How to determine engine speed without a tachometer

The fact is that I installed an on-board computer (like here https://transit-club.com/forum/19-1853-42771-16-1265618457) and set the shaft ratio to 2.22, as many in that thread advised.

So, in this situation, the BC tachometer gives 420 rpm at idle, which is ungodly low (according to the book it should be at least eight hundred). So I want to check somehow - either my shaft ratio is somehow different, so he’s stupidly lying, or there’s really something wrong with my speed. In general, I ask for help and advice)

ps hmm, judging by the discussions on the Internet, a multimeter will not help here at all. (

Having figured out that if everyone has a shaft ratio of 2.22, everything is showing correctly, I decided that the problem was still in my revolutions. Having scoured the forum, I came across a message from Vova about adjusting the injection pump (https://www.transit-club.com/forum/28-2475-1) and at one in the morning I went to tighten the nuts. I raised the idle speed to 650, it froze completely - I’ll continue tomorrow. BUT! I did a control circle around the block and I can say that this is, damn it, NOT MY CAR

The difference in dynamics is so noticeable that I still have a smile from ear to ear) Tomorrow the first thing I’ll do is raise the revs to the book’s eight hundred speed limit) 2.5 Disel, 1997 onwards, short, low, van.

Electrician's online magazine

Typical characteristics for installation dimensions

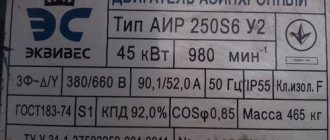

Industrial engines produced in the USSR, like most modern ones, were produced according to state standards and have an established conformity table. Based on this, you can measure the height of the center of the shaft relative to the landing plane, its front and rear diameters, as well as the dimensions of the mounting holes. In most cases, this data will be enough to find the desired engine in the table and not only determine the rotation speed, but also establish its electrical and useful power.

What does the converter provide?

The need to use an electric motor speed controller in the case of asynchronous models is as follows:

Significant savings in electrical energy are achieved. Since not all equipment requires high rotation speeds of the motor shaft, it makes sense to reduce it by a quarter.

Reliable protection of all mechanisms is provided. The frequency converter allows you to control not only temperature, but also pressure and other system parameters. This fact is especially important if a pump is driven by a motor.

A pressure sensor is installed in the container and sends a signal when the required level is reached, causing the motor to stop.

A soft start is performed. Thanks to the regulator, the need to use additional electronic devices is eliminated. The frequency converter is easy to set up and get the desired effect.

Maintenance costs are reduced because the regulator minimizes the risk of damage to the drive and other mechanisms.

Thus, electric motors with speed control turn out to be reliable devices with a wide range of applications.

It is important to remember that the operation of any equipment based on an electric motor will only be correct and safe when the rotation speed parameter is adequate to the conditions of use.

Operating principle of electric tachometers

Electric tachometers use electrical signals or individual pulses to measure. Electrical signals proportional to the crankshaft speed in a gasoline engine are generated by the ignition system and an electric generator, and in a gasoline engine only by the generator. The necessary signal can also be received from the electronic engine control unit.

The simplest way to operate is a tachometer connected to an electric generator. The generator is driven from the crankshaft via a V-belt drive, so the generator rotor speed is always proportional to engine speed. And the magnitude of the EMF generated on the winding depends on the rotation speed of the generator rotor, which is used to connect an electric machine tachometer. In essence, the device is a voltmeter that measures the voltage on the generator and converts it into crankshaft speed readings. The tachometer is connected to the generator through a special connector, which requires adjustment of the device to the specific generator.

