Choosing a windmill size

You need to select the size of this installation based on the desired amount of electricity and wind speed, as well as its density, in your region.

It is immediately necessary to clarify that the power calculation will be made for a factory-made wind generator, not made with your own hands from scrap parts. You can check the amount of electricity required from your bills for the last year or take an arbitrary (desired) amount.

Wind speed and density can be found online, for example on the weather service website. I will not indicate any numbers in this article, since there are many regions and the climate has been changing very quickly in recent years.

There are several formulas

1. The simplest and most understandable to the average person, however, the data obtained may have a certain error. Using it, you can calculate a kinetic wind generator with a horizontal shaft:

AEO = 1.64 * D*D * V*V*V

Where:

- AEO is the electricity you want to receive in a year.

- D is the rotor diameter, which is indicated in meters.

- V is the average annual wind speed, indicated in m/sec.

2. A more complex formula that is used for their calculations by companies involved in the sale and installation of such equipment on a professional level.

P = V3 * ρ * S

Where:

- V – wind speed in meters per second.

- ρ – air density, unit of measurement – kg/m3

- S is the area of the blades over which the air flow blows, the unit of measurement is m2 (you need to look at the manufacturer’s technical description).

- P – Number of kW that can be obtained.

Calculation example P = 53 * 1.25 * 33 = 5156 W

The efficiency of electricity generation directly depends on the diameter of the rotor blades; you can see the approximate performance in the table below.

This table shows approximate data that can be obtained depending on the rotor diameter, installation height of the wind generator and wind speed.

| Maximum generated power, kW | Rotor diameter, m | Mast height, m | Wind speed m/s |

| 0,55 | 2,5 | 6 | 8 |

| 2,6 | 3,2 | 9 | 9 |

| 6,5 | 6,4 | 12 | 10 |

| 11,2 | 8 | 12 | 10 |

| 22 | 10 | 18 | 12 |

3. In cases with a vertical rotor (axis), calculations must be made using a different formula.

P=0.6*S*V^3

Where:

- P

– power Watt - S

– working area of the blades sq.m. - V^3

– Wind speed cubed m/s

More complex but more accurate formula

P*= krV 3S/2, .

Where:

- r

—air density, - V

is the flow velocity in m/s. - S

- flow area in square meters - k

is the efficiency coefficient of the wind generator turbine in the value of

0.2-0.5

When choosing a windmill, you need to look at the wind speed recommended by the manufacturer. As a rule, installations for private use have the following range: 2-11 M per second.

Horizontal wind generators (vane)

Various modifications of horizontal installations have from one to three blades or more. Therefore, the efficiency is much higher than that of vertical ones.

The disadvantages of wind generators are the need to orient them towards the direction of the wind. Constant movement reduces the rotation speed, which reduces its performance.

- Single-bladed and double-bladed. They are distinguished by high engine speeds. The weight and dimensions of the unit are small, which makes installation easier.

- Three-blade. They are in demand in the market. They can produce energy up to 7 mW.

- Multi-blade units have up to 50 blades. They have great inertia. The benefits of torque are used in the operation of water pumps.

Wind generators with designs different from classical ones are appearing on the modern market, for example, there are hybrid ones.

Wind generator designed like a sailboat

The disc-shaped structure, under air pressure, moves the pistons, which activate the hydraulic system. As a result, physical energy is transformed into electrical energy.

The unit does not make noise during operation. High power levels. Easily manageable.

Flying wing wind turbine

Used without mast, generator, rotor and blades. In comparison with classical structures, which operate at low altitudes with variable wind strength, and the construction of high masts is labor-intensive and expensive, the “wing” does not have such problems.

It is launched to a height of 550 meters. Electrical energy production is 1 MW per year. The manufacturer of the “wing” is Makani Power.

Choosing a location for a wind generator

Choosing the right location for installing a wind generator is an important step. It is best to place the device at the highest open point and carefully ensure that it is not below the level of adjacent residential and outbuildings. Otherwise, buildings will become an obstacle to air flow and the efficiency of the unit will greatly decrease.

If the site faces a river or lake, the windmill is placed on the shore, where the winds blow especially often. Elevations on the property or large empty spaces where there are no artificial or natural barriers to air flow are ideal for locating the generator.

When residential real estate (house, cottage, apartment, etc.) is located within the city or is located outside the city, but in densely built areas, a wind energy complex is installed on the roof.

To place a generator on the roof of an apartment building, the written consent of the neighbors is taken and official permission is obtained from the relevant authorities.

When installing a vertical generator on the roof of an apartment building, you should remember that the unit operates quite noisily and can cause inconvenience to both the owners and other residents. Therefore, the device must be placed closer to the center of the roof so that apartment owners on the upper floors do not suffer from the loud hum emitted by the windmill during operation

In a private house with a large garden plot, choosing a suitable location is much easier. The main thing is to take into account that the structure is located at a distance of 15-25 meters from residential premises. Then the sound effects from the rotating blades will not bother anyone.

Wind turbine efficiency

For vertical and horizontal wind generators, the efficiency is approximately the same. For vertical it is 20-30%, for horizontal 25-35%.

