Frequency of checking the resistance of protective grounding of electrical equipment

- Objects that are not classified as particularly dangerous - in accordance with clause 3.6.2 of the PTEEP, the timing of measurements and tests are established by the Consumer's manager, taking into account the following factors: operating conditions and condition of the electrical installation, manufacturer's recommendations, provisions of Appendix 3 of the PTEEP.

- External installations and electrical equipment in particularly hazardous areas - at least once every three years.

- Electrical installations of educational and healthcare institutions, trade, catering, consumer services (dry cleaning and laundry) - at least once every year or six months, if we are talking about particularly dangerous premises. Regulated by departmental regulatory documentation.

Frequency of checking the resistance of lightning protection devices of buildings and structures

- Category I-II – annual monitoring of the system’s condition is required before the onset of thunderstorm season;

- III category – at least once every three years.

NOTE! Acceptance tests of lightning protection devices with subsequent commissioning of the systems are carried out before the transition of construction to the stage of finishing work on a building or structure. If we are talking about an explosive zone, then before the start of a set of measures to test technological equipment

The procedure for testing the ground loop

- During a visual inspection of the grounding device, the level of protection from corrosion and the integrity of the elements accessible for review are monitored.

- The tapping method is used to check the mechanical strength and integrity of the connections of grounding conductors with grounded elements.

- Guided by the method of measuring ground resistance, an artificial circuit of current flow through the ground electrode being tested is created. Using the calibrated M-416 device, the resistivity of the soil and ground electrode is measured. Based on the data obtained during the inspection, a conclusion is made about the quality of the technical condition of the grounding device.

The measurement methodology, volumes and test standards are determined in accordance with the methodological instructions RD 153-34.0-20.525-00 and RD 34.45-51.300-97.

How are the results of checking the protective grounding loop recorded?

- After implementing the entire set of measures to monitor the condition of the grounding device, the customer receives a technical report, which includes a protocol for visual inspection and measurement of grounding resistance (drawn up in accordance with the requirements of GOST R ISO/IEC 17025-2006), a description of the methodology used, and copies of permitting documentation for the electrical laboratory.

- Information about the date of measurements and their results is entered into the logbook for checking the grounding of electrical equipment.

- If inconsistencies are identified, the customer is given recommendations on how to eliminate them.

Protocol for checking the presence of a circuit between grounded installations and elements of a grounded installation

Advantages of the mobile electrical laboratory "SK "OLIMP"

- The list of types of work to which our electrical measuring laboratory is authorized allows, in addition to measuring grounding resistance and testing lightning protection devices, to carry out comprehensive diagnostics of the compliance of electrical equipment and electrical installations with voltages up to 35 kV with the requirements of PUE, PTEEP, RD and SO instructions.

- The issued measurement protocols are accepted by all regulatory authorities.

- Guaranteeing the accuracy and reliability of protective grounding resistance measurements - timely verification of measuring instruments, strict adherence to the methodology, personnel competence (tests are carried out by employees with electrical safety clearance group V).

- Each customer is included in the database of regular customers and receives a discount the next time they contact or order from others.

Why should ground resistance be measured during installation?

The main indicator of grounding quality is the resistance to current spreading of the ground electrode, which depends on the soil resistivity - the greater the soil resistivity, the more difficult it is to obtain the required result. Work on installing the ground electrode should be carried out with resistance measurements during installation. If you buy a grounding kit with a small total length of electrodes, the depth of the ground electrode may not be enough to achieve the required resistance.

The video shows an example of an intermediate measurement of the resistance of the grounding conductor for the neutral wire [at the input to the electrical installation of a country house] during installation: the depth of the grounding conductor is 6 meters, the spreading resistance is 273 Ohms. This is the answer to the question: should installation continue?

The rules do not prescribe a specific value of the resistance of the charger for re-grounding, but establish the maximum permissible value of resistance to current spreading (30 Ohms) - with adjustments depending on the resistivity of the soil and seasonality, and the lower this value, the better. A grounding device made with the maximum permissible resistance value - for a number of reasons, may not fulfill its function in the electrical installation of a house in the event of emergency situations on the supply line. The best option (if possible) is to re-ground the pen (neutral wire) of the electrical installation of a country house/building with a resistance value of the grounding device close to the resistance of the solidly grounded neutral of the power source, which is several times less than the maximum permissible value for re-grounding specified in the PUE. Installation of such grounding will be more labor-intensive.

Where is re-grounding carried out? 5.18. On an overhead line, grounding must be done with a PEN conductor laid on the same supports as the phase wires. At the ends of overhead lines / or branches from them / with a length of more than 200 m, as well as at the inputs from overhead lines to electrical installations that are subject to grounding, the PEN conductor must be re-grounded. What is recommended to use as grounding conductors? 8.1. It is recommended to use the following as natural grounding conductors and grounding devices: 1-underground or underwater parts of steel and reinforced concrete structures and structures for all purposes, including those with protective waterproofing coatings, in non-aggressive and slightly aggressive environments; 2- reinforced concrete foundations of industrial buildings and structures, including those with protective waterproofing coatings, in non-aggressive, slightly and moderately aggressive environments, provided that the anchor bolts of steel columns (reinforcing bars of reinforced concrete columns) are welded to the reinforcing bars of reinforced concrete foundations; 3-technological, cable and combined (steel and reinforced concrete) overpasses of industrial enterprises; 4- metal pipelines laid in the ground for all purposes, except for pipelines of flammable and explosive substances and mixtures, sewage and central heating; 5- openly laid metal stationary pipelines for all purposes, except for pipelines of flammable and explosive substances and mixtures, sewage and central heating; 6-casing pipes of drilling wells; 7- rails of electrified railways at stations and stages, as well as rails of access roads of temporary current traction substations; 8- rails of main non-electrified railways, as well as rails of access roads, in the presence of a deliberate electrical contact device between the rails of each rail thread; 9- rails of the crane track when installing the crane outdoors, in the presence of a deliberate electrical connection between the rails of each rail thread; 10-grounding switches for overhead line supports, connected to the grounding device of the electrical installation using an overhead line lightning protection cable (if the cable is not isolated from the overhead line supports); 11- repeated grounding switches for overhead lines with voltage up to 1 kV, connected to the grounding device of the electrical installation with a PEN conductor, with the number of overhead lines being at least two; 12 - lead sheaths of cables laid in the ground, with at least two cable lines. Repeated grounding of the PEN conductor in DC networks must be carried out using separate artificial grounding conductors, which should not have metal connections to underground pipelines. Grounding devices on DC overhead lines, designed to protect against lightning surges, are recommended to be used for re-grounding the PEN conductor. Grounding conductors for repeated grounding of the PEN conductor must be selected from the condition of long-term passage of a current of at least 25 A. 5.19. The total resistance to spreading of grounding conductors (including natural ones) of all repeated groundings of the PEN conductor of each overhead line at any time of the year should be no more than 5, 10 and 20 Ohms, respectively, at line voltages of 660, 380 and 220 V of a three-phase current source or 380, 220 and 127 V single-phase current source. In this case, the spreading resistance of the grounding conductor of each of the repeated groundings should be no more than 15, 30 and 60 Ohms, respectively, at the same voltages. If the earth resistivity p is more than 100 Ohm m, it is allowed to increase the specified standards by 0.01 p times, but not more than ten times. 5.20. Hooks and pins of phase conductors installed on reinforced concrete supports, as well as the reinforcement of these supports, must be connected to the PEN conductor. Galvanized steel single-wire grounding conductors must have a diameter of at least 8 mm. Hooks and pins of phase conductors installed on wooden supports, where the PEN conductor is re-grounded, must be grounded.

