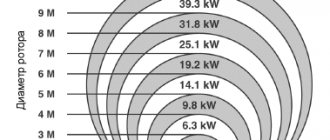

The production of electric current using a wind generator directly depends on its size. The larger the magnets, coils and other elements, the more powerful the current created by them will be. Contrary to the prevailing opinion about the invincibility of hydroelectric power stations in our country, Western engineers demonstrate high wind turbine efficiency, which are much more common in Europe and the USA. The development of powerful devices has been going on for quite some time, and considerable success has been achieved. Let's look at the most noticeable of them.

What is the largest wind generator?

The largest wind generator in the world today is considered to be the brainchild of German engineers from Hamburg Enercon E-126. The first turbine was launched in Germany in 2007, near Emden. The power of the wind turbine was 6 MW, which was the maximum at that time, but already in 2009 a partial reconstruction was carried out, as a result of which the power increased to 7.58 MW, which made the turbine a world leader.

This achievement was very significant and placed wind energy among the full-fledged leaders in the world. The attitude towards it has changed, from the category of rather timid attempts to obtain serious results, the industry has moved into the category of large energy producers, forcing one to calculate the economic effect and prospects of wind energy in the near future.

The palm was taken by MHI Vestas Offshore Wind, whose turbines have a stated power of 9 MW. The installation of the first such turbine was completed at the end of 2021 with an operating power of 8 MW, but already in 2021, 24-hour operation was recorded at a power of 9 MW obtained from the Vestas V-164 turbine.

Such wind turbines are truly colossal in size and are installed, most often, on the shelf of the western coast of Europe and in the UK, although there are some examples in the Baltic Sea. Combined into a system, such wind generators create a total power of 400-500 MW, representing significant competition to hydroelectric power plants.

The installation of such turbines is carried out in places with a predominance of fairly strong and even winds, and the sea coast corresponds to such conditions to the maximum extent. The absence of natural barriers to wind, a constant and stable flow allows us to organize the most favorable mode of operation of generators, increasing their efficiency to the highest values.

Ten largest offshore wind turbines

This article will talk about wind generators in the production stage or those for which delivery orders have been placed; On the sidelines will be those discontinued, experimental installations that have not been put into production, as well as those remaining at the level of drawings on drawing boards; The characteristics of the top ten most powerful wind turbines of our day will be covered in detail.

1st place: model V 164-9.5 MW from MHI Vestas

Rated power 9.5 MW

Rotor diameter 164 m

Transmission Gearbox

Among the turbines available on the market, MHI Vestas models continue to occupy a leading position. The combined enterprise (Mitsubishi Heavy Industries & Vestas - RAVI note), which is now 5 years old, has indicated its intention to continue to develop the V164 platform (with a capacity of 7 MW announced in 2011), while competitors are developing completely new models.

New MHI Vestas CEO Phillippe Kavafyan says it has the potential to become the workhorse of offshore wind and is committed to keeping the platform competitive for several more years, capitalizing on the industry's greater demand for proven technology rather than new technology. , albeit a larger model. An 8-8.8 MW turbine version has been installed (or ready for installation) at several projects in the UK, Holland, Denmark and Germany with a total capacity of 2.24 GW.

The company suffered a small cost in 2021 when a fire in Denmark destroyed a prototype 9.5 MW turbine; The cause of the incident was identified as a defective component damaged during installation. The component was a unique feature of the demonstration mechanism and its failure did not impact the research program, so the model was certified in June 2021.

The V164-9.5MW model has a reference list of approximately 3.7 GW. The model has been named as a priority for deployment at the UK east coast wind farms Moray East (950 MW) and Triton Knoll (860 MW). Each project received support through a tender held in 2021. Installation of such turbines is also planned at the Belgian Northwestern 2 station (224 MW), the German Deutsche Bucht (252 MW) and the Dutch Borssele III & IV (731.5 MW), at which will be the first to use the mono-suction-bucket type of installation (caisson (mono-bucket) with penetration (suction) into the ground with zero vertical deviation).