Efficiency depends on the type of wind generator and wind speed

Some manufacturers increase the efficiency of vertical wind turbines by up to 15% by replacing bearings with permanent neodymium magnets. But such a slight increase in efficiency by only 3-5% leads to a significant increase in the cost of structures.

Both types do not differ in terms of service life. On average, the duration of energy production is designed for 15 - 25 years of service. The bearing assembly and blades wear out the fastest. The service life of which depends on the quality of service.

Is it profitable?

Before spending significant financial resources on purchasing a wind turbine, anyone wants to make sure whether it is profitable.

To get started you need:

Decide what source of power supply the wind generator will serve as.

It could be:

- The main source of electrical energy. In this case, all consumers are connected to the installed device and their power supply is completely dependent on the operation of the wind generator.

- Additional source.

In this case, there may be two options:

- When power is supplied to consumers from traditional power supply networks, part of the power is connected to the wind turbine or it is turned on for a certain time. When used in this way, a reduction in the cost of paying bills for consumed electrical energy from energy supply organizations is achieved;

- When using other alternative sources of electrical energy (solar panels, hydraulic turbines, etc.), wind turbines are part of the electrical supply system.

Study the advantages and disadvantages of wind generators, which are:

The advantages of using such devices include:

- Wind energy is an inexhaustible and renewable source of energy;

- Cost-effective installations. After the initial costs of purchase and installation, you do not subsequently have to pay for the consumed electrical energy;

- Wind energy is an environmentally “clean” source of energy;

- The simple design of the units allows you to independently perform installation and carry out maintenance in the future.

Disadvantages of use include:

- Dependence of installation performance on weather conditions and the presence of wind flows in the region where the units are located;

- Creation of noise and various interference (radio, communications, television) during the operation of installations;

- Removal of land plots on which generators are installed from active use.

- Study the wind potential of the region where the construction of a wind generator is planned. To do this, you can contact the regional weather service or use information on the Internet.

- Select the type, brand and manufacturer of equipment.

When choosing devices, the main criteria will be:

- Efficiency of installations;

- Cost of a set of equipment.

When the necessary calculations have been made, the power supply option has been selected, the wind potential and the range of equipment offered have been studied, each individual makes a conclusion whether it is profitable to use a wind turbine or not.

Cyclic type

In cyclic engines the housing itself is stationary. The air flow rotates, making cyclic movements, its working parts. Mechanical rotational energy is most suitable for generating electricity, a universal form of energy. Cyclic wind engines include wind wheels. Wind wheels, from ancient windmills to modern wind power plants, differ in design solutions and in the complete use of air flow power. The devices are divided into high-speed and low-speed, as well as according to the horizontal or vertical direction of the rotor axis of rotation.

Horizontal

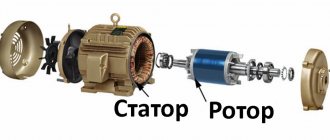

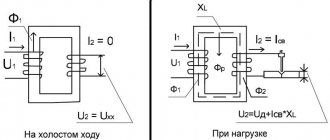

Wind turbines with a horizontal axis of rotation are called vane engines. Several blades (wings) and a flywheel are attached to the rotor shaft. The shaft itself is located horizontally. The main elements of the device: wind wheel, head, tail and tower. The wind wheel is mounted in a head rotating around a vertical axis, in which the engine shaft is mounted, and transmission mechanisms are located. The tail plays the role of a weather vane, turning the head with the wind wheel against the direction of the wind flow.

At high speeds of air flow (15 m/s and above), the use of high-speed horizontal wind turbines is rational. Two and three blade units from leading manufacturers provide KIEV of 30%. A self-made wind turbine has an air flow utilization rate of up to 20%. The efficiency of the device depends on careful calculation and quality of manufacturing of the blades.

Vane wind turbines and wind turbines provide high shaft rotation speed, which allows power to be transferred directly to the generator shaft. A significant disadvantage is that in weak winds such wind turbines will not work at all. There are starting problems when moving from calm to increased wind.

Low-speed horizontal engines have a larger number of blades. The significant area of interaction with the air flow makes them more effective in weak winds. But the installations have significant windage, which requires taking measures to protect them from gusts of wind. The best KIEV indicator is 15%. Such installations are not used on an industrial scale.

Vertical carousel type

In such devices, blades are installed on the vertical axis of the wheel (rotor) to receive the air flow. The housing and the damper system ensure that the wind flow hits one half of the wind wheel, and the resulting resulting moment of application of forces ensures rotation of the rotor.

Compared to vane units, a rotary wind turbine generates more torque. As the air flow speed increases, it reaches operating mode faster (in terms of traction force) and stabilizes in terms of rotation speed. But such units are slow-moving. To convert shaft rotation into electrical energy, a special generator (multipole) capable of operating at low speeds is required. Generators of this type are not very common. The use of gearbox systems is limited by low efficiency.

A carousel wind turbine is easier to operate. The design itself provides automatic control of the rotor speed and allows you to monitor the direction of the wind.