Ground resistance

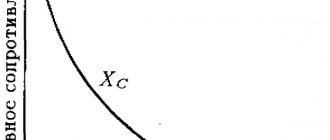

Grounding resistance (resistance to the spread of electric current) is defined as the value of “resistance” to the spread of electric current in the ground, entering it through the ground electrode.

It is measured in Ohms and should have the lowest possible value. The ideal case is a zero value, which means the absence of any resistance when passing “harmful” electric currents, which guarantees their COMPLETE absorption by the earth.

Since the ideal cannot be achieved, all electrical equipment and electronics are created based on certain standardized values of ground resistance = 60, 30, 15, 10, 8, 4, 2, 1 and 0.5 ohms.

- for private homes connected to a 220 Volt / 380 Volt power supply, it is necessary to have local grounding with a recommended resistance of no more than 30 Ohms

When connecting local grounding to the neutral of a transformer/generator in a TN system, the total grounding resistance (local + all repeated + transformer/generator grounding) should be no more than 4 Ohms (PUE 1.7.101). This condition is met without any additional measures if the current source (transformer or generator) is properly grounded.

Read more about this on the “Grounding the Home” page.

- When connecting a gas pipeline to a house, the standard requirement for grounding the house must be met. However, due to the use of dangerous equipment, it is necessary to perform local grounding with a resistance of no more than 10 Ohms (PUE 1.7.103; for all repeated groundings)

Read more about this on the page “Grounding a gas boiler / gas pipeline”. for grounding used to connect lightning rods, the grounding resistance should be no more than 10 Ohms (RD 34.21.122-87, clause.

Read more about this on the “Lightning protection and grounding” page.

for a current source (generator or transformer), the grounding resistance should be no more than 2, 4 and 8 Ohms, respectively, at line voltages of 660, 380 and 220 V of a three-phase current source or 380, 220 and 127 V of a single-phase current source (PUE 1.7.101) for To ensure reliable operation of gas arresters in devices for protecting overhead communication lines (for example, a local network based on a copper cable or a radio frequency cable), the grounding resistance to which they (the arresters) are connected should be no more than 2 Ohms. There are instances with a requirement of 4 ohms. When connecting telecommunications equipment, grounding should usually have a resistance of no more than 2 or 4 ohms

for a 110 kV substation, the resistance to current spreading should be no more than 0.5 Ohm (PUE 1.7.90)

The above grounding resistance standards are valid for normal soils with a specific electrical resistance of no more than 100 Ohm*m (for example, clay / loam).

If the soil has a higher electrical resistivity, then often (but not always) the minimum grounding resistance values increase by 0.01 of the soil resistivity.

For example, with sandy soils with a resistivity of 500 Ohm*m, the minimum local grounding resistance of a house with a TN-CS system increases 5 times - up to 150 Ohm (instead of 30 Ohm).

Requirements for lightning protection grounding resistance

The topic of grounding lightning protection is not as simple as it might seem at first glance. In regulatory documents there are only requirements for the resistance of the grounding conductor, but there are no requirements for the configuration of grounding conductors. Let's consider various technical regulations on this topic.

Let's not delve into grounding problems; let the relevant specialists deal with this.

Initially, I wanted to devote the topic only to grounding a free-standing lightning rod, but then I decided to remember all the requirements for lightning protection grounding rods. Well... or almost everything

TNLA RB:

TKP 336-2011 (Lightning protection of buildings and structures and utilities).

7.2.3 When considering the dissipation of high-frequency lightning current in the ground and in order to minimize any dangerous overvoltages, the configuration and size of the grounding system are important criteria. Generally, a low ground resistance (no more than 10 ohms measured at low frequency) is recommended.

TKP 339-2011 (Instead of PUE).

6.2.8.5 Protection against direct lightning strikes of the outdoor switchgear should, if possible, be carried out by separate lightning rods installed along the perimeter of the substation. Lightning rods must be provided at the maximum distance from the buildings of the control room, main control room, and control panel. Free-standing lightning rods must have separate grounding conductors with a resistance of no more than 80 Ohms at a pulse current of 60 kA.

TKP 181-2009 (02230) (Rules for technical operation of consumer electrical installations).

5.9.1 Electrical installations of Consumers must have protection against lightning and internal overvoltages, made in accordance with the requirements of the rules for the construction of electrical installations. The value of the grounding resistance of lightning rods, if people may be near them during a thunderstorm, should not exceed 10 Ohms.

Table B.29.1 Maximum permissible resistance of grounding devices:

Free-standing lightning rod - 80 Ohm.

TNLA RF:

PUE 7 (Rules for electrical installations).

4.2.137. Protection against direct lightning strikes of outdoor switchgear, on the structures of which the installation of lightning rods is not allowed or is impractical for design reasons, should be carried out with separate lightning rods having separate grounding conductors with a resistance of no more than 80 Ohms at a pulse current of 60 kA.

RD 34.21.122-87 (Instructions for the installation of lightning protection of buildings and structures).

