Power supply systems that use inverters.

- Uninterruptible power supply system for a home or industrial facility in case of loss of the main network.

- Uninterruptible power supply system with solar panels or other alternative power source. In such a system, the inverter/uninterruptible power supply must have a function of priority use of energy from an alternative source (solar batteries, wind generator), thanks to which, first, your electrical appliances receive energy from solar panels, and only if there is not enough energy, electricity will be “added” from the network . This opportunity will allow you to reduce your electricity bills to zero.

- A completely autonomous power supply system when there is no central network at all.

- Traveling, hiking, etc.

With the same power, inverters can differ significantly in capabilities and price, for example:

- inverters with a modified sine wave (outdated technology, since not all equipment can operate from such inverters)

- pure sine inverters

- high frequency

- low frequency

- without charger

- with charger and automatic switching network/inverter (uninterruptible power supply)

- with built-in stabilizer or solar controller

- hybrid inverters

- grid inverters

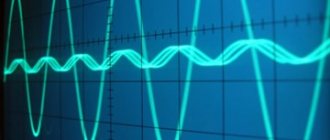

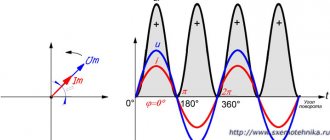

So, what is a modified sine wave and a pure sine wave?

Modified sine

Pure sine

This is the 220V voltage form at the inverter output. The inverter must have a pure sine wave, otherwise many electrical appliances and heating boilers will not work.

High frequency inverters

Usually these are low-power inverters, without a charger, with a small transformer, small capacitors, small size, and low price. Also, the reliability and efficiency of these devices are low.

Most often, these inverters are used in autonomous power supply systems with low consumption.

Inverter operating modes

| Operating mode | Its features |

| Launcher | The power can be 2 times the rated value of the inverter converter for a split second. Acceptable for most devices. |

| Long lasting | Power consumption corresponds to the rated value of the inverter. |

| Overload mode | Power consumption is 1.3 times higher than the nominal value. On average, inverter converters are capable of operating in overload mode for about half an hour. |

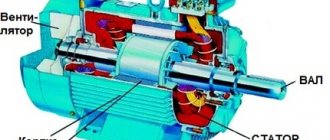

Low frequency inverters

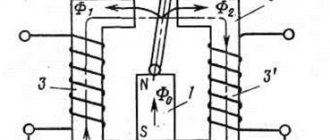

Low-frequency inverters operate at a low frequency of energy conversion from batteries, a frequency of 50 Hz, which corresponds to the frequency of the centralized network. More or less large and heavy transformers operate at this frequency. Such a transformer is an intermediate buffer between the inverter electronics and the load, which increases the reliability of the inverter.

The photo below shows a TrippLite 6 kW inverter (inside, side view, standard transformer on the right)

The HYBRID MAP inverter has 6 kW inside (top view, “tor” transformer on the left). The torus has greater efficiency than a conventional transformer and causes less interference. Also, inverters with a torus have lower self-consumption of electricity at idle.

The transformer occupies slightly less than half of the device body, increasing the size and weight of the low-frequency inverter compared to high-frequency ones. Thanks to the transformer, the power and reliability of inverter systems increases.

The world's most famous and expensive brands, due to the unsurpassed parameters of toruses, use only low-frequency torus-shaped transformers in their inverters.

Application of the inverter in practice

When choosing a voltage inverter, you should remember that it will help you provide lighting if necessary, watch TV, and even boil the kettle. For those who have to spend a long time on the road, a DIY car inverter is an indispensable device that allows you to use ordinary household appliances while traveling.

In most cases, voltage inverters are used as spare phase power supplies. If the current in the outlet disappears, the devices immediately begin to operate on battery power in normal mode. The power supply has been restored - the inverter proceeds to charge the battery, without interfering with the devices working normally from the network. At the same time, he constantly monitors the situation.