Vertical: orthogonal

For large-scale energy production, orthogonal wind turbines and wind turbines are the most promising. The range of use of such units, in terms of wind speed, is from 5 to 16 m/s. The power they generate has been increased to 50 thousand kW. The profile of an orthogonal blade is similar to that of airplane wings. In order for the wing to start working, you need to apply a flow of air to it, as during the takeoff run of an airplane. The wind turbine also needs to be spun up first, expending energy. After this condition is met, the installation switches to generator mode.

Industrial wind generators: a role model

It's no secret that alternative energy really allows you to get electricity literally from the wind. In European countries, industrial wind generators occupy vast areas and operate autonomously for the benefit of people.

They are enormous in size, located in windswept areas, towering above trees and local objects.

And the wind turbines are installed at a distance from each other. Therefore, accidental breakdowns and damage to one cannot cause harm to neighboring structures.

We will take these principles for creating wind generators as the basis for developing homemade devices. They were created according to scientific developments, tested after long-term operation, and work effectively.

Let's start by analyzing the characteristics of the area where we plan to create a wind power plant.

Types of generators

Before deciding how to make a wind generator with your own hands, let’s consider the design features:

According to the location of the generator, the device can be horizontal or vertical

- Classic design - the axis of rotation is parallel to the ground, the plane of the blades is perpendicular. This scheme provides for free rotation around a vertical axis for positioning “downwind.” In order for the plane of rotation to always occupy an effective position perpendicular to the direction of the wind, a tail unit is required, which operates on the principle of a weather vane. The principle of operation is simple: the wind changes direction, acts on the tail plane, the axis of rotation of the generator is always located along the movement of the air flow. The only difficulty is connecting the power cables. If the generator body makes several revolutions around the vertical axis, the wires will wrap around the mast and break. Therefore, a limiter must be installed. It does not allow a full rotation, but leads to the body hanging in dead zones. Industrial samples have an electronic direction tracking controller, and turns the body using a built-in electric motor. The problem can be solved using a cylindrical propeller, which receives air flow both transversely and and along the axis of rotation. True, the effectiveness depends on the angle of attack. The more the wind deviates from an angle of 90°, the lower the efficiency. But such a design is difficult to make with your own hands, due to the difficulties in the aerodynamics of the propulsion unit.

- The best option is vertical generators (that is, the shaft rotation axis is perpendicular to the ground). With this arrangement of the aerodynamic propulsion, you are not at all dependent on the direction of the wind. Rotation is equally effective, and depends only on the strength of the air flow. The shape of the blades can be very different, there is room for engineering. There are many interesting aerodynamic projects developed by scientific institutions. Moreover, the drawings of most of them are presented in the public domain. Moreover, the designs published in technical literature from the times of the USSR sometimes turn out to be the most rational. Rotor screws have an undeniable advantage: the vertical generator is statically fixed, which simplifies the electrical connection. There is no need to install rotation limiters, as in horizontal circuits.

According to the generated voltage rating

- Do-it-yourself 220-volt wind generators do not require additional voltage converters and are direct-use designs. However, their work depends on the strength of the wind. At a minimum, an output stabilizer is needed that acts as a regulator at different shaft speeds. In the absence of wind, the system simply does not work. The advantages are undeniable: as a rule, a powerful electric motor is used, on which a propeller can be installed, directly attaching it to the rotor shaft. Alterations are minimal in terms of labor costs, such motors already have a convenient pedestal, all that remains is to make a support platform. Electric motors can be found with minimal financial costs: from any decommissioned electrical installation. For example, an industrial fan. Motors from household appliances are also suitable: washing machines, vacuum cleaners.

- 12 volts (less often 24 volts). The most popular design is a DIY wind generator made from a car generator. Moreover, it is dismantled from the donor car complete with a voltage converter. No modification of the circuit is required: at the output we get either 14 volts (in a car the battery is charged with this voltage) or the 12 volts required to power your power system. The presence of a pulley allows you to design a belt drive with the required speed ratio. The counter part can also be removed from the donor's car. If desired, the blades are attached directly to the shaft. Such wind generators can be used both for direct connection to the consumer and in automobile mode, reproducing the charging system complete with a battery. If 12 volts are required to organize the power supply, the power is taken directly from the battery terminals. To obtain 220 volts, a converter is used. A suitable option is an uninterruptible power supply. The system works as follows: if the power taken is lower than the generator can provide, the batteries are charged. If the threshold is exceeded, power is generated from the battery.

Types of vertical generators (carousel type)

Vertical wind power converters are often used for domestic purposes. These types of wind generators are easy to maintain. The main components that require attention are located at the bottom of the installations and are free to access.

Generators with Savounis rotor

Consist of two cylinders. Constant axial rotation and wind flow are not dependent on each other. Even with sudden gusts, it spins at the initially set speed.

The absence of wind influence on the rotation speed is undoubtedly a good advantage. The bad thing is that he uses the power of the element not to its full power, but only to a third. The design of the blades in the form of semi-cylinders allows you to operate only a quarter of a turn.

Generators with Daria rotor

They have two or three blades. Easy to install. The design is simple and clear. They start working from manual start.

The downside is that the turbines are not very powerful. Strong vibration causes loud noise. This is facilitated by a large number of blades.

Helicoid rotor

The wind generator rotates evenly thanks to the twisted blades. Bearings are not subject to rapid wear, which significantly extends their service life.