8 ... Until recently, for lightning protection grounding conductors, the impulse resistance to the spreading of lightning currents was standardized: its maximum permissible value was taken to be 10 Ohms for buildings and structures of categories I and II and 20 Ohms for buildings and structures of category III. At the same time, it was allowed to increase the impulse resistance to 40 Ohms in soils with a resistivity of more than 500 Ohm×m while simultaneously removing the lightning rods from Category I objects at a distance that guarantees against breakdown in the air and in the ground. For outdoor installations, the maximum permissible impulse resistance of grounding conductors was taken to be 50 Ohms.

RD 34.45-51.300-97 (Scope and standards for testing electrical equipment).

Table 28.1 - Maximum permissible resistance of grounding devices:

Free-standing lightning rod - 80 Ohm.

Conclusion: once again we can be convinced that the regulatory documents regarding the design of electrical installations in the Republic of Belarus and the Russian Federation are not much different.

I recommend reading:

Dimensions of pits for HDD or punctures

How to connect sockets from an isolation transformer?

Why is a three-phase network better than a single-phase network?

Design of a potential equalization system in a TN system

Neutralization of equipment faults using grounding.

Sometimes an insulation failure occurs and phase voltage enters the metal casing of the electrical appliance. Let's consider various options for protective measures and their results:

- the housing has neither grounding nor an RCD - the most dangerous case

As a rule, such grounding is not detected in time, so any careless touch to the housing under phase potential can cost life

— the housing is grounded, but there is no RCD. If the leakage current in the circuit is high, the fuse trips and the circuit turns off. But this option is unsafe, since the high resistance of the grounding conductor, large fuse ratings, and the electrical potential of the grounded conductor can be very high. For example, the grounding resistance is 4 Ohms, the fuse rating is 25 A, the conductor potential is about 100 volts.

— the housing is not grounded, but an RCD is installed. The phase potential on the device body will not be detected until the path for the leakage current is identified. If a person simultaneously touches a shorted device and a naturally grounded object, the leakage will pass through the person. He will receive a brief electric shock. And the RCD turns off the network only when a leak has already occurred.

— both grounding and RCD are installed on the housing. Here the two defensive actions complement each other. This is the best protection, since in the event of a high leakage, both the fuse and the residual current device often trip.

How re-grounding works

In the modern world, it is difficult to imagine human life without electrical appliances. The number of them in homes is large, and in order to ensure the necessary safety of their use, it is necessary to implement protective measures against accidental electric shock. One such measure is re-grounding.

Main types

Protective grounding allows you to protect a person from electric shock if voltage accidentally occurs on the body of a device or installation. The dangerous potential is removed or the operation of electrical protective devices is ensured with minimal delay.

Natural grounding conductors are any metal objects that are in the ground. The documents establishing the standard do not recommend the use of natural conductors, because it is impossible to take into account such a value as the resistance to the spread of current in the ground from them.

Grounding errors.

1. Incorrect PE conductors

Sometimes you can find not only metal rods as a grounding conductor, but also central heating pipes or water pipes. This cannot be done, since the water supply usually contains non-metallic elements (plastic, etc.), as a result of which the necessary electrical contact is disrupted. Poor grounding may be due to corrosion, which pipes are often subject to. And if part of the pipeline is disassembled for repairs, the conductivity is completely disrupted, as a result of which the grounding suffers.

2. PE conductor and working zero are connected into one whole

Often there is a moment when the working zero and the PE conductor are combined along the current distribution, beyond the separation point, if there is one. This may contribute to the appearance of excess electrical voltage in the PE conductor, which should not become a source of electricity. The second reason is that automatic shutdown protection often triggers falsely.

3. Incorrect division of the PEN conductor

The following case is especially dangerous: the working neutral conductor is determined directly in the socket, a jumper is placed from it to the PE contact of the socket, as a result of which the PE load conductor is connected to the working zero. In this situation, the danger arises from the phase potential arising on the body of the connected device and in the grounding contact of the socket due to:

- rupture or burnout of the neutral conductor between the conductor and the socket, and subsequently further, to the very point where the PEN conductor is grounded;

- swapping the phase and neutral conductors connected to a given socket (in place of the phase conductor was the neutral one, and vice versa).

Grounding resistance.

Grounding resistance (resistance to the spread of electric current) is the amount of “resistance” to the spread of electric current entering the ground through the ground electrode.

The measurement value of grounding resistance is Ohm and it should be minimally low in value. The ideal case is considered if the value is zero, this means that when “harmful” electric currents pass, there is no resistance, which guarantees their COMPLETE absorption by the ground. Since it is almost impossible to achieve the ideal, all electronics and electrical equipment are created on the basis of certain standardized values of grounding resistance equal to 60, 30, 15, 10, 8, 4, 2, 1 and 0.5 Ohms.

To calculate the conductor resistance, you can use the conductor resistance calculator.

When connecting to electrical networks with 220 Volts / 380 Volts, grounding must be provided for private houses with a recommended resistance of no more than 30 Ohms.

According to PUE 1.7.101, when connecting local grounding to the neutral of a transformer / generator in a TN system, the total grounding resistance (local + all repeated + grounding of the transformer / generator) should not exceed 4 Ohms. Without any additional measures, this condition is met if the current source (generator or transformer) is properly grounded.

The standard requirement for grounding a house when connecting a gas pipeline to a house must be met, but it is necessary to carry out local grounding with a resistance of no more than 10 Ohms, due to the use of a dangerous type of equipment (for all repeated groundings, PUE 1.7.103).

The grounding resistance should be no more than 10 Ohms (RD 34.21.122-87, clause for grounding, which is used when connecting lightning rods.

Based on PUE 1.7.101, no more than 2, 4 and 8 Ohms of grounding resistance are required for a current source (generator or transformer), respectively, at line voltages of a three-phase current source: 660, 380 and 220 V or a single-phase current source: 380, 220 and 127 V.

In devices for protecting overhead communication lines (for example, radio frequency cable or local network based on copper cable), the grounding resistance to which gas arresters are connected should be no more than 2 Ohms, this is necessary for their reliable operation. There are also instances that require a value of 4 ohms.

Grounding when connecting telecommunications equipment should have a resistance of no more than 2 or 4 ohms.

The current flow resistance for the substation should not exceed 0.5 Ohm (PUE 1.7.90).

But the above grounding resistance standards are valid only for normal soils that have a specific electrical resistance not exceeding 100 Ohm*m (clay or loam).

