Microwave oven magnetron malfunctions

Microwave ovens have been used in everyday life for quick cooking for quite some time. They began to be mass-produced in 1962, and very quickly these devices became indispensable in almost any kitchen. Cooking in an oven occurs by processing food with short electromagnetic waves with a frequency of 2.45 GHz (centimeter range), which move through space at a speed of 299.79 km/sec. In this case, the microwave oven itself does not produce heat, but only emits ultra-high frequency (microwave) radio waves. Interacting with food, these waves cause the liquid molecules in the food to rotate at high frequency. The friction that arises at the molecular level heats the food. The source of microwave waves is a magnetron, which is an integral part of a microwave oven.

Various magnetrons

Principle of operation and design of the magnetron

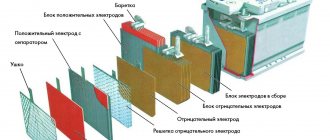

Many owners of microwave ovens, studying the instructions for its operation, ask the question: “What is a magnetron and how does it work?” Magnetron (from the Greek magnetis - magnet, electron) in radio electronics is called a powerful vacuum radio tube-diode, which includes:

- a cylindrical anode-resonator made of copper;

- cathode in which the filament is built;

- ring magnets installed at the ends of the lamp.

A microwave magnetron is a high-power electron tube capable of generating microwaves. This occurs due to the interaction of the cathode and anode, which provokes the appearance of a magnetic field. Microwave radiation, which is released during operation of the magnetron, can affect water molecules that are in food. As a result of radiation, molecules produce vibrations, which become a source of friction, due to which heat arises, warming the food from the inside.

The operating principle of a magnetron is to slow down the flow of electrons in electric and magnetic fields intersecting at an angle of 90°. The distribution of the magnetic field formed by the end magnets is ensured by a magnetic core, the role of which is played by the outer casing of the magnetron, equipped with a flange for attaching it to the waveguide. The interaction of a stream of electrons emitted from the cathode with this magnetic field causes the appearance of microwave waves, which are captured by a wire loop and brought out using a radiating antenna placed in a ceramic cylinder. A special tube (pipe) is used as an antenna, with the help of which air is pumped out of the lamp. A metal cap is tightly pressed onto it.

Magnetron connection.

During operation, the magnetron gets very hot, so its design includes a plate radiator, which is also blown by a fan. In addition, the device is equipped with a thermal fuse. The penetration of high-frequency radiation through the power supply wires is prevented by a high-frequency filter consisting of feed-through capacitors and inductive leads.

A magnetron is a complex electronic device that is not easy to disassemble and repair even for a professional. Therefore, after making sure that it is the magnetron that is not working, it is best to use the services of a service department that has trained employees, as well as the necessary tools and spare parts.

Device

A microwave oven operates using a magnetron. It is located in a special protective case. The emitter is the antenna, it is hidden in the housing. The distribution of waves is carried out by a magnetic circuit, as well as magnets. Another important element is the radiator. It provides cooling to the magnetron; without it, overheating and fire are possible. The device has a number of filters that eliminate harmful effects. The mechanism is quite complex, repairing it yourself is not advisable, but at home it is quite possible to check what the problem is with the work.

Before disassembling the furnace and checking it using special means, you can carry out a visual inspection to understand whether the magnetron is broken or the cause is low voltage. The equipment is disconnected from power and the internal chamber is inspected. As a result of the failure of the magnetron, charring, deformation, and a strong burning smell can be observed inside. If there are signs, then we proceed to checking the magnetron. It should be noted that you cannot look at the magnetron and say what happened; you will need special tools - a megohmmeter, a multimeter, a tester. Without them, there is no particular point in disassembling the microwave; you can take it to a service center. The second point is that repairing a microwave oven is quite expensive. The magnetron is the main element and its price determines the cost of the device. It makes sense to repair a microwave oven if it is expensive. It’s easier to throw away cheap models and buy new equipment. It will be cheaper in terms of money.

Magnetron repair

The magnetron is the most complex and expensive component of a microwave oven. It is extremely difficult to repair it even in specialized workshops. Most often, a faulty magnetron is replaced. However, before you decide to take this step, you need to make sure that this is the problem. Failure of the magnetron is accompanied by external manifestations. Therefore, at the first stage, you should conduct a visual inspection of the microwave chamber. The main external signs indicating a malfunction of the magnetron are unusual sounds, the appearance of smoke or sparking, and the presence of melted or darkened areas on the walls of the chamber.

It will be interesting➡ How to check the zener diode for performance

Then they check the functionality of such microwave oven components as:

- control unit (CU);

- a system that generates high-frequency radio waves.

Useful material: what is a semiconductor diode.

