Manual machine for bending reinforcement, how to make it yourself: photo drawings

and no serious construction project today can be completed without the use of such an important element as reinforcement

, which is largely responsible for the load-bearing characteristics of structures. That is why bending of reinforcement must be carried out professionally and in compliance with all generally accepted requirements.

Reinforcement bending - process features

At any construction site today you can see various equipment, many tools and devices, and almost every one of them has a machine for bending reinforcement.

This is no coincidence: the most effective technology for strengthening fragile concrete structures, protecting them from destructive loads in compression, tension and bending, is reinforcement, which is performed using metal rods - reinforcement.

Without a high-quality reinforcement frame, it is almost impossible to build reliable concrete walls and foundations.

It would seem much easier to reinforce corner concrete structures and adjacent wall areas using straight reinforcing bars. However, in this case, the concrete structure will be greatly weakened and may delaminate. In addition, this is a gross violation of building codes.

In any corner concrete structures it is necessary to use only bending, with an overlap of at least 80 cm on each side.

A machine or a simple device for bending metal rods is also useful if you need to quickly produce various types of connecting elements - hooks, claws, etc.

When bending steel bars used for reinforcement, it is very important to know how to bend foundation reinforcement so that it does not lose its strength characteristics.

To comply with this requirement, it is necessary to perform such an operation only mechanically, using special machines for cutting and bending reinforcement. In this case, it is important to ensure that the bend angle is not sharp, and that the radius of curvature at the bend is from 10 to 15 diameters of the rod itself.

It should be remembered that a steel reinforcing bar bends without losing its strength characteristics up to an angle of 90 degrees, then the strength indicators begin to decrease.

When bending steel reinforcing bars with your own hands, two mistakes are often made:

- a notch is made at the bend site using a grinder or other tool;

- The section of the reinforcement where the bend will be located is heated using a gas burner or blowtorch.

After such procedures are completed, some primitive means for bending is used: a heavy hammer, a sledgehammer, a piece of pipe, a vice, etc.

These bending methods lead to a significant weakening of the reinforcement, which can cause destruction of concrete structures.

In such cases, you should always remember that you need to bend the reinforcing bars without violating their integrity and only if they are in a cold state.

In general, everything here is expensive and serious - full automation and many settings. For home craftsmen, this video is provided for informational purposes only. Since spending 130-180 thousand rubles on such a unit for non-professional use does not make any sense.

Machines and devices for bending reinforcement

In the process of development of construction technologies and metal processing methods, more than one machine for bending reinforcement was created. All such equipment works on the same principle; the difference between the models consists only in certain design features and the maximum diameter of the bending rod.

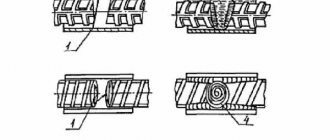

Any bending machine, including a homemade machine for bending reinforcement, works on the following principle: the rod is fixed between two rollers (central and thrust), and with the help of a third roller (bending), the reinforcement is bent at the required angle. Conveniently, the machine for bending metal reinforcement can bend a rod both to the left and to the right. The required bending radius is ensured by the thrust shaft, thanks to which the reinforcement does not deform along its entire length.

Machines designed for bending reinforcement, including those made by yourself, can be of two types:

- manual;

- with mechanical drive.

The main working element of mechanically driven machines is a rotating disk on which the bending and central fingers are fixed.

There is a gap between these fingers, into which the rod to be bent is placed. The reinforcement placed in this gap rests at one end against a roller rigidly fixed to the device body.

As the disc rotates, the bending pin acts on the reinforcement and bends it around the central shaft.

A specific machine for bending reinforcement, depending on its purpose, may belong to one of the following groups:

- light (for bending rods with a diameter of 3 to 20 mm);

- heavy (diameter of processed rods - from 20 to 40 mm);

- extra heavy (for fittings with a diameter of 40 to 90 mm).