As for non-European regions, the manufacturer has signed an agreement for the supply of the V164 8-9.5MW platform with Copenhagen Infrastructure Partners, which owns three sites in Changhua County in western Taiwan.

2nd place: SG 8.0-167 DD from Siemens Gamesa

Rated power 8 MW

Rotor diameter 167 m

Transmission Direct drive

The wind generator from Siemens Gamesa (SGRE) (a member of RAWI) is another example of the progressive and successful evolution of a large wind generator. Originally released in 2011, the model had a power of 6 MW and carried a rotor with a diameter of 120 m.

The SG 8.0-167 was “launched” following the WindEurope conference held in November 2021 in Amsterdam. Despite the indication in the name of a power of 8 MW, it is possible to increase it to 9 MW for a specific model.

The rotor diameter of the latest models is 167 m - the largest on the market. The previous 154-meter sample with a power of 8 MW provides a specific wind flow power of 365 W/m2. The latest generation of turbines also benefited from the merger between Siemens and Gamesa; Gamesa was armed with an 8-megawatt Adwen turbine, which has now ceased to exist both technologically and in terms of its removal from the supply system.

Its 6 MW predecessors, with 154 and 120 m rotors, were installed at Ørsted's (210 MW), Westermost Rough (UK, 252 MW), Gode Wind 2 (Germany) and Dudgeon (UK, 402 MW) sites of Equinors , while subsequent 7 MW models are installed in the Hornsea Project One (1.2 GW) and Walney Extension (UK, 329 MW) wind farms.

Together with the 3.6 MW "pioneer" capacity, all these installations have made the SGRE conglomerate the leading manufacturer of offshore wind turbines in the world.

Within 10 months from the moment the model was launched into production, the new 8-megawatt platform was listed in orders with a total capacity of 5.7 GW; This includes 1.5 GW for the French Adwen wind farm, 900 MW for the Danish wind farms and 1.4 GW for the UK, excluding smaller orders in Germany, the Netherlands and Taiwan, meaning SGRE retains a relatively strong market leadership position .

Unlike rival MHI Vestas, Siemens Gamesa has made no secret of its plans to reach 10 MW or more for its next generation of generators, and the announcement of a 12 MW prototype earlier this year only made things easier.

3rd place: GW 154/6.7 MW from Goldwind

Rated power 6.7 MW

Rotor diameter 154 m

Transmission Direct drive with permanent magnet generator.

In November, China's leading turbine maker revealed details of a new 6-megawatt direct drive platform, although the company has remained silent on further progress since then. Three possible design options were named: a 6.7 MW turbine with a rotor diameter of 154 m, or a 6.45 MW turbine with a rotor diameter of 164 m or 171 m, respectively. The specific power of the air flow varies from 281 W/m2 for the GW171/6.45 model and up to 360 W/m2 for the GW154/6.7 MW model.

The GW171/6.45 is expected to have a larger rotor diameter than the options currently offered by MHI Vestas and Siemens Gamesa. At the same time, blade supplier LM Wind Power has experience in creating 88.4-meter blades for the canceled Adwen AD 8-180 turbine project. Production of the 75.1 meter blades - the longest ever produced in China - for the 6.7 MW model started in September 2021. Priority for distribution is given to the GW154/6.7M wind turbines, which are designed for installation in areas with high winds: coastal zones eastern provinces of Fujian and Guangdan.

Lower rated models with longer blades will be concentrated in sites with lower average wind speeds. Goldwind says Japan and South Korea are the main potential markets besides China, although Europe and India could also provide commercial opportunities.

4th place: 6.2 M 152 from Senvion

Rated power 6.15 MW

Rotor diameter 152 m

Transmission High-speed with gearbox.

First seen in 2004 in the form of a 5-megawatt mechanism with a rotor diameter of 126 m, the offshore wind turbine, at that time produced under the Repower brand, is now “living out its life”, despite the rotor diameter having grown to 152 m and up to 6 .15 MW – the power stated in the title.