Control unit diagnostics

You can verify that the control unit is faulty by checking with a multimeter whether voltage is being supplied to the input of the step-up transformer. If, when the timer is turned on and the operating mode is selected, there is no voltage at the transformer terminals, then the control unit is faulty.

Magnetron in a microwave oven.

The control unit, equipped with a mechanical timer and manual operating mode switches, is easy to repair. As a rule, to do this, it is enough to visually inspect it and check with a tester the presence of electrical signals at the contacts of switches and relays. Identified damage (broken parts, oxidized and burnt contacts, torn wires, etc.) is repaired.

If the microwave oven is equipped with an electronic control unit, the initial diagnosis will help with the display, which displays incorrect information when a malfunction occurs. If the screen does not light up, then check the integrity of its built-in fuse.

The electronic control unit is designed in such a way that it is capable of independently diagnosing a breakdown. By turning on the diagnostic mode and checking the error codes on the display with their interpretation table (shown in the operating manual), you can obtain the necessary information about the cause of the malfunction.

An electronic control unit is a complex radio-electronic unit that cannot be repaired without special measuring instruments. Once you are convinced that it is faulty, you need to take the stove to the nearest repair shop for complex household appliances.

Checking the radio wave emission system

If the control unit is working properly, then check the components related to the microwave radiation system. In the general case, it consists of a high-voltage power transformer and elements of the voltage booster electrical circuit (voltage shift circuit). Microwave ovens use specially designed high-voltage transformers such as MOT (microwave oven transformator). Structurally, they contain three windings:

- primary 220 V;

- step down 3V;

- increasing 2 kV.

The performance of the transformer is checked by sequentially ringing all windings with a tester. In this case, the step-down winding (magnetron heating) has the least resistance, and the high-voltage winding has the greatest resistance. If the measuring device shows a break in one or more windings, then the transformer must be replaced.

Important! An interturn short circuit may occur in the high-voltage winding of the transformer. This will be indicated by insufficient operating heating temperature and/or increased hum. It is impossible to measure the voltage at the output terminals of this winding with a conventional tester. Special measuring instruments are required. In the event of an interturn short circuit, the transformer must also be replaced.

Next, check the integrity of the elements included in the voltage multiplier circuit. In addition to the magnetron, it includes high-voltage radioelements: a capacitor and a diode. At the same time, it is impossible to check a high-voltage diode for breakdown with a tester - its internal resistance is quite high. It can only be measured using a megger. If a part malfunction is detected, the high-voltage diode should be replaced. Then the capacitor must be checked for breakdown.

When measuring, a working device will show a resistance close to “0”, which should increase to infinity in a few seconds. For a faulty one, there is no dynamic change in resistance, which indicates a lack of contact with the capacitor covers. The oven may also heat less efficiently due to leakage between the plates of the device. This is checked using a megger and a high test voltage source. Faulty high-voltage radio elements are replaced.

How to check the magnetron

Causes of magnetron malfunctions

It is impossible to check the magnetron in a microwave without using special instruments, but it may fail due to a malfunction of one or more parts included in its design.

- A protective cap that ensures the vacuum of the rod. If it sparks, it means it's burned out. The damaged cap must be removed and replaced.

- A filament that can break due to overheating. Check it using a regular tester. The filament resistance should be between 2 and 7 ohms. If the measuring device shows “infinity”, then you need to check the integrity of the connection of the chokes to the magnetron terminals.

- Circuit board with elements of the electrical circuit for powering the magnetron. In addition to a visual inspection, it is also necessary to test the components installed on it with a tester.

- Thermal fuse, which is also checked using a tester. In normal condition, its resistance is “0”.

- Feed-through capacitors, the integrity of which is checked by measuring the resistance between the magnetron body and the terminals. They are operational if their resistance is equal to infinity. In all other cases, the capacitors must be replaced.

It will be interesting➡ How to make a microphone from a phone with your own hands

When replacing capacitors, do not use regular solder. It is imperative to use refractory solder. You can also use a resistance welding device.

This is interesting! All about semiconductor diodes.

Magnetron replacement

After making sure that the microwave is not functioning due to the failure of the magnetron, the device is replaced. It is better, of course, to entrust this operation to qualified service center specialists, but it can be carried out by anyone who knows how to work with a screwdriver and a tester. When choosing a new magnetron, pay special attention to:

- the power indicators of it and the microwave oven were the same, the required parameter is indicated in the accompanying documentation for the microwave oven;

- the mounting holes and the location of the connecting contacts matched those of the dismantled magnetron;

- the length and diameter of the antenna corresponded to the geometric dimensions of the antenna of the old product.

Dismantling a faulty magnetron and correctly connecting a new one in its place is not difficult, but you must ensure that the new product fits tightly to the waveguide.

Magnetron control board

Since magnetron repair is not carried out even in well-equipped workshops, you will have to purchase a new one. Before removing the magnetron from the microwave, you need to mark the connector contacts so as not to confuse them when installing a new part. If the leads are connected incorrectly, the magnetron will not work.

You can do the replacement yourself if you have at least once used a screwdriver for its intended purpose and rang a couple of diodes. This does not require special skills or knowledge of how a magnetron works. If it is impossible to find a specific magnetron for a microwave, you will have to use a suitable analogue.

Its power must be equal to or greater than that of the original, and the fastening and location of the connector must be the same. The design of the magnetron is the same among manufacturers, but the design may differ, so you need to ensure that the fit of the analogue to the waveguide is tight. If the heat-conducting paste on the thermal fuse is dry, replace it with fresh one.

When purchasing a new magnetron, it is necessary that the power matches, the contacts and mounting holes match. If at least one of the conditions does not match, you have purchased a part that is not suitable for you.

Burnout of protective mica

The most common malfunction is the failure of the waveguide cover in the microwave oven chamber. This is caused by splashes from cooking. This starts sparking between the magnetron antenna and the protective cover. Untimely removal of burnt food leads to local burnout of the lid and complete destruction.

Local burnout of the mica plate of the lid can be removed using alcohol or solvent 646. It is enough to carefully wipe the burnt area.

Burnout of mica

If the mica plate of the lid is in clearly poor condition, is greased or has become discolored, it should be replaced. Removing the diffuser plate is not difficult at all. This can be done using a regular sharpened knife. Usually the mica plate is attached with a self-tapping screw or rivets. Carefully place the old plate on the new template and cut out a new one. It is best to do this with a knife - scissors can break the mica. We make holes in the new plate with a sharp screwdriver and sand the edges of the plate fields with sandpaper. We install the new plate in place of the old one.

The question often arises: what to replace mica for microwaves with? Any dielectric with a similar dielectric constant characteristic is suitable for these purposes. For example, fluoroplastic or Teflon.

Fault prevention

The service life of the magnetron can be significantly increased by constantly keeping the mica gasket clean, which protects the waveguide from particles of fat and/or food getting into it. Otherwise, food fragments on the plate will char and become electrically conductive, causing sparks to occur in the chamber. You can also protect the magnetron from damage by connecting the microwave oven to the mains via a stabilizer, which will eliminate fluctuations in the mains voltage, which cause accelerated wear of the filament.

Possible faults

Malfunction of the magnetron can occur for the following reasons:

- The protective cap has burnt out and therefore sparks during operation. Replaced with any whole one, since they are the same for all magnetrons.

- Filament burnout.

- Depressurization of the magnetron due to overheating.

- High voltage diode breakdown.

- The high voltage fuse has blown.

- There is no contact in the thermal fuse.

- The high-voltage capacitor is broken.

For all malfunctions, except for depressurization, repairs can be made with your own hands.

How to find out the service life of different models

You should ask when purchasing how much you can trust the safety of the microwave you are purchasing. You need to focus on the service life of the product presented by the manufacturer . The longer this period, the longer we are insured against harmful consequences caused by the use of faulty equipment.

Pay attention to the warranty period . Usually on a microwave oven it ranges from 1 to 3 years . The longer it is, the longer you will not have to bear the financial costs of repairing equipment. The warranty period is indicated in the technical passport for the equipment, which the seller must issue.

Troubleshooting

To find out why the oven is not working, you need to unplug it and remove the lid.

- The inside is carefully inspected for melting, burning, or unsoldered wires. The condition of the high-voltage fuse is visible to the naked eye. The fuse with the broken thread is replaced with a intact one, and if during testing of the stove it blows again, the search continues.

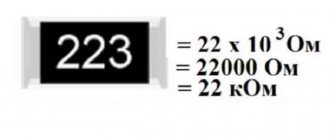

- For further diagnostics, you will need a multimeter or tester. The test begins with a printed circuit board on which the magnetron power supply circuit is assembled, consisting of resistors, diodes, capacitors, and varistors. Parts can be called locally, without soldering.

- After that, the thermal fuse is checked with a tester. With normal contacts, the resistance is zero.

- Testing a high-voltage capacitor with a multimeter is only possible for breakdown. If the device shows a short circuit, the part is replaced. Since some types of capacitors have built-in resistors for discharging, a working capacitor will show a resistance of 1 MOhm, instead of infinity.