Which inverter to choose for 12, 24 or 48 Volts

Rechargeable batteries can be 2, 6 and 12 volt, and they can be switched in series or parallel, or series-parallel, increasing their total capacity. Most often, inverters are produced designed for 12 V or 24 V or 48 V. It is very rare to find 96 V models, because such tension is already considered dangerous. Voltage 12 V can be found in the on-board network of a car, 24 V - in buses and on yachts. In principle, any of these voltages can be used with an inverter to provide uninterrupted power to electrical equipment at home. However, low voltage does not technically allow for greater power. So, for example, it is impossible to obtain a power of more than 3 kW from 12 volts, more than 9 kW from 24 volts, and more than 18 kW from 48 volts. It is clear that high-frequency inverters are usually made at 12 V and with a power of up to 3 kW (and they are designed for use in cars), and powerful low-frequency inverters are usually represented by 24 or 48 V models with a power of 3 kW and above (and they are designed for use in a home or building). This is on average. But there are exceptions when, for example, high-frequency inverters, primarily due to their low price, try to occupy their niche in the home segment, or vice versa, uninterruptible power supplies made using low-frequency technology with a toroid power of only 900 W, having a relatively large weight and price, are trying to occupy a niche in the segment of high-frequency inverters due to its qualities such as reliability, powerful charging capabilities and wide functionality.

Inverters with built-in stabilizer

What is a voltage stabilizer? Usually this is a separate device that allows, over a wide range and with good accuracy, to equalize the voltage of an industrial network if it is very low or high. For example, a high-quality stabilizer allows you to raise the mains voltage to 220 V, even if the network is only 120 V. Or, conversely, lower the mains voltage, say from 270 V, to the same 220 V. High-quality stabilizers are made on durable and high-speed triacs and have a minimum 8 switchable thresholds. Well, now look at the characteristics of the stabilizer function built into the inverter. Usually these are only 2 or 3 thresholds; not triacs are used, but relays are used. As a result, low durability and a narrow range of equalizing mains voltage. And there is another unpleasant feature of inverters with a built-in stabilizer. They are not suitable for use in autonomous conditions, that is, where there is no network at all. After all, even with a good built-in charger, they cannot charge batteries from most conventional gasoline/diesel generators. Why? Because precisely because of the built-in stabilizer, they require very high-quality and stable voltage at their network input. Those. the generator must be expensive and have a large power reserve (and this costs several times more than conventional generators).

Why does the stabilizer built into the inverter so increase its requirements for the quality and power of a gasoline/diesel or gas generator? Judge for yourself. When the load increases, the generator automatically increases speed in order to keep the voltage around 220 V. When the load decreases, the speed decreases for the same reason. Now consider the chain generator - stabilizer - inverter - changing load. Let's say something is turned on, for example a 2 kW electric kettle. The load will be supplied to 220 V, passing through the stabilizer, from a running generator. The voltage will begin to fail in the first fraction of a second. What do you think - who will react first - the stabilizer or the generator? That's right, a stabilizer, since the generator is more inertial, you won't instantly increase the speed.

So, the stabilizer will switch to the boost winding to compensate for the dip. But then this failure still reaches the generator. The generator, for its part, will also increase the voltage. The stabilizer will again react to this increase and lower the threshold, the generator will again react to the stabilizer, etc. An oscillatory process will arise that can go wild. And then one of two things - the system will shut down in an emergency, or this oscillatory process will quickly die out and everything will return to normal. So everything “settles down” almost instantly, if the generator is of high quality and has a large power reserve. Then he will react to a 2 kW kettle as if “a fly flew into the window”, because then the kettle will not be able to increase its speed. But such generators are too expensive.

Welding inverter

Welding converter

Welding current value

First of all, the welding inverter allows you to easily implement a convenient operating mode. Anti-stick mode (automatic shutdown in the event of a short circuit) is easily implemented into the devices, and other features are present. Today, the statement about the high cost of a welding inverter has lost its force. A huge part of the models consume so little energy that they are suitable for use at home. Those wishing to buy Resanta sometimes find it difficult to understand how many watts will be required to supply the device with energy.

Welders, as opposed to most equipment, take a different approach to measuring the capabilities of a device. It is known that to use an electrode of a specified thickness, it is necessary to obtain a certain current at the output of the inverter. These values are usually indicated in the instructions. For example, for the “four” the current ranges from 120 to 200 A. This will light the arc, preventing the chance of completely burning everything down. If you try to set the current to less, it will simply be impossible to complete the work.