In total, Senvion installed 72 units of this model (with a smaller rotor diameter of 126 m) in 2021: 54 at the Nordsee one wind farm and 18 at Nordergrunde - each of which is located in German waters of the North Sea.

At the Trianel Borkum II wind farm (203 MW), models with longer blades are currently being installed and installed, the declared increase in energy production for which, according to Senvion, is 20% at wind speeds of 9.5 m/s; the specific power of wind flow is 339 W/m2. But after this announcement about supplies to the mentioned wind farms, no new entries were added to the company’s list of orders.

Senvion's plans to build 10 MW-plus turbines have continued industry interest, especially if the company is to compete with MHI Vestas, Siemens Gamesa and GE in offshore wind. On May 1, 2021, the European Commission allocated a grant of 25 million euros for the development of such a wind turbine as part of a pan-European project. Participants in the project included ABB, EnBW, Jan de Nul and Principle Power. According to the project, abbreviated as RealCoE, by 2021 it is planned to deploy a number of pre-production turbine samples in sea-based conditions.

5th place: Haliade 150-6 MW from GE

Rated power 6 MW

Rotor diameter 150.8 m

Transmission Direct drive

The service life of this type of direct-drive marine turbine turned out to be short and its productivity was low. GE (a member of RAVI) already has plans to upgrade its production facility at St Nazaire (pictured below left) in northern France so that its premises can accommodate a subsequent 12-megawatt unit (pictured below right) as series production is set to begin already in 2021

GE acquired the turbine after purchasing France's Alstom's power grid business in 2015. The 6 MW Haliade turbine has been on order for many long-delayed French wind projects.

An example of the first commercial operation is the installation of this model on the east coast of the United States at the Block Island wind farm with a capacity of 30 MW. Outside France, the only major order was from the owners of the Merkur project (396 MW), located in the German sector of the North Sea and currently under construction.

6th place SCD 6.0 from Ming Yang

Rated power 6 MW

Rotor diameter 140 m

Transmission Medium speed with gearbox

This original two-bladed wind turbine with a leeward location relative to the mast was developed by the German engineering and consulting company Aerodyn (a member of RAWI); It was believed that thanks to its use, Chinese offshore wind energy would be able to “move” further from the coast to the deep sea areas, where wind speeds reach maximum values.

But instead, the Chinese offshore wind sector has shown little desire to move in this direction, understandably remaining faithful to long-proven offshore technologies.

As a result, almost ten years after Ming Yang received a license to manufacture this unit, it has still not been put into mass production. The first prototype was installed in China at the Longyuan Rudong tidal wind farm in 2014.

The turbine was designed to withstand typhoon conditions and carry a helicopter landing pad integrated into the gondola section. The rotor diameter is 140 m, and the specific power of the air flow is 309 W/m2.

7th place: WindS 5500 from Doosan

Rated power 5.5 MW

Rotor diameter 140 m

Transmission High-speed with gearbox

Korean firm Doosan has secured the rights to manufacture the 5.5-megawatt offshore wind turbine in 2021, following in the footsteps of Dongfang and Hyundai Heavy Industries, each of which has entered into a licensing agreement with the model's developer, US-based ASMC Windtec Solutions.

The wind turbine already has some track record behind it. Dongfang installed the first prototype on land in China back in 2012, and the second the following year in eastern China at the Rudong intertidal wind farm.

A prototype produced by Hyundai was installed on the South Korean island of Jeju in 2014.

However, neither of the two companies has decided to open mass production, and it remains unclear whether Doosan will take steps in this direction.

AMSC offers a choice between a permanently excited generator and a dual-fed asynchronous generator. It is also the sole supplier of electrical control systems for this wind turbine.

The installation with a high-speed power transmission with a gearbox is equipped with a 140-meter rotor, has a specific wind power of 357 W/m2 and is intended for regions with high wind speed conditions.