Power driven equipment can be used to bend multiple rebar bars at the same time. Modern industry produces machines that can be used for bending rods whose diameter ranges from 3 to 90 mm.

For those cases where it is necessary to bend reinforcement at different angles, it is best to use hydraulically driven equipment. Such a universal machine for bending reinforcement allows you to obtain a bending surface without cracks and folds, which can lead to the formation of internal stresses.

This equipment also makes it possible to adjust the bending angle to 180 degrees.

On the modern market, you can optimally select a machine for bending various types of reinforcement, including portable ones, which are easy to use and affordable.

Bending of reinforcement can be done either using special equipment or using a pipe bender, which is installed on ordinary workbenches.

You can make such bending devices yourself.

However, they are used for bars with a diameter of no more than 14 mm and are not intended for cases where high productivity is required. Most often, such devices are used in private construction.

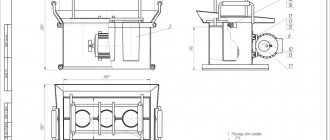

Design of a homemade bending machine

A manual machine for bending reinforcement is quite simple in its design, so you can make it yourself, but for this it is advisable to find drawings of such a device. The basis of such a machine, specially designed for bending reinforcement with your own hands, is a metal frame, to which a round pin or an ordinary corner is welded.

This sample is similar to the previous one, but here one corner is used and is much shorter, and instead of the second corner a movable pin is used

The second element of this device is the rotating platform. A lever, central and bending pins are welded to it.

The distance that should be maintained between the central and bending pins depends on the maximum diameter of the reinforcement used for bending.

In order for such a manual device for bending metal reinforcement to be used for rods with a diameter of 6–12 mm, the legs of its frame must be securely fixed to the floor.

If you need a portable homemade machine for high-quality bending of reinforcement, then all its elements are fixed on a massive plate.

Such a portable plate can be attached to the work site using bolted joints or special pins welded to its lower part.

However, a homemade manual bending machine for reinforcement can only be used to work with metal rods whose diameter does not exceed 10 mm.

Another design option for the machine: a slot in the central element, which is also the axis of rotation of the lever, allows you to fix the reinforcement

How to bend reinforcement without a special device

There are often cases when it is not possible to use machines for bending metal reinforcement, even homemade ones, but it is necessary to bend the reinforcement.

In all such situations, it should be remembered that any attempt to bend a metal bar with your own hands can lead to serious injury. When bending in this way, the reinforcement can spring back and cause serious harm to your health.

Quick option. The main thing is to have something to make cuts in the channel

With good physical preparation, bending reinforcement with your own hands can be done without using a machine, if its diameter does not exceed 8 mm. However, you should be prepared for the fact that the bend radius will be too large, and such bent reinforcement will not meet all the requirements that are placed on it.

A homemade device consisting of two steel pipes, with the help of which you can even bend large-diameter rods at home, can significantly improve the result. The diameter of bendable fittings can be increased by using longer pipes.

The scheme by which such a homemade reinforcement bender works is quite simple: one end of the reinforcement is fixed in one pipe, and the second pipe is put on the free end of the rod. In order to bend the rod, you need to step on one of the pipes, and lift the second one, together with the end of the fittings that are in it, up.

For more reliable fastening, one of the pipes with fittings can be clamped in a vice, dug into the ground, or even concreted.

Source of information website: https://metallprokat93.ru/

Types of equipment

Two types are available:

- Mechanical devices.

- Electrically driven devices.

The manual bending machine and drive apparatus are designed to give the reinforcement the required configuration for subsequent use in reinforced concrete work.

The operation scheme of both types of devices is the same: the part is rigidly fixed between the central and thrust shaft. The latter prevents the workpiece from turning or moving. Deformation to the desired angle is carried out using a third, bending roller. Rounding is carried out in any direction - clockwise and counterclockwise.

If a manual unit operates at an angle of no more than 90°, less often up to 110°, then an electric bending machine for reinforcement allows adjustment in the range from 5° to 180°, while the loss of metal strength parameters at extreme bending values does not exceed 10%.

