Source: List of economic plans necessary to create a business.

Conventional LEDs have confidently occupied their niche and have seriously displaced traditional lighting devices. In parallel with this, multi-color, or RGB, LEDs are expanding their scope. They are able to work in groups and create various types of controlled lighting. For example, with a microcontroller they can produce moving images. The capabilities of RGB diodes are great and have not yet been fully explored. Let's take a closer look at them.

How 3 color LED diodes work

From a design point of view, RGB LED is three color LEDs installed in one housing, or, as experts say, on one matrix. Common types of high-power lighting fixtures contain three chips of the same color. Multi-color LEDs use red, green and blue crystals (Red Green Blue is an abbreviation for three-color LEDs).

Each of them has an independent connection to the power source, so instead of the usual two pins, they have at least 4 contacts - one for each crystal and one common. This allows you to use one of three chips, create different combinations, change and mix colors in a group. If you arrange the connection mode of individual crystals using a microcontroller, you can get a lot of interesting lighting effects. Similar technologies have been known for a long time and are used in color printing, color televisions, etc.

RGB

With paper printing everything is clear, but with display on the screen everything is different. The fact is that the screen is a bunch of glowing pixels that work on a different principle. If we do not put a single drop of ink on the paper when printing, it will remain white. But if we don’t turn on a single pixel on the screen, it will remain black. The thing is that paper reflects light, and the screen, on the contrary, emits it.

Each pixel on a monitor screen consists of three subpixels - red, green and blue.

Subpixels in the matrix of a computer or smartphone screen

On paper, when mixing ink, we got darker colors. But on the screen it’s the other way around: when mixed, we get brighter and lighter colors. This happens because when we blend, we increase the number of luminous pixels and the amount of light that the eye sees.

As a result, colors in RGB can be more vivid, bright, rich and contrasting - after all, you do not reflect or absorb, but emit color.

And if all three subpixels glow with one hundred percent brightness, then we will see white color:

Kinds

There are several types of RGB LEDs:

- common-cathode elements that are driven by positive signals applied to the anodes of the chips. Such elements are marked with the letters CA;

- with a common anode. Commands to change the operating mode are sent to the cathodes of the elements. CC marking;

- own pair of contacts for each crystal (6 pins).

This variety of options was created to facilitate the management of groups of devices. The third group demonstrates the greatest independence - with 6 conclusions. A unified pinout standard has not yet been adopted, so in each case it is necessary to determine the type of polarity of RGB LEDs.

Connection

The easiest way to connect RGB LEDs to a power source is to connect to an Arduino microcontroller. The common lead (usually the longest one) is soldered to the "Gnd" pin, and the rest are connected to the corresponding points marked D12, D10 and D9. Contacts cannot be soldered directly; each of them (except the common one) must have a current-limiting resistor.

When connecting an LED with a common anode, the negative contact “Gnd” is used, located in the same row as the cathodes. If a common cathode connection is used, the positive “Gnd” contact from the opposite row is used.

Controlling an RGB LED on Arduino

For this lesson we will need:

The RGB LED module can be connected directly to the board, without wires or a breadboard. Connect the module with a full-color RGB LED to the following pins: Minus - GND, B - Pin13, G - Pin12, R - Pin11 (see first photo). If you are using RGB LED (Light Emitting Diode), then connect it according to the diagram in the photo. After connecting the module and assembling the circuit on Arduino, upload the sketch to the board.

Sketch for blinking RGB LED on Arduino

Explanations for the code:

Control

The easiest way to control the operation of RGB LEDs is using an Arduino microcontroller. Changing color occurs by mixing two or three colors in different ratios. If all chips are lit at full brightness, the result will be a white glow. To change the hue and obtain the desired colors, it is necessary to control the brightness of each crystal. This is done using pulse width modulation. Rectangular signals with different depths are supplied to the control contacts. The wider the peak (or lower the borehole), the brighter the crystal glows.

There are ways to control RGB LEDs using analogue methods. A circuit is assembled using transistors that regulate the brightness of the corresponding crystals. In both cases, it is important to correctly determine the polarity of the LEDs, otherwise the expected effect will not occur.

Design and purpose of an RGB LED

To display the entire palette of shades, three colors are sufficient, using RGB synthesis (Red - red, Green - green, Blue - blue).