8th place: HTW 5.2-136 from Hitachi

Rated power 5.2 MW

Rotor diameter 126/136 m

Transmission Medium speed with gearbox

The slow pace of development in Japan's offshore wind industry means the temporary suspension of production of Hitachi's 5.2 MW downwind wind turbine.

The company has developed two versions: with a 127-meter rotor for use at high wind speeds and a 136-meter sample for more moderate conditions. Both samples are developments of an earlier 5 MW model with a rotor diameter of 126 m.

18 units of each type of wind turbine are intended for the Kashima Port North and South projects, work on which has not yet begun.

Hitachi has decided to focus on floating structures for this wind turbine development, although both of the Kashima Port projects are located quite close to shore in shallow waters and the plants will likely be built on standard mono-foundations.

A key feature of the setup is a separate torsion shaft connecting the hub to the gearbox. For the HTW5.2-127 model, the specific air flow power is 410 W/m2, and for the higher version HTW5.2-136 – 358 W/m2.

9th place: H 151-5.0 MW from CSIC Haizhuang

Rated power 5 MW

Rotor diameter 151 m

Transmission High-speed with gearbox

The model, which is unlikely to find its way into any market other than its native Chinese market, is currently represented by at least 20 examples operating alongside the 4 MW Sewind units at the Huaneng Rudong offshore wind farm (300 MW), located 14 km away offshore in eastern Jiangsu province.

The wind farm was fully commissioned in October 2021. The familiar three-blade design, high-speed power transmission with gearbox, windward location relative to the mast, and a distinctive 151-meter rotor are features that reflect the turbine’s focus on operating in low to medium wind speed conditions.

The air flow power density is 279 W/m2, which is extremely low for an offshore wind turbine of this size. The 73-meter blades are manufactured and purchased from LM Wind Power, while the gearbox is manufactured in-house by the company.

The company is also believed to be working on a related model with a 127-metre rotor for use in high wind speed areas, but details are unknown at this time.

10th place: AD 5-135 from Adwen

Rated power 5 MW

Rotor diameter 135 m

Transmission Low speed with gearbox

Adwen's AD 5-135 generator is at the bottom of this list by the finest of margins, largely due to the fact that it was recently (October 2021) commissioned at the German Wikinger wind farm (350 MW) by the Spanish multinational energy company Iberdrola.

The line of generators, of course, was to be continued with an 8 MW model, but the takeover of Adwen by the Siemens-Gamesa conglomerate resulted in the turbine not leaving the prototype stage (see link).

Mechanical engineering and consulting company Aerodyn (a member of RAVI) from Germany was involved in the original development, as well as innovative hybrid powertrain technology. The first prototype was installed in 2004; Commercial use began in 2007, when French utility Areva acquired a majority stake in German wind turbine designer and manufacturer Multibrid.

Just under 200 models, equipped with 116m rotors, are currently operating in coastal waters across Europe. Under the new name - Adwen - and deeply modernized samples with a rotor diameter of 135 m in the amount of 70 pieces are now located at the Wikinger wind farm, located in the Baltic Sea.

“Stillborn”: prototypes of offshore wind power generators that were never put into mass production

Adwen's AD 8-180 wind turbine is the latest in a line of large offshore wind turbines with dreams of a "bright future" left in the past. At the time of its initial launch in 2021, the 8 MW capacity, wide range of further conversion options combined with the class-leading 180-meter rotor were seen as extremely attractive features of this model.

But it became a victim of market consolidation: Adwen became a division of Siemens Gamesa Renewable Energy, which had plans to develop and promote its own 8-megawatt development. The only prototype was installed last year at a wind farm in the German port of Bremerhaven.

The 7-megawatt Sea Angel installation from Mitsubishi suffered a similar fate: it was abandoned after the successful registration of a joint venture between Mitsubishi Heavy Industries and Vestas. Two prototypes were built: one for the Hunterston (UK) ground test site, now decommissioned; the second is located in Japan on a floating platform at the Fukushima wind farm.