Installing the unit takes time and is fraught with assembly difficulties. Complex manufacturing technology resulted in a high price.

Multi-blade rotor

The vertical-axis design with a large number of blades makes it sensitive to even very light winds. The efficiency of such wind generators is very high.

This is a powerful converter. Wind energy is used to the maximum. It's expensive. Disadvantage: high background sound. Can produce a large amount of electric current.

Orthogonal rotor

Begins to generate energy at a wind speed of 0.7 m/sec. Consists of a vertical axis and blades. Doesn't make much noise and has a beautiful, unusual design. Service life is several years.

The heavy weight of the blade makes it bulky, which complicates installation work.

The positive aspects of vertical wind generators:

- The use of generators is possible even in low winds.

- They do not adjust to wind currents, as they do not depend on its direction.

- They are installed on a short mast, which allows servicing of systems on the ground.

- Noise within 30 dB.

- Varied, pleasant appearance.

The main flaw is that the force and energy of the wind are not fully used due to the low rotational speed of the rotor.

DIY windmill. How to do it and what is required?

Due to the fact that a ready-made wind generator kit is quite expensive, and the very idea of obtaining free electrical energy without the participation of supplying organizations is very attractive, the issue of making it yourself is very relevant and interesting for people who have basic knowledge of electrical engineering and the skills to perform special work.

To make a turbine you will need the following materials and tools.

Materials

- Pipe with a diameter of 60 cm made of stainless steel or other metal that is not subject to corrosion;

- Plastic, textolite, ebonite or other similar material, with a diameter of 60 cm in the amount of 2 pieces;

- Metal corners for attaching blades – 36 pieces;

- Automotive hub;

- Fasteners (nuts, washers, bolts).

Tools

- Electric jigsaw;

- Angle grinder angle grinder (“grinder”);

- Electric drill or screwdriver;

- Set of wrenches;

- Screwdriver Set.

As well as safety glasses and gloves.

Manufacturing

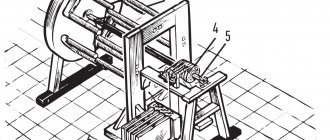

To make a windmill, the pipe is cut lengthwise to produce six identical blades. Two identical circles are cut out of plastic - these are the upper and lower supports for the turbine.

The hub holes are marked and holes are drilled for fastening in the lower plastic support.

The location of the blades is marked according to the template (two triangles forming a star). Mark places for future fastening. On two supports they should be the same. Places for attaching the corners are marked on the blades, and holes are drilled along the marks. Using corners, the blades are attached to the base circles with bolts and nuts with the installation of washers and engravers. A self-exciting generator is selected from automobile or tractor equipment and the structure is assembled.

On a prepared mast, which can be made from available materials, a bracket for mounting the generator stator is installed, and a hub is fixed above it. A generator is mounted on the hub studs, the stator of which is connected to a bracket fixedly fixed to the mast. A bladed turbine is attached to the second rotor plate. The wires from the stator are connected to a voltage regulator, which can also be for automotive use.

The assembled installation is mounted in the selected location, for which the base is concreted with preliminary installation of mounting plates, bolts or studs. A hinge mechanism is made, with the help of which the mast will rise to a vertical position. One half of the hinge is attached to the poured base, and the second to the manufactured mast, the parts of the hinge are connected and the mast is raised to the working position.

When making a mast, it is necessary to provide a device for fastening guy wires, and when raising the mast, also use them. Lifting can be done by crane or by pulling a rope using a winch or by any vehicle. The only condition for this method of lifting is to overcome the “dead spot”, for which you still need a truck crane, or you need to build an additional portal with a pulley device.

After raising the mast, the installation is removed from the hinge, rigidly attached to the base and secured with guy wires.

You might also like the following materials:

Thank you for reading to the end! Don't forget if you liked the article!

Share with friends, leave your comments

Add to our group on VK:

ALTER220 Portal about alternative energy

and suggest topics for discussion, together it will be more interesting!!!

Choosing blades for a windmill

It is not very difficult to assemble a wind generator with a horizontal axis based on a bicycle motor. The wind wheel is the most important element in the generator. There are many options for blade shapes. Today, the most effective for home use is a winged one, reminiscent of an airplane wing. This design minimizes opposing forces. The optimal angle of the blades on the axis is 10-12°C.

It is better to cut out the shape of the wing blade using a template. For a low-speed windmill, it is easier to use a PVC pipe with a wall thickness of at least 0.4 cm. For example, a pressure sewer pipe with a diameter of 160 mm or more. To attach the blades to the motor body, make a head of mild steel 0.6-1 cm thick with welded plates of the same material, 1.2 cm thick and about 3 cm long, according to the number of blades. The strips need holes, to which, using bolts with The head is secured with locknuts.

Attention! There must be at least 25 cm between the blades and the generator so that when there is a gust of wind, the blades do not break on the body of the windmill.

When choosing the number of “wings” it is important to find the “golden mean”. Don't chase windmills that are too fast. 2- or 3-blade ones are really fast and also cheap, but they have the following disadvantages:

Wind generator

- Higher speed means more wear on the axle. If the structure or its components fall off during operation, they will pose a threat to life and health. For the same reason, it is not recommended to make blades from fragile plastic.