However, if the soil has a higher electrical resistivity, then very often (but not always) the minimum value of grounding resistance increases by an amount equal to 0.01 of the soil resistivity.

For example, with a resistivity of 500 Ohm*m, the minimum local grounding resistance of a house with a TN-CS system in sandy soils increases 5 times, instead of 30 Ohms, it becomes 150 Ohms.

To calculate the grounding resistance, special methods and formulas have been developed that describe the dependences on the given factors.

The main qualitative indicator of a grounding conductor is the grounding resistance and it depends directly on the following factors:

1. Soil resistivity

2. Configuration of the ground electrode, in particular on the area of electrical contact of the ground electrodes with the ground

Requirements for grounding devices

a) Electrical installations with voltages above 1000 V with high ground fault currents

. According to the PUE, the resistance of the grounding device in these electrical installations should not exceed 0.5 Ohm. However, limiting the resistance of the grounding device alone does not provide acceptable touch and step voltages for ground fault currents of several kiloamperes.

Fig.8-11. Potential equalization using additional equalizing conductors with a contour grounding system

For example, with a short circuit current of 6 kA, the grounding device will have a voltage of 3 kV. Therefore, in addition to limiting the resistance of the grounding device, the following measures are also provided:

1) fast shutdown for ground faults;

2) equalization of potentials within the territory in which the electrical installation is located and on its borders.

To equalize potentials on the territory of an electrical installation, a grid of equalizing conductors should be laid at a depth of 0.5-0.8 m (Fig. 8-11). Longitudinal conductors are laid parallel to the axes of the equipment at a distance of 0.8 - 1 m from the foundations or bases of the equipment and are connected to each other over the entire area by transverse conductors with a pitch of no more than 6 m. To improve alignment at the boundary of the contour, the outermost conductors of the mesh, from which greater flow occurs current into the ground, laid at a depth of about 1 m.

Potential equalization should also be carried out at the entrances and entrances to the territory of the electrical installation by laying two additional strips with gradual deepening; at a distance of 1 and 2 m from the ground electrode at a depth of 1 and 1.5 m, respectively.

When placing an electrical installation on a sufficient area, the distance from the boundaries of the grounding conductor to the fence of the electrical installation must be at least 3 m, and the fence in this case is not grounded. In areas frequently visited by personnel and at entrances and exits, it is advisable to install paths coated with low-conductivity asphalt or gravel.

In order to prevent the potential from being carried outside the territory of an electrical installation with a large ground fault current, it is prohibited to supply power to receivers located outside the territory of the electrical installation from transformers with a grounded neutral at voltages of 380/220 or 220/127 V located within the territory of the electrical installation. If necessary, such receivers are powered from transformers with an isolated neutral.

To prevent potential carryover, rail tracks entering the territory of an electrical installation are not connected to the grounding circuit of the electrical installation, and at the exit from the electrical installation, the rails are grounded at several points. Since the rails have zero potential, the possibility of a person coming under significant step voltage within the electrical installation when he touches the ground with one foot and the rail with the other must be excluded. This possibility is excluded when the railway track is embanked with coarse crushed stone, pebbles, and shell rock, which have low conductivity.

If the ground electrode is not located inside the fenced area, it can be expanded beyond the electrical installations with mandatory potential equalization at the boundary of the circuit by gradually deepening the outermost conductors of the grid. In this case, the metal parts of the fence and the reinforcement of the reinforced concrete fence posts must be connected to the ground electrode.

When locating electrical installations with a large ground fault current near the workshops of industrial enterprises, the following measures must be taken:

1) all adjacent buildings must be included in the common grounding loop;

2) measures must be taken to equalize potentials within workshops;

3) around buildings at a distance of 1 m from the walls at a depth of 1 m, a conductor must be laid connected to grounding conductors inside the building, and at the entrances and entrances to buildings potential equalization must be carried out by laying additional strips with gradual deepening;

4) asphalted blind areas 1-1.5 m wide should be installed around buildings.

Since short circuit currents to ground in the installations under consideration are large, the thermal resistance of the grounding conductors must be ensured. The cross-sections of the grounding conductors must be selected such that when the rated currents of single-phase ground faults flow through them, their temperature during the time before the main protection is triggered does not exceed the permissible level (400 ° C). In accordance with this, the minimum cross-sections of conductors for permissible heating by a single-phase ground fault current are determined by the formula:

(8-11)

where I zm is the steady-state short-circuit current, A; t p — reduced time of passage of current to ground, s; c - constant: for steel 74, for thick copper conductors 195, for cables with voltage up to 10 kV with copper conductors 182, for bare aluminum conductors and cables with aluminum conductors with voltage up to 10 kV 112.

As a steady-state short-circuit current. in the calculations, the maximum current passing through the conductor during a short circuit on the device in question or during single-phase ground faults outside it is taken for the network circuit possible in operation, taking into account the distribution of the short-circuit current. to the ground between grounded network neutrals.

b) Electrical installations with voltages above 1000 V with low ground fault currents

. In accordance with the requirements of the PUE in electrical installations without capacitive current compensation, the resistance of the grounding device when the rated current flows through it at any time of the year must satisfy the condition, Ohm

(8-12)

where I calculated is the calculated current through the grounding device, A; U calculated is the calculated voltage on the grounding device in relation to the ground, V.

The calculated current is the full tone of a ground fault when the connections of the electrically connected network are fully switched on.

The estimated ground fault current can be found from the expression, A

where U is the phase-to-phase network voltage, kV; l к, l в - total length of electrically interconnected cable and overhead lines, km.

If the grounding device is used only for electrical installations with voltages above 1000 V, I calculated is taken equal to 250 V; if the grounding device is also used for electrical installations with voltages up to 1000 V, I calculated = 125 V.

The resistance of the grounding device for networks with voltages above 1000 V with low ground fault currents should be no more than 10 Ohms.

In networks with capacitive current compensation, the resistance of the grounding device is calculated using formula (8-12). In this case, the following should be taken as the calculated current:

1) for grounding devices to which compensating devices are connected, a current equal to 125% of the rated current of these devices;

2) for grounding devices to which compensating devices are not connected, the highest residual ground fault current that can occur in the network when the most powerful compensating device is disconnected, but not less than 30 A.