But neither the turbine nor its innovative hydraulic drive system likely has a production future.

The South Korean company Samsung, before leaving the wind energy sector, produced one sample of an offshore wind turbine with a capacity of 7 MW.

The prototype was sold in 2015 to the English research and development enterprise ORE Catapult, and is currently operating as part of a high-tech demonstration and research project after its installation at the Levenmouth onshore wind farm in Scotland. The data collected from this wind generator is used by the ORE Catapult to create a “virtual wind farm.” Source WindPower Monthly

Specifications

The dimensions of such turbines are impressive:

- blade span - 154 m (the length of one blade on the Vestas V-164 turbine is 80 m)

- the height of the structure is 220 m (with the blade raised vertically), for Enercon E-126 the height from the ground to the axis of rotation is 135 m

- rotor revolutions per minute - from 5 to 11.7 in nominal mode

- the total weight of the turbine is about 6000 tons, incl. foundation - 2500 t, support (bearing) tower - 2800 t, the rest is the weight of the generator nacelle and rotor with blades

- wind speed at which the blades start rotating is 3-4 m/s

- critical wind speed at which the rotor stops is 25 m/s

- amount of energy produced per year (planned) - 18 million kW

It must be taken into account that the power of these structures cannot be considered as something permanent and unchangeable. It depends entirely on the speed and direction of the wind, which exists according to its own laws. Therefore, the total energy production is much less than the maximum values obtained to determine the turbines' capabilities. And, nevertheless, large complexes (wind farms), consisting of dozens of turbines combined into a single system, are capable of providing electricity to consumers across a fairly large state.

What analogues exist, their operating parameters

There are quite a few manufacturers of wind power generators in the world, and they are all striving to increase the size of their turbines. This is profitable, allows you to increase the performance of your products, increase the amount of energy generated and interest large companies and governments in promoting the wind energy program. Therefore, almost all major manufacturers are actively producing structures of maximum power and size.

It should be noted that it is impossible to endlessly increase the size of wind turbines, since with each meter of height the weight and material consumption of turbines increases, the payback period of which has already exceeded 40 years.

Among the most notable manufacturing companies of large wind generators are the already mentioned MHI Vestas Offshore Wind, Erkon. In addition, the Haliade150 or SWT-7.0-154 turbines from the well-known company Siemens are known. The list of manufacturers and their products can take a long time, but this information is of little use. The main thing is the development and promotion of wind energy on an industrial scale, the use of wind energy in the interests of humanity.

The technical characteristics of wind generators from different manufacturers are approximately equal. This equality is due to the use of almost identical technologies, compliance with the characteristics and parameters of structures in a single dimension. There are currently no plans to create larger wind turbines, since each such giant costs a lot of money and requires significant maintenance and upkeep costs.

Repair work on such a structure costs significant sums; if the size is increased, then the costs will increase exponentially, which will automatically cause an increase in electricity prices. Such changes are extremely destructive for the economy and raise serious objections among everyone.

Do-it-yourself windmills for home: review of designs

As you already understood, the very first part that receives wind energy is the wind wheel. Not a single windmill scheme for a home can do without it.

It can be done:

- with a vertical axis of rotation;

- or horizontal.

Vertical wind generator

I’ll show you a photograph of one of the easy-to-manufacture structures, made from an ordinary steel barrel.

Such a vertical wind generator, made by hand, and located above the ground itself, surrounded by buildings and plants, will not be able to develop normal speed to generate enough electricity to power a private house.

It will be able to perform only some single tasks for low-power equipment. Moreover, the low rotation speed of its rotor will require the mandatory use of a step-up gearbox, which means additional energy losses.

Such designs were popular at the beginning of the last century on steamships. The water wheel, with its blades located along the direction of movement of the vessel, ensured its movement.