The operation of the electronic tachometer connected to the ignition system is a little more complex. The ignition system generates current pulses necessary to produce a spark in the spark plugs. In this case, the frequency of sparking is directly related to the frequency of rotation of the crankshaft - otherwise the fuel-air mixture in the cylinders would not be ignited in time. The frequency of sparking depends on the number of engine cylinders and the order of their operation. In four-cylinder engines, the ignition system generates two sparks per revolution of the crankshaft - one spark for every 180°. It is this circumstance that is used to operate electronic tachometers - the measuring unit measures the sparking frequency and converts it into engine speed readings. An electronic tachometer is connected to the primary (low-voltage) circuit of the ignition system and measures the number of pulses per unit of time, which is why this type of device is often called pulse.

Types and types of tachometers

Tachometers used in transport are divided into several types according to the principle of operation, the method of signal processing and indication, the method of connection and applicability.

According to the principle of operation and method of connection, tachometers are:

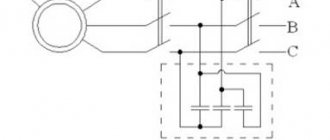

Connecting an electronic tachometer to a contactless ignition system

Connecting an electronic tachometer to a contact ignition system

According to the method of signal processing, tachometers are either analog or digital.

According to their applicability, tachometers are divided into several groups:

As a rule, tachometers are manufactured for use on certain brands and models of cars, tractors and other equipment; some devices can be used on various vehicles equipped with the same engines, ignition systems, etc.

Fur and without a tachometer, 90 km engine speed.

Some believe that accurate information about engine speed. Silver teaspoons. Anyone interested in the design of internal combustion engines will quickly find out. I can’t say anything about mechanics; I had a Japanese one with fur and without a tachometer, but if this connector is there, I think it will work. Find the same car with normal speeds, and set yourself to approximately the same speed by ear. How about a multimeter with a frequency measurement function? It measures very accurately, just don’t forget to change the Hertz to the revolutions per minute. Archive of how to determine engine speed without a tachometer engine engine determination of engine speed in avlepsheshekov without a tachometer. Determination of engine speed in avlepeshekoby without a tachometer. And more precisely, how to calculate for UAZ? For example, a 4-speed gear is fully synchronized, not synchronized. I would like to know how to determine engine speed if the car does not have a tachometer. The motor is not familiar to me yet, so I can’t tell by the sound. What other ways are there? How to measure electric motor speed? Together with how to determine the speed of an asynchronous motor without a tachometer, people often look for a diagram of the speed controller of an asynchronous motor on a microcontroller; a diagram of an electronic tachometer for a boat motor; show a diagram for connecting a tachometer to a Ural motorcycle. How to find out engine speed without a tachometer? I propose a method for measuring the rotation speed of an unknown asynchronous electric motor. You can easily assemble such a strobe yourself; you will need a light source with low inertia: LEDs, neon lamps. How to find out engine speed without a tachometer? How to make a pulley out of nothing - master class from dad.

How to find out engine speed without a tachometer?

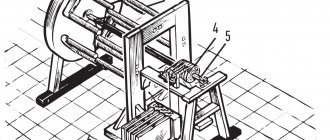

I propose a method for measuring the rotation speed of an unknown asynchronous electric motor

Measuring engine speed at home

Engine speed measurement

at home.

Operating principle of magnetic tachometers

The operation of a magnetic tachometer is based on the phenomenon of induction of eddy currents (Foucault currents) in a non-magnetic disk by a rotating constant field. In its normal state, an aluminum or copper disk does not have magnetic properties, but if you place it in a rotating magnetic field, eddy currents arise in it. These currents interact with the magnetic field, so the non-magnetic disk also begins to rotate after the magnet.

To operate the tachometer, an arrow is attached to the disk, on the shaft of which a return spring is attached. The magnet is connected to the crankshaft or one of the transmission shafts via a flexible shaft. The higher the engine speed, the faster the magnet rotates, and the higher the force deflecting the non-magnetic disk fixed by the spring - all this is reflected in the position of the arrow.