In order to facilitate the grounding arrangement, the PUE allows in all electrical installations with low ground fault currents to calculate grounding devices according to formula (8-12), taking as the calculated operating current of the relay protection or the melting current of the fuses, if this protection ensures the disconnection of ground faults. In this case, the minimum ground fault current under operating conditions must be at least one and a half times the relay protection operating current or three times the rated current of the fuses.

c) Electrical installations with voltage up to 1000 V with solid neutral grounding

. According to the PUE, the resistance of the grounding device in installations with voltages up to 1000 V with solid grounding of the neutral should be no more than 4 Ohms. The exception is electrical installations in which the total power of installed generators and transformers does not exceed 100 kVA. In these cases, grounding devices can have a resistance of no more than 10 ohms.

Parts of electrical installations to be grounded must have a reliable metal connection with the neutral of the power source, made using grounding conductors or a neutral wire. With overhead lines, the metallic connection with the neutral of the power source is carried out using a special neutral wire, laid on supports in the same way as the phase wires. In this case, every 250 m, as well as at the ends of lines and branches longer than 200 m, the neutral wire must be re-grounded. The resistance of the grounding devices of each of the repeated groundings should be no more than 10 Ohms. In networks with a total power of supply generators and transformers of 100 kVA or less, for which the resistance of the main grounding device is allowed to be 10 Ohms, the resistance of the grounding devices of each of the repeated groundings should be no more than 30 Ohms, with at least three of them.

In order to ensure automatic disconnection of a section with a single-phase fault, the grounding conductors must be selected in such a way that when a short circuit to the body or to the neutral wire occurs, a short circuit current exceeds:

1) 3 times the rated current of the fuse link of the nearest fuse;

2) 3 times the rated current of the delayed release of the circuit breaker, which has a characteristic inversely dependent on the current.

When protecting networks with automatic circuit breakers that have only an electromagnetic release, the grounding conductors must be selected in such a way that in the phase-zero loop a short circuit current is provided equal to the setting current of the electromagnetic release, multiplied by a factor taking into account the spread, and by a safety factor equal to 1.1. In the absence of factory data on the spread, the multiplicity of the short circuit current relative to the setting current of the electromagnetic release should be taken equal to: for machines with a rated current of up to 100 A 1.4; for other machines 1.25.

The total conductivity of the grounding conductors in all cases must be at least 50% of the conductivity of the phase conductor.

Conditions regarding earth fault current must be verified by tests or measurements before the electrical installation is put into operation and periodically during its operation. In order to meet the specified requirements for fault current, it is recommended that grounding conductors be laid together or in close proximity to phase conductors.

The use of lead cable sheaths as grounding conductors is not allowed.

Under design conditions to check the disconnection of short circuits between the phase and neutral wires, the single-phase fault current is determined by the approximate formula:

(8-13)

where Uф is the phase voltage of the network; Zt.o is the zero-sequence impedance of the transformer; Z - loop impedance phase - zero.

When the neutral and phase wires of the line are jointly suspended, the specific reactance of the loop wires made of non-ferrous metals is assumed to be 0.6 Ohm/km; with steel wires, the external specific reactance of the loop wires is also taken to be 0.6 Ohm/km, and the internal reactive and active resistances are determined for the current actually passing through the wires under single-phase circuit conditions. As a first approximation, they can be determined for a fault current exceeding the protection operation current by a specified number of times.

The noted approximation of formula (8-13) consists in replacing the geometric addition of the impedances of the transformer and the phase-zero circuit with an arithmetic one, since the vectors of these resistances are almost parallel and the error from such a replacement does not exceed 5% in the direction of increasing the calculated resistance.

In DC installations, grounding is carried out in the same way as in AC installations.

A feature of the passage of direct current in the ground is electrolytic corrosion of underground structures (water supply and other pipelines, cable sheaths, building structures).

The danger of corrosion exists in installations with long-term flow of operating current through the ground electrode (working grounding of one pole) or in the presence of leakage currents (electrolysis installations, electric rail transport). Therefore, when installing grounding in DC installations, you should not use underground structures as grounding devices, the corrosion of which leads to large losses. Grounding switches of DC installations should not be combined with grounding switches of other systems. Grounding elements must be of sufficient thickness to prevent rapid destruction. If DC electrical installations are connected to AC electrical installations (converters), then common grounding devices can be used.

In DC networks, repeated grounding of the neutral wire must be carried out using separate artificial grounding conductors, which should not have metal connections to underground pipelines, cable sheaths, etc.

d) Electrical installations with voltage up to 1000 V with an insulated neutral

. The resistance of the grounding device, according to the PUE, should not exceed 4 Ohms, and in electrical installations with a total power of parallel operating generators and transformers of 100 kVA and below should not exceed 10 Ohms.

At the installation site of transformers, when sharing a grounding device for networks with voltages up to 1000 V and higher, the resistance of the grounding device must satisfy formula (8-12) with a design voltage on the grounding device Ucalc - 125 V. This requirement provides for the reduction of dangerous consequences in case of damage to the transformer with a short circuit between the high and low voltage windings. In this case, if the fault does not cause a disconnection from the action of the high-side protection, a high-voltage network ground fault current will flow through the breakdown fuse and the grounding device.

During single-phase faults in networks up to 1000 V, a current flows at the fault point due to the conductivity of the (active and capacitive) phases to the ground.

The voltage on the ground electrode relative to the zero potential point is:

Umeas = Imeas Rmeasures

where where I zm is the circuit current, A; R zm - resistance of the grounding device, not exceeding 4 Ohms (or 10).

The highest value of touch voltage is several tens of volts. Therefore, in short networks with low conductivity to ground, the advantages of networks with an isolated neutral from the point of view of electrical safety are undeniable.

Excerpt from the Industrial Power Supply Handbook

under the general editorship of A. A. Fedorov and G. V. Serbinovsky

Methods for determining the presence of grounding

There are known professional methods for testing grounding devices that are part of a circuit that covers the entire protected object. However, the cost of the equipment used to implement these methods will not be affordable for the average user. In this regard, simpler methods are used to determine the presence of a local circuit or grounding PE conductor in a particular house or apartment.

Checking with a multimeter

A ground test using a multimeter can be carried out under the following conditions:

- Before checking the grounding in a country house or apartment, the input circuit breaker must be turned off in the distribution panel.

- Then you will need to select one of the sockets located in the room and completely disassemble it.