Now it is a rarity that has lost its relevance. In aviation, such a design not only did not take root, but was not even considered.

Onipko rotor

Among low-speed wind wheel designs, the Onipko rotor is now being widely distributed via the Internet. Advertisers show it spinning even in very light winds.

However, for some reason I also have a critical attitude towards this development, although repeating it with your own hands is not so difficult. I did not find rave reviews among buyers, nor did I find scientific calculations of the economic feasibility of its use.

If any of the readers can dissuade me from this opinion, I will be grateful.

Horizontal wind generator

From the very beginning, aircraft engines began to use a propeller that drives air flow along the body of the aircraft. Its shape and design are chosen so as to use a reactive component in addition to the active pressure force.

Any horizontal wind generator, whether made industrially or with your own hands, works on this principle. I show an example of a homemade design with a photograph.

Based on the principle of using wind energy, this is a more efficient design, and in terms of its design, it is low-power for providing household energy supply issues.

A small electric motor, the rotor of which spins a windmill, can, even with optimal pressure and wind strength, produce only low power as a generator. You can connect a weak LED light bulb to it.

Think for yourself whether you need to assemble such a weather vane with lighting or not. This design will not cope with other tasks. Although it can still be used to scare away moles on the site. They really don't like noises accompanied by the rotation of metal parts.

In order to fully use the electricity obtained from the wind, the impeller of the wind generator must have dimensions corresponding to the power consumption. Count on approximately five meters in diameter.

When creating it, you will encounter a technical difficulty: you will have to accurately balance large parts. The center of mass must always be at the midpoint of the axis of rotation.

This will minimize bearing beating and rocking of the structure located at a high altitude. However, this balancing act is not so easy to achieve.

How to install a wind generator: a reliable mast diagram for mounting at height

The weight of the impeller for normal production of electrical energy is quite decent. It cannot be installed on a simple stand.

It will be necessary to create a solid concrete foundation for the metal mast and guy anchor bolts. Otherwise, the entire structure, assembled with great difficulty, may collapse at any inopportune moment.

A stand for a wind generator raised to a height can be made:

- in the form of a prefabricated mast assembled from sections with braces;

- or conical tubular support.

Both schemes will require reinforcement against capsizing by creating several tiers of guy ropes, which are necessary to hold the mast in heavy gusts of wind. They will have to be securely attached to stoppers and anchors.

From personal unsuccessful experience: while using analog television, the “Spider Web” antenna with a hoop diameter of 2 m worked. It was located at a height of 8 meters and was fixed on a wooden pole with two levels of guy wires. Heavy gusts of wind rocked it so much that the stand fell apart.

Modern digital television, fortunately, requires the use of much smaller antennas. Not only are they easy to make with your own hands, but they are also not that difficult to attach.

How to make a mast for a windmill

Immediately pay attention to creating a durable, trouble-free structure. Otherwise, just repeat the sad experience of YantarEnergo workers, who had an accident during a storm: a multi-ton mast collapsed, and fragments from the blades scattered throughout the area.

The construction of the mast will require calculating the amount of materials required to create a structure from a steel angle of various sections. The shape and dimensions are selected according to local conditions.

It is made of three or four vertical posts. Each of them is mounted on a stop from below. At the top of the mast a platform is created for installing a wind turbine.

Since the length of the corners is limited, the mast is assembled from several sections. The rigidity of the overall fastening is provided by side ribs attached through braces.

A mandatory element of the foundation are embedded metal elements. They will be used to fasten parts. You will have to take care of welding and connecting bolts.

Don't neglect additional braces.

How to make a pipe support

A telescopic structure made from steel pipes of the appropriate profile is easier to assemble, but it should be more carefully calculated for strength. The bending moment created by the heavy top during a storm wind should not exceed a critical value.

In this case, difficulties will arise with preventive maintenance, inspection and repair of the assembled air power plant. If you can climb to a height using a mast like a ladder, it is problematic to do this using a pipe. And working at the top is very dangerous.