Using a strobe effect detector

If the engine is in use, you can avoid having to uncouple it from the actuator and remove the rear casing just to get to the alignment hole. The exact number of revolutions in these cases can also be measured using a strobe detector. To do this, a longitudinal white mark is applied to the motor shaft and a light catcher of the device is installed opposite it. When you turn on the engine, the device will determine the exact number of revolutions per minute based on the frequency of the appearance of a white spot. This method is used, as a rule, for diagnostic examination of powerful electrical machines and the dependence of rotation speed on the applied load.

Functions and equipment of the car tester

Modern digital multimeters allow you to measure most parameters of a car's electrical network:

- Voltage (including at the battery, generator, ignition coil, etc.);

- Current strength;

- Resistance;

- Duration of electrical pulses (for the ignition system);

- Angle of closed state of distributor contacts (for carburetor engines);

- Engine speed;

- Temperature (using thermocouple).

The multimeter can also be used as a simple tester for various types of tests:

- Checking diodes;

- Checking fuses and other parts;

- Checking the integrity and quality of electrical connections;

- Search for wire breaks.

All measurements can be carried out only with certain sensors or probes that come with the device:

- Conventional probes for measuring voltage, current, resistance and continuity of circuits;

- Alligator clips for the same measurements;

- Thermocouple for temperature measurement;

- Clamps for non-contact measurements (for high-voltage ignition circuits);

- Adapters for testing fuses, diodes, etc.

In general, a multimeter is a universal device that replaces many other devices and allows you to carry out simple diagnostics of the car’s electrical system and identify faults without visiting a car service center.

The warm season, especially spring and summer, is the season for cycling, nature walks and family holidays. In the AvtoALL.RU online store you will find everything to make your vacation enjoyable and useful.

The May holidays are the first truly warm weekend, which can be usefully spent outdoors with family and close friends! The range of products from the AvtoALL online store will help you make your outdoor leisure time as comfortable as possible.

It's hard to find a child who doesn't like active play outside, and every child has dreamed of one thing since childhood - a bicycle. Choosing children's bicycles is a responsible task, the solution of which determines the joy and health of the child. Types, features and selection of a children's bicycle is the topic of this article.

The warm season, especially spring and summer, is the season for cycling, nature walks and family holidays. But the bike will be comfortable and bring pleasure only if it is chosen correctly. Read the article about the choice and features of buying a bicycle for adults (men and women).

Swedish Husqvarna tools are known all over the world and are a symbol of true quality and reliability. Among other things, chainsaws are also produced under this brand - read all about Husqvarna saws, their current model range, features and characteristics, as well as the issue of choice in this article.

Heaters and pre-heaters from the German company Eberspächer are world-famous devices that increase the comfort and safety of winter operation of equipment. Read the article about the products of this brand, their types and main characteristics, as well as the selection of heaters and preheaters.

Many adults do not like winter, considering it a cold, depressing time of year. However, children have a completely different opinion. For them, winter is an opportunity to roll around in the snow, ride the slides, i.e. have fun. And one of the best helpers for children in their non-boring pastime is, for example, all kinds of sleds. The range of children's sleds on the market is very extensive. Let's look at some types of them.

So gentlemen parasites

There is a motorcycle MT-10-36 Single In relatives

I bought a multimeter on the market for 15 years with the ability to measure rotational speed, although within the range of 2 - 20 kHz

In the course of reflection and climbing the forum threads and also because of the natural bear ear, it was decided to adjust the carburetors using a tester

Yesterday I came to the garage Started the motorcycle I must say it started from the first kick although it sat all winter Warmed up the engine and drove around the garages a bit

Then I decided to look at the speed using a tester. I connected one wire to ground and the second to the low-voltage wire of the ignition coil that comes from the breaker.

As a result, at idle I got 0.120-0.100 with the multimeter knob positioned at 2 kHz

It turns out that the slider rotates with a frequency of 100-120 Hz. Now the next task arises

How to convert Hz to crankshaft revolutions per minute?

Google gave: rpm = Hz * 60