- In order for the design efficiency to be high, you need to be very picky about the aerodynamic component. Even a small error can greatly reduce efficiency.

- The installation is more difficult to balance on the tower (mast).

- High noise level.

Advice. For these reasons, experts recommend stopping at 5-6 blades. In a home workshop, it is optimal to make a generator for 6 parts with a diameter of about 2 m.

Screw

The easiest to manufacture are sail and rotor propellers. The first consists of lightweight curved tubes mounted on a central plate. Blades made of durable fabric are pulled over each tube. The large windage of the propeller requires hinged fastening of the blades so that during a hurricane they fold and do not become deformed.

Wind turbine sail propeller

The rotary wind wheel design is used for vertical generators. It is easy to manufacture and reliable in operation.

Homemade wind generators with a horizontal axis of rotation are powered by a propeller. Home craftsmen assemble it from PVC pipes with a diameter of 160-250 mm. The blades are mounted on a round steel plate with a mounting hole for the generator shaft.

Plastic pipe blade configuration

What is a wind generator?

When wind passes through a turbine, the blades begin to rotate due to the kinetic energy of the wind. This rotates the internal shaft, which is connected to a gearbox, which increases the speed of rotation and is connected to a generator that generates electricity. Most often, wind turbines consist of a hollow steel mast, the height of which can reach 100 m, a turbine rotor, blades, a generator axis, a gearbox, a generator, an inverter and a battery. Wind turbines are often equipped with equipment to evaluate and automatically turn in the direction of the wind, and can also change the angle or "pitch" of the blades to optimize energy use.

Types of wind generators

Modern wind turbines fall into two main groups;

- with a horizontal axis of rotation, as in traditional windmills used for pumping water;

- with a vertical axis of rotation, these are rotor and blade designs of Daria.

Most modern wind generators have a horizontal turbine rotation axis.

Typically they consist of:

- masts are hollow inside, made of metal or concrete;

- gondola , which is mounted at the top of the mast and contains shafts, gearbox, generator, controller and brake;

- rotor , which includes the blades and hub;

- low-speed shaft , which is driven by the rotor;

- high-speed shaft , which is connected to the generator;

- gearbox , which mechanically connects the low-speed and high-speed shafts, increasing the rotation speed of the latter;

- generator , which generates electricity;

- controller , which controls the operation of the wind generator;

- weather vane , which determines the direction of the wind and orients the turbine in the required direction;

- anemometer , which determines wind speed and transmits data to the controller;

- brakes to stop the rotor in critical situations.

Vertical generators, features, pros and cons

Vertical wind generators are less efficient due to the stopping effect of the wind flow on the reverse sides of the blades. This is practically the only drawback. Vertical structures do not need to be pointed into the wind, do not require installation on high masts, and are available for repair, maintenance or self-production.

It is vertical structures that provide such a variety of rotor shapes and models created by professional designers and talented amateurs. Let's consider some design options for vertical rotors:

Rotor Daria

It differs in the configuration of the blades, which are located vertically and tangentially to the circle of rotation. In addition, the shape of the blade has a structure similar to that of an airplane wing, so when rotated, a lifting force is created, facilitating movement and facilitating work with weak wind flows.

Savonius wind turbine

This type has two blades mounted opposite each other. The shape of the blades resembles a gutter; when exposed to wind flow on the reverse side, the air stream splits, which partially goes to the side, and partially slides from the reverse side of one blade to the working part of the second. The Savonius wind generator is one of the oldest developments, but is still quite successfully used in both industrial and home-made devices.

Selecting a vertical wind generator

In order to correctly select the design of a vertical wind generator, it is necessary to take into account the dimensions of the rotor, the wind strength in the region, the need for a certain amount of electricity, and compare these values. The larger the rotor, the heavier it is and the more difficult it is for it to start rotating. The ability to start rotating in weak winds is not inherent in every type of vertical device, so the most sensitive designs should be used for large windmills.

There are many options to choose from, their parameters differ little from each other, but there is some difference. If the design in question is not able to provide the desired amount of energy, it should be abandoned and another option should be considered.

Main types of wind generators

Models of wind generators come in different designs and differ in power. According to the rotation geometry of the main rotor axis, they are divided into:

- Vertical type - the turbine is located vertically relative to the ground plane. Starts working in light winds.

- Horizontal type - the rotor axis rotates parallel to the earth's surface. It has great power to convert wind energy into alternating and direct current.

Let's look at these types in more detail, since each of them has developments and improvements.

Wind speed

Unfortunately, there are not many regions in our country where the wind speed is at least 5-7 meters per second. The data is taken on average per year. In the vast majority of latitudes suitable for habitation, this same speed is a maximum of 2-4 m/s.

This means that your wind turbine will simply not work most of the time. For stable generation of electricity, it needs a wind of about 10 m/s.

If the wind in your area is 7 m/s, then the generator will operate at a maximum of 50% of its nominal value. And if it’s only 2 m/s, then by 5%.

In fact, in an hour, a 2kW generator will give you no more than 100W.