Therefore, it is immediately necessary to consider the option of safely lowering the equipment to the ground and an accessible way to lift it. This allows you to do one of two schemes with:

- Rotary axis on the main support.

- The thrust lever on the bottom of the support post.

In the first case, a solid foundation is created for installing the main support. A welded pipe structure with a windmill and a pulley system on steel cables is attached to its axis of rotation.

There is a counterweight located at the bottom of the pipe, which facilitates the work of lifting and lowering using a hand winch.

The picture does not show the safety ropes of the guy belts. They simply hang from their mountings down to the ground as the mast is raised and lowered, and are attached to permanent concrete stakes for permanent operation.

The diagram for installing and lowering the windmill according to the second option is shown below.

The mast and a thrust lever with a counterweight located at right angles to it, reinforced with a stiffening rib, are turned in the vertical direction by a winch with a pulley system.

The axis of rotation of the created structure is located at the apex of the right angle and is fixed in guides built into the foundation. When raising or lowering the mast, the guy ropes are removed from the stationary fastenings on the ground. They can be used as safety lines.

Wind generator: device and principle of operation of the electrical circuit in simple words

Industrial wind farms are designed to be able to immediately supply electrical energy to the grid for consumers. You can't do this with your own hands.

When choosing a generator that will spin a wind wheel, the principle of reversibility of electric machines is used. Torque is applied to the electric motor and the stator windings are excited.

However, the idea of spinning the rotor of a three-phase asynchronous electric motor as a generator to produce an electric current of 220/380 volts is realized from internal combustion engines, water pressure, but not wind.

The overall design of the generator with the rotor will have a lot of weight, otherwise it will not be possible to ensure high shaft speeds.

For small capacities you can:

- use a car generator that produces 12/24 volts;

- use a wheel motor from an electric bike;

- assemble a structure from neodymium magnets with coils of copper wire.

You can also use a windmill sold in China as a basis. But he needs to immediately carry out an audit: pay attention to the quality of installation of the windings, the condition of the bearings, the strength of the blades, and the overall balancing of the rotor.

You will have to be prepared for the fact that the output voltage of the generator will vary greatly depending on the wind speed. Therefore, batteries are used as an intermediate link.

They must be charged by the controller.

Household appliances on a 220-volt network must be powered by alternating current from a special converter - an inverter. The simplest diagram of a home wind power plant is as follows.

It can be significantly simplified because consumer digital electronics: computers, televisions, telephones operate on DC 12 volt power supplies.

If they are excluded from operation and digital equipment is powered directly from batteries, then electrical energy losses will be reduced by eliminating double conversion in the inverter and units.

Therefore, I recommend making separate 12-volt sockets and powering them directly from batteries.

Inside the electrical circuit, you will have to maintain the same power balance as in the mechanical design. Each connected load must comply with the energy characteristics of the upstream source.

220 volt household appliances should not overload the inverter. Otherwise, it will be disconnected from the built-in protection, and if it malfunctions, it will simply burn out. Batteries, power contacts of the controller, and the generator itself work on the same principle.

Circuit breaker protection of a domestic wind turbine must be carried out without fail.

To do this, it must be correctly selected strictly according to scientific recommendations, tested and adjusted.

An accidental overload, much less the occurrence of a short circuit current, cannot be foreseen. Therefore, this module must be installed as the main protection.

The connection diagram for batteries, inverter and controller for a wind generator is practically no different from that used in solar stations with light panels.

Therefore, a reasonable conclusion immediately suggests itself: to assemble a combined home power plant powered by wind and solar energy simultaneously. These two sources together complement each other well, and the cost of assembling single stations is significantly reduced.

There are a lot of channels on YouTube dedicated to wind generators for the home. I liked the work of the owner of Solar Panels. I believe that he is quite objective when presenting this topic. Therefore, I recommend that you take a closer look.