- After this, it is necessary to visually determine whether the wire of the corresponding color is connected to the ground terminal or not.

If it is present, you should make sure that the ground bus is connected to the protective circuit and that it is really effective. To do this, armed with a tester, you need to do the following operations:

- Apply power to the circuit by turning on the previously “cut off” input circuit breaker on the electrical panel.

- Set the central switch of the device to the desired voltage measurement limit (up to 750 Volts).

- Measure this indicator between the phase and neutral wires and record it.

- Carry out similar measurements, but between the phase and the supposed “ground”.

If in the last operation a reading appears on the multimeter display that is only slightly different from the first result, this means that there is indeed grounding in the outlet and that it is operational.

But another option is also possible, when the readings in the second case do not appear at all. With this outcome of measuring the ground loop with a multimeter, we can safely say that it is missing or for some reason does not work as expected.

Checking with a test lamp

In the event that there is no multimeter on hand, you can check the grounding using a test light assembled from parts that are at hand. Making this device yourself is not at all difficult; To do this, just find a socket from an old lamp or chandelier 1, two wires 2 and contact connectors 3 securely insulated on one side.

After assembling such a simple device for checking grounding, you can perform all the previously described operations using a digital multimeter.

This must be done for the reason that some unscrupulous electricians do not pay attention to the color of the insulation and in a hurry connect the blue wire to the phase, and the red or brown wire to zero. Using an indicator screwdriver, you can accurately determine which contact the phase is active on. When the end of the phase wire touches it, the neon indicator lights up (if you simultaneously place your thumb on the contact patch of the screwdriver). For the neutral wire, the same operation does not lead to the neon lighting up.

After this, you should take a test lamp and touch the identified phase terminal with one end of the wire, and zero, respectively, with the other. If there is voltage in the network, a working light bulb will light up in any case. Then the first end should be left in place, and the second should be touched to the grounding contact antenna.

When the light comes on, we can conclude that the circuit is working. The effect of a dim glow of the filament indicates poor quality of grounding or its complete absence.

Please note: If an RCD is included in the supply line along with the machine, during testing it may trip and turn off the circuit. This also indicates the good condition of the ground loop (indirectly). This also indicates the good condition of the ground loop (indirectly)

This also indicates the good condition of the ground loop (indirectly).

Why is grounding checked?

Checking the grounding condition is an important measure aimed at protecting people from electric current. To solve the problem of how to check grounding in a private house, special equipment is used. The results obtained make it possible to determine the state of the grounding, whether it complies with established standards and whether it is capable of performing its functions. Typically, such measurements are carried out by qualified specialists from the organization servicing the home network.

Periodic grounding checks must be carried out, despite the fact that all electrical equipment in the house was installed by professional electrical technicians. There are often cases when incorrect connection of the circuit causes its premature wear. In this regard, it is recommended to measure and check in a timely manner the condition of the soil and the electrodes placed in it, as well as grounding conductors, busbars and metal bonding elements.

This procedure, which determines whether there is grounding, is carried out in residential buildings at least once every 3 years, and at industrial production facilities - annually.

During the measurement process, the tester determines the resistance of the circuit, the value of which must correspond to the established standards. If the indicators are higher than the norm, they can be reduced. To do this, you simply need to increase the interaction area by adding electrodes or raising the total conductivity of the soil by increasing the concentration of salts contained in the soil.

It should be borne in mind that a conventional grounding device can only reduce the voltage supplied to the equipment frame. A residual current device - an RCD, installed in conjunction with grounding, will help make protection more reliable. Any protective equipment is designed and selected individually, in accordance with operating conditions. The choice is made taking into account humidity, soil structure and other factors.

It is also necessary to remember that many types of modern electrical devices are equipped with a built-in RCD, which is triggered only when plugged into a grounded outlet. Therefore, their normal operation depends entirely on the correct connection of the protection and further checks of its functionality.

Re-grounding - what is it for and how does it work?

Re-grounding is an integral part of the overall grounding system.

It is used for grounding the neutral protective conductor of PE and PEN electrical networks up to 1000 Volts in a TN system with a solidly grounded transformer neutral. For re-grounding devices, natural grounding conductors are used. The resistance of natural grounding electrodes is not determined by anything and its value can change at any time, therefore artificial grounding with predetermined parameters is used.

Installation of such a device is necessary to reduce the risk of electric shock to people in close proximity to electrical installations. Repeated grounding is installed at the entrance to the building where the electrical installation is located.

With such a device in emergency situations, the voltage on the housings of electrical installations and electrical appliances is reduced. The potential difference between the ground and the body of the electrical installation is reduced, and a person touching the body of the electrical device becomes protected from electric shock.

Application of TN system

To supply the main part of industrial electrical installations up to 1000 Volts, residential buildings and apartments, the TN system is used. To ensure reliable operation of protection devices and increase electrical safety, it is necessary to ground the neutral wire.

The TN system is divided into the following types:

- TN-C, when the neutral working conductor N is combined with the neutral protective conductor PE.

- TN-S, when the neutral working and neutral protective conductors at the substation are separated.

- TN-CS, when the neutral working and neutral protective conductors at the substation are combined, and when entering the building, the electrical installation is divided into two conductors.

Application of the TN-C system

This grounding system was and remains the most widespread in the country. With such a system, the transformer neutral is grounded at the substation. The neutral conductor is connected to the grounded neutral at the substation. In this case, the neutral conductor performs the functions of working and protective conductors and is called a PEN conductor.

Electrical installations are powered by two wires for single-phase power or four wires for three-phase power. When using the TN-C system, there is no grounding contact in electrical sockets, and the housings of all industrial electrical appliances and electrical installations in production are grounded.

Application of the TN-CS system

The TN-CS system is the main one for use in accordance with the PUE. In it, from the transformer substation to the entrance to the building, a combined conductor PEN is used, which at the entrance to the building is connected to repeated grounding and is divided into a working conductor N and a protective conductor PE.

This separation is usually carried out in the main electrical panel of an industrial facility or residential building. Further, after the main electrical panel, the N and PE conductors are separated throughout the building. In this case, electrical sockets have a grounded contact to which a PE conductor is connected.

The TN-CS system is the most optimal in terms of price and electrical safety. It is used in designed residential and industrial buildings.