You will also encounter another wind problem that manufacturers are silent about. Near the ground, its speed is much lower than at the top, where industrial installations with a height of 25-30m are installed.

You will install your unit at a maximum of ten meters. Therefore, do not even rely on wind tables from different sites. This data is not suitable for you.

Manufacturers modestly keep silent about the fact that for their wind resource maps, measurements are made at an altitude of 50 to 70 meters! In addition, data on turbulence and eddies are not taken into account.

If you try to raise it higher than 10m, you will definitely think about lightning protection. Blades electrified by air friction, a very tasty bait for discharges!

In addition, for some reason everyone only worries about such a parameter as wind speed, and at the same time forgets about its density or pressure. And the difference for energy is quite significant. The dependence of electricity generation on wind pressure is disproportionate.

So, when the wind pressure doubles, the generated power increases eight times!

In addition, there is a certain deceit in the specified technical characteristics of the generators.

Of course, you can trust them, but only under ideal conditions. Because:

These readings are taken in a wind tunnel

and in laminar flow with constant direction and increased density

At your dacha, the wind speed may be such that you won’t even be able to turn the shaft, let alone generate energy.

And this is in spring or autumn. It is during this period that the most active movements of air masses occur.

Do not forget that the windmill does not operate in idle mode, but must spin the generator rotor surrounded by neodymium magnets.

And this is only as long as the electrical potential of the windmill is lower than the battery voltage. When the voltage is sufficient to begin charging, the battery turns into a load.

If you use low-speed designs with a vertical axis of rotation, then there is already a step-up gearbox. Have you tried to spin up the boost gearbox? This design becomes more complicated, increasing weight, windage, and cost.

Even at the lighthouses of the Northern Fleet, given the constant winds and polar night, experts prefer to use solar panels. When asked why this is so, the answer is simple – there are fewer problems!

Cost of wind generators

Prices for wind generators are quite high. These are bulky structures made from expensive material. Includes batteries, controller, inverter and mast.

The kit may consist of: 1 - the wind generator itself, 2 - Mast, 3 - Foundation, 4 - Set of batteries, 5 - Inverter, 6 - Controller, as well as wires, connectors, rack, diesel generator and other consumables necessary for installation

The technical characteristics of wind generators also affect the cost.

- The simplest is a generator with low power up to 300 watts. Produces energy at a wind force of 10-12 m/sec. A set of the simplest windmill with only a controller costs from 15,000 rubles. When equipped with an inverter, battery and mast, the price reaches 50,000 rubles.

- Generators with a declared power of 1 kW. With low winds, on average they produce energy from 30-100 kW per month. For a large house with high electricity consumption, it is recommended to use diesel and gasoline units in addition. They will also charge batteries on days with no wind. Such a wind generator costs from 150,000 rubles. It reaches up to 300-400 thousand rubles with a more complete set.

- Electrical consumption in a large house with a garden will require a windmill with a capacity of 3-5 kW. Sufficient number of batteries, more powerful inverter, controller, high mast. One set costs from 300,000 rubles to a million.

If the house was also heated by wind, then the installation should be selected with a power of 10 kW. And take care of additional sources, such as solar panels. You may also need a gas generator. It all depends on how much energy you have to keep in reserve in case of windless and cloudy days.

Which location should I choose to install a wind generator?

low trees as open as possible.

An important factor in choosing a place to install such a device is the presence of neighbors nearby. The fact is that wind generators are by no means silent devices. In addition, as mentioned above, birds sometimes crash on their blades. Not every neighbor is ready to endure such inconveniences. In this regard, it is better to install wind turbines at a distance of at least 250 meters from the nearest residential buildings.

In general, a wind turbine is the most environmentally friendly source of energy, unlike, for example, a diesel station. Compared to solar panels, which also do not emit waste into the environment, it is more affordable. In addition, the wind blows both day and night.

However, the price of a wind generator is still high, so installing it should be reasonable. If you purchase such a device for reasons only of environmental protection or in the hope of saving crazy money, this device will bring you nothing but disappointment. However, a wind generator will be the best solution for you if:

- the wind in the area where you plan to install a windmill blows many days a year at a speed of at least 4 m/s;

- your home is not connected to the power grid or your energy costs are very high;

- there is enough space on your site to install such a bulky device;

- the fact of installing a wind generator has been agreed upon with the neighbors;

- you have sufficient funds to purchase and maintain a wind power device.

Whether to use electricity from a regular network, purchase an autonomous source, or try to make it yourself - the choice is yours. If you choose a wind generator, remember that this decision should be dictated by necessity, and not just a fashionable trend. Only by carefully thinking through everything down to the smallest detail, weighing all the pros and cons, can you purchase the most profitable source of alternative energy.

Air wind generators

After World War II, the Italian Massimo Ippolito decided to harness wind energy through kites. But there was no technology for this yet, and the idea was shelved. But towards the end of the 20th century, it began to acquire its real embodiment. By this time, a map of the Earth's high-altitude winds had been created, and it turned out that it was over Europe and Patagonia, at altitudes from 0.8 to 10 km, that there were always powerful air currents.

Italian Master of Engineering L. Foggiano wrote a thesis on the capabilities of the Kitegen wind generation system.