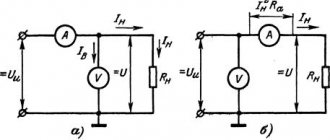

So, a welding inverter is characterized by a specific range of operating currents, from which the master makes a conclusion about the suitability of the equipment in a particular case. For home use, do not take a tool with a current of more than 200 A. This is enough to use 5 mm electrodes. And from above it limits the power. The indicator does not appear in the parameters, but the value is calculated using a typical formula. Each welding inverter has a plate that indicates, in addition to the current, the operating voltage. For readers, the picture shows how power is calculated.

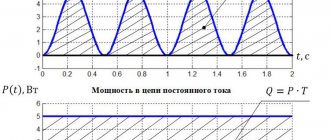

This is an important parameter; a welding inverter can easily burn wiring. Most devices have a duty cycle parameter (shown in the picture as a percentage), which determines how much time the active part takes from the total. Readers will immediately have a question: how long does the total interval last? According to generally accepted conventions, it is considered to be 10 minutes. If the figure indicates that a current of 160 A is used to cook 70% of the time, this means 7 minutes. Then you need to take a 3-minute break and let the equipment cool down.

Applying a value table

The specified characteristics do not affect the welding inverter itself. Most equipment produces adjustable current. But only a welding inverter allows you to change the settings extremely smoothly. In detail, welding can be done with direct current or alternating current. The example considers an inverter of the first type. This is clear from the icon located to the left of the cycle duration in percentage (two straight lines, the lower dotted line). Alternating current is widely used for welding non-ferrous metals.

DC or AC

In some cases, our own technology is used. For example, aluminum is often welded with reverse polarity current, which helps remove the oxide film from the surface. The electrodes need to be dried; separate recommendations for the use of flux are offered. A lot of technologies have been developed, and a welding inverter usually implements only part of them. This mainly involves DC welding of ferrous metals. In other cases, you need to carefully study the literature. As mentioned above, welding of non-ferrous metals is carried out with both direct and alternating current, and it is important to maintain the correct polarity.

We emphasize that the welding inverter becomes only a technology for producing alternating or direct current necessary for the correct operation of the electrodes. The master is responsible for the rest, determining what type of current is used, where to get the electrodes, and how to connect them correctly. A number of terms that go hand in hand with welding:

- Arc welding. The term is popular in the sources. This means that during the welding process an arc of ionized air is formed - a dazzling radiance visible during work. The resulting shock increase in temperature allows the electrode (or wire) to melt without difficulty. No other type of welding is found in garages.

- The word semi-automatic means automatic feeding of the electrode (usually wire), the master can only walk along the seam at a given speed. A semi-automatic machine is quite capable of turning out to be an inverter; this is complex equipment that most people cannot afford.

- Typically, the designation system refers to welding of ferrous metals. For this, ordinary electrodes are used; flux is usually not needed, nor is an inert gas environment: the devices serve, as a rule, to protect delicate non-ferrous metals from the aggressive action of oxygen. The polarity is straight. Grounding is connected to the black terminal, and the welding electrode is connected to the red one. We said above that for non-ferrous metals the exact opposite happens, but these are subtleties that a conventional welding machine is not designed for.

Welder's manual

What current to use is described in any decent welding reference manual. We strongly recommend that you find the book and use it as opposed to the opinion of familiar masters.

Inverters with built-in solar controller

Now let's see how correctly it is to integrate a solar controller inside the inverter. In general, a solar controller is necessary so that solar panels (some call them solar panels) can be connected to batteries, the same ones to which the inverter is connected. The solar controller converts energy from the high voltage of the solar panels to the lower voltage of the batteries. There are not many such inverters with a built-in solar controller. But this solution has advantages - after all, the price of such a solution is somewhat lower and, in addition, there will be slightly fewer connection wires. Now let's look at the disadvantages of this solution. High-quality and powerful solar controllers (with 98% efficiency, high input voltage and control of external loads) are quite large and cannot be inserted inside the inverter. Look at the disassembled solar controller IES Dominator 200/100.