Application of the TN-S system

The TN-S system is the best in terms of electrical safety, but the most expensive. When installing it, it is necessary to lay five wires from the transformer substation for a three-phase power supply and three wires for a single-phase power supply. This increases financial costs compared to TN-C and TN-CS systems. The PE conductor must be regrounded.

Overhead power lines

On the supports of overhead power lines, it is necessary to re-ground the PEN conductor coming from the transformer substation. This must be done to increase the electrical safety of overhead line sections and for the reliable operation of circuit breakers. The number of repeated groundings along the overhead line route is determined by the power supply design.

Such a device is necessarily used on supports at the end of overhead power lines, on supports before entering an industrial building or private house, before a branch from an overhead line route more than 200 m long. The underground part of the support is used for installation. If it is not enough, an additional ground loop is used, usually consisting of one or two ground electrodes.

On street lighting poles, grounding of lamp housings and all metal parts of the pole must be organized. For this purpose, special grounding conductors and grounding conductors are used. In urban areas, it is not always possible to install standard vertical grounding conductors; therefore, horizontal strips buried in the ground are often used as grounding conductors.

After installing the grounding conductors, be sure to monitor the resistance of the grounding device using special devices. The presence of such grounding makes it safe to operate street lighting poles.

Compatible with shutdown devices

To make a person’s work as safe as possible, the PUE recommends the use of RCDs or automatic devices. Such devices can be used in the TN-CS system, when the PEN wire is divided into PE and N conductors.

This separation occurs in the incoming electrical panel on the main grounding bus. Moreover, the connection of the main grounding bus is made to repeated grounding or to a PEN conductor grounded at the entrance to the building.

An RCD or automatic circuit breaker reacts to leakage currents in the load. When a leak occurs in the insulation or when humidity increases, leakage currents appear. When a certain leakage current value is exceeded, the RCD de-energizes the protected circuit. The differential circuit breaker de-energizes the circuit when a short circuit occurs in the load.

The use of a secondary grounding device for the neutral wire affects the operation time of circuit breakers. The lower the grounding resistance, the faster and more reliably the circuit breaker will operate, which means the higher human safety in emergency situations in electrical networks.

Resistance standards for grounding devices

The loop resistance of this type of grounding is a characteristic of current flow during emergency situations in electrical equipment. In accordance with the rules for electrical installations, the resistance of the grounding system must be standardized.

For overhead power line supports and street lighting supports, the grounding resistance of the neutral wire should be no more than 30 Ohms.

Source: https://220.guru/electroprovodka/zazemlenie-molniezashhita/kontur-povtornogo-zazemleniya.html

Methods and methods for measuring indicators

There are several ways to check grounding. There are special instruments for measuring ground resistance parameters. Let's consider the main measurement methods using electrical equipment:

- current clamps;

- ammeter-voltmeter;

- specialized devices.

It is possible to measure resistance using current clamps. When using them, there is no need to disconnect the device itself and use additional electrodes. The process of how to measure grounding is quick and quite accurate. Let's look at the principle of operation of current clamps in more detail.

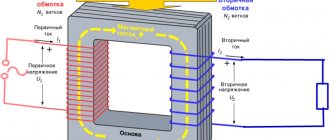

Alternating current passes through the secondary winding. To make the calculation, you need to divide the resulting value of the conductor EMF by the numerical determination of the current. When measuring at home, mites S.A 6412, S.A 6415, S.A 6410 are used.

Let's look at how to check the ground loop using an ammeter-voltmeter. You will need to assemble an electrical circuit. In it, the current will move through the ground electrode being tested and the additional electrode. It is necessary to add a potential electrode to the circuit. Its purpose is to detect voltage surges. The distance from the potential electrode to the current electrode and the ground electrode is the same, it is in the range of harmless potential and affects the grounding. To obtain the resistance value, you need to use Ohm's law to calculate using the formula R=U/I.

For testing and checking resistance parameters at home, a multifunctional multimeter will not be convenient. In this case, it is better to use the following resistance meters:

- ISZ-2016;

- MS-08;

- F4103-M1;

- M-416.

Let's look at how to measure grounding resistance using the M-416 device as an example in more detail.

Measurement techniques

Let's look at how to measure the resistance of a ground loop. The initial stage of all electrical checks will be preparatory work. These include the following operations:

- visual inspection of grounding devices for integrity;

- checking welds;

- measuring the distance from the building;

- inspection of fasteners;

- confirmation of the absence of current leaks from the busbars.

Checking grounding is a consistent and uncomplicated process. To carry out all of the above operations yourself at home, use a grounding and grounding resistance meter. All data that will be obtained during the measurement of grounding parameters must comply with the rules. All grounding data is regulated by the PUE standards.

Let's consider the grounding measurement step by step:

Checking the voltage. If it is missing, we install a group of nutrients (batteries, accumulators). It is necessary that they have dimensions of 1.5x3 and with the correct polarity ratio. The device must be picked up and placed on a flat horizontal surface. It is necessary to strictly ensure that all corners of the device are at the same level. This will be followed by a calibration procedure for the measuring apparatus. Find the range switch on the device toolbar. Set it to the “control” position. By pressing the red button, using the rotating knob, we set the display arrow to the zero position. In the case of measuring grounding with the M416 device, the scale at this stage will show 5 (with a deviation of “+” or “-” 0.3). If the data does not correspond to the standard, the device must be sent for repair. We choose a more convenient location and decide on the scheme according to which the device should operate. We make a calculation. If it is necessary to obtain enlarged data, we connect the first and second pins with a jumper. We switch the M416 device into a three-clamp circuit. If it is necessary to take measurements using a four-clamp circuit, we focus on the procedure presented on the device. We drive the umbrella rod and the electrode, which performs an auxiliary function, into the soil masses

It is important to consider that the minimum permissible penetration depth of the probe and electrode is 0.5 m. In the process of driving the probe into the ground, we make only smooth impacts, which will reduce the resistance of the grounding loop. Wires going to grounding must be thoroughly cleaned of various impurities, dust deposits and paints. It is best to use a file for these purposes, to which a cable with a cross-section of 2.5 mm2 is attached at the other end. When all of the above measures have been taken, the scheme has been determined, the location of the device has been corrected, and the calculation can begin. We fix the switch at the “x1” mark, rotate the knob and set the arrow to zero. The resulting value is multiplied by the corresponding number. For example, if the lever points to the “x10” mark, multiply the value by 10. The measurement results are entered into the grounding test report (it is also called the grounding test report).