From the calculations it followed that if you build a ring generator with a diameter of 1.6 km and launch 6 dozen high-altitude automatic kites, they will be able to spin this giant wheel at a speed of 15 rpm. Which makes it possible to generate 1 GW of electricity, i.e. power comparable to a nuclear power plant.

But for now we have focused on small projects, capacity up to 300 MW,

Its development has been completed, and small prototypes with a performance of 150-200 kW have already been tested in Italian Sardinia.

Compared to conventional wind generators of similar power, the Italian project Kitegen is an order of magnitude ahead of its competitors.

However, the Americans are not lagging behind. They developed their project X Development LLC, which is already an all-metal airframe.

To launch, energy is required, which is transmitted through a cable combined with a cable, but after reaching the calculated height, it begins to soar like a kite in the oncoming air currents.

And small generators on the wings generate electricity, which is transmitted via cable to the base. It (the base) can be either land-based or sea-based.

The prototype is already being tested from 2021. No particular difficulties were noticed; the calculated generation capacities were achieved.

But the pedantic Germans have advanced the furthest; they have truly fantastically bold projects and, by the way, have already been translated into reality. Not only that, they are ready for sale! The concept of a German airborne flying generator from Enerkite is called “EK 30”.

The operating principle of EnerKítes is cyclic, two-stage:

Stage 1 “Working phase” - the wing flies across the wind with maximum rope tension. The rope is released and pulls the generator winch away from the base.

Stage 2 “Return phase” - the wing interrupts the eighth approach, glides quickly and with little effort back to the starting altitude, then the cycle is repeated.

The full cycle takes about a minute. The first stage requires about 7-12% of the energy received. Unlike classic flying wind turbines, electrical energy is generated on the ground. From there the wing is also controlled so that only what belongs in the air moves in the air. All work is done automatically.

The secret of generation is in the patented cable winding drum.

There is also a more serious model “EnerKíte EK200” - a portable aviation wind turbine for decentralized and uninterruptible power supply. It provides clean and reliable electricity at prices ranging from 7 to 12 eurocents/kWh. Housed in a 20 pound container, weighs 12.5 tons. Working height up to 300 m. Rated power 100 kW. Temperature range from -20 to +50˚C.

The EnerKíte EK200 wind generator can cover the own needs of small businesses. It replaces expensive diesel electricity in undeveloped regions.

DIY windmill. Fun or real savings?

Let’s say right away that making a wind generator with your own hands that is complete and effective is not easy. Proper calculation of the wind wheel, transmission mechanism, selection of a generator suitable for power and speed is a separate topic. We will give only brief recommendations on the main stages of this process.

Generator

Car generators and electric motors from direct drive washing machines are not suitable for this purpose. They are capable of generating energy from the wind wheel, but it will be insignificant. To operate efficiently, self-generators need very high speeds, which a windmill cannot develop.

Motors for washing machines have another problem. There are ferrite magnets there, but the wind generator needs more efficient ones - neodymium ones. The process of self-installation and winding of current-carrying windings requires patience and high precision.

The power of a device assembled by yourself, as a rule, does not exceed 100-200 watts.

Recently, motor-wheels for bicycles and scooters have become popular among DIYers. From a wind energy standpoint, these are powerful neodymium generators that are optimally suited for working with vertical wind wheels and charging batteries. From such a generator you can extract up to 1 kW of wind energy.

Motor-wheel - a ready-made generator for a homemade wind power plant

Private wind farms

For Russia, the most pressing issue is the distribution of small stations that supply one house or estate. The construction of large wind farms in the climatic conditions of our country is impractical and unprofitable. The greatest value of wind turbines lies in the ability to provide energy to backward or remote communities where there is no grid connection.

For such areas, the use of small private stations is the best way to solve the problem, since the operation of a wind turbine does not require the provision of fuel, the device is simple and can be easily repaired. Providing such regions with additional equipment is much easier and cheaper than allocating large amounts of money for power transmission lines, especially when it comes to mountainous areas. Small wind turbines can generate a sufficient amount of energy without the need for maintenance or fuel costs, making them a very promising and attractive solution to the problem.

Types of vertical wind generators

The appearance and characteristics of vertical wind generators largely depend on the structural structure of these devices. Let's look at the main ones.

Orthogonal systems

Vertical wind generators 10 kW

The technical characteristics of a vertical wind generator of an orthogonal type imply not very high efficiency with large dimensions, when compared with horizontal-axis devices, however, independence from the wind direction makes it a higher priority.

- The design of these generators is based on a central axis of rotation (vertical) and several flat blades located parallel to it.

- All blades are removed from the center of rotation at a certain distance.

- With this arrangement, the drive mechanism can be placed at ground level, which greatly facilitates maintenance and repair activities.

Rotor Daria

Vertical wind generators 10 kW with Daria rotor

The blades of this generator are completely different from the previous ones. Usually these are two or three stripes of a characteristic curved shape that do not have an aerodynamic profile. They are attached at the base and at the top of the central axis of rotation.

The wind direction is also not important for the turbine. The device is capable of developing high rotation speeds. The drive can also be placed at the base.