The RGB palette is used not only in graphic editors, but also in website development. By mixing colors in different proportions you can get almost any color. The advantages of RGB LEDs are their simplicity of design, small size and high light output efficiency. RGB LEDs combine three crystals of different colors in one package. RGB LED has 4 pins - one common (the anode or cathode has the longest pin) and three color pins. A resistor must be connected to each color output. In addition, the RGB LED Arduino module can be directly mounted on the board and have built-in resistors - this option is more convenient for robotics classes.

Photo. RGB LED pinout and RGB LED module for Arduino

The RGB LED pinout is shown in the photo above. Note also that many full-color (tri-color) LEDs require diffusers, otherwise the color components will be visible. Next, we will connect a three-color LED to the Arduino and make it first blink in different colors, and then smoothly shimmer in different colors using “pulse width modulation”.

RGBW LEDs

It is quite difficult to obtain pure white light on standard RGB devices. The problem is adjusting the brightness. If you need a white, but rather dull shade, you have to very accurately adjust the power supply of the three crystals. Given that each of them has its own voltage rating that varies nonlinearly, obtaining soft tones is a difficult task.

To simplify the process and increase the capabilities of LEDs, four-color, or RGBW, devices are produced (from the English Red, Green, Blue and White). The additional white chip takes the load off the controller, makes calculations easier and improves color rendering quality. Power for such devices is provided by special controllers with infrared remote controls.

RGB or CMYK color model for photo printing? Choosing the right one

If you've ever wondered why the colors in your photos look a little different when printed than they do on your monitor, it's time to learn more about RGB and CMYK. In this article, we'll explain the differences between these two color models and how to choose between RGB or CMYK to get high-quality images when printing.

Don't be surprised if the printed photo looks different from the one you saw on your computer screen. Colors appear differently on different materials. Color models are used to explain the behavior of light on various materials. The most common models are RGB and CMYK.

- RGB (Red - red; Green - green; Blue - blue) is a color model that determines how light-emitting objects, such as light bulbs, behave. This model is additive: when you mix three primary colors, you get white.

- CMYK is a model that defines how different colors of paint or ink interact with each other. The abbreviation stands for Cyan, Magenta, Yellow and Key/Black. This is a subtractive model, meaning when you combine ink with the tones mentioned, you get black.

The purpose of using color models is to ensure accurate tonal reproduction when printing digital files. It is very important that what you see on the screen matches what you see on paper. Most photo editing programs, such as Photoshop, have CMYK and RGB color models for digital and printed work, respectively. You need to know what media you will be using to display your images so that you get the most accurate version.

RGB

If you look at a digital screen, you will find that it is made up of red, green and blue dots. To display certain tones and shades, each point changes its light output to obtain the desired color. To create white, all the RGB dots on the screen light up brightly. For black they don't light up at all.

To display other colors on the screen, certain combinations of red, green and blue are used. For example, to create the color magenta, red and blue glow, but green does not.

All digital screens use RGB. But there are many types of displays, from AMOLED to LCD, which creates color inconsistency.

AMOLEDs are like tiny light bulbs that emit light. Meanwhile, LCD displays themselves do not emit light. Therefore, they require a white backlight to display color.

Both systems have their pros and cons. For example, AMOLED displays produce brighter tones. But at the same time, LCD displays display white color much better. AMOLED technology is often found on TV and phone screens. Meanwhile, LCDs are more often used in laptop displays and monitors.

In the image below you can see the differences in color between a phone and a laptop displaying the same photo. The computer has an LCD screen, the phone has an AMOLED screen.

In order for the screen to display accurate colors, it must be calibrated. Buying a screen with 100% sRGB coverage will be a big help. In other words, it must be able to display the entire spectrum of RGB colors. And, if you plan to print your work regularly, you'll also need a display with a wide color gamut. Such a screen can display the colors of images that will later be printed.

CMYK

CMYK is often used for printing. If you look at your printer, you will see that it uses CMYK ink cartridges. Often CMY is in one cartridge and K (black) is in another.

In some ways, CMYK works the same as RGB. It uses specific combinations of primary colors to create thousands of tones. But since CMYK is used for printing, the process for creating colors is slightly different.

In theory, the combination of cyan, magenta, and yellow creates the color black, just like the combination of RGB creates the color white. But to save ink, it is much better to use a key color (black) instead. And since CMYK cannot reproduce white, printers use white paper to display that specific color.

The display of colors using CMYK is also different from RGB. Instead of using dots, he often layers one layer of ink on top of another to create different tones. The same concept as RGB is used to create other colors. For example, combining cyan and magenta produces blue. Meanwhile, yellow and blue create green.

