. The design is not designed to withstand vibration, mechanical shock or shaking. The work cycle is quite long. The equipment is turned off for scheduled repairs and maintenance. If signs of malfunction appear, in an emergency situation, the power is immediately turned off.

The ambient temperature can reach from +40 to -45ºС for category U1. Climatic modification HL1 allows operation in the range from +40 to -60ºС. Relative humidity is 80%. The above conditions contribute to long-term, efficient operation of the equipment.

Having considered the features, operating principles and designations of STMI transformers, you can choose the right device that meets the needs of consumers.

Requirements for operation

To use and inspect the unit for the purpose of maintenance, it is necessary to strictly observe safety precautions in protective work clothing, a mask, and dielectric gloves. The indoor transformer must be installed in a dry room with a floor-mounted type, and at the beginning of operation the TMG frequency must be 50 Hz.

Do not start the device if you know about its external damage in the form of holes and dents. When checking equipment, the power supply in the networks is temporarily interrupted. Before use, check the oil level to ensure there is no leakage. It is also necessary to check the operation of the voltage switch. Adjustment is possible in the range – ± 5%.

Also read: Three-phase power transformer - TMZ

Maintenance and checking the operation of the device must be carried out with the device turned off.

User manual

Installation and commissioning of the TMG must be carried out by a specialist, in accordance with strict adherence to safety rules, instructions and “Regulations for the technical operation of power plants and electrical networks”:

- It is forbidden to work with the device without grounding, with a broken clamp and without proper repair.

- You cannot start a transformer that does not meet the required coolant oil level.

- Before adding oil, you must make sure that it meets the declared parameters and characteristics of the manufacturer, and has a quality certificate.

- Do not use oil that has been used for other purposes.

- Oil is topped up if necessary, with a breakdown voltage within 35 kV.

- If possible, it is advisable to check the operation of the floor-standing unit daily.

- TMG must be connected to the network with the specified current frequency.

- All acceptable forms of vibration must be eliminated.

- It is necessary to strictly observe the connection in accordance with the switching and starting diagram, after an external audit.

- It is also necessary to ensure the required microclimate in the room and exclude direct exposure to sunlight.