The equipment is characterized by the following features:

1. The simplest design. In essence, this is a standard pipe bender used for small diameter fittings - up to 12 mm, less often up to 20.

2. Relatively light weight - on average about 15-25 kg.

3. Mobility. It belongs to the category of portable equipment and is installed on any flat base or workbench.

4. Reasonable price. A new device will be available for purchase at a price of 5,000 rubles, the cost of used products is approximately 1.5-3 times cheaper (depending on the degree of wear).

5. Possibility of assembling a homemade machine.

The design of manual equipment is simple - a lever and several shafts; with a little skill, it’s not difficult to make it yourself. To do this, you need to weld a round pin or corner to a metal base (frame, plate), which will act as a stop. Then a rotating steel platform is manufactured, which is equipped with a lever, a central shaft and a bending shaft. The distance between the elements is calculated in advance and depends on the diameter of the reinforcing bars. The legs of the structure must be firmly attached to the floor, otherwise the device will not allow working with rods with a diameter of 8-12 mm.

A unit welded onto a stove can be classified as a portable option. For it, it is necessary to provide methods of fastening. For example, these could be holes for bolts for subsequent screwing to the base.

An electrically driven machine for bending reinforcement is used in the serial production of bent products. This type of installation is characterized by:

1. High performance. The operation takes no more than 10 seconds.

2. Work with rolled products of any diameter. Machines are produced for light reinforcement with a cross-section of up to 20 mm, heavy reinforcement – 22-40, extra-heavy – 40-80.

3. Electric drive power – up to 5 kW.

4. Availability of an automatic control system. Operator participation is minimal and involves several levels of protection. Some models are equipped with a mixed control unit, so the unit can operate in both manual and automatic mode.

5. Stationarity. The bending machine is installed on a flat, dry, rigidly fixed platform and is strictly centered. Frequent movements are not encouraged.

6. Decent weight – reaches 400 kg.

7. High price - starts from 85,000 rubles and above. Used devices can be rented with a daily (from 1000 rubles) or monthly payment (from 25,000) with the obligatory payment of a deposit.

Do-it-yourself device for bending reinforcement

ipmet.ru » Do-it-yourself » Do-it-yourself reinforcement bending machine » A device (manual machine) for do-it-yourself reinforcement bending

The principle of operation of all designs of manual devices for bending metal (sometimes called manual machines) is the same: a “lever of the first kind” is used. If you have:

- the desire (initiated by need) to create a bending device for reinforcement;

- plumbing skills;

- necessary tools (including a bench with a vice)

- then you have come to the right place. With our hint, you can create a device (manual machine) for bending reinforcement with your own hands. The device of the proposed design can bend steel reinforcement with a diameter of ≤ Ø 15 mm .

What tool will you need?

In addition to a set of plumbing tools, which every skilled owner has for performing “work around the house and in the country,” you will need:

Description of the bending device

The bending device consists of two parts:

- motionless. It's called the base;

- mobile. It's called a lever.

The processed rod is placed between the mandrels and is deformed under the influence of a pin installed on the lever. The amount of force is determined by the length of the lever handle (usually about 500 mm long) and the physical capabilities of the mechanic. If necessary, provision should be made for extending the handle (for example, with a hollow pipe).

Manufacturing technology of fixtures for bending reinforcement

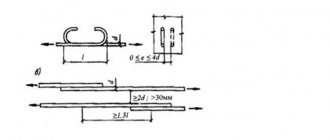

It is necessary to prepare 3 mandrels Ø 20 mm and a pin Ø 25 mm, 50 mm long each (see drawings). The lever should fit freely onto the pin. This is achieved by processing a size of Ø 25 mm on the pin using an abrasive machine.

Base

For the base, we cut out a steel plate with a thickness of ≥ 10 mm (see plate drawing below). Drill holes on it:

- Ø 20 mm for mandrel;

- Ø 25 mm for pin.

The basis of the bending device.