Like RGB screens, different printing processes also differ in the way CMYK is applied. Various options include offset printing to digital printing. Photoshop sometimes includes CMYK models that apply to certain commercial printers.

So, if you are working with professional print labs, it is best to check with the technicians to see which model they are using.

When should you use RGB or CMYK?

RGB is the default color profile for displaying digital images. So unless you plan on printing pictures, there's no reason to switch at all. However, you will need to use CMYK if you want to publish your work. If you don't do this, you will end up with inaccurate colors.

How to convert RGB to CMYK?

If you're working with a digital image, its default color model is likely RGB. To make sure your file is using RGB, you can go to the Image tab in Photoshop. When the drop-down menu appears, go to Mode and check which model is checked there.

If the image needs to be printed, you will need to convert its color model. To convert the RGB file, go to Edit. Then click Convert to Profile.

Now click on the Destination Space field.

As you can see, there are many color model options available to you. In most cases, the best default option is Working CMYK US Web Coated (SWOP) v2. It works with regular office and home printers.

As mentioned earlier, if you are working in a professional print lab, it would be best to check exactly what type of CMYK model they are using. This way you can ensure that you receive accurate colors.

Now let's see the difference between RGB and CMYK.

Image using RGB profile

Image with CMYK profile

Color variations can be so subtle that you barely notice them. But the CMYK version looks a little more faded and dull than the RGB version. If you are using your own image for printing, that is acceptable. But if you're going to publish it online, even small changes like these can affect the overall quality. This is again due to the larger color gamut of RGB compared to CMYK.

Conclusion

If you are going to print your work, you should be well aware of the difference between RGB and CMYK models. This is the only way you won’t get crazy tones when publishing photos in a magazine, for example. But if you want to save your work on your computer, there's no reason to convert your files to CMYK. RGB is the ideal default option.

Application

All RGB LEDs are used for decoration and design of objects. They perform different tasks:

- create advertising backlight;

- lighting effects at concert venues;

- design of entertainment events;

- decoration and ceremonial lighting of buildings;

- decoration of fountains, monuments, bridges, etc.

Interesting! In addition, lighting design of interiors is becoming fashionable, in which designer multi-color solutions are actively used. When you change the shade of the glow, the color of the furniture visually changes, and the room gets a new, unusual look.

RGB LED - operating principle and types of color LEDs. Multicolor RGBW

The idea of creating a three-color LED is based on the optical effect of obtaining various shades by mixing 3 basic colors. The base colors typically used are red (R), green (G) and blue (B). That's why the rgb LED was created.

How 3 color LED diodes work

Structurally, a three-color LED consists of 3 color LEDs mounted in a common housing, or, to be more precise, 3 crystals integrated on one matrix. Figure 1 shows a micrograph of an integrated rgb LED. The colored squares in the photo are crystals of primary colors.

Kinds

To adapt to different control circuit options, RGB diodes are produced in several modifications:

- Common cathode version

- Version with common anode

- Without common anode or cathode, with six terminals

In the first case, the LED is controlled by positive polarity signals supplied to the anodes, in the second - by negative pulses supplied to the cathodes. The third modification of the design allows any switching options and is usually produced in the form of an SMD component.

Connection

As an example, we will give a diagram for connecting RGB diodes to the Arduino universal automation unit, created on the basis of the ATMEGA microcontroller. In Fig. Figure 2 shows a connection diagram for an rgb led with a common cathode.

Below is a diagram with a common anode:

The RGB pins in both cases are connected to the digital outputs (9, 10,12). The common cathode in Fig. 2 is connected to the minus (GND), the common anode in Fig. 3 is connected to the power supply positive (5V).

Arduino is a simple controller for beginner roboticists, which allows you to create various devices on its base, from ordinary LED color music to intelligent robots.

Control

The LED turns on when direct current passes, when the anode is connected to the plus, the cathode to the minus. A multi-color emission spectrum can be obtained by changing the intensity of the channels (RGB). The resulting hue is determined by the ratio of brightnesses of individual colors. If all 3 colors are equal in luminescence intensity, the resulting color is white.

Periodic rectangular voltage pulses are formed at the digital outputs of the Arduino board, as in Figure 4, with a variable duty cycle.

For those who forgot. The duty cycle is the ratio of the duration of the pulse repetition period to the pulse duration.

The lower the duty cycle of the channel pulses, the brighter the glow of the corresponding LED diode. The program for controlling the duty cycle of color channel pulses is hardwired into the controller chip. This change in the duty cycle of pulses, carried out for the purpose of controlling the process, is called PWM (pulse width modulation).

Figure 4 shows examples of diagrams of rectangular pulses of various duty cycles.

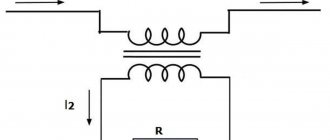

The color and intensity of the rgb diode can be controlled without PWM. The diagram below uses analog control of three-color LEDs. Its essence is to regulate the direct current of diodes of a certain color.

In the diagram (Fig. 5) rgb diodes (led1-led10) have a common anode. The cathodes of the same color of all diodes are combined, and through resistors R4.1, R4.2, R4.3 are connected to the emitter of the corresponding transistor. Thus, all red LEDs are connected to transistor VT1.1, green LEDs are connected to VT1.2, blue LEDs are connected to VT1.3.

When you move the sliders of potentiometers R1.1, R1.2, R1.3, the base current of the corresponding transistor changes. The magnitude of the base current determines the degree of opening of the emitter-collector junction, and, ultimately, the brightness of the corresponding color.

Before connecting, you need to correctly determine the polarity of the LED, otherwise it will not light.

The use of digital programmable controllers provides virtually limitless color control possibilities. In those cases where the creation of dynamic color images is not required, an analog control method can be used. These can be external or interior lamps for static lighting with a choice of colors.

By the way. The use of such regulation in the lighting systems of vehicle instrument panels allows the driver to choose any shade and brightness.

RGBW LEDs

In order to obtain a pure white color using a multi-colored rgb LED, it is necessary to accurately balance the brightness of the glow across the crystal of each color. In practice this can be difficult.

Therefore, to reproduce white color and increase the variety of color effects, the rgb diode was supplemented with a fourth white crystal. Most often, RGBW LEDs are used in RGBW SMD LED strips.

To power such LED strips, special RGBW controllers have been created, usually controlled by infrared remote controls.

The photo shows a powerful four-color LED module SBM-160-RGBW-H41-RF100 manufactured by Luminus Devices Ink.

Application

The main area of application of rgb LEDs is the creation of lighting effects for advertising, stage design of concert venues, entertainment events, festive decoration of buildings, illumination of fountains, bridges, monuments.

Interesting results are obtained when using rgb led diodes for designer lighting design of interiors.

For these purposes, the production of various lighting equipment based on rgb and rgbw diode technology has been launched, the range of which continues to expand and conquer new areas of application.

Video

To consolidate the material discussed, we recommend watching a video, the author of which talks very clearly and interestingly about multicolor RGB LEDs.

Main conclusions

The use of RGB LEDs is constantly expanding. They perform various tasks:

- creating dynamic lighting effects;

- decoration of buildings, structures, interiors;

- illumination and accentuation of advertising structures;

- design of public events, concerts, performances.

The area of use of RGB LEDs is increasing and actively developing. New lighting options are emerging. Software packages are being developed for use in microcontrollers. Share your ways of using RGB LEDs in the comments.

Ways to connect the address tape

Unlike RGB LED, simply applying voltage to the address strip will do nothing. To check the functionality, a special programmable device is required.

However, if you simply touch the information contact (DI) with your hand, the first few modules will light up. Drivers will perceive the induced noise as a control signal.

It is impossible to fully check without Arduino or without a controller. For ease of connection, the addressable LED strip has a beginning and end marking. The arrows indicate the direction of the signal. The beginning and end cannot be swapped. The strip consists of 60 modules. A small section (up to 5 LEDs) can be powered from the Arduino board itself, but to connect a strip of maximum length, an additional power source is used.

The figure below shows a diagram of connecting the control unit to a strip with an additional power supply.

As noted above, to create the necessary lighting effect, Arduino is used. You also need a special program, popularly called “sketch”. It’s not difficult to write it yourself, but you can use existing ones, for example, use the projects of blogger Alex Guyver.

You can select the necessary sketch on the Internet. To do this, you can copy the QR code printed on the tape and use it to select the required protocol.

Or use libraries. For example, FastLED and Adafruit NeoPixel, there are ready-made sketches inside the libraries. Based on them, you can create your own unique options. All that remains is to connect the Arduino to the computer and load the sketch into memory. After which you can install and turn on the lighting system.