Batteries for a wind generator: another problem for the home owner

One of the costly challenges of a wind or solar power plant is the issue of storing electrical energy, which only batteries can solve. They will have to be purchased and updated, and the cost is quite high.

To select them, you need to know the operating characteristics: voltage and capacitance. Usually, composite batteries from 12 V batteries are used, and the number of ampere-hours in each specific case should be determined experimentally, based on the power of consumers and their operating time.

You will have to choose batteries for a wind generator from a fairly wide range. I will limit myself to not a complete review, but only to four popular types of acid batteries:

- conventional automotive starter;

- AGM type;

- gel;

- armored.

Sellers do not recommend purchasing starter batteries for wind power plants because they are designed to operate in critical vehicle operating conditions:

- when stored in cold weather, they must withstand the enormous starter currents that are created when spinning up a cold engine;

- are subject to vibrations and shaking while driving;

- recharging occurs in buffer mode from the generator when the car is moving at different engine speeds.

Wherein:

- serviced batteries, requiring periodic electrolyte levels and topping up with distilled water, are designed to withstand 100 discharge/charge cycles;

- maintenance-free - have a more complex design and the number of cycles is 200.

However, the wind generator battery when used inside the house:

- usually placed in the basement, where the temperature, maintained year-round at +5÷+10 degrees, is optimal;

- not subject to shocks and vibrations, permanently installed in a stationary state;

- do not receive extreme loads during starter start, and when turning on household appliances through the inverter, they operate in a gentle mode;

- are charged from the generator with small currents, which have a beneficial effect on the desulfation mode of the plates.

All this is the most favorable conditions for their operation. Therefore, I suggest taking note of this option for those who are not too lazy to periodically monitor the voltage on the banks and monitor the electrolyte level in them.

AGM batteries are more complex in design. They have the same plates, but glass mats are impregnated with acid, which simultaneously act as a dielectric layer. Their discharge/charge cycle is 250÷400. Overcharging is dangerous.

Goal batteries are also created with a maintenance-free design with a sealed case and an electrolyte thickened to a gel state. They really don't like overcharging, but are more resistant to deep discharge. The number of calculation cycles is 350.

Armor-mounted batteries are among the most modern developments. Their electrode plates are protected by polymers from acid attack. Range of operating cycles: 900÷1500.

All these four types of batteries differ significantly in price and operating conditions. If you take into account the recommendations of sellers, you will have to shell out a fairly decent amount of money.

However, I recommend that you first listen to the useful advice that the same owner of “Solar Batteries” gives in his video “How to choose batteries for a wind farm and a solar station.”

He has his own, opposite opinion on this matter. How you treat him is your own business. However, to know information from opposing sources and choose the most suitable option from it: the optimal solution for a thinking person.

Comparison with traditional power plants, should we expect a transition to wind energy?

The transition to wind energy is possible where there is no worthy alternative. If for the countries of Western Europe the creation of hydroelectric power stations is difficult or completely impossible, then, naturally, they have to look for a way out of the situation using alternative energy sources.

Nuclear power plants are constantly criticized for using “dirty” sources that pose the risk of spreading radiation contamination. In addition, nuclear waste requires proper disposal or storage, for which there is no place or conditions in overpopulated Europe. For states located on the Atlantic coast, the use of large wind turbines is a necessity, especially since this method of generating energy is quite suitable for them.

For Russia, as a state with a large number of rivers, which creates a lot of opportunities for hydropower, the creation of large wind turbines is not economically feasible.

An exception may be areas of the Far North, remote regions of Siberia or the Far East, where there are no nearby energy sources. At the same time, the complexity of climatic conditions calls into question the very possibility of using such large mechanisms, the maintenance of which at temperatures of -40° is simply unrealistic. Therefore, there is no question of switching to wind energy in the near future.

Another thing is that it is necessary to develop and promote this initiative, especially on a relatively small, local scale. The possibility of obtaining energy with small investments is very attractive for residents of such regions, forcing them to more carefully consider wind energy as one of the possible sources.