- The tester is not suitable for testing a high-voltage diode because it has a small resistance measurement range. To correctly assess the condition of the diode, you will need a megohmmeter with a scale of up to 200 MOhm. But it is unlikely to be found in a home workshop. Therefore, a diagnostic method is used using a two-wire home electrical network with mandatory compliance with safety rules. One terminal of the diode is connected to the network wire. A multimeter is connected between the second and the other conductor of the network to measure DC voltage in the range up to 250 V. If the diode is intact, the device will show the presence of rectified voltage. In the event of a breakdown or break, the arrow will remain at zero. Any high-voltage diode with an operating voltage of 5 kV and a current of 0.7 A is suitable for replacement.

- Checking the magnetron begins with testing the filament. To do this, the resistance between its terminals is measured, which for a working filament is several ohms. If the tester shows infinity, this does not mean that the thread is burned out. To be completely sure, after removing the cover, the integrity of the connections of the chokes with the magnetron terminals is checked.

- Some craftsmen recommend removing the throttles. Under no circumstances should this be done, as the operating mode of the transformer is disrupted, which could result in a fire.

- After measuring the resistance between the terminals and the housing, you can judge the condition of the feed-through capacitors. At infinity - everything is fine, at zero - they are broken, and if there is resistance - with current leakage. Faulty capacitors are cut off with wire cutters and new ones with a capacity of at least 2000 pF are soldered in their place.

- If all the elements are intact, but the magnetron radiation is not enough to fully heat the food, it means that the cathode has lost emission. This problem can only be corrected by replacement. When replacing capacitors, you cannot use conventional solder; refractory grades or a compact resistance welding machine are required.

It will be interesting➡ How to make a pinout of twisted pair RJ45

Useful tips

The following simple recommendations will help extend the life of the magnetron:

- If something crackles and sparks in the microwave when you turn it on, you need to stop using the oven and find out the reason. Fixing the problem will cost less than buying a new part. In this case, the culprit is usually a burnt-out cap, which causes the microwave oven to spark.

- It is necessary to constantly monitor the condition of the mica pad, which protects the output of the waveguide into the chamber from the ingress of fat and food crumbs. If the cap is faulty, the mica may become burnt, which leads to failure of the magnetron. The pad should be kept clean, as any fat that gets on it becomes charred under the influence of temperature and becomes electrically conductive. Interacting with radiation, it causes sparking in the chamber.

- If the voltage is unstable, it is better to connect the microwave through a stabilizer, since even a slight drop negatively affects the operation of the oven. The power drops and wear of the magnetron cathode accelerates. For example, at a network voltage of 200 V, the power is halved.

- A microwave has many uses, so if it malfunctions, the usual order of things is disrupted. The cause of the breakdown is not necessarily the magnetron or its power supply circuit. First, you should check the voltage level at the place where the furnace is connected to the network and the condition of the mica plate.

Checking the magnetron with a multimeter

Troubleshooting

The search for a breakdown in a microwave oven is carried out on the basis of “symptoms”. This allows you to gradually eliminate possible causes and find the real one. So, if the oven does not turn on at all, then it is worth checking the following points:

- Integrity of the power cord.

- Door position and closing system.

- Status of the mains fuse and thermal relay.

In the first case, the situation is simple - there is no power due to a damaged power cord. A similar situation occurs when the outlet is damaged or overloaded. In this case, it is enough to replace this element, everything is in order with the microwave itself.

Next, you should check the operation and position of the door. The fact is that operating a microwave oven with the door open is dangerous for others. Therefore, the design allows for operation only when it is completely closed. If the latch, locking system or testing element on the door is broken, the security system will not allow the device to start.

The last points also concern the furnace protection systems. The fuse prevents damage to the device due to power surges, and the thermal relay ensures complete shutdown of the system when the door is open. Both can fail; replacing them is quite easy.

It is also worth checking the network voltage and the number of devices connected to the outlet. The microwave is very demanding on power supply, so minor deviations can interfere with the operation of the device.

Procedure if there is no heating

Most models suffer from common problems and have similar, typical faults. For example, if the microwave operates but does not heat, this indicates a malfunction of the capacitor, diode or magnetron. To repair a microwave oven yourself, you will need a simple set of tools: pliers, wire cutters, a screwdriver, an adjustable wrench and a five-point wrench, as well as a soldering iron with the necessary equipment.

When repairing a microwave microwave yourself, you should remember safety precautions. The two most important factors presenting danger when repairing a microwave oven are high voltage in the oven components and microwave radiation. Do not turn it on if the door lock is faulty or the mesh on the viewing window is damaged. You cannot make independent holes in the housing and introduce any conductive objects into the units and elements of the furnace. Under no circumstances should you touch the internal parts and components while the microwave is operating. Be sure to use a tester or other electrical measuring instruments to measure DC and AC current.