For example, if the lever points to the “x10” mark, multiply the value by 10. The measurement results are entered into the grounding test report (it is also called the grounding test report).

Protective grounding

During the existence of the Soviet electric power industry, many electrical installations, plants, factories were built, and residential and public buildings were electrified.

To power them, a system called TN-C is used, which, in addition to three phases, uses a conductor previously called “ zero ”. Now, according to the new PUE, it is called PEN . It combines the functions of a protective and working conductor.

At transformer distribution substations, at inputs to buildings and at overhead line supports, ground loops .

TN-C grounding system

The main circuit for grounding the PEN conductor is the circuit at the substation, the rest are called “ repeated ”. The requirement for them is milder: if at a transformer substation at a voltage of 380 V the resistance of the grounding loop does not exceed 4 Ohms, then on the supports it is 30 Ohms, and the resistance of the re-grounding loop at the entrance to the building is not standardized.

Important

It is impossible to work in the production shops of enterprises without a grounding loop. It is necessary to connect the housings of all electrical devices with it: distribution boards, electric motors, as well as metal structures that support and mechanically protect cable lines.

To do this, a steel strip is attached along the perimeter of the building along the wall, to which the grounded equipment is connected with the same strips or flexible connections.

This strip is connected to the ground loop, and the zero (and now PEN) bus of the switchgear at the entrance to the building is connected to it.

Ground strip in a building

In fact, it turns out very similar to the TN-S , in which the functions of protective and working conductors are separated. The neutral conductors of the cables supplying electrical equipment are used to conduct working current, and in the event of a short circuit of the phase working conductors to the housing, a steel strip comes into play, diverting life-threatening potential to the ground.

Checking grounding in sockets

You can independently determine the grounding in an outlet in several ways. Before starting work, you will need an indicator screwdriver - it identifies the zero and phase wires. If the light comes on upon contact with the terminal, this is a phase. If the indicator does not light, it is zero.

Checking with a multimeter

Testing is carried out even if the colors match the standards. You need to work with a multimeter like this:

- Turn on the power supply to the house at the switchboard.

- Measure the voltage in the sockets. One probe is placed on phase, the second – on zero.

- Move the sensor probe from zero to the grounding conductor - PE.

- See what the tester shows. If the result has not changed, everything is fine with the system. If the readings are zero, the system needs to be grounded again.

Checking with a control light

To make a control, you will need a light bulb with a socket and two copper wires attached to it. Insulation is needed between all contacts of a homemade device. The control check is carried out according to the principle of a multimeter:

- The first probe is connected to zero, the second to phase.

- The probe moves from zero to the ground connection.

- The serviceability of the circuit is indicated by a lit lamp.

- A weak light indicates that the circuit is not working properly and that an RCD needs to be installed.

When there is wiring in the room without color indicators, you can find out the grounding like this:

- To determine zero and phase, one limit switch is output to the ground terminal, the second - in turn to other connections.

- The phase is at the point at which the indicator light comes on.

- If the lamp does not light, the PE does not work.

Indirect evidence of the absence of PE

There are several points by which one can judge the absence of PE. Owners of apartments and houses should be wary of:

- stable electric shocks from the boiler, washing machine, dishwasher, refrigerator;

- speaker noise when playing music;

- the presence of a large amount of dust near old batteries.

Testing with a pointer (digital) voltmeter

Checking the voltage value and its presence is carried out using AC voltmeters. Pointer instruments operate without a power source, while digital instruments operate in any position and are not damaged by mechanical impact.

The correct algorithm for using a voltmeter:

- The maximum permissible measurement value for the device is determined by the largest number on the scale.

- Clarification of the units of measurement of the device - microvolts, volts, millivolts.

- Connecting a voltmeter in parallel to a section of the electrical network and checking the polarity with a wire.

- Screwing the switch device wires to nuts and screws. Constant voltage models have plus and minus designations.

What does grounding resistance depend on?

As mentioned above, current has one important feature - it flows through that part of the circuit that least resists it. The resistance value itself depends on many factors:

- Material. A number of materials have a special (atomic) structure, which implies the presence of a large number of free electrons. If such materials are exposed to any magnetic field or connected to a power source, they easily conduct electric current. For the most part, this statement applies to metals. Other materials have no free electrons and their resistance to current is extremely high. If the voltage (the force “pushing” the electrons) is below the permissible value, then the conductivity will be zero or extremely small values. If the indicator is exceeded, a breakdown will occur and the resulting deposit will have the properties of a conductor. It is logical that only representatives of the first group of materials can be grounding materials - it is this group that provides the minimum resistance.

- His temperature. Temperature determines how quickly electrons move within a material. Therefore, the lower it is for a conductor, the better it conducts charge. The inverse dependence is also in the nature of a direct proportion - after its increase, its resistance will fall. The calculation of grounding resistance must be made taking this parameter into account.

- Presence of impurities. The main part of the conductors is made of copper. Old wires were made of aluminum, but such solutions have several disadvantages. Unfortunately, cables and wires made of this material overheat and melt faster, and the resistance of industrially mined aluminum is lower than that of copper. Chemically pure metal is the best conductor, surpassing even silver in conductivity. The thing is with impurities: they have much higher resistance values. The same point should be taken into account when calculating grounding.

It is clear that ideally the resistance should be minimal - for this you need to use a copper circuit with a large cross-section. But the fact is that copper oxidizes quickly, and the cost of such a solution will be extremely high. Consequently, standards have been developed for the minimum grounding threshold. This indicator does not need to be exceeded so that at the right moment under load the circuit fulfills its assigned function and discharges the charge to the ground.

Registration of measurement results (protocol).

After completing the measurements, you need to draw up a protocol of the measurement results. The protocol is a form of a certain form, which reflects the name of the object, the installation diagram of grounding rods and their connections (for this you will need a passport of the object and an act for hidden work). The protocol should also reflect the ground loop diagram and the method by which the measurement was carried out. The protocol must include a column indicating the device or tester (its type, serial number, etc.) with which the test was carried out. The results obtained during the measurement are entered into the grounding device passport. The transient resistance test report is presented separately. Transition resistance (also called metal bonding) is the possible losses along the current path associated with welding, bolting and other connections of the entire ground loop. This test is carried out with a special tester - a microohmmeter.