The efficiency of such a wind generator is also not very high due to the same dynamic loads that also fall on the rotating components. In this case, only a gust of wind of sufficient strength can start the generator - if the flow intensifies evenly, there will be no start.

Savonius rotor

Vertical axis wind generator with Savonius rotor

These installations have a semi-cylindrical blade system.

- These generators are distinguished from other designs by their high starting torque.

- The system is able to operate efficiently even in low wind conditions.

- The power of manufactured generators of this type does not exceed 5 kW.

- They are rarely used as separate energy sources, being used mainly to create starting torque in Daria rotors.

- Among the disadvantages of the system, one can note the high consumption of metal, and, consequently, the weight.

- The efficiency of the device is also lower than that of generators on a horizontal axis.

Multi-blade rotors with guide system

Vertical wind generator 10 kW multi-bladed

This design, in fact, is not much different from the classical orthogonal system, except that the rotor consists of two rows of blades (external and internal).

- The outer row acts as a guiding contour. Being static, its task is to capture the wind flow, compress it and direct it inward. Thus, the wind flow actually increases.

- The inner row rotates from the air flow, which is reflected from the outer row at a certain angle.

- Experts believe that these generators are the most efficient, but the too high price makes this category of devices less profitable.

- The efficiency of the design is very high, which allows it to operate efficiently even at low wind speeds.

Wind generators with helicoidal rotors

Wind turbine with helicoid rotor

Such rotors are also called Gorlov installations. In fact, we are again faced with a modification of the orthogonal system, however, the blades are not straight, but twisted in an arc.

- This design makes it easy to capture even small air flows and rotate smoothly, without jerking, which significantly reduces the dynamic load, and the bases and rotating units work for a long time and properly.

- The reliability of such rotors is very high, but we cannot leave a fly in the ointment. During operation of the unit, fairly loud sound effects are created, including short-range sound waves.

- Manufacturing blades of complex shape is quite expensive, and therefore the cost of the finished installation is quite high.

Vertical axis rotors

Axial rotor with vertical blades

The blades of such a generator are located vertically, bend smoothly and are a bit like an airliner wing.

- These units quickly pick up operating speed and make virtually no noise, which means they do not disturb others.

- The design is very effective and has a fairly solid working life.

- The production of the installation also cannot be considered the most expensive, so they are in good demand.

New vertical wind generators

Great interest in wind energy, its capabilities and prospects have created a powerful movement for the independent development and design of various devices. Many new, unusual designs of wind generators have been created, some of which are highly efficient, as a result of which they can become prototypes of energy devices of the future. Let's look at some of them:

Hyperboloid type wind turbine

A design whose main idea is to maximize efficiency by reducing the wind pressure on the back sides of the blades. It is a vertical rotor with rod blades located along the circle of rotation, creating a hyperboloid-shaped outline. The useful area exposed to the flow increases significantly. The efficiency of such a device is much higher than that of conventional designs; the rotor can be started with a wind of only 1.4 m/s.

Tretyakov wind generator

Tretyakov's design is a rather complex, but very effective device. The operating principle of the Tretyakov rotor is based on capturing the air flow and organizing its direction in such a way that no resistance is created.

The impeller with blades is located inside an air intake structure that receives the flow of the oncoming wind and distributes it so that it acts on the blades in the direction from bottom to top. This point is quite important - the vector of the applied force reduces the coefficient of friction, making it easier to start rotation and allowing you to work effectively at low wind speeds. At the same time, despite the vertical type of construction, the device is demanding on the direction of the wind and needs to be oriented in the direction of the flow. This happens automatically; the shape of the hull facilitates turning in the wind.

The ability to work with weak flows is important for most regions of our country, and the compactness and reliability of the design guarantees long-term use.

Bolotov wind rotor turbine

The wind generator, based on the developments of the Bolotov family, is intended primarily to solve problems of energy supply for private houses, mobile units or other point areas, both stationary and mobile. The design is a vertical rotor equipped with modular blades installed sectionally, one above the other.

A fixed straightening apparatus is installed outside, capturing wind flows and directing them at the desired angle, eliminating the balancing effect on the reverse sides of the blades. The straightener simultaneously performs the function of a stator, which increases the power and efficiency of the wind generator.

The main feature of the device is that it does not require a mast to rise above ground level. In addition, the wind force required to start rotation is relatively small, which allows the design to be used in any region.

Revolution air designer wind generator

This device is the brainchild of French designer Philippe Starck. The design is a type of helicoidal rotor. It is planned to produce two standard sizes with a power of 1 kW and 400 W. Accordingly, the size of the windmill will be 140 and 90 cm.

The design parameters are frankly weak - the wind speed required for launch is 14 m/s, and the cost of the models is 3500 and 2500 euros, respectively. Such qualities do not allow the design to be seriously considered as a solution to the energy supply problem, turning the device only into an expensive status toy.

Solving power supply issues in remote regions often falls on the shoulders of the residents themselves, forcing them to resort to alternative sources. Industrial models are most often unavailable due to high prices, so you have to use homemade installations. The abundance of developments that have high efficiency and efficiency compared to factory samples contributes to the spread and promotion of wind generators of alternative designs.