Therefore, charge controllers built into inverters, like built-in stabilizers, are somewhat limited in their capabilities.

Compare in the photo an inverter with a built-in solar controller (left) and two full-fledged separate solar controllers. A separate controller is almost half the size of an inverter. The difference in functionality and parameters is also noticeable.

Another disadvantage is that if the solar controller is damaged, you will have to send the entire device for repair, i.e. lose the inverter. Just like in the case of damage to the inverter, you will also lose the controller.

In general, the most expensive and high-quality branded inverters never contain either stabilizers or solar controllers. Therefore, their very presence in the inverter indicates the level of the product. It says that for the sake of advertising the presence of ephemeral advantages or a seemingly lower price (based on the sum of supposedly two products in one), the manufacturer is ready to make some kind of compromise with real expediency. This is especially true for the built-in stabilizer. Our advice is to purchase inverters with a built-in stabilizer or with a built-in solar controller if you are short on money, and provided that they are not used in complete autonomy, but as a backup system.

Grid inverter

A grid-tied inverter is both an inverter and a solar controller with MPPT technology. But the network inverter has a completely different ideology than the conventional high-frequency inverter with a built-in solar controller that we discussed above, connected to batteries. It is fundamentally different. This ideology has its origins in other conditions of the Eurozone countries, the USA, etc.

This is what, for example, a 500 W network inverter looks like. At first glance, nothing unusual. The only surprise is the lack of terminals for connecting batteries.

The ideology of the network inverter is to convert the energy received from solar panels (connected to HIGH voltage, usually in the range of 200 - 600 V) directly into alternating HIGH voltage 220 V and immediately supply it to the industrial network, synchronizing with it. Since the voltage at the input and output is high, you can do without transformers, which should reduce the cost of network inverters (although for some reason they cost 2 times more than conventional battery inverters).

How are grid-connected inverters used abroad? If the load in the house is large, and little solar energy is supplied, then all of it is spent on home consumption. If there is almost no load, and the sun is at its zenith, then this energy not used by the owner is pumped into the industrial power grid. Those. its counter spins in the opposite direction, rewinding the readings. In addition, the grid-connected inverter does not require batteries! Otherwise, they would have to be connected to a very high voltage (on the line between the solar controller node and the inverter node), which is very dangerous. It turns out that instead of batteries, a huge electrical network is used. You can pump solar electricity into it, turning the meter to a big minus, and then, in the evening, or much later, in the winter, you can get back what you gave in the summer! The industrial power grid is a giant inexhaustible battery, eternal and without losses. But, unfortunately, so far in Russia there are two factors that negate all the advantages of network inverters:

- We do not allow individuals to upload anything online. And there are no such counters (which allow you to subtract reverse energy). Moreover, many modern meters will add this energy (which is supplied back to the network) to the consumed energy, and electricity bills will increase!

- If in Europe electricity is practically never turned off, and there it is often possible not to have a backup system on batteries, then in Russia such outages and accidents are not uncommon.

Therefore, rechargeable batteries are vital not only in the case of complete autonomy, but also for backup, even if a 220 V network is available. We would like to draw your attention to the fact that if the industrial 220 V is turned off, the network inverter will not produce its 220 V even if the sun is shining and there is an abundance of energy. Its design is made in such a way that industrial 220 V is the reference and leading voltage for it. And, in addition, according to safety requirements - so that when an unsuspecting electrician turns off the 220 V network supply and, say, starts repairing the network with his bare hands - so that he does not get killed, the network inverter should not continue to generate 220 V. Therefore, If the electricity in the network disappears, and only a grid-tied inverter with solar panels is installed, then you will be left without electricity. A lot of money has been spent, and there will be no backup power supply. And this will remain so until the power grid regulations are changed, until our power supply failures stop, until electricity stops being turned off as planned...