If you are the happy owner of a durable and strong workbench, you can drill 4 holes Ø 8...10 mm (indicated Ø 8 mm in the drawing) in the base to attach the fixture to it.

If the strength of the workbench is in doubt, then the base should be welded to a corner 100 x 100 (mm) with a length of 1000 mm and the above holes should be drilled in the corner for fastening.

Insert a mandrel and a pin into the drilled holes Ø 20 mm and Ø 25 mm (as shown in the drawing) and weld.

Lever arm

For the lever, we cut out a steel plate with a thickness of ≥ 10 mm (see plate drawing below). Drill holes on it:

- Ø 20 mm for mandrel;

- Ø 25 mm for pin.

Bending device lever.

We weld a mandrel and a handle Ø 20 mm and length 550 mm to the lever. To prevent industrial injuries, you can put some kind of protection on the end of the handle (for example, a plastic champagne cork).

Conclusion

After all work has been completed, the welding area should be cleaned from welding slag with a carriage brush. All sharp edges should be “filled” using a fine file.

The device will be used outdoors, and therefore an anti-corrosion coating should be provided - in this case, pentaphthalic paint of the "PF" type is sufficient (just do not forget to prepare the surface - clean it with an appropriate solvent).

At the junction of the lever with the pin, the surfaces should be lubricated with any grease (solidol, autol, grease, etc.). The condition of this unit should be constantly monitored and lubricated (this will greatly facilitate your work and extend the “life” of the device).

Operating rules

The principle of operation of this device is extremely simple - it is easy to understand if you look at the photograph. Simple safety rules should be followed:

You should not process steel reinforcement with a diameter ≥ Ø 15 mm; before starting work, you should check the technical condition of the device. If the fastenings of the mandrels or pins are loose, it is necessary to carry out repairs and only then begin work;

the workplace should be freed from all unnecessary things.

The video shows how it works, the machine is a little different, but the essence is clear.

Compliance with these simple requirements will save your health.

;

Website: https://mosmonolit.rf/;

Address: 117997, Moscow, st. Obrucheva, house No. 21;

Phones: +7-(495)-647-92-71, +7-(495)- 647-69-81;

The company sells a manual machine for bending reinforcement with a diameter of up to 16 mm. Cost: 3999.00 rubles.

Reinforcement bender: how to do it yourself

› Locksmith tool

When building a house at several stages of construction, the use of reinforcement is required:

- When laying the foundation;

- When constructing floors;

- When installing an armored belt.

The reinforcement is delivered to the construction site in the form of straight concrete rods, and in order to lay it around the perimeter of the house, it will need to be bent in some places. Incorrect bending of reinforcement (with undercuts, heating of bending points) can lead to a decrease in strength characteristics. For “correct” bending, special tools are used - reinforcement benders.

Scope of application of rebar bending machines

Bending machines are available with manual or electric drive. The former are more often used to simplify construction work and to solve everyday problems:

- For bending reinforcement directly on the construction site during the construction of buildings and structures at the stage of reinforcement of reinforced concrete structures;

- For the manufacture of individual reinforced concrete products;

- For the manufacture of frames, frames, fastenings;

- For the production of machine parts and mechanisms.

Electrically driven machines are used in the mass production of metal and reinforced concrete products.

Equipment Features

Manual benders are available in three different designs:

- Based on a simple lever - in this system, the longer the lever, the less bending force needs to be applied.

- Static, which serve to securely fix the rod. With such bending machines you need to use additional devices - keys.

- On a lever system - thanks to a system of several levers, they allow you to bend reinforcement with a diameter of up to 16 mm at any angle on your own.

Electric benders operate on an electric motor and do not require operator effort to perform bending operations - the operator only needs to control the machine using a foot pedal. There are electric CNC machines.

The principle of bending reinforcement

The principle of operation of the bending machine is based on the fact that the reinforcement is firmly fixed (one or two ends) and, when pressed by the operator, reinforced by a lever or a system of levers, it is bent at the desired angle.

