Main characteristics

Waterproofing concrete can be implemented at the construction stage of the building or during operation. In practice, maximum efficiency can be achieved using an integrated approach.

Reinforced concrete products can be processed using the following materials:

- sheet and roll coverings (geosynthetics or PVC membranes);

- liquid compositions – bitumen mastics, liquid rubber;

- sheet metal (metal-based materials are not used for waterproofing the floor);

- mixtures based on bentonite clay;

- mineral-based binders;

- penetrating mixtures;

- Waterproofing concrete is used for surface treatment of reinforced concrete structures.

Waterproofing concrete joints can be implemented:

- at the joints of walls and foundation slabs of a house, floor slabs, lintels, etc. (with materials like “Dehydrol”). To waterproof the joints of concrete slabs, grooves of 20x20 mm/30x30 mm are installed. Material consumption 0.8 kg/m.p of concrete;

- on prefabricated reinforced concrete structures. Recently, special sealing tape has been used to waterproof joints. The material is fixed on the surface of the structure in the abutment zone, after which it acquires waterproof properties;

- joints of balcony slabs, various canopies and walls, other external seams, including foundation ones, are best treated with coating waterproofing.

Insulation of floors must be carried out using penetrating materials. The slabs are processed from below or from the outside . In technical rooms it is better to use rolled materials or bitumen mastic.

Waterproofing seams

The channels for the penetration of atmospheric and groundwater into structures are the seams between their elements, including deformation ones.

The latter are always included in the design to reduce loads on parts of the structure during temperature deformations, seismic vibrations, and soil subsidence.

To protect the seams between structural elements, special suture waterproofing is used, which must meet the following requirements:

- resistance to groundwater pressure;

- good adhesion to building materials;

- environmentally friendly, harmless to health;

- chemical inertness, eliminating reinforcement corrosion;

- no shrinkage during operation leading to loss of tightness.

Penetrating concrete waterproofing

This is the most common insulation method, allowing you to work with any concrete surfaces and hard-to-reach joints. Based on the name, it is clear that the active components of the working composition are introduced deep into the concrete structure , which provides protection both under counter and direct water pressure.

In private construction, such mixtures as “Penetron”, “Wateplug”, “Penecrete” have proven themselves well , which can be used in combination for work in basements, on the foundations of the first floor of a house, swimming pools and other concrete buildings.

Principles of work:

- the penetrating mixture is applied to a damp surface;

- Both the internal and external sides can be processed;

- work can be carried out on both old and new concrete.

Advantages of Lakhta suture waterproofing

A serious competitive advantage of Lakhta suture waterproofing is the price. Not inferior in quality and ease of use to imported compounds, Lakhta remains affordable for the mass consumer. The undeniable advantages of Lakhta waterproofing include compliance with the requirements of GOST 31357-2007 for this type of suture moisture-proof materials.

The material has some limitations that you should know about before buying Lakhta suture waterproofing:

- the composition is not used for moisture protection of expansion joints;

- periodic and variable loads should not exceed values at which the composition retains the ability to maintain waterproofing of joints;

- The material is not recommended for use on damaged surfaces of concrete that has lost its strength.

It makes sense to buy cement-based suture waterproofing during construction, reconstruction and repair:

- civil objects: residential and public buildings;

- service underground facilities: car parks, basements;

- industrial facilities: workshops, mine tunnels;

- hydraulic facilities: swimming pools, water reservoirs (including drinking water), dams, wells, treatment and port facilities, dams, water canals.

Concrete floor in a private house

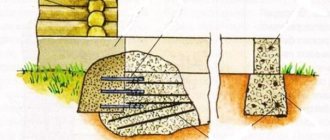

Sealing concrete floors in the basement can be achieved by laying the so-called “pie”:

- crushed stone;

- fatty clay;

- thin concrete layer;

- a layer of mastic with waterproofing properties;

- roll waterproofing - two layers;

- thin concrete layer;

- reinforced screed.

In this case, it is highly not recommended to use films and membranes, since they are not able to withstand seasonal soil shifts when there is high friction between materials and the foundation.

Waterproofing a concrete floor in a basement should always be multi-layered, since its recess will likely be exposed to groundwater, particularly in the spring.

Materials (dry mixtures) for waterproofing joints

• high quality Portland cement;

• additives with various functional purposes;

• quartz filler.

The mixtures are easily prepared for use by dissolving with water. Seam processing ensures the pores of concrete are blocked, increasing water resistance and frost resistance.

The composition of materials for waterproofing is divided into types:

— for use in seams with deformation;

— not recommended for use in seams that show signs of deformation.

Waterproofing with liquid glass

Liquid glass forms an impermeable layer that blocks the access of water . The basis of the composition is sodium or calcium silicate with additives of quartz sand and soda.

The material, in addition to hydrophobic properties, performs the following functions:

- antiseptic (antibacterial activity);

- hardener – the pores are filled, which increases the density of the surface;

- protection against acid attack;

- fire resistance.

A multi-layer coating (2-4 layers) is applied to the concrete . One layer should be completed in one go, the thickness of which should be within 3-5 mm. There should be no “blind”, untreated zones on the surface.

Technology:

- surface preparation – removal of rust, plaster, paint. Work can be carried out using sandpaper or a stiff brush;

- the cleaned area is removed from dust using a construction or household vacuum cleaner;

- the solution is applied to the surface and dispersed using a spatula;

- then pass over the surface with a needle roller on a long handle to eliminate bubbles and unevenness;

- final alignment is done using a squeegee;

- The finished waterproofing can be coated with epoxy or polyurethane varnish, which will give the floor transparency and shine, increasing the effectiveness of the coating.

Each subsequent layer is applied no earlier than half an hour, so that the liquid glass can penetrate into all microcracks and pores and dry.

Materials for waterproofing cracks and seams

When waterproofing seams and cracks, the following materials are usually used:

- Penetrating waterproofing mixtures, consisting mainly of quartz sand, special cement and various chemical additives.

- So-called hydraulic seals, which are installed both when there is a need to temporarily eliminate a leak, and on a permanent basis.

- Materials for injection waterproofing of seams, used, as a rule, to eliminate mistakes that were made during the construction stage of the building and led to leaks.

- Waterproofing dowels used to protect seams from moisture penetration through them, as well as to compensate for the mobility of the structure.

- The cord is waterproofing, which tends to swell when in contact with moisture, thereby eliminating even the slightest gaps for moisture penetration.

By choosing the right material for waterproofing and performing the work in accordance with the instructions provided, you can save the problematic structure from moisture penetration for many years.

Waterproofing a concrete floor in a bathhouse

The work can be carried out using cement, polymer-cement, penetrating and roll-coated waterproofing.

Recommendations for carrying out work are disclosed in the indicated manner. It is acceptable to use any method:

- the base should be as smooth and clean as possible;

- before laying out the roll-coating materials, the area is primed, then cold mastic or hot bitumen is applied to it, on which roofing material is placed (in 2-3 layers);

- penetrating waterproofing is realized using special powder compositions that dissolve in water. In practice, products of the brands “Penetron” and “Infiltron-100” are used. Both mixtures crystallize in the pores of the material, blocking the penetration of moisture, but it remains open to steam. It is advisable to provide a vapor barrier;

- polymer cement mixtures are also sold in ready-made form (Ceresit CL50). This material can bridge cracks up to 5.0 mm. You can pay attention to two-component compositions such as Maxseal Flex, in which the cement mixture is sealed with a liquid polymer;

- Cement waterproofing is also a dry mixture that can be used for work in rooms with high humidity. The composition contains polymer modifying and hydrophobic additives. These are coating materials that are applied over a primer to a previously prepared, moistened state. This group includes mixtures of the Hydrostop brand;

- if the floor of the bathhouse is covered with sheet insulation, it is protected on both sides with roofing felt or plastic film, covering the seams and covering the ends.

Waterproofing expansion joints

Expansion joints are designed to reduce stress in concrete, brick and other critical building structures. Depending on the purpose, such seams are divided into several types:

- temperature - to compensate for the uneven thermal expansion of materials;

- sedimentary - reduce the imbalance of loads on the ground due to the different masses of parts of the structure.

In addition, there are shrinkage, anti-seismic, structural and insulating seams.

The creation of seams leads to the division of the building into relatively independent blocks, at the junctions of which risk zones are formed, where leaks of precipitation or groundwater are likely. Despite the fact that such sections of structures are subjected to special sealing, over time the waterproofing of expansion joints is broken, which is why moisture seeps into the masses of enclosing structures and premises.

The result is gradual corrosive degradation of the reinforcement, and at subzero temperatures, the destruction of wall materials, floor slabs and foundations by freezing liquid begins. Mold growths grow in the interior spaces and the finishing is destroyed. Because of these factors, the sealing of junctions, butt and separating zones of building elements requires the most careful approach, as well as regular monitoring of their condition.

Waterproofing a concrete floor in a garage

Waterproofing for concrete garage floors can be represented by a special water-repellent impregnation. It is better to choose those compositions that are solvent-based - they will penetrate deeper into the concrete.

The cost of such work is 17-25 rubles/m² . The waterproofing will go a few centimeters deep into the concrete and this, as a rule, is enough to prevent the material from allowing moisture to pass through from the ground.

If the problem is more serious and water periodically “stands” on the floor, it is necessary to install capital waterproofing, for which penetrating mixtures with a cement binder are used. All joints and seams must be processed, especially if the concrete was poured in several stages.

Thus, in addition to waterproofing the monolithic surface, it is necessary to groove these areas and put material of a thicker consistency into the grooves. After this, you can make a self-leveling floor, however, this is an expensive undertaking.

Main types of suture waterproofing

Seam protection is performed using two main types of materials:

- sealants, including compounds that expand in volume (foams);

- cement-based mixtures.

Expanding joint waterproofing is made on the basis of artificial rubber and synthetic polymers. Such materials are subject to special requirements in terms of elasticity and strength. When in contact with water, such compositions can multiply in volume, filling the joint space.

Similar materials are available in the form:

- bandage tapes;

- sealing harnesses;

- profile; sealing mass.

Waterproofing on the ground

The work is carried out as follows:

- the soil is compacted;

- sand filling is carried out (moistening and compaction);

- crushed stone or expanded clay backfill is performed;

- waterproofing is carried out (using the selected material);

- a rough screed is laid;

- vapor barrier and thermal insulation are installed;

- reinforcement and finishing screed are implemented;

- the selected floor covering is installed.

Waterproofing installation:

- rolled bitumen material or polymer membrane is rolled out over the base; All strips are laid out in one direction, the overlaps are fixed with construction tape;

- the material should extend onto the walls by 15-20 cm;

- then the rough screed is implemented.

Waterproofing on the ground requires the arrangement of a drainage system, otherwise the work will be ineffective. Concrete floors on a concrete base with waterproofing are much easier to install.

Protecting a private home from moisture is a serious step that any builder can implement.

How to practically make penetrating waterproofing of concrete is shown in the video:

Injection waterproofing of seams

Today this method is considered one of the most advanced and reliable technologies for protecting structures from moisture penetration. It allows you to restore the hydrophobic properties of structures and their joints in the most inaccessible places without opening the surface layers, including finishing.

The essence of the technology is that waterproofing compounds are pumped into cracks that have formed over time in brick, concrete or similar materials, as well as expansion or installation joints using an injection pump. Thanks to their low viscosity and high injection pressure, the preparations evenly fill even the smallest channels. Then the material quickly polymerizes (within a few minutes), which ensures reliable blocking of liquid penetration.

For injection, the following types of elastic materials can be used to waterproof seams subject to deformation:

- polyurethane resins;

- acrylic resins.

There are also injections based on epoxy resins. However, their use is most justified for restoring the mechanical integrity of the structure, since they have a powerful adhesive effect. In this case, the connection turns out to be quite rigid, which may not satisfy the operating conditions of the expansion joint.

The choice of a specific method of waterproofing concrete and other joints in each specific case is determined by a specialist, but according to most reviews, a combination of several methods will be the most effective.

Waterproofing the ceiling in the garage

Garage cooperatives, so widespread throughout our country, were built for the most part by the hands of car owners themselves. There was no need to talk about full compliance with the technology then, and water flow, both in the lower floor and on the ceiling of the main room, can be observed quite often.

The appearance of wet spots (and in more serious cases, leaks) indicates that water has found its way from outside to inside the room. In a one-story building, we are talking about precipitation, and if the garage is multi-story and the box is not on the top floor, we are talking about emergency flooding with water from the upper floors due to damage to communications.

The most effective method of dealing with external leakage is to block the flow of water from outside. The easiest way to do this is at the construction stage, when there is direct access to the floor panels from the outside. Here, waterproofing is carried out step by step in combination with thermal insulation. But if there is a leak in the garage, then there is a violation of the existing coating.

Most garages are covered with soft roofing materials. To eliminate the damage, you need to carefully inspect the entire roof.

Most often, water can seep in places where ventilation ducts and electrical wiring are installed, when there is a through communications input through the ceiling panel.

There may also be cracks or cuts as a result of careless snow removal or falling heavy branches.

The easiest way is to carry out local repairs at the site of damage. This can be done by applying a patch of rolled waterproofing material or with a special repair mastic. It is faster and more convenient to eliminate leaks from the outside using polymer-bitumen mastics. They are available in different containers, including small ones - 3-5 kg, do not require special equipment, and are applied with a regular brush. They may be called “Liquid roofing”, “Liquid rubber”, etc. An example of such local repairs can be seen in the video.

Methods for waterproofing seams

There are several ways to waterproof seams. They are united by the need for a plastic and durable material that compensates for the mobility of the structure. Rigidity is unacceptable, since in this case cracks and voids are inevitable. The main materials are presented in three groups.

Gernite cords

Theoretically, ordinary rubber, which is characterized by acceptable elasticity, is sufficient to seal internal expansion joints. It is no longer suitable for outdoor work, since at sub-zero temperatures the target qualities are lost.

Gernite cords contain various additives that allow them to maintain ductility in any conditions. Moreover, the material is resistant to mechanical damage and is characterized by the ability to increase in volume, filling the free space.

Sealants

In its initial state, it is a liquid material that fills the entire body of the seam. As the sealant hardens, it becomes an elastic and elastic substance. Being waterproof and chemically inert, it retains these properties even at low temperatures.

Waterstops

A relatively young material that serves as good waterproofing for all types of expansion joints. Made from a special grade of rubber or PVC with a moving part, waterstops are waterproof, durable, flexible and strong. In addition, they are resistant to aggressive environments, mechanical loads and negative temperatures.

What to choose? Waterproofing expansion joints is an extremely important task, so the ideal option would be a comprehensive solution. The one she proposed was the PeneBand waterproofing complex. It combines the benefits of all types of protection, guaranteeing an impeccable moisture barrier and compensation for structural displacements.

Using the PeneBand system for waterproofing expansion joints

Preparing the base

The surface must be durable and clean. Application on loose, excessively porous substrates is not allowed. Concrete should be cleaned of grease, oil products, etc. Defective areas should be dismantled down to the reinforcement and restored with the repair compound Skrepa M500. Sharp edges must be processed before rounding; chips and voids along the seam are repaired, again, with a mixture of Skrepa M500.

Before using the PeneBand complex, expansion joints must be waterproofed with penetrating material Penetron. If the seam intersects with an area with a pressure leak, a hydraulic seal is performed using quick-setting Peneplug or Waterplug (all of these are Penetron system materials).

To caulk the expansion joint against water pressure, it is recommended to use the injection method with polyurethane elastic resin PeneSplitSil.

Application of PeneBand

PenePoxy sealant is applied along the seam in a layer of 2-3 mm and a minimum width of 8 mm on each side. Before applying to a dry surface, it is advisable to slightly moisten the base - this will enhance adhesion. Next, the tape is laid on the glue and rolled with a roller to remove air and water (if the seam is hidden under water, the glue can be applied to the base of any level of humidity). Treatment with a roller can be considered sufficient if excess glue protrudes from under the tape, at least 5 mm wide. The same excess is used to putty the edges of the tape 10-15 mm wide.

It is very important after installation to provide strong pressure on the tape for about a day. If the length of the seam is longer than the length of the tape, PeneBand is glued overlapping with a step of at least 100 mm. For large displacements of the seam, it is necessary to make a compensation loop.

The choice of tape width depends on the task. If the task is not specific, then the minimum width of the tape should be 200 mm plus the width of the seam. When there is a mechanical load on the PeneBand, the system is protected with metal expansion joints.

Waterproofing expansion joints is a very important undertaking. Illiterate work is fraught with leaks and/or stress on the concrete structure - with all that it entails. We recommend contacting specialists. "BASIS-Pro" will carry out waterproofing with a 100% guarantee. And by calling the number provided, you will receive detailed professional advice.