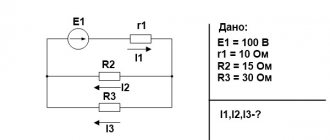

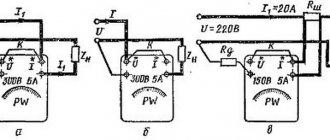

Voltage inverter circuit

The most common voltage inverter circuit consists of four IGBT transistors VT1...VT4 , connected in a bridge circuit, and four reverse diodes, designated VD1...VD4 , connected in parallel to controlled semiconductor switches in the opposite direction. The converter powers an active-inductive load. It is the most common one, so it was taken as a basis.

The inverter input terminals are connected to Uip . If such a source is a diode rectifier, then its output is necessarily shunted by capacitor C.

In power electronics, transistors with an insulated gate IGBT (they are shown in the diagram) and GTO, IGCT thyristors are most widely used. When operating with lower powers, MOSFET field-effect transistors have no competition.

At time t1 VT1 and VT4 open , and VT2 and VT3 are closed. A single path is formed for the current to flow through the load: “+” Uip – VT1 – load RнLн – VT4 – “-” Uip . Thus, in the time interval t1 - t2, a closed circuit is created for the flow of in in the corresponding direction.

Circuit operation mode

To change the direction of in, control pulses are removed from the bases VT1 and VT4 and signals are sent to open the second and third VT2,3 . At point t2 on the t , the first and fourth VT1,4 are closed, and the second and third are open. However, since the load is active-inductive, it cannot instantly change direction to the opposite. This will be prevented by the energy stored in the inductance Lн . Therefore, it will maintain the same direction until all the energy stored in the inductance in the form of a magnetic field, equal to Wм = (Lн∙i2)/2, .

In this regard, in the time interval t2 - t3 , the current will flow through diodes VD2 and VD3 , maintaining the same direction to RнLн , but will pass in the opposite direction through Uip or capacitor C , if the energy source is a diode rectifier. Therefore, it is imperative to install a capacitor C if the converter is connected to a diode rectifier. Otherwise, the flow path of in , resulting in a strong overvoltage that can damage the insulation of the consumer and damage semiconductor devices.

At time t3, all the energy stored in the inductance will drop to zero. Starting from moment t3 to moment t4 , under the influence of the applied Uip , through the open semiconductor switches VT2 and VT3 in will flow through LnRn in the other direction.

At point t4 , located on the time axis t , the control signal is removed from VT1,3 , and VT1 and VT4 open. However, in continues to flow in the same direction until the energy stored in the inductance is consumed. This will happen in the time interval t4 – t5 .

Circuit operation

Starting from moment t5, in changes direction and flows from Uip through LnRn along the path through VT1 and VT4 . Further, all processes occurring in the electrical circuit will be repeated. On LnRn, the voltage shape will be rectangular, but the current on the active-inductive load will have a sawtooth shape due to the presence of inductance, which does not allow it to instantly rise and fall. If the consumer is purely active in nature (inductance and capacitance are practically equal to zero), then the shapes in and un will be in the form of rectangles.

Since VT1...VT4 were opened in pairs throughout the entire length of the corresponding half-cycles, the maximum possible in , therefore, in of flowed LnR . However, it is often necessary to ensure a smooth increase in power at the consumer, for example, to gradually increase the brightness of lighting or the engine speed.

It should be clarified that the signals coming from the control system of the control system are not sent directly to the bases of the semiconductor switches, but through the driver. Since modern control systems are built on meringue microcontrollers that produce low-power signals that are not capable of opening an IGBT, an intermediate link – a driver – is used to increase the power of the opening pulse. In addition, the driver often performs many additional functions - it protects the transistor from short circuits, overheating, etc.

Hybrid inverters

What is a hybrid inverter (HYBRID)? This is the pinnacle of inverter evolution. This is both a regular, that is, a battery-powered, and a network inverter, combined into one, that is, a hybrid!

A hybrid inverter, like a network inverter, can synchronize with an industrial network and pump energy there both from batteries and from solar panels with a solar controller. Those. it can do not only the same as a network inverter, but also more. For example, to “power up” the network during overloads - if the need arises, he will be able to add power from batteries and/or from a solar controller to the allocated network power. The hybrid will also work if the 220 V network disappears. The hybrid, at your request, can limit the pumping of solar energy only to the home network or to an external network. Those. The problem with meters that add the supplied energy to the bills for payment is removed.