According to building codes, the bend angle of the rod must be such that the concrete in the finished reinforced concrete product is not damaged or crumbled at the bend site.

The bending of the rod along a notch or under the influence of elevated temperature is not allowed - this will reduce the strength characteristics of the rod, and, as a consequence, the future structure. Reinforcement can only be bent “cold”.

The simplest bending machine consists of two angles connected by a bolt. In the simplest, but not the most reliable, version, they don’t even need to be welded together.

Performing a bend

When bending, you must comply with construction regulations for a specific type of reinforcement: for example, the permissible bend angle A-III is 90 degrees, provided that the bend radius is not less than 6-8 rod diameters. If the reinforcing bar is bent by 180%, the strength will decrease by 10%.

How to make a device for bending reinforcement

Small diameter rods can be bent using simple tools. To make frames and clamps from 6-8 mm rods, you can use a wooden support (piece of log) and three pieces of reinforcement as stops.

Two rods are driven into the support along one axis, one between them - at a distance from the axis equal to the diameter of the reinforcement being bent.

Thin reinforcement can also be bent on a corner with a lower stop, welded to any vertical surface (wall, pole).

Sequencing

- Make the base of the machine (bed). The larger the diameter of the rods that are planned to be bent on the tool, the more securely the machine should be fixed to the floor.

- Weld a metal plate with a pre-welded axial pin or angle on which the reinforcing bar will rest on the frame.

- Build a rotating platform. A lever (you can use a piece of pipe as a lever) and central and bending pins (stops) around which the reinforcement will bend are mounted on the platform.

The distance between the stops is selected based on the maximum size of the bending reinforcement.

Drawings of a homemade reinforcement bender are shown in the figure below:

Homemade vs factory made

As you can see from the article, making a homemade machine is quite simple and cheap. However, factory-made manual reinforcement benders are not much more expensive than homemade ones and have better build quality than homemade ones. It makes sense for someone who already has experience in making homemade tools to undertake the manufacture of a homemade machine.

Advantages of manual benders

Manual benders are often used in both professional and domestic spheres because:

- serve to simplify and speed up construction work;

- at the same time they are easy to use;

- they are portable and light in weight;

- despite their portable design, they can work with large volumes,

- do not require additional maintenance or repair;

- If they are factory-made, they rarely break and last a long time.

Reinforcement bender: how to make it yourself Link to main publication

How to make a device for bending reinforcement

Small diameter rods can be bent using simple tools. To make frames and clamps from 6-8 mm rods, you can use a wooden support (piece of log) and three pieces of reinforcement as stops. Two rods are driven into the support along one axis, one between them - at a distance from the axis equal to the diameter of the reinforcement being bent. Thin reinforcement can also be bent on a corner with a lower stop, welded to any vertical surface (wall, pole).

Design of a homemade bending machine

A homemade bending machine is a more complex and more reliable device. A do-it-yourself reinforcement bender is made from a metal plate no less than 6-8 mm thick and reinforcing bars and angles.

Sequencing

- Make the base of the machine (bed). The larger the diameter of the rods that are planned to be bent on the tool, the more securely the machine should be fixed to the floor.

- Weld a metal plate with a pre-welded axial pin or angle on which the reinforcing bar will rest on the frame.

- Build a rotating platform. A lever (you can use a piece of pipe as a lever) and central and bending pins (stops) around which the reinforcement will bend are mounted on the platform.

The distance between the stops is selected based on the maximum size of the bending reinforcement. Drawings of a homemade reinforcement bender are shown in the figure below:

Homemade vs factory made

As you can see from the article, making a homemade machine is quite simple and cheap. However, factory-made manual reinforcement benders are not much more expensive than homemade ones and have better build quality than homemade ones. It makes sense for someone who already has experience in making homemade tools to undertake the manufacture of a homemade machine.

Do-it-yourself reinforcement bending machine: drawings, video – Metal Profi

A simple homemade bending machine for reinforcement and rods, a detailed description of manufacturing with step-by-step photos.

Greetings to all DIY lovers! Today we will look at making a homemade manual machine for bending reinforcement and rods. With the help of such a device, you can bend various products, including decorative ones for the manufacture of gates, wickets, gratings and other things.

The homemade machine is made on the basis of a large bearing, around which the entire structure revolves.

Materials used:

- - large bearing;

- — profile pipes;

- — fittings;

- — round pipe (for the bearing cage);

- - a piece of durable steel (a piece of spring will do);

- — two bearings, a bolt, a nut (for the roller);

- - a piece of round pipe of small diameter (for a bolt).

The manufacturing process of the machine is shown in the photo:

We start by making a cage to match the diameter of the bearing. As a holder, the author used a piece of pipe with a slightly larger diameter than the diameter of the bearing. To reduce the diameter of the holder, simply cut out a piece of metal from the pipe, and then bend the pipe with a hammer and weld the joint.

As planned, a square profile pipe should go into the center of the bearing; it is made removable so that different attachments can be installed on the machine. As a result, we need to make a square hole in the center of the bearing; to solve the problem, the author used two pieces of angle iron.

We simply grind the corner so that it fits into the hole, and then firmly weld the corner to the inside of the bearing. Before welding, the author removed the protective plastic rings to prevent them from melting. Finally, lubricate the bearing with grease and put the rings in place.

We weld a lever to the holder, or rather a piece of pipe into which the long lever will be installed. We also weld pieces of a round pipe to this piece of profile pipe; a thrust bolt will be installed in them, so it will be possible to adjust the desired bending radius.

We make a stop into which the end of the bent rod or reinforcement will go. The emphasis must be strong, there will be heavy loads. The author welded profile pipes as an axis, and the support itself was made of springs. The spring steel chosen is excellent and springs back under heavy loads. The manufactured axle will eventually be clamped in a vice.

- The author welded the lever for the machine from reinforcement; it must be long and strong, so a minimum amount of force is required to bend the reinforcement.

As for the roller, for such purposes the author has adapted two small radial bearings, and a bolt with a nut acts as an axis. The machine easily bends fairly thick reinforcement, which is not so easy to bend using other methods.

Using a bending machine, you can bend a steel rod into a spiral; we use a piece of square pipe as an axis, and the end of the rod is inserted into the hole in the pipe. As a stop, you can use not a roller, but a piece of steel pipe; a pin from a car’s piston system is perfect.

- Additionally, you can make a device for cold forging - a “snail”.

- With the help of such a simple device, you can easily bend reinforcement, rods, and make cold forging elements.

- In this video you can see a bending machine in operation:

Author of the homemade product: Igor Andreychuk.

DIY devices for bending reinforcement

You can also bend foundation reinforcement with hand-made devices; there are several options for this. One of the most effective methods to solve this problem is actually very simple. You need to dig a pipe into the ground or concrete it.

The pipe should be small in diameter and naturally hollow. The fittings are lowered into the pipe to the required length, and the part that remains outside is bent to the side. The more suitable the diameter of the pipe, the more reliable the fixation of the reinforcing rod will be. To bend the reinforcement to the desired angle, it is enough to apply a little effort; you may need helpers. To simplify the process, you can use a second pipe, placing it on top of the rod.

There is a slightly different variation of this method, which is also convenient to use when laying a foundation, since there is always a place for this on a construction site. You won’t have to search for the necessary materials for a long time either. To make this device you will need the following materials.

- Two steel pipes, their diameter directly depends on the cross-section of the reinforcement, which should be smaller. It is also worth noting that the longer the pipes are, the less physical effort you will have to use to bend the reinforcement.

- Two pins.

The pins are firmly dug into the ground, steel pipes are put on the reinforcement at both ends. The buried pins will serve as a support for you; leaning on them and connecting the pipes, you can easily bend the reinforcement to the desired curvature. Of course, you can use something else instead of pins; you will probably find what you need among the building materials.