The hybrid superimposes its sine on the network sine with a slightly larger amplitude and can take over the entire load or part of the load. If the menu allows pumping until the voltage on 1 battery is above 12.7 V (which corresponds to 100% charge), then in the absence of external energy supply (for example from the Sun), pumping will stop, and then everything will then be powered only from the network. When the Sun appears, pumping will continue again, as much as this solar energy allows, or as much as consumers consume.

Note that batteries, if there is a 220 V mains supply, are not consumed or deteriorated, although solar energy is pumped into the network. But you can also allow a small discharge of the batteries - this will allow you to pump up the accumulated amount in the evening, although the life of the batteries will then be reduced to a small extent.

Pumping the necessary energy directly into the home network is an order of magnitude better than automatically switching consumers from the network to 220 V received from batteries and solar panels, not only because in the latter case the batteries are consumed and therefore deteriorated, but also because frequent switching lead to accelerated wear of the internal relay in a conventional inverter.

The presence of batteries as a reserve allows hybrid inverters to operate even when 220 V disappears in the network.

Another advantage of hybrids is that only they can provide three-phase autonomous or backup voltage. In this case, three inverters are used, each for its own phase. They are interconnected by additional wires to ensure synchronous operation with a phase shift of 120 degrees. Naturally, it is also possible to generate all three phases from batteries, or to regenerate one or two missing phases. But if you need to provide power to three-phase motors or three-phase pumps, you cannot do without such inverters.

It turns out that only hybrid inverters are the only ideal solution for Russia.

Inverter: what is it outside the welding process?

In addition to welding, the term “inverter” is found in other areas of our life. In order not to list all the characteristics by equipment model, it is easier to distribute them by application area. Thus, it will be much easier to understand which inverter models are needed.

1) Inverters in heating boilers

Nowadays, the boiler is an indispensable element of a private home (most). Complex automation requires a constant supply of electricity, but it is impossible to insure against interruptions. An inverter is used to organize an alternative energy source. The unit converts 12.24 and 48 V to standard 220 V.

What tasks does the inverter perform in boilers:

- alternative power source in case of power outages from the network;

- restoration of normal voltage in the event of a voltage drop in the network;

- in the absence of antifreeze in the coolant, the inverter prevents freezing;

- protection of the control board from power surges in the network.

Modern boiler assemblies have charging, control modules, and so on. A simple UPS provides only 20-30 minutes of recharge, when the inverter is capable of providing a flow of electrical charges to equipment for 3 hours or more.

| Inverter type for boiler | Peculiarities |

| Off-line | The simplest to assemble, acting as backup power sources. When the boiler is operating from the mains, the inverter is inactive, but when the voltage in the network decreases or is disconnected, it comes into operation. A similar scenario occurs when voltage surges are higher than standard (260-300 V). The price tag is from 4,000 rubles. |

| Line-interactive | A universal option for boilers. There is all the functionality of an Off-line inverter, with the addition of a voltage stabilizer. Such a unit increases the efficiency of the boiler + reduces the frequency of battery use. Expensive models are equipped with their own power supply, which can compensate for the network for 30-150 minutes. |

| On-line | The most top-end assemblies with a high price tag. The design provides a double conversion algorithm - first AC to DC (up to 12 V), and then 12-V transforms into 220 V with an ideal frequency of 50 Hz. The batteries in such assemblies serve as a buffer capacity, which reduces the risk of breakdown due to voltage to zero. Another thing is that efficiency decreases to 85%. |

The latest models of boiler inverters are among the most expensive. The sacrifice in efficiency is compensated by the protection of the hardware of the equipment, but in terms of convenience, this unit cannot be called optimal for 50% of families with an average level of income. Here everyone decides for themselves.

Please note: by analogy with boilers, a person can buy a similar inverter for refrigeration equipment. The selection conditions are the same.

The most popular models from TM CyberPower, Exmork and POWERMAN ONLINE. According to the selection criteria, I will highlight 5 - the minimum required power, input voltage range, amplitude of sinusoid distortion, efficiency and the presence of additional protections.

Analysis of the mechanics of behavior of inverters when used in everyday life and industry: